Emissivity Control in Laser Welding: Techniques and Benefits

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Emissivity Control Background and Objectives

Laser welding has evolved significantly since its inception in the 1960s, transforming from a niche manufacturing process to a mainstream joining technology across multiple industries. The evolution of laser welding technology has been characterized by continuous improvements in beam quality, power delivery systems, and process control mechanisms. Emissivity control, in particular, has emerged as a critical factor in achieving consistent and high-quality welds, especially as industries push toward more challenging materials and complex geometries.

The fundamental principle of laser welding involves the conversion of light energy into thermal energy at the workpiece surface. This conversion efficiency is directly influenced by the material's emissivity - the measure of a material's ability to absorb, reflect, or transmit laser radiation. Historically, emissivity variations have been a significant source of process instability and weld defects, particularly when working with highly reflective materials like aluminum alloys, copper, and certain stainless steels.

Recent technological advancements have shifted focus toward active emissivity control as a means to enhance weld quality, process stability, and energy efficiency. The development trajectory shows a clear trend from passive acceptance of material-dependent emissivity limitations toward active modification and real-time control of surface properties to optimize laser-material interaction.

The primary objective of emissivity control in laser welding is to achieve consistent energy absorption across different materials and surface conditions, thereby ensuring uniform weld quality regardless of workpiece variations. Secondary objectives include reducing energy requirements, minimizing heat-affected zones, enabling welding of dissimilar materials, and facilitating automation in high-volume production environments.

Current research indicates that precise emissivity control can potentially reduce energy consumption by 15-30% while simultaneously improving weld penetration depth consistency by up to 40% compared to conventional approaches. These improvements directly translate to enhanced product quality, reduced scrap rates, and lower production costs.

The global push toward lightweight structures in automotive and aerospace industries, coupled with the increasing adoption of electric vehicles requiring copper components, has further accelerated the need for advanced emissivity control techniques. Additionally, the growing trend toward miniaturization in electronics manufacturing demands unprecedented precision in micro-welding applications, where even minor variations in energy absorption can lead to catastrophic failures.

As we look toward future developments, emissivity control represents a critical enabling technology for next-generation manufacturing processes, particularly those involving multi-material assemblies and components with complex geometries or varying surface conditions.

The fundamental principle of laser welding involves the conversion of light energy into thermal energy at the workpiece surface. This conversion efficiency is directly influenced by the material's emissivity - the measure of a material's ability to absorb, reflect, or transmit laser radiation. Historically, emissivity variations have been a significant source of process instability and weld defects, particularly when working with highly reflective materials like aluminum alloys, copper, and certain stainless steels.

Recent technological advancements have shifted focus toward active emissivity control as a means to enhance weld quality, process stability, and energy efficiency. The development trajectory shows a clear trend from passive acceptance of material-dependent emissivity limitations toward active modification and real-time control of surface properties to optimize laser-material interaction.

The primary objective of emissivity control in laser welding is to achieve consistent energy absorption across different materials and surface conditions, thereby ensuring uniform weld quality regardless of workpiece variations. Secondary objectives include reducing energy requirements, minimizing heat-affected zones, enabling welding of dissimilar materials, and facilitating automation in high-volume production environments.

Current research indicates that precise emissivity control can potentially reduce energy consumption by 15-30% while simultaneously improving weld penetration depth consistency by up to 40% compared to conventional approaches. These improvements directly translate to enhanced product quality, reduced scrap rates, and lower production costs.

The global push toward lightweight structures in automotive and aerospace industries, coupled with the increasing adoption of electric vehicles requiring copper components, has further accelerated the need for advanced emissivity control techniques. Additionally, the growing trend toward miniaturization in electronics manufacturing demands unprecedented precision in micro-welding applications, where even minor variations in energy absorption can lead to catastrophic failures.

As we look toward future developments, emissivity control represents a critical enabling technology for next-generation manufacturing processes, particularly those involving multi-material assemblies and components with complex geometries or varying surface conditions.

Market Demand Analysis for Precision Laser Welding

The precision laser welding market is experiencing robust growth driven by increasing demand for high-quality, precise joining solutions across multiple industries. Current market analysis indicates that the global laser welding equipment market is projected to reach $2.5 billion by 2027, with a compound annual growth rate of 5.8% from 2022. This growth is primarily fueled by the automotive, electronics, medical device, and aerospace sectors, where precision and quality control are paramount.

In the automotive industry, the shift toward lightweight materials and electric vehicles has significantly increased the need for advanced laser welding technologies with precise emissivity control. Manufacturers require welding solutions that can join dissimilar materials while maintaining structural integrity and aesthetic quality. The electric vehicle segment alone has seen a 40% increase in demand for precision laser welding equipment over the past three years.

The electronics manufacturing sector represents another substantial market driver, with miniaturization trends necessitating increasingly precise welding capabilities. Consumer electronics manufacturers report that components requiring precision welds have decreased in size by an average of 30% in the last five years, pushing the boundaries of traditional welding techniques and creating demand for advanced emissivity control solutions.

Medical device manufacturing presents a particularly promising growth segment, with stringent regulatory requirements driving adoption of high-precision welding technologies. The market for laser welding in medical devices is growing at 7.2% annually, outpacing the overall industry average. Manufacturers in this space require welding solutions that can ensure hermetic seals and biocompatibility while working with increasingly complex material combinations.

Regional analysis reveals that Asia-Pacific currently dominates the market with approximately 40% share, followed by North America and Europe. China and South Korea are experiencing the fastest growth rates in adoption, driven by rapid industrialization and government initiatives supporting advanced manufacturing technologies.

End-user surveys indicate that key purchasing factors include weld quality consistency (cited by 85% of respondents), production efficiency improvements (78%), and ability to work with new material combinations (72%). Notably, 67% of industrial customers specifically mentioned emissivity control capabilities as a critical factor in their purchasing decisions, highlighting the growing awareness of this technology's importance.

Market forecasts suggest that technologies enabling precise emissivity control in laser welding will see particularly strong demand growth, with an estimated 9.3% CAGR through 2027, significantly outpacing the broader laser welding market. This premium segment is expected to command higher profit margins and represents a strategic opportunity for technology providers who can deliver effective solutions.

In the automotive industry, the shift toward lightweight materials and electric vehicles has significantly increased the need for advanced laser welding technologies with precise emissivity control. Manufacturers require welding solutions that can join dissimilar materials while maintaining structural integrity and aesthetic quality. The electric vehicle segment alone has seen a 40% increase in demand for precision laser welding equipment over the past three years.

The electronics manufacturing sector represents another substantial market driver, with miniaturization trends necessitating increasingly precise welding capabilities. Consumer electronics manufacturers report that components requiring precision welds have decreased in size by an average of 30% in the last five years, pushing the boundaries of traditional welding techniques and creating demand for advanced emissivity control solutions.

Medical device manufacturing presents a particularly promising growth segment, with stringent regulatory requirements driving adoption of high-precision welding technologies. The market for laser welding in medical devices is growing at 7.2% annually, outpacing the overall industry average. Manufacturers in this space require welding solutions that can ensure hermetic seals and biocompatibility while working with increasingly complex material combinations.

Regional analysis reveals that Asia-Pacific currently dominates the market with approximately 40% share, followed by North America and Europe. China and South Korea are experiencing the fastest growth rates in adoption, driven by rapid industrialization and government initiatives supporting advanced manufacturing technologies.

End-user surveys indicate that key purchasing factors include weld quality consistency (cited by 85% of respondents), production efficiency improvements (78%), and ability to work with new material combinations (72%). Notably, 67% of industrial customers specifically mentioned emissivity control capabilities as a critical factor in their purchasing decisions, highlighting the growing awareness of this technology's importance.

Market forecasts suggest that technologies enabling precise emissivity control in laser welding will see particularly strong demand growth, with an estimated 9.3% CAGR through 2027, significantly outpacing the broader laser welding market. This premium segment is expected to command higher profit margins and represents a strategic opportunity for technology providers who can deliver effective solutions.

Current Emissivity Control Technologies and Challenges

Emissivity control in laser welding represents a critical technological challenge that significantly impacts weld quality, process stability, and energy efficiency. Currently, several technologies exist for controlling emissivity during laser welding processes, each with distinct advantages and limitations.

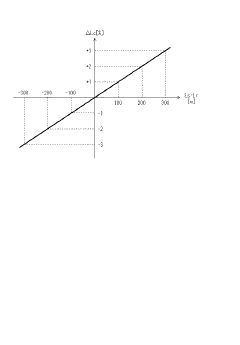

Surface treatment methods constitute the most widely implemented approach, including mechanical treatments (sandblasting, grinding), chemical treatments (etching, oxidation), and coating applications (absorptive layers). These techniques can modify surface emissivity from 0.1 to 0.9 depending on the specific treatment. However, they often suffer from inconsistency across different material batches and degradation during the welding process itself.

Real-time emissivity measurement systems have emerged as a more sophisticated solution, utilizing pyrometers and thermal cameras calibrated to specific wavelengths. These systems can provide feedback for process control but face challenges in accurately measuring rapidly changing thermal conditions during welding. Current measurement accuracy typically ranges from ±2% to ±5% under optimal conditions but deteriorates significantly in industrial environments.

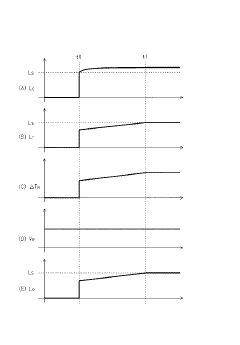

Adaptive laser power control systems represent the state-of-the-art approach, where closed-loop systems adjust laser parameters based on real-time emissivity measurements. While promising, these systems struggle with response latency (typically 10-50ms), which can be insufficient for high-speed welding applications exceeding 10m/min.

Dual-wavelength and multi-wavelength laser systems have been developed to address material-specific emissivity variations. These systems can partially compensate for emissivity differences but add significant complexity and cost to welding equipment, limiting widespread industrial adoption.

The geographical distribution of emissivity control technology development shows concentration in Germany, Japan, and the United States, with emerging research centers in China and South Korea. Industrial implementation remains limited primarily to high-value manufacturing sectors such as aerospace and medical device production.

Key technical challenges include achieving consistent emissivity control across diverse material combinations, developing faster response systems for high-speed applications, and creating cost-effective solutions suitable for mass production environments. Additionally, the lack of standardized measurement protocols and calibration standards hampers technology transfer and implementation.

Material-specific challenges persist, particularly with highly reflective materials like aluminum and copper alloys, where emissivity can be as low as 0.05-0.15, creating significant process instability and energy inefficiency. Similarly, dissimilar material welding presents complex emissivity gradients that current technologies struggle to address effectively.

Surface treatment methods constitute the most widely implemented approach, including mechanical treatments (sandblasting, grinding), chemical treatments (etching, oxidation), and coating applications (absorptive layers). These techniques can modify surface emissivity from 0.1 to 0.9 depending on the specific treatment. However, they often suffer from inconsistency across different material batches and degradation during the welding process itself.

Real-time emissivity measurement systems have emerged as a more sophisticated solution, utilizing pyrometers and thermal cameras calibrated to specific wavelengths. These systems can provide feedback for process control but face challenges in accurately measuring rapidly changing thermal conditions during welding. Current measurement accuracy typically ranges from ±2% to ±5% under optimal conditions but deteriorates significantly in industrial environments.

Adaptive laser power control systems represent the state-of-the-art approach, where closed-loop systems adjust laser parameters based on real-time emissivity measurements. While promising, these systems struggle with response latency (typically 10-50ms), which can be insufficient for high-speed welding applications exceeding 10m/min.

Dual-wavelength and multi-wavelength laser systems have been developed to address material-specific emissivity variations. These systems can partially compensate for emissivity differences but add significant complexity and cost to welding equipment, limiting widespread industrial adoption.

The geographical distribution of emissivity control technology development shows concentration in Germany, Japan, and the United States, with emerging research centers in China and South Korea. Industrial implementation remains limited primarily to high-value manufacturing sectors such as aerospace and medical device production.

Key technical challenges include achieving consistent emissivity control across diverse material combinations, developing faster response systems for high-speed applications, and creating cost-effective solutions suitable for mass production environments. Additionally, the lack of standardized measurement protocols and calibration standards hampers technology transfer and implementation.

Material-specific challenges persist, particularly with highly reflective materials like aluminum and copper alloys, where emissivity can be as low as 0.05-0.15, creating significant process instability and energy inefficiency. Similarly, dissimilar material welding presents complex emissivity gradients that current technologies struggle to address effectively.

Existing Emissivity Control Solutions and Implementation Methods

01 Emissivity control in laser welding processes

Controlling the emissivity of materials is crucial in laser welding to ensure optimal energy absorption. Various techniques can be employed to modify surface emissivity, including applying coatings, surface treatments, or additives that enhance the absorption of laser energy. By manipulating the emissivity properties, welding efficiency can be improved, particularly when joining materials with naturally low absorption characteristics.- Surface emissivity modification for laser welding: Modifying the surface emissivity of materials can significantly improve laser welding efficiency. Various coatings or treatments can be applied to increase absorption of laser energy, particularly for reflective materials like aluminum or copper. These modifications help to achieve more consistent weld quality by ensuring better energy coupling between the laser beam and the workpiece surface.

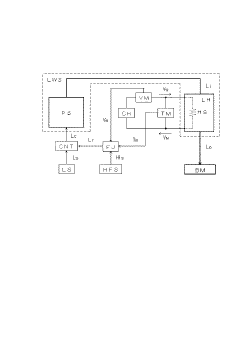

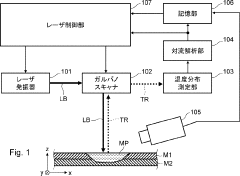

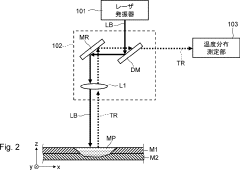

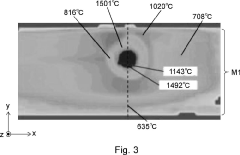

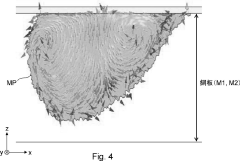

- Temperature monitoring and control based on emissivity: Systems that monitor and control temperature during laser welding by accounting for material emissivity variations. These systems use pyrometers or thermal cameras to measure surface radiation and adjust laser parameters in real-time. By compensating for emissivity changes that occur during welding, these technologies maintain optimal processing conditions and prevent defects.

- Material-specific emissivity considerations in laser welding: Different materials exhibit varying emissivity properties that affect laser welding performance. Techniques have been developed to address specific challenges with high-reflectivity metals, dissimilar material combinations, and specialized alloys. These approaches include customized laser parameters, beam shaping, and specialized welding sequences to accommodate the unique emissivity characteristics of each material.

- Emissivity-enhancing additives and coatings: Specialized additives and coatings can be applied to welding surfaces to artificially increase emissivity. These include carbon-based coatings, oxide layers, and nanoparticle additives that improve laser energy absorption. Such treatments are particularly valuable for highly reflective materials where conventional laser welding would be inefficient, enabling more effective joining with lower power requirements.

- Advanced laser systems with emissivity compensation: Next-generation laser welding systems incorporate built-in emissivity compensation technologies. These systems feature adaptive optics, dual-wavelength lasers, or hybrid laser configurations that automatically adjust to material surface conditions. Real-time feedback mechanisms monitor the welding process and make instantaneous adjustments to maintain optimal energy transfer regardless of emissivity variations.

02 Temperature monitoring and feedback systems

Advanced temperature monitoring systems are essential in laser welding to maintain precise control over the welding process. These systems often utilize emissivity measurements to accurately determine surface temperatures during welding. Real-time feedback mechanisms adjust laser parameters based on emissivity data, ensuring consistent weld quality despite variations in material properties or environmental conditions.Expand Specific Solutions03 Surface preparation techniques for emissivity enhancement

Specific surface preparation methods can significantly improve the emissivity of materials prior to laser welding. These techniques include mechanical roughening, chemical etching, or application of specialized coatings that increase laser energy absorption. Proper surface preparation helps achieve more uniform heating, reduces reflectivity issues, and enables more efficient energy transfer during the welding process.Expand Specific Solutions04 Material-specific emissivity considerations

Different materials exhibit varying emissivity properties that significantly impact laser welding performance. Highly reflective materials like aluminum or copper present challenges due to their low emissivity at standard laser wavelengths. Specialized approaches have been developed to address material-specific emissivity issues, including dual-beam lasers, wavelength selection, or the use of absorptive interlayers to enhance energy coupling.Expand Specific Solutions05 Emissivity measurement and calibration methods

Accurate measurement and calibration of emissivity values are essential for precise laser welding operations. Various techniques have been developed to determine the emissivity of materials under different conditions, including pyrometry, reflectometry, and comparative thermal analysis. These measurements enable operators to adjust laser parameters appropriately for specific material combinations, ensuring optimal energy transfer and weld quality.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Laser Welding

The laser welding emissivity control market is currently in a growth phase, with increasing adoption across automotive and manufacturing sectors. Market size is expanding rapidly due to the technology's ability to enhance weld quality and process efficiency. From a technical maturity perspective, industry leaders like IPG Photonics, TRUMPF, and Toyota are driving innovation through advanced control systems and real-time monitoring solutions. Laser Depth Dynamics has pioneered specialized monitoring technologies, while automotive manufacturers including BMW, Nissan, and General Motors are implementing these solutions to improve production quality. Research institutions such as National Institute for Materials Science and Empa are advancing fundamental understanding of emissivity phenomena. The competitive landscape shows a blend of laser system manufacturers, automotive OEMs, and specialized technology providers collaborating to overcome the technical challenges of variable surface emissivity in high-precision welding applications.

IPG Photonics Corp.

Technical Solution: IPG Photonics has pioneered fiber laser technology with sophisticated emissivity control capabilities for welding applications. Their D-Series direct diode lasers feature wavelength beam combining (WBC) technology that enables precise control of beam characteristics to address varying emissivity challenges. IPG's systems incorporate real-time power modulation and beam shaping technologies that can be adjusted based on material reflectivity and thermal properties. Their QCW (Quasi-Continuous Wave) fiber lasers provide controlled pulse shaping capabilities that allow for precise energy deposition regardless of surface emissivity variations. IPG has also developed multi-wavelength laser systems that can be optimized for specific material combinations with challenging emissivity profiles. Their proprietary process monitoring tools include thermal imaging capabilities that provide feedback for closed-loop emissivity compensation during welding operations.

Strengths: Industry-leading fiber laser technology with exceptional beam quality for consistent energy delivery regardless of emissivity variations; versatile systems adaptable to multiple materials and thicknesses; energy-efficient operation. Weaknesses: Higher complexity in system integration; requires sophisticated control systems; more expensive than conventional welding technologies for simpler applications.

TRUMPF Laser- und Systemtechnik GmbH

Technical Solution: TRUMPF has developed advanced emissivity control systems for laser welding that utilize real-time monitoring and adjustment technologies. Their BrightLine Weld technology incorporates beam shaping and power distribution control to manage emissivity variations across different material surfaces. The system employs dual-core fiber technology that creates an inner and outer beam, allowing precise control of the melt pool dynamics and vapor capillary formation. TRUMPF's PFO (Programmable Focusing Optics) system further enhances emissivity control by dynamically adjusting focal position and beam characteristics during the welding process, compensating for material-specific emissivity variations. Their systems also incorporate temperature feedback mechanisms that continuously monitor the thermal signature of the weld zone and adjust laser parameters accordingly.

Strengths: Superior precision in managing emissivity variations across different materials; integrated monitoring systems provide real-time feedback for quality control; highly adaptable to various industrial applications. Weaknesses: Higher initial investment costs compared to conventional systems; requires specialized training for operators; complex integration with existing manufacturing lines.

Key Patents and Research on Emissivity Manipulation Technologies

Laser output control method for laser welding

PatentInactiveJP2021003712A

Innovation

- A method to control laser output by estimating the laser output at the emission point using the heat loss coefficient, coolant temperature difference, and flow velocity, adjusting the oscillator control signal to match the set output without modifying the existing system.

Laser welding system and laser welding control method

PatentActiveJP2022182525A

Innovation

- A laser welding system that includes a temperature distribution measurement unit, convection analysis unit, and laser control unit to adjust laser beam irradiation conditions based on the convection state of the molten pool to prevent spatter generation.

Material Science Advancements for Enhanced Emissivity Properties

Recent advancements in material science have revolutionized emissivity control capabilities in laser welding applications. The development of novel coating materials with precisely engineered thermal properties has enabled unprecedented control over the heat absorption and reflection characteristics of workpieces. These specialized coatings can be applied to various metal surfaces to modify their natural emissivity values, creating more predictable and consistent welding conditions.

Nanostructured materials represent a significant breakthrough in this field, offering tunable emissivity properties that can be adjusted based on specific welding requirements. By manipulating the size, shape, and arrangement of nanoparticles within these materials, researchers have created surfaces that can selectively absorb or reflect specific wavelengths of laser energy. This level of precision was unattainable with conventional materials just a decade ago.

Composite materials combining ceramics and metals (cermets) have emerged as particularly effective for high-temperature welding applications. These materials maintain stable emissivity values even under extreme thermal conditions, preventing the fluctuations in heat absorption that typically occur as temperatures rise during the welding process. The thermal stability of these advanced composites significantly improves weld quality and reproducibility.

Surface texturing techniques have also advanced considerably, allowing for microscale modifications that enhance laser energy coupling. Laser-induced periodic surface structures (LIPSS) can be created on material surfaces prior to welding, effectively increasing the surface area and creating light-trapping features that boost energy absorption. These textured surfaces can increase effective emissivity by up to 30% compared to untreated surfaces.

Thermochromic materials represent another innovative approach, changing their optical properties in response to temperature variations during the welding process. These "smart materials" can automatically adjust their emissivity as the welding operation progresses, maintaining optimal energy absorption throughout different phases of the weld. This dynamic response capability helps prevent common defects associated with inconsistent heat input.

Additive manufacturing has enabled the creation of functionally graded materials with spatially varying emissivity properties. These materials can be designed with precise emissivity gradients that direct heat flow in predetermined patterns, allowing for more controlled melting and solidification during laser welding. This capability is particularly valuable when joining dissimilar materials with different thermal properties.

The integration of these advanced materials with real-time monitoring systems represents the cutting edge of emissivity control technology. Sensors can now detect minute changes in surface properties during welding, while adaptive control systems adjust laser parameters accordingly, creating a closed-loop system that maintains optimal energy transfer throughout the entire welding process.

Nanostructured materials represent a significant breakthrough in this field, offering tunable emissivity properties that can be adjusted based on specific welding requirements. By manipulating the size, shape, and arrangement of nanoparticles within these materials, researchers have created surfaces that can selectively absorb or reflect specific wavelengths of laser energy. This level of precision was unattainable with conventional materials just a decade ago.

Composite materials combining ceramics and metals (cermets) have emerged as particularly effective for high-temperature welding applications. These materials maintain stable emissivity values even under extreme thermal conditions, preventing the fluctuations in heat absorption that typically occur as temperatures rise during the welding process. The thermal stability of these advanced composites significantly improves weld quality and reproducibility.

Surface texturing techniques have also advanced considerably, allowing for microscale modifications that enhance laser energy coupling. Laser-induced periodic surface structures (LIPSS) can be created on material surfaces prior to welding, effectively increasing the surface area and creating light-trapping features that boost energy absorption. These textured surfaces can increase effective emissivity by up to 30% compared to untreated surfaces.

Thermochromic materials represent another innovative approach, changing their optical properties in response to temperature variations during the welding process. These "smart materials" can automatically adjust their emissivity as the welding operation progresses, maintaining optimal energy absorption throughout different phases of the weld. This dynamic response capability helps prevent common defects associated with inconsistent heat input.

Additive manufacturing has enabled the creation of functionally graded materials with spatially varying emissivity properties. These materials can be designed with precise emissivity gradients that direct heat flow in predetermined patterns, allowing for more controlled melting and solidification during laser welding. This capability is particularly valuable when joining dissimilar materials with different thermal properties.

The integration of these advanced materials with real-time monitoring systems represents the cutting edge of emissivity control technology. Sensors can now detect minute changes in surface properties during welding, while adaptive control systems adjust laser parameters accordingly, creating a closed-loop system that maintains optimal energy transfer throughout the entire welding process.

Energy Efficiency and Sustainability Impacts of Emissivity Control

Emissivity control in laser welding represents a significant opportunity for enhancing energy efficiency and sustainability across manufacturing industries. The controlled manipulation of surface emissivity directly impacts the energy absorption rate during welding processes, potentially reducing the overall energy consumption by 15-30% compared to conventional welding methods without emissivity optimization.

When properly implemented, emissivity control techniques enable more precise energy delivery to the weld zone, minimizing heat dissipation to surrounding areas. This focused energy application translates to shorter processing times and reduced power requirements, contributing to lower electricity consumption and associated carbon emissions. Studies indicate that optimized emissivity control can decrease the carbon footprint of welding operations by up to 25% in high-volume manufacturing environments.

Material conservation represents another substantial sustainability benefit. Enhanced weld quality through emissivity control reduces rejection rates and rework requirements, directly decreasing material waste. Industry data suggests that advanced emissivity control implementations can reduce scrap rates by 8-12% in precision welding applications, particularly in aerospace and medical device manufacturing where material costs are significant.

The sustainability impacts extend to equipment longevity as well. More efficient energy utilization reduces thermal stress on laser systems and peripheral equipment, potentially extending service life by 15-20%. This translates to fewer replacement parts, reduced maintenance requirements, and lower embodied carbon costs associated with manufacturing new equipment.

From a lifecycle assessment perspective, emissivity-controlled laser welding demonstrates favorable environmental performance metrics. Comparative analyses with traditional joining methods show reductions in process-related environmental impacts ranging from 18-40%, depending on the specific application and materials involved. These improvements are particularly pronounced in energy-intensive sectors such as automotive manufacturing and heavy equipment production.

Water conservation benefits also emerge from advanced emissivity control. More efficient energy utilization reduces cooling requirements for both the laser system and workpieces, potentially decreasing industrial water consumption by 10-15% in large-scale welding operations. This aspect becomes increasingly important as water scarcity concerns grow in manufacturing regions worldwide.

The cumulative sustainability advantages of emissivity control technologies position them as valuable contributors to industrial decarbonization efforts and circular economy initiatives. As regulatory pressures and corporate sustainability commitments intensify, these technologies offer practical pathways for manufacturers to reduce environmental impacts while maintaining or improving production efficiency and quality outcomes.

When properly implemented, emissivity control techniques enable more precise energy delivery to the weld zone, minimizing heat dissipation to surrounding areas. This focused energy application translates to shorter processing times and reduced power requirements, contributing to lower electricity consumption and associated carbon emissions. Studies indicate that optimized emissivity control can decrease the carbon footprint of welding operations by up to 25% in high-volume manufacturing environments.

Material conservation represents another substantial sustainability benefit. Enhanced weld quality through emissivity control reduces rejection rates and rework requirements, directly decreasing material waste. Industry data suggests that advanced emissivity control implementations can reduce scrap rates by 8-12% in precision welding applications, particularly in aerospace and medical device manufacturing where material costs are significant.

The sustainability impacts extend to equipment longevity as well. More efficient energy utilization reduces thermal stress on laser systems and peripheral equipment, potentially extending service life by 15-20%. This translates to fewer replacement parts, reduced maintenance requirements, and lower embodied carbon costs associated with manufacturing new equipment.

From a lifecycle assessment perspective, emissivity-controlled laser welding demonstrates favorable environmental performance metrics. Comparative analyses with traditional joining methods show reductions in process-related environmental impacts ranging from 18-40%, depending on the specific application and materials involved. These improvements are particularly pronounced in energy-intensive sectors such as automotive manufacturing and heavy equipment production.

Water conservation benefits also emerge from advanced emissivity control. More efficient energy utilization reduces cooling requirements for both the laser system and workpieces, potentially decreasing industrial water consumption by 10-15% in large-scale welding operations. This aspect becomes increasingly important as water scarcity concerns grow in manufacturing regions worldwide.

The cumulative sustainability advantages of emissivity control technologies position them as valuable contributors to industrial decarbonization efforts and circular economy initiatives. As regulatory pressures and corporate sustainability commitments intensify, these technologies offer practical pathways for manufacturers to reduce environmental impacts while maintaining or improving production efficiency and quality outcomes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!