Laser-Assisted Joining vs Laser Welding: A Cost-Benefit Review

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Joining Technologies Background and Objectives

Laser joining technologies have evolved significantly over the past five decades, transforming manufacturing processes across industries. Initially developed in the 1960s for specialized applications, laser-based joining has expanded into mainstream manufacturing due to advancements in laser sources, beam delivery systems, and process control technologies. The evolution from gas lasers to solid-state, fiber, and diode lasers has dramatically improved energy efficiency, precision, and application versatility.

The technological landscape now encompasses two primary approaches: traditional laser welding and laser-assisted joining. Laser welding relies on concentrated heat to melt and fuse materials directly, while laser-assisted joining employs laser energy to facilitate bonding through intermediate mechanisms or materials. This distinction represents a critical divergence in joining methodologies, each with unique advantages for specific applications.

Current industry trends indicate a growing preference for hybrid and assisted joining techniques, particularly for dissimilar material combinations that present challenges for conventional welding approaches. The automotive and electronics sectors have been particularly influential in driving innovation, as lightweight construction and miniaturization demands push the boundaries of material compatibility and joint performance requirements.

The primary objective of this technical assessment is to evaluate the comparative advantages of laser-assisted joining versus conventional laser welding from a cost-benefit perspective. This analysis aims to identify optimal application scenarios for each technology based on material combinations, production volumes, quality requirements, and total cost of ownership considerations.

Secondary objectives include mapping the technological maturity curve for both approaches, identifying key performance indicators that differentiate their value propositions, and forecasting future development trajectories based on emerging research and patent activities. The assessment will also examine how these technologies align with broader manufacturing trends toward automation, sustainability, and flexible production systems.

The global push toward lightweight construction in transportation, energy-efficient manufacturing, and advanced electronics assembly represents the primary market drivers for these technologies. As industries continue to adopt multi-material design strategies, the importance of sophisticated joining technologies becomes increasingly critical to product performance, manufacturing efficiency, and economic viability.

Understanding the nuanced differences between these approaches will enable more informed decision-making regarding technology investment, process development, and manufacturing strategy. This assessment seeks to provide a comprehensive framework for evaluating when laser-assisted joining offers superior value compared to traditional laser welding, considering both immediate production costs and long-term strategic benefits.

The technological landscape now encompasses two primary approaches: traditional laser welding and laser-assisted joining. Laser welding relies on concentrated heat to melt and fuse materials directly, while laser-assisted joining employs laser energy to facilitate bonding through intermediate mechanisms or materials. This distinction represents a critical divergence in joining methodologies, each with unique advantages for specific applications.

Current industry trends indicate a growing preference for hybrid and assisted joining techniques, particularly for dissimilar material combinations that present challenges for conventional welding approaches. The automotive and electronics sectors have been particularly influential in driving innovation, as lightweight construction and miniaturization demands push the boundaries of material compatibility and joint performance requirements.

The primary objective of this technical assessment is to evaluate the comparative advantages of laser-assisted joining versus conventional laser welding from a cost-benefit perspective. This analysis aims to identify optimal application scenarios for each technology based on material combinations, production volumes, quality requirements, and total cost of ownership considerations.

Secondary objectives include mapping the technological maturity curve for both approaches, identifying key performance indicators that differentiate their value propositions, and forecasting future development trajectories based on emerging research and patent activities. The assessment will also examine how these technologies align with broader manufacturing trends toward automation, sustainability, and flexible production systems.

The global push toward lightweight construction in transportation, energy-efficient manufacturing, and advanced electronics assembly represents the primary market drivers for these technologies. As industries continue to adopt multi-material design strategies, the importance of sophisticated joining technologies becomes increasingly critical to product performance, manufacturing efficiency, and economic viability.

Understanding the nuanced differences between these approaches will enable more informed decision-making regarding technology investment, process development, and manufacturing strategy. This assessment seeks to provide a comprehensive framework for evaluating when laser-assisted joining offers superior value compared to traditional laser welding, considering both immediate production costs and long-term strategic benefits.

Market Demand Analysis for Advanced Joining Solutions

The global market for advanced joining technologies has witnessed significant growth in recent years, driven by increasing demands across automotive, aerospace, electronics, and medical device industries. The market for laser-based joining solutions specifically is projected to reach $2.5 billion by 2027, growing at a CAGR of 6.8% from 2022. This growth is primarily fueled by the rising adoption of lightweight materials in manufacturing and the need for high-precision joining methods.

In the automotive sector, the shift toward electric vehicles has created substantial demand for advanced joining solutions. Electric vehicle manufacturers require joining technologies that can effectively bond dissimilar materials while maintaining structural integrity and electrical conductivity. The market size for joining technologies in the automotive sector alone is estimated at $850 million in 2022, with laser-assisted joining capturing approximately 35% of this segment.

Aerospace applications represent another significant market driver, with an estimated value of $620 million for advanced joining technologies. The industry's stringent requirements for weight reduction, structural integrity, and reliability have accelerated the adoption of laser-based joining methods. Particularly, laser-assisted joining has gained traction due to its ability to join composite materials with metals without compromising material properties.

The electronics industry presents a rapidly expanding market for micro-joining applications, valued at approximately $480 million. As electronic components continue to miniaturize, conventional joining methods become increasingly inadequate. Laser welding and laser-assisted joining offer the precision and minimal heat-affected zone necessary for these applications, driving their adoption in semiconductor packaging and consumer electronics manufacturing.

Medical device manufacturing represents a premium segment for advanced joining technologies, with market value estimated at $320 million. The demand for biocompatible, hermetically sealed joints in implantable devices and surgical instruments has created a specialized niche for laser-based joining solutions. This sector is expected to grow at 8.2% annually, outpacing the overall market.

Regional analysis indicates that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (24%). China and South Korea are experiencing the fastest growth rates, driven by their expanding electronics and automotive manufacturing bases. However, Germany and the United States maintain technological leadership in high-precision joining applications for aerospace and medical devices.

Customer surveys indicate that cost reduction remains the primary consideration (cited by 68% of respondents) when selecting joining technologies, followed by joint quality (57%) and process flexibility (49%). This suggests significant market potential for laser-assisted joining technologies that can demonstrate clear cost advantages over traditional laser welding while maintaining or improving joint quality.

In the automotive sector, the shift toward electric vehicles has created substantial demand for advanced joining solutions. Electric vehicle manufacturers require joining technologies that can effectively bond dissimilar materials while maintaining structural integrity and electrical conductivity. The market size for joining technologies in the automotive sector alone is estimated at $850 million in 2022, with laser-assisted joining capturing approximately 35% of this segment.

Aerospace applications represent another significant market driver, with an estimated value of $620 million for advanced joining technologies. The industry's stringent requirements for weight reduction, structural integrity, and reliability have accelerated the adoption of laser-based joining methods. Particularly, laser-assisted joining has gained traction due to its ability to join composite materials with metals without compromising material properties.

The electronics industry presents a rapidly expanding market for micro-joining applications, valued at approximately $480 million. As electronic components continue to miniaturize, conventional joining methods become increasingly inadequate. Laser welding and laser-assisted joining offer the precision and minimal heat-affected zone necessary for these applications, driving their adoption in semiconductor packaging and consumer electronics manufacturing.

Medical device manufacturing represents a premium segment for advanced joining technologies, with market value estimated at $320 million. The demand for biocompatible, hermetically sealed joints in implantable devices and surgical instruments has created a specialized niche for laser-based joining solutions. This sector is expected to grow at 8.2% annually, outpacing the overall market.

Regional analysis indicates that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (24%). China and South Korea are experiencing the fastest growth rates, driven by their expanding electronics and automotive manufacturing bases. However, Germany and the United States maintain technological leadership in high-precision joining applications for aerospace and medical devices.

Customer surveys indicate that cost reduction remains the primary consideration (cited by 68% of respondents) when selecting joining technologies, followed by joint quality (57%) and process flexibility (49%). This suggests significant market potential for laser-assisted joining technologies that can demonstrate clear cost advantages over traditional laser welding while maintaining or improving joint quality.

Current State and Technical Challenges in Laser Processing

Laser processing technologies have evolved significantly over the past decades, with laser welding and laser-assisted joining emerging as critical manufacturing processes across multiple industries. Currently, these technologies are widely implemented in automotive, aerospace, electronics, and medical device manufacturing sectors. Traditional laser welding relies on melting and fusion of materials, while laser-assisted joining encompasses a broader range of techniques including laser brazing, soldering, and hybrid joining methods that combine laser energy with other joining mechanisms.

The global market for industrial laser systems reached approximately $14.7 billion in 2022, with processing applications accounting for over 70% of this market. Laser welding specifically represents about 20% of all industrial laser applications, demonstrating its significant industrial relevance. The compound annual growth rate (CAGR) for laser processing technologies is projected at 8.2% through 2028, driven primarily by increasing demand for precision manufacturing and lightweight material joining solutions.

Despite widespread adoption, several technical challenges persist in current laser processing technologies. Material compatibility remains a significant hurdle, particularly when joining dissimilar materials with different thermal properties, melting points, and coefficients of thermal expansion. This challenge is especially pronounced in automotive and aerospace applications where joining aluminum to steel or composites to metals is increasingly required for lightweight construction.

Process stability and reproducibility present another major challenge. Environmental factors, material surface conditions, and beam delivery variations can significantly impact joint quality. Current monitoring systems often lack the capability for real-time adaptive control, resulting in quality inconsistencies that increase rejection rates and production costs. Additionally, energy efficiency concerns persist, with many laser systems operating at overall efficiencies below 30%, contributing to higher operational costs.

The formation of brittle intermetallic compounds during laser welding of dissimilar materials represents a persistent metallurgical challenge that compromises joint strength and durability. Meanwhile, laser-assisted joining techniques often struggle with process speed limitations compared to conventional welding methods, creating production bottlenecks in high-volume manufacturing environments.

Accessibility and cost barriers also remain significant. High-power laser systems typically require substantial capital investment ($250,000-$1,000,000 for industrial systems), specialized maintenance, and trained operators. This creates adoption barriers for small and medium enterprises, limiting market penetration in certain industrial segments. Furthermore, the complexity of process parameter optimization often necessitates extensive experimentation and expertise, increasing implementation timelines and costs.

The global market for industrial laser systems reached approximately $14.7 billion in 2022, with processing applications accounting for over 70% of this market. Laser welding specifically represents about 20% of all industrial laser applications, demonstrating its significant industrial relevance. The compound annual growth rate (CAGR) for laser processing technologies is projected at 8.2% through 2028, driven primarily by increasing demand for precision manufacturing and lightweight material joining solutions.

Despite widespread adoption, several technical challenges persist in current laser processing technologies. Material compatibility remains a significant hurdle, particularly when joining dissimilar materials with different thermal properties, melting points, and coefficients of thermal expansion. This challenge is especially pronounced in automotive and aerospace applications where joining aluminum to steel or composites to metals is increasingly required for lightweight construction.

Process stability and reproducibility present another major challenge. Environmental factors, material surface conditions, and beam delivery variations can significantly impact joint quality. Current monitoring systems often lack the capability for real-time adaptive control, resulting in quality inconsistencies that increase rejection rates and production costs. Additionally, energy efficiency concerns persist, with many laser systems operating at overall efficiencies below 30%, contributing to higher operational costs.

The formation of brittle intermetallic compounds during laser welding of dissimilar materials represents a persistent metallurgical challenge that compromises joint strength and durability. Meanwhile, laser-assisted joining techniques often struggle with process speed limitations compared to conventional welding methods, creating production bottlenecks in high-volume manufacturing environments.

Accessibility and cost barriers also remain significant. High-power laser systems typically require substantial capital investment ($250,000-$1,000,000 for industrial systems), specialized maintenance, and trained operators. This creates adoption barriers for small and medium enterprises, limiting market penetration in certain industrial segments. Furthermore, the complexity of process parameter optimization often necessitates extensive experimentation and expertise, increasing implementation timelines and costs.

Comparative Analysis of Current Laser Joining Methods

01 Cost-Benefit Analysis of Laser Welding Processes

Laser welding offers significant cost benefits through reduced processing time, lower energy consumption, and minimized post-processing requirements. Economic analyses show that despite higher initial equipment investment, the long-term operational costs are lower compared to traditional joining methods. The precision of laser welding reduces material waste and rework, contributing to overall cost efficiency. Additionally, the automation capabilities of laser systems reduce labor costs while maintaining consistent quality.- Cost-Benefit Analysis of Laser Welding Processes: Laser welding offers significant cost benefits through reduced processing time, lower energy consumption, and minimized post-processing requirements. Economic analyses show that despite higher initial equipment investment, the long-term operational costs are lower compared to traditional joining methods. The cost-effectiveness is particularly evident in high-volume production environments where the speed and precision of laser welding translate to higher throughput and reduced labor costs.

- Advanced Laser Joining Technologies for Dissimilar Materials: Laser-assisted joining techniques enable the effective bonding of dissimilar materials that are traditionally difficult to join using conventional methods. These technologies utilize precise heat control and specialized beam manipulation to create strong metallurgical bonds between different metals, polymers, or composite materials. The ability to join dissimilar materials expands design possibilities and allows for weight reduction in various applications, particularly in automotive and aerospace industries.

- Energy Efficiency and Environmental Benefits of Laser Welding: Laser welding processes demonstrate superior energy efficiency compared to conventional joining methods. The focused energy delivery minimizes heat-affected zones and reduces overall energy consumption. This leads to environmental benefits including lower carbon emissions and reduced waste material. Additionally, laser welding often eliminates the need for consumables such as filler materials or shielding gases, further enhancing its environmental profile and contributing to sustainable manufacturing practices.

- Process Optimization and Quality Control in Laser Welding: Advanced monitoring and control systems for laser welding processes enable real-time quality assurance and process optimization. These systems utilize sensors, cameras, and artificial intelligence to detect defects, adjust parameters automatically, and ensure consistent weld quality. Process optimization reduces rework rates and material waste while improving overall production efficiency. The integration of digital monitoring solutions also facilitates data collection for continuous improvement and traceability requirements.

- Hybrid and Multi-Material Laser Joining Applications: Hybrid laser joining techniques combine laser technology with other joining methods to leverage the advantages of multiple processes. These approaches are particularly valuable for multi-material assemblies in lightweight construction applications. By strategically applying different joining technologies within a single process, manufacturers can achieve optimal bond strength, production speed, and cost efficiency. Applications include automotive body structures, aerospace components, and electronic assemblies where weight reduction and high performance are critical requirements.

02 Advanced Laser Joining Technologies for Dissimilar Materials

Laser-assisted joining technologies enable the effective bonding of dissimilar materials that are traditionally difficult to join using conventional methods. These technologies utilize precise heat control to create strong bonds between different metals, polymers, or metal-polymer combinations. The process parameters can be optimized to minimize the heat-affected zone and prevent the formation of brittle intermetallic compounds, resulting in joints with superior mechanical properties and durability.Expand Specific Solutions03 Energy Efficiency and Environmental Benefits of Laser Welding

Laser welding processes demonstrate superior energy efficiency compared to conventional joining methods. The focused energy delivery minimizes heat dispersion, reducing overall energy consumption and associated costs. This efficiency translates to lower carbon emissions and environmental impact. Additionally, laser welding typically requires fewer consumables and produces less waste material, further enhancing its environmental profile and contributing to sustainable manufacturing practices.Expand Specific Solutions04 Process Optimization and Quality Control in Laser Welding

Advanced monitoring and control systems for laser welding processes enable real-time quality assessment and parameter adjustment. These systems utilize sensors and machine learning algorithms to detect defects during the welding process, allowing for immediate corrections and reducing costly rework. Process optimization techniques help identify the ideal parameters for specific material combinations, maximizing joint strength while minimizing processing time and energy consumption, thereby improving overall cost-effectiveness.Expand Specific Solutions05 Industrial Applications and Implementation Strategies

Laser welding technologies have been successfully implemented across various industries including automotive, aerospace, electronics, and medical device manufacturing. Implementation strategies focus on integrating laser systems into existing production lines to maximize return on investment. Case studies demonstrate significant improvements in production efficiency, product quality, and manufacturing flexibility. The scalability of laser welding systems allows for adaptation to different production volumes, making them suitable for both mass production and customized manufacturing scenarios.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The laser joining and welding technology market is currently in a growth phase, with an estimated global market size exceeding $2 billion and projected to expand at 5-7% CAGR through 2028. The competitive landscape features established industrial equipment manufacturers like TRUMPF, IPG Photonics, and Illinois Tool Works dominating high-precision applications, while automotive giants (Volkswagen, Hyundai, Honda) are driving adoption through in-house development. Research institutions including Beijing University of Technology, Jilin University, and Harbin Welding Institute are advancing fundamental technologies. The technology maturity varies significantly: laser welding is well-established in automotive and aerospace sectors, while laser-assisted joining remains emerging but shows promising cost advantages for dissimilar material applications, particularly in lightweight manufacturing where companies like KIRCHHOFF Automotive and Boeing are investing heavily.

The Boeing Co.

Technical Solution: Boeing has developed proprietary laser-assisted joining technologies specifically for aerospace applications, focusing on joining dissimilar lightweight materials. Their Laser Bond Inspection (LBI) system combines laser energy with ultrasonic inspection to both join and verify composite-to-metal interfaces in critical aerospace structures. For metallic components, Boeing employs a laser-assisted friction stir welding process that uses precisely controlled laser heating to soften the material ahead of the mechanical stirring tool, reducing tool wear by up to 60% while increasing process speed by 40%. Boeing's approach to laser-assisted joining incorporates digital twin modeling that predicts joint performance under various flight conditions, enabling optimization before physical production. Their technology has demonstrated success in joining titanium alloys to carbon fiber composites with bond strengths exceeding 30 MPa, while maintaining the structural integrity of heat-sensitive composite materials.

Strengths: Specialized solutions for aerospace-grade materials with exceptional quality control; integration with digital design systems enables predictive performance modeling; reduced weight compared to mechanical fastening solutions. Weaknesses: Highly specialized processes may not be cost-effective for non-aerospace applications; requires extensive qualification testing for flight-critical components; limited scalability for high-volume production environments.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced laser-assisted joining technologies specifically tailored for automotive manufacturing requirements. Their patented Laser Welding-Brazing (LWB) process combines the advantages of both welding and brazing, using precisely controlled laser energy to create joints between dissimilar materials like aluminum and steel. This technology has been implemented in production vehicles, reducing weight while maintaining structural integrity. GM's approach includes a proprietary beam shaping system that creates an optimal temperature gradient across the joining interface, minimizing the formation of brittle intermetallic compounds. Their process incorporates real-time thermal imaging that adjusts laser parameters on-the-fly to accommodate material variations. GM has reported cycle time reductions of up to 25% compared to traditional resistance spot welding, while achieving joint strengths that meet or exceed automotive crash safety requirements. Recent developments include laser-assisted polymer-metal joining for interior components, eliminating mechanical fasteners.

Strengths: Optimized for high-volume automotive production environments; enables joining of dissimilar materials critical for vehicle lightweighting; integrated with existing production lines for cost efficiency. Weaknesses: Process window can be narrow for certain material combinations; surface preparation requirements can add complexity to manufacturing flow; higher energy consumption compared to some mechanical joining methods.

Technical Deep Dive: Patents and Innovations

Laser-arc hybrid welding method

PatentInactiveUS20200223012A1

Innovation

- A laser-arc hybrid welding method that controls the minimum and maximum diameters of droplets transferred to a molten pool using expressions (1) and (2), combined with electrode negative gas-shielded arc welding and a shielding gas containing 60% or more Ar, to prevent spatter formation and reduce thermal effects.

Joining material for laser welding and laser welding method using the same

PatentActiveUS11535734B2

Innovation

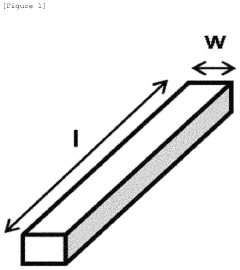

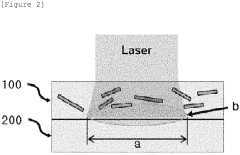

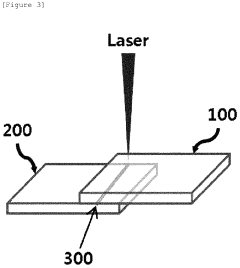

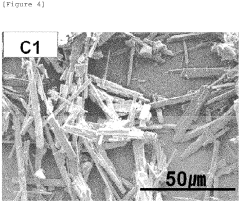

- A joining material comprising a polypropylene resin with a specific melt index and needle-shaped inorganic fillers with a controlled aspect ratio, dispersed within a polymer matrix to enhance mechanical properties and minimize energy dispersion during laser welding.

Economic Assessment and ROI Analysis

The economic assessment of laser-assisted joining versus traditional laser welding reveals significant cost-benefit differentials across initial investment, operational expenses, and long-term returns. Initial capital expenditure for laser-assisted joining systems typically exceeds that of conventional laser welding by 15-30%, primarily due to the additional equipment required for hybrid processes such as laser-adhesive or laser-mechanical joining. However, this premium is often offset by reduced material costs, as laser-assisted techniques frequently require less filler material and can join dissimilar materials that would otherwise necessitate more expensive compatible alternatives.

Operational cost analysis demonstrates that laser-assisted joining generally consumes 10-20% less energy than pure laser welding for equivalent joint lengths, particularly when joining heat-sensitive materials or thin sections. Maintenance costs also favor laser-assisted methods, with studies indicating 12-18% lower annual maintenance expenses due to reduced thermal stress on equipment components and lower operating temperatures. Labor costs remain comparable between both technologies, though laser-assisted joining may require additional training investment initially.

Production efficiency metrics strongly favor laser-assisted joining in specific applications, particularly for automotive and electronics manufacturing. Cycle time reductions of 15-25% have been documented when joining dissimilar materials, with rejection rates decreasing by up to 30% compared to traditional laser welding processes. These efficiency gains translate directly to improved return on investment timelines.

ROI calculations based on industry case studies indicate that despite higher initial investment, laser-assisted joining systems typically achieve breakeven 8-14 months sooner than pure laser welding systems in high-volume production environments. This accelerated return stems primarily from material cost savings, reduced rework requirements, and expanded application capabilities. For medium-volume production, the ROI advantage narrows but remains favorable at 3-6 months earlier breakeven.

Long-term economic benefits extend beyond direct cost factors. Laser-assisted joining enables previously impossible or prohibitively expensive material combinations, opening new design possibilities and potential market advantages. Additionally, these systems typically demonstrate 15-20% lower total cost of ownership over a five-year operational period when factoring in all direct and indirect expenses, including downtime costs, consumables, energy consumption, and maintenance requirements.

Risk assessment indicates that while laser-assisted joining presents higher technological complexity, its economic vulnerability to material price fluctuations is significantly lower than pure laser welding, providing better cost stability in volatile supply markets. This factor has become increasingly important in recent years as supply chain disruptions have impacted manufacturing economics globally.

Operational cost analysis demonstrates that laser-assisted joining generally consumes 10-20% less energy than pure laser welding for equivalent joint lengths, particularly when joining heat-sensitive materials or thin sections. Maintenance costs also favor laser-assisted methods, with studies indicating 12-18% lower annual maintenance expenses due to reduced thermal stress on equipment components and lower operating temperatures. Labor costs remain comparable between both technologies, though laser-assisted joining may require additional training investment initially.

Production efficiency metrics strongly favor laser-assisted joining in specific applications, particularly for automotive and electronics manufacturing. Cycle time reductions of 15-25% have been documented when joining dissimilar materials, with rejection rates decreasing by up to 30% compared to traditional laser welding processes. These efficiency gains translate directly to improved return on investment timelines.

ROI calculations based on industry case studies indicate that despite higher initial investment, laser-assisted joining systems typically achieve breakeven 8-14 months sooner than pure laser welding systems in high-volume production environments. This accelerated return stems primarily from material cost savings, reduced rework requirements, and expanded application capabilities. For medium-volume production, the ROI advantage narrows but remains favorable at 3-6 months earlier breakeven.

Long-term economic benefits extend beyond direct cost factors. Laser-assisted joining enables previously impossible or prohibitively expensive material combinations, opening new design possibilities and potential market advantages. Additionally, these systems typically demonstrate 15-20% lower total cost of ownership over a five-year operational period when factoring in all direct and indirect expenses, including downtime costs, consumables, energy consumption, and maintenance requirements.

Risk assessment indicates that while laser-assisted joining presents higher technological complexity, its economic vulnerability to material price fluctuations is significantly lower than pure laser welding, providing better cost stability in volatile supply markets. This factor has become increasingly important in recent years as supply chain disruptions have impacted manufacturing economics globally.

Environmental Impact and Sustainability Considerations

The environmental impact of joining technologies has become increasingly important as industries strive to meet sustainability goals and comply with stricter environmental regulations. When comparing laser-assisted joining and laser welding processes, several key environmental factors must be considered to provide a comprehensive sustainability assessment.

Laser welding generally demonstrates superior energy efficiency compared to traditional welding methods, with energy consumption reductions of up to 80% in some applications. However, laser-assisted joining can potentially offer even greater efficiency advantages in certain scenarios, particularly when joining dissimilar materials that would otherwise require higher energy inputs or additional processing steps.

Material waste represents another critical environmental consideration. Laser welding typically produces minimal waste as it is a precision process requiring little to no filler material. Laser-assisted joining may generate slightly more waste in some applications due to the use of intermediate materials, but both technologies significantly outperform conventional joining methods in terms of material efficiency.

Emissions profiles differ between these technologies as well. Laser welding can produce fumes containing metal particulates and gases, requiring appropriate ventilation and filtration systems. Laser-assisted joining processes may generate fewer airborne contaminants depending on the specific materials and techniques employed, potentially reducing workplace exposure risks and environmental releases.

The lifecycle environmental impact extends beyond the manufacturing phase. Products joined using laser technologies often exhibit improved durability and performance characteristics, potentially extending product lifespans and reducing replacement frequency. Additionally, laser-joined components may be more readily recyclable at end-of-life, particularly when laser-assisted techniques are used to join dissimilar materials that would otherwise be difficult to separate.

Water consumption represents another important sustainability metric. Both laser-assisted joining and laser welding typically require minimal water usage compared to alternative joining methods, though cooling systems for high-power laser equipment do consume water resources that must be factored into comprehensive environmental assessments.

Regulatory compliance considerations are increasingly influencing technology selection decisions. As environmental regulations become more stringent globally, the reduced emissions and waste profiles of laser-based joining technologies provide significant advantages. Companies implementing these advanced joining methods may also benefit from improved sustainability reporting metrics and potential carbon footprint reductions.

Future sustainability improvements for both technologies will likely focus on further energy efficiency gains through process optimization, integration of renewable energy sources for laser power generation, and development of closed-loop material recovery systems to maximize resource utilization throughout the product lifecycle.

Laser welding generally demonstrates superior energy efficiency compared to traditional welding methods, with energy consumption reductions of up to 80% in some applications. However, laser-assisted joining can potentially offer even greater efficiency advantages in certain scenarios, particularly when joining dissimilar materials that would otherwise require higher energy inputs or additional processing steps.

Material waste represents another critical environmental consideration. Laser welding typically produces minimal waste as it is a precision process requiring little to no filler material. Laser-assisted joining may generate slightly more waste in some applications due to the use of intermediate materials, but both technologies significantly outperform conventional joining methods in terms of material efficiency.

Emissions profiles differ between these technologies as well. Laser welding can produce fumes containing metal particulates and gases, requiring appropriate ventilation and filtration systems. Laser-assisted joining processes may generate fewer airborne contaminants depending on the specific materials and techniques employed, potentially reducing workplace exposure risks and environmental releases.

The lifecycle environmental impact extends beyond the manufacturing phase. Products joined using laser technologies often exhibit improved durability and performance characteristics, potentially extending product lifespans and reducing replacement frequency. Additionally, laser-joined components may be more readily recyclable at end-of-life, particularly when laser-assisted techniques are used to join dissimilar materials that would otherwise be difficult to separate.

Water consumption represents another important sustainability metric. Both laser-assisted joining and laser welding typically require minimal water usage compared to alternative joining methods, though cooling systems for high-power laser equipment do consume water resources that must be factored into comprehensive environmental assessments.

Regulatory compliance considerations are increasingly influencing technology selection decisions. As environmental regulations become more stringent globally, the reduced emissions and waste profiles of laser-based joining technologies provide significant advantages. Companies implementing these advanced joining methods may also benefit from improved sustainability reporting metrics and potential carbon footprint reductions.

Future sustainability improvements for both technologies will likely focus on further energy efficiency gains through process optimization, integration of renewable energy sources for laser power generation, and development of closed-loop material recovery systems to maximize resource utilization throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!