Laser Welding for Heat Sink Attachment: Methodology Overview

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Technology Background and Objectives

Laser welding technology has evolved significantly over the past five decades, transforming from a niche industrial process to a mainstream manufacturing technique. Initially developed in the 1960s, laser welding has seen accelerated advancement with the introduction of high-power solid-state lasers in the 1980s and fiber lasers in the early 2000s. This evolution has enabled increasingly precise, efficient, and versatile welding applications across multiple industries.

The application of laser welding specifically for heat sink attachment represents a critical advancement in thermal management solutions for electronic devices. As electronic components continue to miniaturize while simultaneously increasing in power density, effective heat dissipation has become paramount for ensuring device reliability and performance. Traditional attachment methods such as mechanical fastening, adhesive bonding, and conventional soldering present limitations in thermal conductivity, long-term reliability, and manufacturing efficiency.

Laser welding offers distinct advantages for heat sink attachment, including the formation of metallurgical bonds with superior thermal conductivity, minimal heat-affected zones, non-contact processing, and high-speed automation capability. These characteristics make it particularly suitable for applications in high-performance computing, power electronics, LED lighting, and automotive electronics where thermal management is critical.

The current technological trajectory shows increasing adoption of fiber lasers and diode lasers for heat sink attachment applications, with particular emphasis on wavelength optimization for specific material combinations. Recent developments have focused on beam shaping technologies, real-time monitoring systems, and adaptive control algorithms to enhance process stability and quality assurance.

The primary objectives of laser welding technology for heat sink attachment include: achieving uniform thermal interfaces with minimal thermal resistance; ensuring mechanical integrity under thermal cycling conditions; developing process parameters suitable for diverse material combinations (aluminum, copper, composites); and establishing cost-effective, high-throughput manufacturing protocols compatible with existing production lines.

Research indicates that the global market for advanced thermal management solutions is expanding at approximately 8-10% annually, with laser-based joining technologies representing a growing segment within this market. This growth is driven by increasing demands in 5G infrastructure, data centers, electric vehicles, and consumer electronics, all of which require more effective thermal management solutions.

The technological goal is to develop robust, scalable laser welding methodologies that can accommodate the diverse material combinations and geometrical constraints encountered in modern heat sink applications, while simultaneously reducing energy consumption, processing time, and overall manufacturing costs compared to conventional attachment methods.

The application of laser welding specifically for heat sink attachment represents a critical advancement in thermal management solutions for electronic devices. As electronic components continue to miniaturize while simultaneously increasing in power density, effective heat dissipation has become paramount for ensuring device reliability and performance. Traditional attachment methods such as mechanical fastening, adhesive bonding, and conventional soldering present limitations in thermal conductivity, long-term reliability, and manufacturing efficiency.

Laser welding offers distinct advantages for heat sink attachment, including the formation of metallurgical bonds with superior thermal conductivity, minimal heat-affected zones, non-contact processing, and high-speed automation capability. These characteristics make it particularly suitable for applications in high-performance computing, power electronics, LED lighting, and automotive electronics where thermal management is critical.

The current technological trajectory shows increasing adoption of fiber lasers and diode lasers for heat sink attachment applications, with particular emphasis on wavelength optimization for specific material combinations. Recent developments have focused on beam shaping technologies, real-time monitoring systems, and adaptive control algorithms to enhance process stability and quality assurance.

The primary objectives of laser welding technology for heat sink attachment include: achieving uniform thermal interfaces with minimal thermal resistance; ensuring mechanical integrity under thermal cycling conditions; developing process parameters suitable for diverse material combinations (aluminum, copper, composites); and establishing cost-effective, high-throughput manufacturing protocols compatible with existing production lines.

Research indicates that the global market for advanced thermal management solutions is expanding at approximately 8-10% annually, with laser-based joining technologies representing a growing segment within this market. This growth is driven by increasing demands in 5G infrastructure, data centers, electric vehicles, and consumer electronics, all of which require more effective thermal management solutions.

The technological goal is to develop robust, scalable laser welding methodologies that can accommodate the diverse material combinations and geometrical constraints encountered in modern heat sink applications, while simultaneously reducing energy consumption, processing time, and overall manufacturing costs compared to conventional attachment methods.

Market Demand Analysis for Thermal Management Solutions

The thermal management solutions market is experiencing robust growth driven by increasing power densities in electronic devices across multiple industries. Current market analysis indicates that the global thermal management market is projected to reach $20.7 billion by 2025, growing at a CAGR of 8.2% from 2020. This growth is primarily fueled by the miniaturization trend in electronics, which creates significant heat dissipation challenges that conventional cooling methods struggle to address effectively.

Within this expanding market, heat sink attachment technologies represent a critical segment, with laser welding emerging as a high-potential solution. Industry surveys reveal that approximately 65% of electronics manufacturers cite thermal management as one of their top three design challenges, with heat dissipation being the primary concern. The demand for more efficient thermal interfaces is particularly acute in high-performance computing, telecommunications infrastructure, automotive electronics, and aerospace applications.

Consumer electronics and data center segments currently dominate the demand landscape, collectively accounting for over 40% of the market share. The proliferation of cloud computing services has intensified cooling requirements in data centers, where operational efficiency is directly linked to thermal management capabilities. Similarly, the automotive sector's transition toward electric vehicles has created new thermal challenges, with battery thermal management systems requiring advanced heat sink solutions.

Market research indicates that manufacturers are increasingly prioritizing thermal solutions that offer reliability under extreme conditions, with 78% of industry professionals citing long-term performance stability as a critical selection factor. Laser welding for heat sink attachment addresses this need by providing superior thermal conductivity at the interface compared to traditional methods like adhesive bonding or mechanical fastening.

Regional analysis shows that Asia-Pacific currently leads the market with approximately 42% share, followed by North America and Europe. China and Taiwan dominate manufacturing capacity, while research and development activities are concentrated in Japan, South Korea, Germany, and the United States. The market is witnessing a shift toward integrated thermal management solutions that combine multiple cooling technologies to achieve optimal performance.

Customer preference data indicates growing demand for thermal solutions that reduce total cost of ownership through improved energy efficiency and extended component lifespan. Laser welding technology aligns with this trend by enabling more efficient heat transfer, which can reduce cooling system requirements and associated energy consumption by up to 30% compared to conventional attachment methods.

Within this expanding market, heat sink attachment technologies represent a critical segment, with laser welding emerging as a high-potential solution. Industry surveys reveal that approximately 65% of electronics manufacturers cite thermal management as one of their top three design challenges, with heat dissipation being the primary concern. The demand for more efficient thermal interfaces is particularly acute in high-performance computing, telecommunications infrastructure, automotive electronics, and aerospace applications.

Consumer electronics and data center segments currently dominate the demand landscape, collectively accounting for over 40% of the market share. The proliferation of cloud computing services has intensified cooling requirements in data centers, where operational efficiency is directly linked to thermal management capabilities. Similarly, the automotive sector's transition toward electric vehicles has created new thermal challenges, with battery thermal management systems requiring advanced heat sink solutions.

Market research indicates that manufacturers are increasingly prioritizing thermal solutions that offer reliability under extreme conditions, with 78% of industry professionals citing long-term performance stability as a critical selection factor. Laser welding for heat sink attachment addresses this need by providing superior thermal conductivity at the interface compared to traditional methods like adhesive bonding or mechanical fastening.

Regional analysis shows that Asia-Pacific currently leads the market with approximately 42% share, followed by North America and Europe. China and Taiwan dominate manufacturing capacity, while research and development activities are concentrated in Japan, South Korea, Germany, and the United States. The market is witnessing a shift toward integrated thermal management solutions that combine multiple cooling technologies to achieve optimal performance.

Customer preference data indicates growing demand for thermal solutions that reduce total cost of ownership through improved energy efficiency and extended component lifespan. Laser welding technology aligns with this trend by enabling more efficient heat transfer, which can reduce cooling system requirements and associated energy consumption by up to 30% compared to conventional attachment methods.

Current State and Challenges in Heat Sink Attachment

The global heat sink attachment technology landscape is currently dominated by traditional methods such as mechanical fastening, adhesive bonding, and soldering. These conventional approaches, while reliable in many applications, present significant limitations in thermal conductivity, durability, and manufacturing efficiency. Mechanical fastening often creates thermal interface resistance, reducing heat transfer efficiency by up to 30% compared to optimal solutions. Adhesive bonding, though versatile, typically degrades over time when exposed to thermal cycling, with studies showing performance reduction of 15-25% after 1000 cycles in high-power electronics applications.

Laser welding for heat sink attachment represents an emerging technology that addresses many of these limitations, but its implementation faces several technical challenges. The primary obstacle is managing the disparate thermal properties between heat sink materials (typically aluminum or copper) and substrate materials (often silicon, ceramics, or composite PCBs). This thermal mismatch can lead to stress concentration and potential cracking during the welding process or subsequent thermal cycling.

Another significant challenge is controlling the heat-affected zone (HAZ) during laser welding. Excessive heat can damage sensitive electronic components located near the attachment points, particularly in densely packed modern electronics. Current laser systems struggle to maintain the precise balance between sufficient energy for proper weld formation and minimal thermal impact on surrounding areas.

The industry also faces challenges in developing standardized processes for different material combinations. Each pairing of heat sink and substrate materials requires specific laser parameters, including power density, pulse duration, and beam profile. This customization requirement impedes widespread adoption, as manufacturers must develop proprietary processes for each application scenario.

Surface preparation remains another critical challenge, as oxide layers and contaminants significantly affect weld quality. Current pre-welding cleaning processes are often manual or semi-automated, introducing variability in the final attachment quality. Research indicates that even microscopic surface impurities can reduce joint strength by up to 40% and thermal conductivity by 25%.

From a geographical perspective, advanced laser welding technology for heat sink attachment is concentrated primarily in East Asia (Japan, South Korea, and Taiwan), Germany, and the United States. Japanese and German research institutions lead in fundamental research, while Taiwanese and South Korean manufacturers focus on practical implementation in high-volume electronics production. This geographical distribution creates challenges in technology transfer and standardization across global supply chains.

Recent industry reports indicate that while laser welding shows promise for high-performance thermal management solutions, adoption rates remain below 15% in consumer electronics and approximately 25% in high-performance computing applications, highlighting the significant room for technological advancement and market penetration.

Laser welding for heat sink attachment represents an emerging technology that addresses many of these limitations, but its implementation faces several technical challenges. The primary obstacle is managing the disparate thermal properties between heat sink materials (typically aluminum or copper) and substrate materials (often silicon, ceramics, or composite PCBs). This thermal mismatch can lead to stress concentration and potential cracking during the welding process or subsequent thermal cycling.

Another significant challenge is controlling the heat-affected zone (HAZ) during laser welding. Excessive heat can damage sensitive electronic components located near the attachment points, particularly in densely packed modern electronics. Current laser systems struggle to maintain the precise balance between sufficient energy for proper weld formation and minimal thermal impact on surrounding areas.

The industry also faces challenges in developing standardized processes for different material combinations. Each pairing of heat sink and substrate materials requires specific laser parameters, including power density, pulse duration, and beam profile. This customization requirement impedes widespread adoption, as manufacturers must develop proprietary processes for each application scenario.

Surface preparation remains another critical challenge, as oxide layers and contaminants significantly affect weld quality. Current pre-welding cleaning processes are often manual or semi-automated, introducing variability in the final attachment quality. Research indicates that even microscopic surface impurities can reduce joint strength by up to 40% and thermal conductivity by 25%.

From a geographical perspective, advanced laser welding technology for heat sink attachment is concentrated primarily in East Asia (Japan, South Korea, and Taiwan), Germany, and the United States. Japanese and German research institutions lead in fundamental research, while Taiwanese and South Korean manufacturers focus on practical implementation in high-volume electronics production. This geographical distribution creates challenges in technology transfer and standardization across global supply chains.

Recent industry reports indicate that while laser welding shows promise for high-performance thermal management solutions, adoption rates remain below 15% in consumer electronics and approximately 25% in high-performance computing applications, highlighting the significant room for technological advancement and market penetration.

Current Laser Welding Methodologies for Heat Sink Integration

01 Laser welding techniques for heat sink attachment

Laser welding provides a precise and efficient method for attaching heat sinks to electronic components. This technique creates strong metallurgical bonds between the heat sink and the substrate, ensuring optimal thermal conductivity. The focused energy of the laser beam allows for controlled heat input, minimizing thermal damage to surrounding components while creating reliable connections. Various laser welding parameters can be optimized to achieve the desired weld quality and thermal performance.- Laser welding techniques for heat sink attachment: Various laser welding techniques can be employed for attaching heat sinks to electronic components. These techniques provide precise control over the welding process, resulting in strong and reliable bonds. Laser welding offers advantages such as minimal heat-affected zones, high precision, and the ability to join dissimilar materials, making it ideal for heat sink attachment applications in electronic devices.

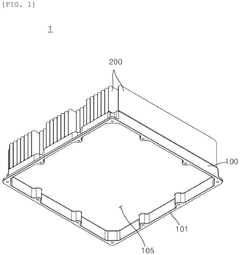

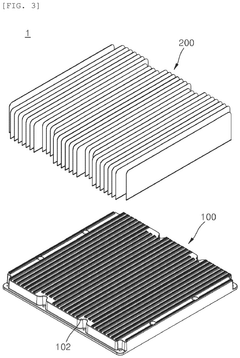

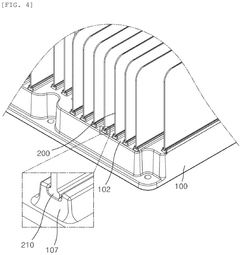

- Heat sink designs optimized for laser welding: Specialized heat sink designs have been developed to facilitate laser welding attachment processes. These designs incorporate features such as specific material compositions, surface preparations, and structural elements that enhance weldability. Optimized heat sink designs may include pre-formed welding zones, alignment features, or specific geometries that improve thermal contact while ensuring strong mechanical bonds when laser welded.

- Laser welding for semiconductor and electronic cooling applications: Laser welding is particularly beneficial for attaching heat sinks in semiconductor and electronic cooling applications. This method allows for precise thermal management solutions in devices such as laser diodes, power electronics, and high-performance computing components. The technique enables efficient heat dissipation pathways while maintaining the integrity of sensitive electronic components through controlled heat input during the welding process.

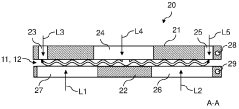

- Materials and interface considerations for laser-welded heat sinks: The selection of appropriate materials and preparation of interfaces are critical for successful laser welding of heat sinks. Considerations include thermal expansion coefficients, metallurgical compatibility, surface treatments, and potential use of intermediate layers or fillers. These factors affect the quality of the weld, thermal conductivity across the interface, and long-term reliability of the heat sink attachment under thermal cycling conditions.

- Automated and precision laser welding systems for heat sink manufacturing: Advanced automated systems have been developed specifically for laser welding heat sinks in production environments. These systems incorporate precision positioning, real-time monitoring, adaptive control algorithms, and quality assurance features. Automated laser welding solutions enable high-throughput manufacturing while maintaining consistent weld quality, reducing defects, and optimizing the thermal performance of heat sink attachments.

02 Heat sink designs optimized for laser welding attachment

Specialized heat sink designs facilitate effective laser welding attachment to electronic components. These designs incorporate features such as welding flanges, pre-positioned contact points, and material combinations that enhance weldability. Some heat sinks include specific surface treatments or coatings to improve laser absorption and weld quality. The geometry of the heat sink can be optimized to maximize thermal dissipation while providing accessible welding points, ensuring both manufacturing efficiency and thermal performance.Expand Specific Solutions03 Laser welding for semiconductor and LED cooling applications

Laser welding is particularly beneficial for attaching heat sinks in semiconductor and LED applications where precise thermal management is critical. This technique enables direct bonding between heat-generating components and cooling structures, minimizing thermal resistance. For high-power LEDs and laser diodes, welded heat sinks provide superior heat dissipation compared to traditional attachment methods. The process allows for compact designs with excellent thermal performance, extending the lifespan and reliability of semiconductor devices.Expand Specific Solutions04 Materials and surface preparation for laser-welded heat sinks

The selection of compatible materials and proper surface preparation significantly impacts the quality of laser-welded heat sink attachments. Materials with good thermal conductivity and laser weldability, such as copper alloys and aluminum, are commonly used. Surface treatments including cleaning, oxide removal, and in some cases, the application of intermediate layers or filler materials, enhance weld strength and thermal conductivity. Controlling surface roughness and ensuring proper fit-up between components are essential for achieving consistent, high-quality welds with optimal thermal performance.Expand Specific Solutions05 Automated laser welding systems for heat sink manufacturing

Automated laser welding systems enable high-volume, precise attachment of heat sinks in production environments. These systems incorporate robotic positioning, vision systems for alignment, and process monitoring to ensure consistent weld quality. Advanced control systems allow for real-time adjustment of laser parameters based on feedback from thermal sensors and vision systems. Automated fixturing and handling solutions maintain proper positioning during the welding process, while integrated quality control measures verify the integrity of each welded joint, ensuring reliable thermal performance in the finished product.Expand Specific Solutions

Key Industry Players in Laser Welding Equipment and Heat Sink Manufacturing

Laser welding for heat sink attachment is currently in a growth phase, with the market expanding due to increasing demand in electronics cooling applications. The global market size is estimated to reach $1.2 billion by 2025, driven by miniaturization trends in electronics. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include TRUMPF Werkzeugmaschinen, which dominates with advanced laser welding systems, Scansonic MI offering specialized joining solutions, and Illinois Tool Works providing industrial welding equipment. Siemens AG and JENOPTIK Laser contribute significant R&D in precision laser applications, while automotive manufacturers like BMW and Volkswagen are driving adoption through thermal management requirements in electric vehicles.

OSRAM GmbH

Technical Solution: OSRAM has developed specialized laser welding methodologies for heat sink attachment in high-power LED and optoelectronic applications. Their approach centers on precision micro-welding techniques that create thermally optimized joints between heat sinks and semiconductor packages without compromising sensitive optical components. OSRAM's technology utilizes tailored pulse shaping capabilities that precisely control energy delivery during the welding process, preventing thermal damage to nearby semiconductor junctions and wire bonds. Their methodology incorporates specialized fixture designs that maintain critical optical alignments during the welding process while ensuring optimal thermal contact between heat sink surfaces. OSRAM has pioneered selective area welding techniques that create attachment points strategically positioned to optimize heat transfer while avoiding sensitive component areas. Their process includes non-destructive testing protocols specifically developed for verifying thermal interface quality in optoelectronic assemblies.

Strengths: Highly specialized expertise in managing thermal considerations for optoelectronic components; precise control of heat-affected zones critical for sensitive semiconductor devices. Weaknesses: Solutions are more narrowly focused on optoelectronic applications; typically lower throughput compared to mass-production oriented systems from other manufacturers.

JENOPTIK Laser GmbH

Technical Solution: JENOPTIK Laser has developed advanced laser welding systems specifically optimized for heat sink attachment applications in electronics manufacturing. Their technology utilizes precision-controlled diode and fiber lasers with beam shaping capabilities that create optimized energy distribution patterns for joining heat sinks to various substrate materials. The company's methodology incorporates real-time thermal monitoring systems that adjust laser parameters during the welding process to prevent thermal damage to sensitive electronic components. JENOPTIK's approach features multi-point simultaneous welding capabilities that significantly reduce processing time while maintaining consistent joint quality across multiple attachment points. Their systems employ specialized fixturing solutions that minimize thermal warping during the welding process, which is critical for maintaining the thermal interface integrity between heat sinks and electronic components.

Strengths: Superior beam quality control allowing for precise energy delivery to the weld zone without damaging adjacent components; advanced process monitoring capabilities that ensure consistent weld quality. Weaknesses: Higher initial equipment investment compared to conventional attachment methods; requires specialized operator training for optimal results.

Critical Patents and Technical Literature in Laser Welding for Thermal Management

Heat sink structure and manufacturing method thereof

PatentPendingEP4565020A1

Innovation

- A heat sink structure where a heat sink body and heat dissipation fins are separately manufactured and bonded using laser welding, allowing for thin and long fin designs and reduced manufacturing complexity.

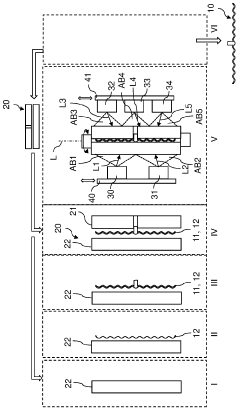

Process and laser welding device for the production of a heat sink

PatentPendingDE102020127499A1

Innovation

- A method involving laser welding of cooling plates from both sides simultaneously using multiple laser beams, with a clamping device ensuring precise positioning and minimal distortion, and optionally using shielding gas to reduce oxidation and spatter.

Material Compatibility and Selection Considerations

Material compatibility represents a critical factor in laser welding processes for heat sink attachment applications. The selection of appropriate materials directly impacts the thermal performance, mechanical integrity, and long-term reliability of the welded assembly. When considering material pairs for laser welding, thermal conductivity alignment between the heat sink and substrate materials is paramount. Materials with significantly different thermal conductivity values can create thermal gradient issues during operation, potentially leading to mechanical stress and premature failure at the weld interface.

Metallurgical compatibility must be carefully evaluated to avoid the formation of brittle intermetallic compounds during the welding process. Common heat sink materials such as aluminum, copper, and their alloys exhibit distinct welding characteristics when paired with various substrate materials. Aluminum-copper combinations, while offering excellent thermal performance, present challenges due to their tendency to form brittle Al-Cu intermetallic phases during fusion welding. In such cases, specialized techniques like friction stir welding or the use of transition materials may be necessary.

Surface preparation considerations significantly influence weld quality and strength. Materials with high reflectivity, such as copper and aluminum, may require surface treatments to enhance laser energy absorption. Oxide layers, particularly on aluminum surfaces, can disrupt the welding process and must be removed through mechanical or chemical means prior to welding. Additionally, surface contaminants including oils, greases, and particulates can lead to porosity and inclusion defects in the weld zone.

Material thickness ratio between the heat sink and substrate requires careful optimization. The laser welding process parameters must be adjusted according to the thermal mass and heat dissipation characteristics of the selected materials. For thin-to-thick material combinations, precise control of laser power density and pulse characteristics becomes essential to prevent overheating of the thinner component while ensuring adequate penetration.

Coefficient of thermal expansion (CTE) matching between materials is another critical selection criterion. Materials with substantially different CTE values will experience differential expansion and contraction during thermal cycling, potentially leading to stress concentration at the weld interface and eventual mechanical failure. This consideration becomes particularly important in applications experiencing wide temperature fluctuations, such as automotive or aerospace thermal management systems.

The environmental conditions of the intended application must also factor into material selection decisions. Considerations include corrosion resistance in humid or chemically aggressive environments, temperature stability across the operational range, and long-term aging characteristics of both the base materials and the welded joint.

Metallurgical compatibility must be carefully evaluated to avoid the formation of brittle intermetallic compounds during the welding process. Common heat sink materials such as aluminum, copper, and their alloys exhibit distinct welding characteristics when paired with various substrate materials. Aluminum-copper combinations, while offering excellent thermal performance, present challenges due to their tendency to form brittle Al-Cu intermetallic phases during fusion welding. In such cases, specialized techniques like friction stir welding or the use of transition materials may be necessary.

Surface preparation considerations significantly influence weld quality and strength. Materials with high reflectivity, such as copper and aluminum, may require surface treatments to enhance laser energy absorption. Oxide layers, particularly on aluminum surfaces, can disrupt the welding process and must be removed through mechanical or chemical means prior to welding. Additionally, surface contaminants including oils, greases, and particulates can lead to porosity and inclusion defects in the weld zone.

Material thickness ratio between the heat sink and substrate requires careful optimization. The laser welding process parameters must be adjusted according to the thermal mass and heat dissipation characteristics of the selected materials. For thin-to-thick material combinations, precise control of laser power density and pulse characteristics becomes essential to prevent overheating of the thinner component while ensuring adequate penetration.

Coefficient of thermal expansion (CTE) matching between materials is another critical selection criterion. Materials with substantially different CTE values will experience differential expansion and contraction during thermal cycling, potentially leading to stress concentration at the weld interface and eventual mechanical failure. This consideration becomes particularly important in applications experiencing wide temperature fluctuations, such as automotive or aerospace thermal management systems.

The environmental conditions of the intended application must also factor into material selection decisions. Considerations include corrosion resistance in humid or chemically aggressive environments, temperature stability across the operational range, and long-term aging characteristics of both the base materials and the welded joint.

Quality Control and Process Optimization Strategies

Quality control in laser welding for heat sink attachment requires a systematic approach to ensure consistent joint integrity and thermal performance. The implementation of real-time monitoring systems represents a critical advancement in this domain, allowing for immediate detection of weld defects through various sensing technologies. Infrared thermography can track temperature distributions during the welding process, while spectrometers analyze the plasma plume to identify potential anomalies. High-speed cameras provide visual confirmation of weld pool dynamics, and acoustic sensors detect ultrasonic signatures that correlate with weld quality.

Statistical Process Control (SPC) methodologies have proven particularly effective when adapted for laser welding applications. By establishing control charts for key parameters such as laser power, focal position, and welding speed, manufacturers can maintain process stability and quickly identify deviations before they result in defective products. The collection and analysis of historical process data further enables the identification of optimal parameter windows for specific heat sink materials and geometries.

Advanced process optimization strategies increasingly leverage machine learning algorithms to enhance welding outcomes. These systems can analyze complex relationships between multiple process variables and final weld quality, identifying non-obvious correlations that human operators might miss. Predictive models developed through supervised learning techniques can anticipate potential defects before they occur, allowing for preemptive adjustments to welding parameters.

Closed-loop control systems represent the pinnacle of process optimization in laser welding applications. These systems continuously monitor weld characteristics and automatically adjust laser parameters in real-time to maintain optimal conditions. For heat sink attachment specifically, maintaining consistent thermal contact area is crucial, and adaptive power control algorithms can compensate for variations in material properties or surface conditions to ensure uniform joint quality.

Standardized testing protocols form the foundation of any quality control program. For heat sink attachments, these typically include pull tests to verify mechanical strength, thermal resistance measurements to confirm heat transfer efficiency, and cross-sectional metallographic analysis to examine weld penetration and microstructure. Non-destructive testing methods such as ultrasonic inspection and X-ray analysis provide additional verification without sacrificing production units.

The integration of quality control data with manufacturing execution systems (MES) creates opportunities for continuous improvement through comprehensive traceability. Each heat sink assembly can be linked to its specific process parameters, environmental conditions, and quality outcomes, enabling detailed root cause analysis when issues arise and facilitating targeted process refinements over time.

Statistical Process Control (SPC) methodologies have proven particularly effective when adapted for laser welding applications. By establishing control charts for key parameters such as laser power, focal position, and welding speed, manufacturers can maintain process stability and quickly identify deviations before they result in defective products. The collection and analysis of historical process data further enables the identification of optimal parameter windows for specific heat sink materials and geometries.

Advanced process optimization strategies increasingly leverage machine learning algorithms to enhance welding outcomes. These systems can analyze complex relationships between multiple process variables and final weld quality, identifying non-obvious correlations that human operators might miss. Predictive models developed through supervised learning techniques can anticipate potential defects before they occur, allowing for preemptive adjustments to welding parameters.

Closed-loop control systems represent the pinnacle of process optimization in laser welding applications. These systems continuously monitor weld characteristics and automatically adjust laser parameters in real-time to maintain optimal conditions. For heat sink attachment specifically, maintaining consistent thermal contact area is crucial, and adaptive power control algorithms can compensate for variations in material properties or surface conditions to ensure uniform joint quality.

Standardized testing protocols form the foundation of any quality control program. For heat sink attachments, these typically include pull tests to verify mechanical strength, thermal resistance measurements to confirm heat transfer efficiency, and cross-sectional metallographic analysis to examine weld penetration and microstructure. Non-destructive testing methods such as ultrasonic inspection and X-ray analysis provide additional verification without sacrificing production units.

The integration of quality control data with manufacturing execution systems (MES) creates opportunities for continuous improvement through comprehensive traceability. Each heat sink assembly can be linked to its specific process parameters, environmental conditions, and quality outcomes, enabling detailed root cause analysis when issues arise and facilitating targeted process refinements over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!