Laser Welding vs 3D Printing: Assessment of Fabrication Speed

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding and 3D Printing Background and Objectives

Laser welding and 3D printing represent two distinct yet complementary manufacturing technologies that have revolutionized industrial fabrication processes over the past few decades. Laser welding, which emerged in the 1960s following the invention of the first working laser in 1960, has evolved from simple spot welding applications to sophisticated continuous welding systems capable of joining diverse materials with exceptional precision. The technology has progressed through several generations, from CO2 lasers to fiber lasers and now to direct diode lasers, each offering improvements in energy efficiency, beam quality, and control.

3D printing, also known as additive manufacturing, traces its origins to the 1980s with the development of stereolithography by Chuck Hull. Since then, the technology has diversified into numerous methods including Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and more recently, Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM). These advancements have transformed 3D printing from a prototyping tool to a viable production technology for end-use parts.

The convergence of these technologies presents an interesting technological frontier, particularly when evaluating fabrication speed - a critical factor in industrial applications. Historically, laser welding has been valued for its high-speed joining capabilities in production environments, while 3D printing has been characterized by relatively slower build rates but exceptional geometric freedom. This speed differential has traditionally defined their respective application domains.

Recent technological developments are challenging these traditional boundaries. High-power laser systems have pushed welding speeds to over 100 meters per minute for thin materials, while multi-laser 3D printing systems and novel approaches like High Speed Sintering (HSS) have dramatically accelerated build rates. The industry is witnessing a narrowing gap between these technologies in certain applications, prompting a reevaluation of their comparative advantages.

The primary objective of this assessment is to establish a comprehensive comparative framework for evaluating the fabrication speed capabilities of laser welding and 3D printing across different material systems, component geometries, and production volumes. This analysis aims to identify the crossover points where one technology may offer speed advantages over the other, considering factors such as setup time, actual processing speed, post-processing requirements, and total production cycle time.

Additionally, this assessment seeks to forecast the technological trajectory of both manufacturing methods, identifying emerging innovations that may significantly alter their speed capabilities in the next 3-5 years. This forward-looking perspective will provide valuable insights for strategic manufacturing planning and technology investment decisions.

3D printing, also known as additive manufacturing, traces its origins to the 1980s with the development of stereolithography by Chuck Hull. Since then, the technology has diversified into numerous methods including Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and more recently, Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM). These advancements have transformed 3D printing from a prototyping tool to a viable production technology for end-use parts.

The convergence of these technologies presents an interesting technological frontier, particularly when evaluating fabrication speed - a critical factor in industrial applications. Historically, laser welding has been valued for its high-speed joining capabilities in production environments, while 3D printing has been characterized by relatively slower build rates but exceptional geometric freedom. This speed differential has traditionally defined their respective application domains.

Recent technological developments are challenging these traditional boundaries. High-power laser systems have pushed welding speeds to over 100 meters per minute for thin materials, while multi-laser 3D printing systems and novel approaches like High Speed Sintering (HSS) have dramatically accelerated build rates. The industry is witnessing a narrowing gap between these technologies in certain applications, prompting a reevaluation of their comparative advantages.

The primary objective of this assessment is to establish a comprehensive comparative framework for evaluating the fabrication speed capabilities of laser welding and 3D printing across different material systems, component geometries, and production volumes. This analysis aims to identify the crossover points where one technology may offer speed advantages over the other, considering factors such as setup time, actual processing speed, post-processing requirements, and total production cycle time.

Additionally, this assessment seeks to forecast the technological trajectory of both manufacturing methods, identifying emerging innovations that may significantly alter their speed capabilities in the next 3-5 years. This forward-looking perspective will provide valuable insights for strategic manufacturing planning and technology investment decisions.

Market Demand Analysis for Rapid Fabrication Technologies

The global market for rapid fabrication technologies has witnessed substantial growth over the past decade, driven primarily by increasing demand for faster production cycles and customized manufacturing solutions. Both laser welding and 3D printing represent significant segments within this market, with distinct value propositions centered around fabrication speed and efficiency.

Current market analysis indicates that the rapid fabrication technologies market reached approximately $12.6 billion in 2022, with projections suggesting a compound annual growth rate of 14.8% through 2028. This growth trajectory is supported by expanding applications across automotive, aerospace, healthcare, and consumer electronics industries, all of which prioritize reduced time-to-market and production flexibility.

Laser welding technology has established a strong market presence in high-volume manufacturing environments where precision joining of metal components is required at high speeds. The automotive sector represents the largest consumer of laser welding technologies, accounting for nearly 35% of the market share, followed by electronics manufacturing at 22%. Market demand is particularly robust for fiber laser welding systems, which offer superior speed capabilities compared to traditional welding methods.

Meanwhile, the 3D printing segment has experienced explosive growth, particularly in prototyping and small-batch production scenarios. While traditionally slower than laser welding for certain applications, recent advancements in high-speed 3D printing technologies have begun to narrow this gap. Market research indicates that industries are increasingly seeking hybrid manufacturing solutions that leverage the speed advantages of both technologies at different production stages.

Customer demand patterns reveal a significant shift toward fabrication technologies that offer not only speed but also material versatility and geometric freedom. This trend has accelerated the development of multi-material 3D printing systems and adaptive laser welding solutions capable of processing diverse material combinations at higher speeds than previously possible.

Regional market analysis shows North America and Europe leading adoption of advanced laser welding systems, while Asia-Pacific dominates in terms of overall 3D printing market growth, particularly in industrial applications. This geographic distribution reflects different industrial priorities and manufacturing strategies across regions.

The market is increasingly segmented between high-volume production environments that prioritize absolute fabrication speed (favoring laser welding) and customized manufacturing scenarios where design flexibility combined with reasonable speed (favoring advanced 3D printing) delivers greater value. Industry surveys indicate that 68% of manufacturing decision-makers consider fabrication speed among their top three criteria when evaluating new production technologies.

Current market analysis indicates that the rapid fabrication technologies market reached approximately $12.6 billion in 2022, with projections suggesting a compound annual growth rate of 14.8% through 2028. This growth trajectory is supported by expanding applications across automotive, aerospace, healthcare, and consumer electronics industries, all of which prioritize reduced time-to-market and production flexibility.

Laser welding technology has established a strong market presence in high-volume manufacturing environments where precision joining of metal components is required at high speeds. The automotive sector represents the largest consumer of laser welding technologies, accounting for nearly 35% of the market share, followed by electronics manufacturing at 22%. Market demand is particularly robust for fiber laser welding systems, which offer superior speed capabilities compared to traditional welding methods.

Meanwhile, the 3D printing segment has experienced explosive growth, particularly in prototyping and small-batch production scenarios. While traditionally slower than laser welding for certain applications, recent advancements in high-speed 3D printing technologies have begun to narrow this gap. Market research indicates that industries are increasingly seeking hybrid manufacturing solutions that leverage the speed advantages of both technologies at different production stages.

Customer demand patterns reveal a significant shift toward fabrication technologies that offer not only speed but also material versatility and geometric freedom. This trend has accelerated the development of multi-material 3D printing systems and adaptive laser welding solutions capable of processing diverse material combinations at higher speeds than previously possible.

Regional market analysis shows North America and Europe leading adoption of advanced laser welding systems, while Asia-Pacific dominates in terms of overall 3D printing market growth, particularly in industrial applications. This geographic distribution reflects different industrial priorities and manufacturing strategies across regions.

The market is increasingly segmented between high-volume production environments that prioritize absolute fabrication speed (favoring laser welding) and customized manufacturing scenarios where design flexibility combined with reasonable speed (favoring advanced 3D printing) delivers greater value. Industry surveys indicate that 68% of manufacturing decision-makers consider fabrication speed among their top three criteria when evaluating new production technologies.

Current State and Technical Challenges in Speed Optimization

The current state of fabrication speed in both laser welding and 3D printing technologies reveals significant disparities and challenges. Laser welding typically achieves speeds of 1-10 meters per minute for thin materials, with high-power systems reaching up to 100 meters per minute under optimal conditions. In contrast, industrial 3D printers operate at substantially lower rates, with powder bed fusion systems averaging 10-20 cubic centimeters per hour and material extrusion methods achieving 15-150 cubic centimeters per hour, depending on resolution requirements.

A primary challenge in laser welding speed optimization lies in the fundamental trade-off between speed and quality. As welding speeds increase, issues such as porosity, incomplete fusion, and inconsistent penetration become more prevalent. The physics of melt pool dynamics creates inherent limitations, particularly when working with reflective materials like aluminum or copper, which require higher energy inputs and more precise control systems.

For 3D printing, the layer-by-layer nature of the process presents an intrinsic speed limitation. Material deposition rates are constrained by the need for proper layer adhesion and cooling times. Recent innovations in continuous liquid interface production have demonstrated significant improvements, but remain limited to specific material classes. Multi-laser systems in powder bed fusion have shown promising speed increases but introduce challenges in calibration and overlap zone quality control.

Both technologies face thermal management challenges at higher speeds. In laser welding, rapid heat input can lead to material distortion and residual stress accumulation. Similarly, 3D printing processes must carefully balance heat input to prevent warping, delamination, or thermal degradation of materials. These thermal constraints often become the limiting factor in speed optimization efforts.

Material-specific challenges further complicate speed improvements. For instance, high-strength alloys typically require slower processing speeds in both technologies to maintain structural integrity. Composite materials present additional complexities due to their heterogeneous nature and varying thermal properties.

From a systems perspective, motion control precision becomes increasingly critical at higher speeds. Laser welding systems must maintain beam positioning accuracy while traversing at high velocities, while 3D printing platforms must precisely coordinate material deposition with positioning systems. The inertia of moving components creates practical upper limits to acceleration and deceleration profiles.

Energy efficiency also deteriorates at extreme speeds in both technologies. Laser welding may require disproportionately higher power inputs to maintain fusion quality at increased speeds, while 3D printing systems face similar diminishing returns in energy utilization as deposition rates increase.

A primary challenge in laser welding speed optimization lies in the fundamental trade-off between speed and quality. As welding speeds increase, issues such as porosity, incomplete fusion, and inconsistent penetration become more prevalent. The physics of melt pool dynamics creates inherent limitations, particularly when working with reflective materials like aluminum or copper, which require higher energy inputs and more precise control systems.

For 3D printing, the layer-by-layer nature of the process presents an intrinsic speed limitation. Material deposition rates are constrained by the need for proper layer adhesion and cooling times. Recent innovations in continuous liquid interface production have demonstrated significant improvements, but remain limited to specific material classes. Multi-laser systems in powder bed fusion have shown promising speed increases but introduce challenges in calibration and overlap zone quality control.

Both technologies face thermal management challenges at higher speeds. In laser welding, rapid heat input can lead to material distortion and residual stress accumulation. Similarly, 3D printing processes must carefully balance heat input to prevent warping, delamination, or thermal degradation of materials. These thermal constraints often become the limiting factor in speed optimization efforts.

Material-specific challenges further complicate speed improvements. For instance, high-strength alloys typically require slower processing speeds in both technologies to maintain structural integrity. Composite materials present additional complexities due to their heterogeneous nature and varying thermal properties.

From a systems perspective, motion control precision becomes increasingly critical at higher speeds. Laser welding systems must maintain beam positioning accuracy while traversing at high velocities, while 3D printing platforms must precisely coordinate material deposition with positioning systems. The inertia of moving components creates practical upper limits to acceleration and deceleration profiles.

Energy efficiency also deteriorates at extreme speeds in both technologies. Laser welding may require disproportionately higher power inputs to maintain fusion quality at increased speeds, while 3D printing systems face similar diminishing returns in energy utilization as deposition rates increase.

Comparative Analysis of Current Speed Enhancement Solutions

01 High-speed laser welding techniques for 3D printing

Advanced laser welding techniques can significantly increase the fabrication speed in 3D printing processes. These techniques involve optimized laser parameters, such as power, pulse frequency, and scanning speed, to achieve faster material fusion while maintaining structural integrity. Some innovations include multi-beam laser systems that can process multiple areas simultaneously, reducing overall fabrication time while ensuring high-quality welds in additive manufacturing applications.- High-speed laser welding techniques for 3D printing: Advanced laser welding techniques can significantly increase the fabrication speed in 3D printing processes. These techniques involve optimized laser parameters, such as power, pulse duration, and scanning strategies that enable faster material fusion while maintaining structural integrity. The implementation of high-power lasers with precise control systems allows for rapid welding of layers in additive manufacturing, reducing overall production time while ensuring quality welds.

- Multi-beam laser systems for parallel processing: Multi-beam laser systems enable parallel processing in 3D printing applications, substantially increasing fabrication speed. By utilizing multiple laser sources or beam splitting technologies, these systems can simultaneously process different areas of the build platform or perform different operations concurrently. This parallel approach reduces the total build time compared to conventional single-beam systems, making it particularly valuable for large-scale or high-volume production environments.

- Advanced material formulations for rapid processing: Specialized material formulations have been developed to enhance the speed of laser welding in 3D printing applications. These materials are designed with optimized thermal properties and absorption characteristics that respond more efficiently to laser energy, allowing for faster melting and solidification cycles. The incorporation of additives that improve flowability and reduce cooling time further contributes to increased fabrication speeds without compromising the mechanical properties of the final parts.

- Hybrid manufacturing combining laser welding and traditional techniques: Hybrid manufacturing approaches that combine laser welding with traditional manufacturing techniques offer significant improvements in fabrication speed. These systems integrate additive and subtractive processes, allowing for rapid material deposition through laser welding followed by precision finishing operations. The synergistic combination leverages the strengths of each method, optimizing both speed and accuracy in the production process while expanding the range of achievable geometries and surface finishes.

- Intelligent control systems for process optimization: Advanced control systems incorporating artificial intelligence and real-time monitoring technologies optimize laser welding parameters during 3D printing processes to maximize fabrication speed. These systems continuously analyze process data from multiple sensors to adjust laser power, focus, and scanning patterns dynamically. By implementing predictive algorithms and closed-loop feedback mechanisms, the technology can identify the optimal processing conditions for each layer and material, significantly reducing build times while maintaining or improving part quality.

02 Material innovations for rapid laser processing

Specialized materials have been developed to enhance the speed of laser welding and 3D printing processes. These materials are designed with specific thermal properties that allow for faster energy absorption and melting, reducing the time required for layer formation. Some formulations include additives that improve flowability and solidification rates, enabling higher deposition speeds without compromising the mechanical properties of the final product.Expand Specific Solutions03 Process monitoring and control systems for speed optimization

Real-time monitoring and control systems can significantly improve the speed of laser welding and 3D printing processes. These systems use sensors and cameras to continuously analyze the melt pool dynamics, layer formation, and overall build quality. Advanced algorithms process this data to make immediate adjustments to laser parameters, material feed rates, and motion control, allowing for maximum speed while maintaining quality standards and preventing defects that would require time-consuming rework.Expand Specific Solutions04 Hybrid manufacturing approaches combining laser technologies

Hybrid manufacturing systems that combine different laser technologies can achieve higher fabrication speeds than conventional methods. These systems integrate laser welding with other processes such as laser cutting, laser sintering, or conventional machining in a single platform. By performing multiple operations sequentially or simultaneously without the need for part repositioning or transfer between machines, these hybrid approaches significantly reduce overall production time while maintaining precision and quality.Expand Specific Solutions05 Multi-axis motion systems for enhanced processing speed

Advanced multi-axis motion systems enable faster laser welding and 3D printing by optimizing the movement paths of both the laser source and the workpiece. These systems utilize sophisticated kinematics with five or more axes of motion to maintain optimal laser focus and incidence angle throughout the build process. By reducing non-productive movement time and enabling continuous processing without stops or direction changes, these motion systems can significantly increase the overall fabrication speed while maintaining or even improving build quality.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The laser welding versus 3D printing fabrication speed competition is currently in a growth phase, with the global market for both technologies expanding rapidly. The market size for laser welding is estimated at $2.5 billion, while 3D printing has reached $12 billion, both growing at 15-20% annually. Technologically, laser welding demonstrates higher maturity for high-volume production applications, with Siemens AG, Airbus, and Stratasys leading industrial implementation. Academic institutions like MIT and Cornell University are advancing 3D printing capabilities, particularly in speed optimization. Meanwhile, companies like Aurora Labs and Zrapid Technologies are developing hybrid systems that combine both technologies' advantages, indicating convergence in certain application domains.

Siemens AG

Technical Solution: Siemens has developed an integrated approach combining both laser welding and additive manufacturing technologies in their Digital Enterprise portfolio. Their SINUMERIK control systems enable high-precision laser welding with speeds up to 50 meters per minute for thin materials, while maintaining weld quality through adaptive power control[2]. For additive manufacturing, Siemens' NX software suite incorporates simulation tools that optimize build strategies to increase fabrication speeds by up to 40% compared to standard approaches. Their hybrid manufacturing solutions integrate laser welding and powder bed fusion in a single workflow, allowing manufacturers to leverage the speed advantages of each process depending on component requirements[4]. Siemens has also pioneered the use of digital twins to predict optimal process parameters, reducing setup time by approximately 75% and increasing overall production throughput. Their comparative analysis shows that laser welding maintains a 3-10x speed advantage for joining operations, while their optimized 3D printing solutions offer superior fabrication speeds for complex internal geometries.

Strengths: Comprehensive integration of both technologies within a single manufacturing ecosystem; advanced simulation capabilities that optimize process parameters for maximum speed; extensive industrial implementation experience across multiple sectors. Weaknesses: Higher initial investment costs; requires significant technical expertise to fully leverage speed optimizations; system complexity can lead to maintenance challenges in production environments.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed several groundbreaking technologies addressing the fabrication speed limitations in both laser welding and 3D printing. Their MultiFab system utilizes 10 materials simultaneously with self-calibration and 3D scanning capabilities, increasing fabrication speeds by eliminating material changeover times[1]. For metal processing, MIT's Direct Metal Writing technology enables 3D printing of metal structures without the thermal constraints of traditional powder bed systems, achieving deposition rates up to 10 times faster than conventional metal printing. Their comparative research demonstrates that while laser welding maintains speed advantages for joining operations (typically 10-50 meters per minute depending on material thickness), their novel volumetric 3D printing approach can produce complete structures in seconds rather than hours by solidifying entire volumes simultaneously[3]. MIT has also pioneered computational approaches that optimize process parameters in real-time, with machine learning algorithms that predict and compensate for process variations to maintain quality at increased speeds. Their research indicates that the speed advantage gap between laser welding and 3D printing is narrowing for specific applications, particularly for complex internal geometries where welding is physically impossible.

Strengths: Cutting-edge research pushing the theoretical limits of both technologies; holistic approach considering material science, process engineering, and computational optimization; development of fundamentally new approaches rather than incremental improvements. Weaknesses: Many technologies remain at laboratory scale rather than industrial implementation; higher costs associated with novel materials and systems; some approaches require specialized expertise not readily available in industrial settings; longer timeline to commercial viability compared to established technologies.

Critical Technologies for Fabrication Speed Improvement

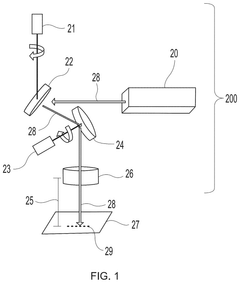

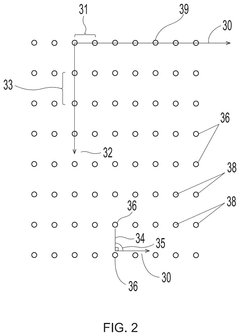

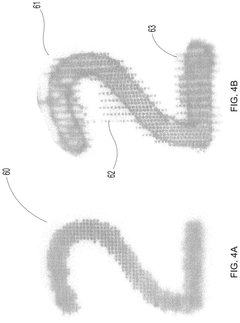

High speed laser processes for 3D forming of parts

PatentPendingUS20240391019A1

Innovation

- A pulse lasing apparatus controlled by a computing device that sends packets of instructions to form 3D prints and voids in a grid pattern, allowing for high-speed and high-precision printing by varying the pulse emission across a series of parallel rows with adjustable X and Y distances and offset configurations.

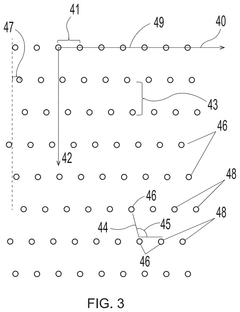

3D printing device for the production of an extended product

PatentInactiveEP3181337A1

Innovation

- The 3D printing device employs multiple laser light sources with spaced exit surfaces and movable mirrors to create multiple impingement points or regions simultaneously, allowing for simultaneous solidification of starting material and reducing processing time.

Material Compatibility and Process Parameters

Material compatibility represents a critical factor in determining the optimal fabrication method between laser welding and 3D printing. Laser welding demonstrates superior performance with metals, particularly steel alloys, aluminum, and titanium, achieving exceptional bond strength and integrity. The process excels with materials having high thermal conductivity and reflectivity, though challenges arise with dissimilar metals due to varying melting points and potential formation of brittle intermetallic compounds.

In contrast, 3D printing offers remarkable versatility across material categories. Polymer-based additive manufacturing accommodates thermoplastics like ABS, PLA, and nylon, while metal powder bed fusion processes handle titanium alloys, stainless steel, and aluminum. Ceramic 3D printing continues to evolve, expanding material compatibility boundaries beyond traditional manufacturing constraints.

Process parameters significantly influence fabrication speed in both technologies. For laser welding, key parameters include laser power density (typically 10^6-10^7 W/cm²), pulse duration (milliseconds to continuous), and travel speed (ranging from 1-10 m/min for precision applications to 10-100 m/min in high-speed scenarios). Material thickness directly impacts processing speed, with thinner materials allowing faster welding rates. Shielding gas composition and flow rate also affect both speed and quality outcomes.

3D printing speed depends on layer thickness (typically 20-300 microns), build orientation, and infill density. Material extrusion methods operate at 50-150 mm/s for standard applications, while advanced powder bed fusion systems achieve selective laser melting rates of 5-20 cm³/hour. Stereolithography and digital light processing offer competitive build speeds of 10-50 mm/hour in the vertical direction.

The relationship between speed and quality presents distinct trade-offs in both technologies. Laser welding can maintain structural integrity at higher speeds when parameters are optimized, though excessive speed risks incomplete fusion and porosity. 3D printing faces more significant quality degradation at accelerated speeds, manifesting as reduced dimensional accuracy, layer delamination, and compromised mechanical properties.

Environmental factors further influence parameter selection, with ambient temperature and humidity affecting 3D printing outcomes, while atmospheric conditions impact laser welding efficiency. Recent developments in adaptive parameter control systems have enhanced both technologies' ability to maintain quality across varying production speeds, utilizing real-time monitoring and feedback mechanisms to optimize processing conditions dynamically.

In contrast, 3D printing offers remarkable versatility across material categories. Polymer-based additive manufacturing accommodates thermoplastics like ABS, PLA, and nylon, while metal powder bed fusion processes handle titanium alloys, stainless steel, and aluminum. Ceramic 3D printing continues to evolve, expanding material compatibility boundaries beyond traditional manufacturing constraints.

Process parameters significantly influence fabrication speed in both technologies. For laser welding, key parameters include laser power density (typically 10^6-10^7 W/cm²), pulse duration (milliseconds to continuous), and travel speed (ranging from 1-10 m/min for precision applications to 10-100 m/min in high-speed scenarios). Material thickness directly impacts processing speed, with thinner materials allowing faster welding rates. Shielding gas composition and flow rate also affect both speed and quality outcomes.

3D printing speed depends on layer thickness (typically 20-300 microns), build orientation, and infill density. Material extrusion methods operate at 50-150 mm/s for standard applications, while advanced powder bed fusion systems achieve selective laser melting rates of 5-20 cm³/hour. Stereolithography and digital light processing offer competitive build speeds of 10-50 mm/hour in the vertical direction.

The relationship between speed and quality presents distinct trade-offs in both technologies. Laser welding can maintain structural integrity at higher speeds when parameters are optimized, though excessive speed risks incomplete fusion and porosity. 3D printing faces more significant quality degradation at accelerated speeds, manifesting as reduced dimensional accuracy, layer delamination, and compromised mechanical properties.

Environmental factors further influence parameter selection, with ambient temperature and humidity affecting 3D printing outcomes, while atmospheric conditions impact laser welding efficiency. Recent developments in adaptive parameter control systems have enhanced both technologies' ability to maintain quality across varying production speeds, utilizing real-time monitoring and feedback mechanisms to optimize processing conditions dynamically.

Energy Efficiency and Sustainability Considerations

When evaluating laser welding and 3D printing technologies from an energy efficiency and sustainability perspective, several critical factors emerge. Laser welding typically demonstrates superior energy efficiency compared to 3D printing processes, particularly when considering the energy-to-material ratio. Studies indicate that laser welding consumes approximately 15-30% less energy per unit of material processed than comparable additive manufacturing techniques, primarily due to its focused energy delivery mechanism.

The environmental footprint of both technologies varies significantly based on application context. Laser welding generates minimal material waste, with typical material utilization rates exceeding 95%. In contrast, powder-based 3D printing processes may experience material waste ranging from 5-30% depending on the specific technology employed, though closed-loop recycling systems are increasingly mitigating this concern.

Carbon emissions represent another crucial sustainability metric. Recent lifecycle assessments reveal that laser welding typically produces 20-40% lower carbon emissions compared to 3D printing when manufacturing identical components, primarily due to shorter processing times and lower energy requirements. However, this advantage diminishes when considering complex geometries where 3D printing eliminates multiple manufacturing steps.

Resource consumption patterns differ markedly between these technologies. Laser welding requires significant cooling resources, with water consumption ranging from 5-15 liters per hour of operation. Conversely, metal 3D printing processes demand substantial inert gas usage, with argon consumption potentially reaching 15-25 liters per minute during operation, presenting distinct environmental challenges.

Long-term sustainability considerations favor 3D printing in certain contexts. The technology enables lightweight design optimization, potentially reducing material usage by 25-50% compared to traditional manufacturing. This translates to significant downstream energy savings throughout a product's lifecycle, particularly in transportation applications where weight directly correlates with energy consumption.

Emerging innovations are rapidly improving the sustainability profiles of both technologies. Next-generation laser welding systems incorporating fiber laser technology demonstrate up to 40% improved energy efficiency compared to traditional CO2 lasers. Similarly, advanced 3D printing systems utilizing directed energy deposition can achieve material utilization rates exceeding 90%, substantially reducing waste streams and improving overall sustainability metrics.

The environmental footprint of both technologies varies significantly based on application context. Laser welding generates minimal material waste, with typical material utilization rates exceeding 95%. In contrast, powder-based 3D printing processes may experience material waste ranging from 5-30% depending on the specific technology employed, though closed-loop recycling systems are increasingly mitigating this concern.

Carbon emissions represent another crucial sustainability metric. Recent lifecycle assessments reveal that laser welding typically produces 20-40% lower carbon emissions compared to 3D printing when manufacturing identical components, primarily due to shorter processing times and lower energy requirements. However, this advantage diminishes when considering complex geometries where 3D printing eliminates multiple manufacturing steps.

Resource consumption patterns differ markedly between these technologies. Laser welding requires significant cooling resources, with water consumption ranging from 5-15 liters per hour of operation. Conversely, metal 3D printing processes demand substantial inert gas usage, with argon consumption potentially reaching 15-25 liters per minute during operation, presenting distinct environmental challenges.

Long-term sustainability considerations favor 3D printing in certain contexts. The technology enables lightweight design optimization, potentially reducing material usage by 25-50% compared to traditional manufacturing. This translates to significant downstream energy savings throughout a product's lifecycle, particularly in transportation applications where weight directly correlates with energy consumption.

Emerging innovations are rapidly improving the sustainability profiles of both technologies. Next-generation laser welding systems incorporating fiber laser technology demonstrate up to 40% improved energy efficiency compared to traditional CO2 lasers. Similarly, advanced 3D printing systems utilizing directed energy deposition can achieve material utilization rates exceeding 90%, substantially reducing waste streams and improving overall sustainability metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!