Laser Welding for Cognitive Production Lines: Future Prospects

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Technology Evolution and Objectives

Laser welding technology has evolved significantly since its inception in the 1960s, transforming from a niche application to a cornerstone of modern manufacturing. The journey began with basic CO2 lasers offering limited power and precision, primarily used for simple joining operations. By the 1980s, the introduction of Nd:YAG lasers marked a significant advancement, enabling more precise welding capabilities for a broader range of materials and thicknesses.

The 1990s and early 2000s witnessed the emergence of fiber and disk lasers, revolutionizing the field with higher power efficiency, improved beam quality, and enhanced control systems. These developments dramatically expanded laser welding applications across automotive, aerospace, electronics, and medical device manufacturing sectors, establishing it as a preferred joining technology for high-precision requirements.

Recent technological evolution has focused on intelligent integration capabilities, with laser welding systems increasingly incorporating sensors, real-time monitoring, and adaptive control mechanisms. This progression aligns with Industry 4.0 principles, enabling systems to detect and respond to variations in material properties, joint geometries, and process conditions autonomously.

The primary objective of contemporary laser welding technology development for cognitive production lines centers on achieving fully adaptive, self-optimizing welding processes. This involves creating systems capable of real-time quality assessment, predictive maintenance, and autonomous parameter adjustment based on machine learning algorithms that continuously improve performance through operational data analysis.

Technical goals include developing more sophisticated sensor arrays that can monitor multiple process parameters simultaneously, including thermal profiles, plasma characteristics, and weld pool dynamics. These sensors must operate at the microsecond scale to enable truly responsive control systems. Additionally, there is a push toward creating unified data architectures that facilitate seamless integration between laser welding stations and broader manufacturing execution systems.

Another critical objective involves enhancing energy efficiency while maintaining or improving weld quality, particularly for challenging materials like high-strength alloys, dissimilar metal combinations, and advanced composites used in lightweight construction. This requires fundamental research into beam-material interactions and the development of novel beam shaping technologies.

Looking forward, the technology roadmap aims to establish predictive quality assurance protocols that eliminate post-process inspection requirements, potentially reducing manufacturing costs by 15-20% while improving overall product reliability. The ultimate vision encompasses cognitive laser welding systems that can autonomously optimize processes for previously unseen components, effectively "learning" optimal parameters without human intervention.

The 1990s and early 2000s witnessed the emergence of fiber and disk lasers, revolutionizing the field with higher power efficiency, improved beam quality, and enhanced control systems. These developments dramatically expanded laser welding applications across automotive, aerospace, electronics, and medical device manufacturing sectors, establishing it as a preferred joining technology for high-precision requirements.

Recent technological evolution has focused on intelligent integration capabilities, with laser welding systems increasingly incorporating sensors, real-time monitoring, and adaptive control mechanisms. This progression aligns with Industry 4.0 principles, enabling systems to detect and respond to variations in material properties, joint geometries, and process conditions autonomously.

The primary objective of contemporary laser welding technology development for cognitive production lines centers on achieving fully adaptive, self-optimizing welding processes. This involves creating systems capable of real-time quality assessment, predictive maintenance, and autonomous parameter adjustment based on machine learning algorithms that continuously improve performance through operational data analysis.

Technical goals include developing more sophisticated sensor arrays that can monitor multiple process parameters simultaneously, including thermal profiles, plasma characteristics, and weld pool dynamics. These sensors must operate at the microsecond scale to enable truly responsive control systems. Additionally, there is a push toward creating unified data architectures that facilitate seamless integration between laser welding stations and broader manufacturing execution systems.

Another critical objective involves enhancing energy efficiency while maintaining or improving weld quality, particularly for challenging materials like high-strength alloys, dissimilar metal combinations, and advanced composites used in lightweight construction. This requires fundamental research into beam-material interactions and the development of novel beam shaping technologies.

Looking forward, the technology roadmap aims to establish predictive quality assurance protocols that eliminate post-process inspection requirements, potentially reducing manufacturing costs by 15-20% while improving overall product reliability. The ultimate vision encompasses cognitive laser welding systems that can autonomously optimize processes for previously unseen components, effectively "learning" optimal parameters without human intervention.

Market Demand Analysis for Smart Manufacturing Solutions

The global smart manufacturing market is experiencing unprecedented growth, driven by Industry 4.0 initiatives and the increasing need for production efficiency. Current market valuations place smart manufacturing solutions at approximately 250 billion USD in 2023, with projections indicating a compound annual growth rate of 12-15% through 2030. Laser welding technologies specifically represent a rapidly expanding segment within this market, with particular demand coming from automotive, aerospace, and electronics manufacturing sectors.

Market research indicates that manufacturers are increasingly seeking cognitive production solutions that can adapt to changing conditions in real-time. A recent survey of manufacturing executives revealed that 78% consider intelligent automation and cognitive manufacturing capabilities as "critical" or "very important" to their competitive strategy over the next five years. This represents a significant shift from just three years ago when only 45% held this view.

The demand for laser welding in cognitive production lines is being fueled by several key market drivers. First, there is increasing pressure for manufacturing precision in industries producing high-value components. Second, labor shortages and rising labor costs worldwide are accelerating automation adoption. Third, sustainability initiatives are pushing manufacturers toward more energy-efficient processes, where laser welding offers advantages over traditional joining methods.

Regional analysis shows that while Europe currently leads in adoption of cognitive manufacturing solutions incorporating advanced laser technologies, the Asia-Pacific region is expected to show the highest growth rate, with China, South Korea, and Japan making substantial investments in smart factory initiatives. North American manufacturers are increasingly focused on retrofitting existing production lines with cognitive capabilities rather than complete system replacements.

Customer demand patterns reveal a growing preference for integrated solutions that combine laser welding with real-time quality monitoring, predictive maintenance capabilities, and seamless integration with existing manufacturing execution systems. End users are particularly interested in solutions that offer demonstrable return on investment through reduced material waste, decreased downtime, and improved product quality.

The market is also witnessing increased demand for flexible manufacturing systems that can handle product customization without sacrificing efficiency. This trend is particularly relevant for laser welding applications, as cognitive production lines can rapidly adjust welding parameters to accommodate different materials and geometries without lengthy retooling processes.

Market research indicates that manufacturers are increasingly seeking cognitive production solutions that can adapt to changing conditions in real-time. A recent survey of manufacturing executives revealed that 78% consider intelligent automation and cognitive manufacturing capabilities as "critical" or "very important" to their competitive strategy over the next five years. This represents a significant shift from just three years ago when only 45% held this view.

The demand for laser welding in cognitive production lines is being fueled by several key market drivers. First, there is increasing pressure for manufacturing precision in industries producing high-value components. Second, labor shortages and rising labor costs worldwide are accelerating automation adoption. Third, sustainability initiatives are pushing manufacturers toward more energy-efficient processes, where laser welding offers advantages over traditional joining methods.

Regional analysis shows that while Europe currently leads in adoption of cognitive manufacturing solutions incorporating advanced laser technologies, the Asia-Pacific region is expected to show the highest growth rate, with China, South Korea, and Japan making substantial investments in smart factory initiatives. North American manufacturers are increasingly focused on retrofitting existing production lines with cognitive capabilities rather than complete system replacements.

Customer demand patterns reveal a growing preference for integrated solutions that combine laser welding with real-time quality monitoring, predictive maintenance capabilities, and seamless integration with existing manufacturing execution systems. End users are particularly interested in solutions that offer demonstrable return on investment through reduced material waste, decreased downtime, and improved product quality.

The market is also witnessing increased demand for flexible manufacturing systems that can handle product customization without sacrificing efficiency. This trend is particularly relevant for laser welding applications, as cognitive production lines can rapidly adjust welding parameters to accommodate different materials and geometries without lengthy retooling processes.

Current Laser Welding Challenges in Cognitive Production

Despite significant advancements in laser welding technology, several critical challenges persist in the context of cognitive production environments. The primary obstacle remains the real-time quality monitoring and control of welding processes. Current sensor technologies struggle to provide comprehensive data on weld quality parameters such as penetration depth, porosity, and microstructural properties during high-speed production. This limitation significantly hampers the implementation of truly adaptive cognitive systems capable of autonomous decision-making.

Material variability presents another substantial challenge. Modern manufacturing increasingly utilizes advanced materials with complex compositions and hybrid structures. These materials often exhibit unpredictable behavior during laser welding, including thermal distortion, cracking susceptibility, and inconsistent absorption of laser energy. Cognitive production systems currently lack sufficient algorithms to predict and compensate for these material-specific challenges in real-time.

Energy efficiency remains a persistent concern in laser welding applications. High-power lasers consume substantial energy, and optimizing power usage while maintaining weld quality requires sophisticated control systems. Current cognitive approaches have not fully addressed the balance between energy conservation and weld quality assurance, particularly in variable production environments where workpiece characteristics may change frequently.

Data integration across the production ecosystem represents a significant technical barrier. While individual welding stations may collect process data, the seamless integration of this information with broader manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms remains problematic. This integration gap prevents truly cognitive production lines from leveraging comprehensive data for predictive maintenance and process optimization.

The human-machine interface (HMI) for cognitive laser welding systems presents unique challenges. Current interfaces often fail to provide operators with intuitive visualization of complex process parameters and predictive analytics. This limitation reduces operator trust in autonomous systems and hampers effective human intervention when required, creating a bottleneck in the cognitive manufacturing workflow.

Standardization issues further complicate implementation. The lack of unified protocols for data exchange between different cognitive manufacturing modules creates interoperability problems. This fragmentation prevents the seamless integration of laser welding processes into broader cognitive production ecosystems, limiting the potential for holistic optimization across manufacturing value chains.

Material variability presents another substantial challenge. Modern manufacturing increasingly utilizes advanced materials with complex compositions and hybrid structures. These materials often exhibit unpredictable behavior during laser welding, including thermal distortion, cracking susceptibility, and inconsistent absorption of laser energy. Cognitive production systems currently lack sufficient algorithms to predict and compensate for these material-specific challenges in real-time.

Energy efficiency remains a persistent concern in laser welding applications. High-power lasers consume substantial energy, and optimizing power usage while maintaining weld quality requires sophisticated control systems. Current cognitive approaches have not fully addressed the balance between energy conservation and weld quality assurance, particularly in variable production environments where workpiece characteristics may change frequently.

Data integration across the production ecosystem represents a significant technical barrier. While individual welding stations may collect process data, the seamless integration of this information with broader manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms remains problematic. This integration gap prevents truly cognitive production lines from leveraging comprehensive data for predictive maintenance and process optimization.

The human-machine interface (HMI) for cognitive laser welding systems presents unique challenges. Current interfaces often fail to provide operators with intuitive visualization of complex process parameters and predictive analytics. This limitation reduces operator trust in autonomous systems and hampers effective human intervention when required, creating a bottleneck in the cognitive manufacturing workflow.

Standardization issues further complicate implementation. The lack of unified protocols for data exchange between different cognitive manufacturing modules creates interoperability problems. This fragmentation prevents the seamless integration of laser welding processes into broader cognitive production ecosystems, limiting the potential for holistic optimization across manufacturing value chains.

Existing Cognitive Laser Welding Implementation Approaches

01 Laser welding techniques for specific materials

Various laser welding techniques have been developed for specific materials, including metals, alloys, and composites. These techniques involve optimizing laser parameters such as power, wavelength, and pulse duration to achieve strong welds while minimizing thermal damage. Different materials require specific approaches to address challenges like thermal conductivity, reflectivity, and potential for cracking during the welding process.- Laser welding techniques for specific materials: Various laser welding techniques have been developed for specific materials, including metals, alloys, and composites. These techniques involve optimizing laser parameters such as power, wavelength, and pulse duration to achieve high-quality welds with minimal thermal distortion. The methods are particularly useful for joining dissimilar materials or heat-sensitive components where traditional welding approaches may cause damage.

- Beam control and manipulation systems: Advanced beam control and manipulation systems enhance laser welding precision and efficiency. These systems include optical components for focusing and directing the laser beam, scanners for rapid beam movement, and monitoring devices that provide real-time feedback. Such technologies enable complex welding patterns, precise energy distribution, and adaptive control during the welding process.

- Process monitoring and quality control: Laser welding systems incorporate sophisticated monitoring and quality control mechanisms to ensure weld integrity. These include sensors that detect thermal signatures, spectroscopic analysis of the plasma plume, and vision systems that inspect weld seams in real-time. The data collected enables automatic adjustment of welding parameters and helps identify defects before they become critical failures.

- Hybrid and specialized welding processes: Hybrid laser welding processes combine laser technology with other welding methods to leverage the advantages of multiple techniques. These include laser-arc hybrid welding, laser-ultrasonic welding, and laser welding with auxiliary heating. Such combinations can improve penetration depth, reduce porosity, enhance energy efficiency, and allow for welding of traditionally difficult materials.

- Automation and robotic integration: Integration of laser welding with robotic systems and automation technologies has revolutionized manufacturing processes. These systems feature programmable motion control, path planning algorithms, and coordination between multiple robots. Automated laser welding cells can perform complex three-dimensional welds with high repeatability, increased throughput, and minimal human intervention, making them ideal for high-volume production environments.

02 Beam control and manipulation systems

Advanced beam control and manipulation systems enhance laser welding precision and quality. These systems include optical components for focusing and directing the laser beam, scanners for rapid beam movement, and monitoring devices that provide real-time feedback. Precise beam control allows for complex weld patterns, consistent penetration depth, and reduced heat-affected zones, resulting in stronger welds with fewer defects.Expand Specific Solutions03 Process monitoring and quality control

Integrated monitoring systems for laser welding processes enable real-time quality control and defect detection. These systems utilize sensors, cameras, and spectroscopic techniques to analyze parameters such as melt pool dynamics, plasma formation, and thermal profiles during welding. Advanced algorithms process this data to identify anomalies and automatically adjust welding parameters, ensuring consistent weld quality and reducing rejection rates in production environments.Expand Specific Solutions04 Hybrid and multi-beam laser welding

Hybrid and multi-beam laser welding approaches combine different energy sources or multiple laser beams to overcome limitations of conventional single-beam welding. These techniques may integrate laser welding with arc welding, utilize multiple synchronized laser sources, or implement beam splitting to create customized energy distributions. Such approaches enable welding of dissimilar materials, increase processing speed, improve energy efficiency, and enhance weld quality for complex geometries.Expand Specific Solutions05 Specialized applications in manufacturing

Laser welding has been adapted for specialized manufacturing applications across various industries. These include precision welding of electronic components, hermetic sealing of medical devices, joining of automotive lightweight structures, and additive manufacturing processes. Each application requires specific laser parameters, fixturing methods, and process controls to address unique challenges such as miniaturization, material compatibility, and geometric complexity.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Laser welding for cognitive production lines is currently in the growth phase, with the market expected to expand significantly due to increasing automation demands in manufacturing. The global market size for smart laser welding systems is projected to reach $2.5 billion by 2027, driven by Industry 4.0 integration. Technologically, the field shows varying maturity levels, with companies like IPG Photonics, TRUMPF, and Coherent leading innovation in high-power fiber laser systems. Precitec and Laser Depth Dynamics are advancing real-time monitoring capabilities, while traditional manufacturers like Toyota and Caterpillar are implementing these technologies in production environments. Chinese players such as Maxphotonics and Han's Laser are rapidly closing the technology gap, particularly in cost-effective solutions for automotive and electronics applications.

PRECITEC ITM GmbH

Technical Solution: Precitec has developed a comprehensive cognitive laser welding solution centered around their Weldline and Weldmaster product families. Their approach integrates multiple sensor technologies including their proprietary Optical Coherence Tomography (OCT) system that provides micrometer-precision measurements of weld seam geometry before, during, and after welding. This enables real-time 3D profiling of the weld joint and detection of defects as they form. Precitec's cognitive system incorporates their Smart Welding software platform that uses machine learning algorithms to analyze sensor data and automatically optimize welding parameters based on material properties and joint characteristics. Their solution features closed-loop control that continuously adjusts laser focus position, power, and beam trajectory to maintain consistent weld quality despite variations in material or positioning. The system also implements their Smart View technology which provides augmented reality visualization of process parameters and quality metrics, enabling operators to quickly identify trends and potential issues before they affect production quality.

Strengths: Industry-leading OCT sensor technology providing unmatched precision in weld monitoring, extensive experience in automotive and precision manufacturing applications, and intuitive operator interfaces that simplify complex data interpretation. Weaknesses: Higher initial investment compared to conventional monitoring systems, requires careful integration with existing production control systems, and more complex calibration procedures.

IPG Photonics Corp.

Technical Solution: IPG Photonics has pioneered cognitive laser welding solutions centered around their high-power fiber laser technology. Their approach integrates advanced beam manipulation capabilities with sophisticated process monitoring systems. IPG's cognitive production line solution incorporates real-time weld pool monitoring using high-speed cameras and spectroscopic analysis to detect defects during formation. Their proprietary algorithms analyze spectral emissions from the welding process to identify material composition variations and adjust laser parameters accordingly. The system employs closed-loop feedback control that modifies laser power, pulse characteristics, and beam profile in milliseconds based on sensor inputs. IPG has also developed multi-sensor fusion technology that combines thermal imaging, optical coherence tomography, and acoustic monitoring to create comprehensive process fingerprints. This data feeds into their machine learning models that continuously improve welding parameters based on historical quality outcomes, enabling predictive quality control rather than post-process inspection.

Strengths: Superior fiber laser technology with exceptional beam quality and control, comprehensive multi-sensor monitoring approach, and significant R&D investment in AI-driven process control. Weaknesses: Solutions often require customization for specific applications, higher initial investment compared to conventional systems, and steeper learning curve for operators transitioning from traditional welding systems.

Key Innovations in Adaptive Laser Welding Control

Method for controlling a laser processing operation by means of a reinforcement learning agent and laser material processing head using the same

PatentActiveEP2585248A1

Innovation

- A method utilizing a Reinforcement Learning Agent to control laser processing, combining multiple sensor signals for adaptive monitoring and closed-loop control, allowing the system to learn from human experts and adapt to different materials and tasks, reducing the need for constant reconfiguration and improving quality assurance.

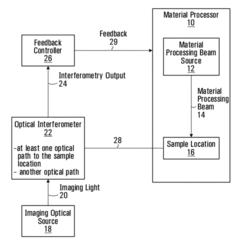

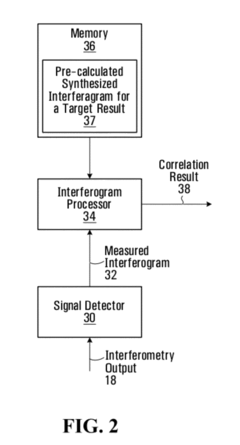

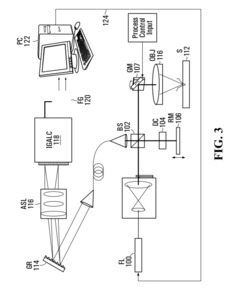

Methods and systems for coherent imaging and feedback control for modification of materials

PatentActiveUS20120138586A1

Innovation

- An apparatus and method utilizing an optical interferometer to generate an interferometry output based on optical path lengths, which is used to control processing parameters of a material modification process, such as laser cutting or welding, to achieve precise depth control through real-time feedback.

Industry 4.0 Integration Frameworks

The integration of laser welding technologies into cognitive production lines represents a critical intersection point for Industry 4.0 implementation. Current integration frameworks focus on establishing seamless communication protocols between laser welding systems and the broader manufacturing ecosystem. These frameworks typically operate on multi-layered architectures, with physical devices at the bottom layer, communication networks in the middle, and intelligent decision-making systems at the top.

Reference Architecture Model Industry 4.0 (RAMI 4.0) provides a comprehensive structure for integrating laser welding into cognitive production environments. This framework addresses horizontal integration across the value chain, vertical integration within manufacturing facilities, and end-to-end engineering integration throughout the product lifecycle. For laser welding applications, RAMI 4.0 enables real-time quality monitoring and adaptive process control through standardized interfaces.

The Industrial Internet Reference Architecture (IIRA) offers another significant framework, emphasizing functional domains including control, operations, information, and business aspects. In laser welding contexts, IIRA facilitates the implementation of digital twins that can simulate and optimize welding parameters before physical execution, significantly reducing material waste and setup time.

Open Platform Communications Unified Architecture (OPC UA) has emerged as the de facto standard for secure, reliable machine-to-machine communication in laser welding applications. This vendor-independent protocol enables seamless data exchange between welding equipment and higher-level systems, supporting features like automatic parameter adjustment based on material variations or environmental conditions.

Time-Sensitive Networking (TSN) standards are increasingly incorporated into integration frameworks to ensure deterministic communication for laser welding processes where timing precision is critical. TSN guarantees bounded latency and minimal jitter, essential for synchronizing multiple laser sources or coordinating welding operations with robotic movements.

Edge computing frameworks are gaining prominence in laser welding integration, allowing for localized processing of high-volume sensor data. This approach reduces latency in critical control loops and enables real-time anomaly detection without overwhelming central systems. Implementations typically utilize containerized applications that can be dynamically deployed and updated without disrupting production.

Cloud-based integration platforms complement edge solutions by providing scalable resources for data analytics and machine learning model training. These platforms aggregate welding performance data across multiple production lines, enabling cross-facility optimization and predictive maintenance scheduling based on comprehensive operational insights.

Reference Architecture Model Industry 4.0 (RAMI 4.0) provides a comprehensive structure for integrating laser welding into cognitive production environments. This framework addresses horizontal integration across the value chain, vertical integration within manufacturing facilities, and end-to-end engineering integration throughout the product lifecycle. For laser welding applications, RAMI 4.0 enables real-time quality monitoring and adaptive process control through standardized interfaces.

The Industrial Internet Reference Architecture (IIRA) offers another significant framework, emphasizing functional domains including control, operations, information, and business aspects. In laser welding contexts, IIRA facilitates the implementation of digital twins that can simulate and optimize welding parameters before physical execution, significantly reducing material waste and setup time.

Open Platform Communications Unified Architecture (OPC UA) has emerged as the de facto standard for secure, reliable machine-to-machine communication in laser welding applications. This vendor-independent protocol enables seamless data exchange between welding equipment and higher-level systems, supporting features like automatic parameter adjustment based on material variations or environmental conditions.

Time-Sensitive Networking (TSN) standards are increasingly incorporated into integration frameworks to ensure deterministic communication for laser welding processes where timing precision is critical. TSN guarantees bounded latency and minimal jitter, essential for synchronizing multiple laser sources or coordinating welding operations with robotic movements.

Edge computing frameworks are gaining prominence in laser welding integration, allowing for localized processing of high-volume sensor data. This approach reduces latency in critical control loops and enables real-time anomaly detection without overwhelming central systems. Implementations typically utilize containerized applications that can be dynamically deployed and updated without disrupting production.

Cloud-based integration platforms complement edge solutions by providing scalable resources for data analytics and machine learning model training. These platforms aggregate welding performance data across multiple production lines, enabling cross-facility optimization and predictive maintenance scheduling based on comprehensive operational insights.

Energy Efficiency and Sustainability Considerations

Laser welding technology in cognitive production lines presents significant opportunities for enhancing energy efficiency and sustainability across manufacturing sectors. Current laser welding systems consume substantial energy, with traditional high-power lasers requiring between 10-50 kW during operation. However, recent advancements in fiber laser technology have demonstrated energy efficiency improvements of up to 30% compared to conventional CO2 lasers, representing a critical step toward more sustainable manufacturing processes.

The integration of intelligent power management systems within cognitive production lines enables dynamic adjustment of laser power based on real-time welding requirements. These adaptive systems can reduce energy consumption by 15-25% through precise control mechanisms that prevent energy waste during idle periods and optimize power delivery during active welding phases. Furthermore, the implementation of predictive maintenance algorithms extends equipment lifespan by approximately 40%, significantly reducing the environmental impact associated with equipment replacement and disposal.

Heat recovery systems represent another promising avenue for sustainability enhancement in laser welding operations. By capturing and repurposing waste heat generated during the welding process, manufacturers can achieve secondary energy savings of 10-15%. This recaptured thermal energy can be redirected to facility heating or integrated into other manufacturing processes, creating closed-loop energy systems that maximize resource utilization.

Material efficiency improvements through precise laser welding techniques contribute substantially to sustainability goals. Cognitive production lines utilizing advanced laser welding can reduce material waste by up to 30% compared to traditional joining methods. The precision of laser welding minimizes the heat-affected zone, preserving material properties and reducing the need for post-processing operations that consume additional energy and resources.

Life cycle assessment studies indicate that modern laser welding systems in cognitive production environments can reduce the carbon footprint of welded components by 20-35% compared to conventional welding methods. This reduction stems from decreased energy consumption, reduced material waste, and longer equipment service life. Additionally, the elimination of consumables such as filler materials and shielding gases in many laser welding applications further enhances environmental performance.

Future developments in laser welding sustainability will likely focus on renewable energy integration, with pilot projects demonstrating the feasibility of powering laser systems through localized renewable energy sources. The combination of high-efficiency laser technologies with renewable energy could potentially reduce operational carbon emissions by 60-80%, establishing laser welding as a cornerstone technology for sustainable manufacturing in the coming decades.

The integration of intelligent power management systems within cognitive production lines enables dynamic adjustment of laser power based on real-time welding requirements. These adaptive systems can reduce energy consumption by 15-25% through precise control mechanisms that prevent energy waste during idle periods and optimize power delivery during active welding phases. Furthermore, the implementation of predictive maintenance algorithms extends equipment lifespan by approximately 40%, significantly reducing the environmental impact associated with equipment replacement and disposal.

Heat recovery systems represent another promising avenue for sustainability enhancement in laser welding operations. By capturing and repurposing waste heat generated during the welding process, manufacturers can achieve secondary energy savings of 10-15%. This recaptured thermal energy can be redirected to facility heating or integrated into other manufacturing processes, creating closed-loop energy systems that maximize resource utilization.

Material efficiency improvements through precise laser welding techniques contribute substantially to sustainability goals. Cognitive production lines utilizing advanced laser welding can reduce material waste by up to 30% compared to traditional joining methods. The precision of laser welding minimizes the heat-affected zone, preserving material properties and reducing the need for post-processing operations that consume additional energy and resources.

Life cycle assessment studies indicate that modern laser welding systems in cognitive production environments can reduce the carbon footprint of welded components by 20-35% compared to conventional welding methods. This reduction stems from decreased energy consumption, reduced material waste, and longer equipment service life. Additionally, the elimination of consumables such as filler materials and shielding gases in many laser welding applications further enhances environmental performance.

Future developments in laser welding sustainability will likely focus on renewable energy integration, with pilot projects demonstrating the feasibility of powering laser systems through localized renewable energy sources. The combination of high-efficiency laser technologies with renewable energy could potentially reduce operational carbon emissions by 60-80%, establishing laser welding as a cornerstone technology for sustainable manufacturing in the coming decades.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!