How to Reduce Maintenance in Laser Welding Equipment

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Maintenance Challenges and Objectives

Laser welding technology has evolved significantly over the past four decades, transitioning from experimental applications to mainstream industrial processes. Initially developed in the 1970s, laser welding has become increasingly sophisticated with advancements in beam quality, power capabilities, and control systems. The evolution from CO2 lasers to fiber and diode lasers has dramatically improved energy efficiency and precision, while reducing the physical footprint of equipment. This technological progression has expanded laser welding applications across automotive, aerospace, medical device manufacturing, and electronics industries.

Despite these advancements, maintenance challenges remain a significant concern for industrial users. Equipment downtime due to maintenance requirements can cost manufacturers thousands of dollars per hour in lost productivity. Current maintenance protocols typically involve scheduled preventive maintenance that may be either excessive or insufficient, leading to unnecessary costs or unexpected failures. The objective of reducing maintenance in laser welding equipment aims to optimize operational efficiency while minimizing total cost of ownership.

Key maintenance challenges include optical component degradation, particularly focusing lenses and protective windows that require regular cleaning or replacement due to spatter accumulation. Cooling system maintenance presents another critical challenge, as coolant contamination and flow issues can lead to thermal instability and subsequent weld quality problems. Additionally, beam delivery systems, including fiber cables and articulated arms, require careful handling and periodic inspection to prevent damage that could compromise beam quality.

The technical goal of maintenance reduction encompasses several specific objectives. First, extending the service intervals between required maintenance actions through improved component durability and contamination resistance. Second, implementing condition-based maintenance approaches using integrated sensors and monitoring systems to replace time-based maintenance schedules. Third, designing systems with improved accessibility and modular components to reduce service time when maintenance is necessary.

Achieving these objectives requires addressing both hardware and software aspects of laser welding systems. Hardware innovations focus on developing more robust optical components, self-cleaning mechanisms, and improved shielding technologies. Software advancements center on predictive analytics and machine learning algorithms that can detect performance degradation before failure occurs. The ultimate goal is to create laser welding systems that maintain consistent performance with minimal human intervention, thereby reducing operational costs and improving manufacturing productivity.

Despite these advancements, maintenance challenges remain a significant concern for industrial users. Equipment downtime due to maintenance requirements can cost manufacturers thousands of dollars per hour in lost productivity. Current maintenance protocols typically involve scheduled preventive maintenance that may be either excessive or insufficient, leading to unnecessary costs or unexpected failures. The objective of reducing maintenance in laser welding equipment aims to optimize operational efficiency while minimizing total cost of ownership.

Key maintenance challenges include optical component degradation, particularly focusing lenses and protective windows that require regular cleaning or replacement due to spatter accumulation. Cooling system maintenance presents another critical challenge, as coolant contamination and flow issues can lead to thermal instability and subsequent weld quality problems. Additionally, beam delivery systems, including fiber cables and articulated arms, require careful handling and periodic inspection to prevent damage that could compromise beam quality.

The technical goal of maintenance reduction encompasses several specific objectives. First, extending the service intervals between required maintenance actions through improved component durability and contamination resistance. Second, implementing condition-based maintenance approaches using integrated sensors and monitoring systems to replace time-based maintenance schedules. Third, designing systems with improved accessibility and modular components to reduce service time when maintenance is necessary.

Achieving these objectives requires addressing both hardware and software aspects of laser welding systems. Hardware innovations focus on developing more robust optical components, self-cleaning mechanisms, and improved shielding technologies. Software advancements center on predictive analytics and machine learning algorithms that can detect performance degradation before failure occurs. The ultimate goal is to create laser welding systems that maintain consistent performance with minimal human intervention, thereby reducing operational costs and improving manufacturing productivity.

Market Demand for Low-Maintenance Welding Solutions

The global market for laser welding equipment has witnessed a significant shift in demand patterns, with an increasing emphasis on low-maintenance solutions. Manufacturing industries across automotive, aerospace, electronics, and medical device sectors are actively seeking welding technologies that minimize downtime and operational interruptions. This trend is primarily driven by the escalating costs associated with maintenance activities, which include not only direct repair expenses but also production losses during equipment downtime.

Research indicates that maintenance-related downtime in industrial welding operations typically accounts for 15-20% of total operational time, translating to substantial revenue losses for manufacturers. Companies operating in high-volume production environments report that even minor reductions in maintenance requirements can yield significant cost savings and productivity improvements over equipment lifecycles.

The demand for low-maintenance laser welding solutions is particularly pronounced in automotive manufacturing, where production lines operate continuously and any interruption directly impacts output targets. Similarly, aerospace and defense contractors require highly reliable welding equipment that can maintain precision performance with minimal intervention, especially for critical components where weld quality directly affects safety and compliance.

Regional market analysis reveals varying degrees of demand intensity. Developed industrial economies in North America and Western Europe show strong preference for advanced low-maintenance systems despite higher initial investment costs, prioritizing total cost of ownership calculations. Meanwhile, rapidly industrializing regions in Asia-Pacific demonstrate growing interest in such solutions as labor costs rise and quality standards become more stringent.

End-user surveys consistently highlight specific maintenance-related pain points that drive market demand. These include the need for reduced frequency of optical component cleaning and replacement, longer intervals between calibration procedures, more durable consumable parts, and simplified troubleshooting processes that require less specialized technical expertise.

The market is also responding to sustainability pressures, with manufacturers seeking welding solutions that not only require less maintenance but also consume fewer resources during operation and maintenance activities. This includes equipment designed for more efficient energy consumption, reduced cooling requirements, and components engineered for longer operational lifespans.

Industry forecasts project that the market segment for low-maintenance laser welding equipment will grow at approximately twice the rate of the overall laser welding market over the next five years, reflecting the strong value proposition these solutions offer to manufacturing operations focused on maximizing productivity and operational efficiency.

Research indicates that maintenance-related downtime in industrial welding operations typically accounts for 15-20% of total operational time, translating to substantial revenue losses for manufacturers. Companies operating in high-volume production environments report that even minor reductions in maintenance requirements can yield significant cost savings and productivity improvements over equipment lifecycles.

The demand for low-maintenance laser welding solutions is particularly pronounced in automotive manufacturing, where production lines operate continuously and any interruption directly impacts output targets. Similarly, aerospace and defense contractors require highly reliable welding equipment that can maintain precision performance with minimal intervention, especially for critical components where weld quality directly affects safety and compliance.

Regional market analysis reveals varying degrees of demand intensity. Developed industrial economies in North America and Western Europe show strong preference for advanced low-maintenance systems despite higher initial investment costs, prioritizing total cost of ownership calculations. Meanwhile, rapidly industrializing regions in Asia-Pacific demonstrate growing interest in such solutions as labor costs rise and quality standards become more stringent.

End-user surveys consistently highlight specific maintenance-related pain points that drive market demand. These include the need for reduced frequency of optical component cleaning and replacement, longer intervals between calibration procedures, more durable consumable parts, and simplified troubleshooting processes that require less specialized technical expertise.

The market is also responding to sustainability pressures, with manufacturers seeking welding solutions that not only require less maintenance but also consume fewer resources during operation and maintenance activities. This includes equipment designed for more efficient energy consumption, reduced cooling requirements, and components engineered for longer operational lifespans.

Industry forecasts project that the market segment for low-maintenance laser welding equipment will grow at approximately twice the rate of the overall laser welding market over the next five years, reflecting the strong value proposition these solutions offer to manufacturing operations focused on maximizing productivity and operational efficiency.

Current Maintenance Issues and Technical Limitations

Laser welding equipment maintenance presents significant challenges in industrial settings, with several persistent issues affecting operational efficiency. Optical component degradation stands as a primary concern, where lenses, mirrors, and protective windows suffer from contamination by weld spatter, fumes, and dust. This contamination gradually reduces beam quality and power transmission, leading to inconsistent weld quality and requiring frequent cleaning or replacement of these costly components.

Cooling system failures represent another critical maintenance challenge. Most industrial laser systems rely on sophisticated cooling mechanisms to maintain optimal operating temperatures. These systems frequently experience problems such as coolant leakage, pump failures, and heat exchanger inefficiency. When cooling systems malfunction, the entire laser welding process must be halted, resulting in costly production downtime.

Fiber delivery systems in modern laser welding equipment face unique vulnerabilities. The fiber optic cables that transmit the laser beam can degrade over time due to mechanical stress, overheating, or improper handling. Damage to these fibers significantly impacts beam quality and may necessitate complete replacement, which involves substantial cost and downtime.

Power supply instability presents ongoing maintenance challenges. Fluctuations in electrical systems can cause inconsistent laser output, affecting weld quality and potentially damaging sensitive electronic components. The complex power management systems require regular inspection and calibration to maintain optimal performance.

Motion system wear constitutes a significant limitation in current laser welding equipment. The precision positioning systems that control the movement of either the laser head or the workpiece experience gradual degradation through normal operation. This wear leads to positioning errors that directly impact weld quality and repeatability.

Technical limitations also exist in monitoring and diagnostic capabilities. Many current systems lack comprehensive real-time monitoring that could predict maintenance needs before failures occur. This reactive rather than predictive approach to maintenance results in unexpected downtime and higher overall maintenance costs.

Material handling systems integrated with laser welding equipment frequently require maintenance attention. Components such as conveyors, robotic arms, and fixtures experience wear from continuous operation, affecting positioning accuracy and ultimately weld quality. These mechanical systems often represent the most maintenance-intensive aspects of the entire welding setup.

Cooling system failures represent another critical maintenance challenge. Most industrial laser systems rely on sophisticated cooling mechanisms to maintain optimal operating temperatures. These systems frequently experience problems such as coolant leakage, pump failures, and heat exchanger inefficiency. When cooling systems malfunction, the entire laser welding process must be halted, resulting in costly production downtime.

Fiber delivery systems in modern laser welding equipment face unique vulnerabilities. The fiber optic cables that transmit the laser beam can degrade over time due to mechanical stress, overheating, or improper handling. Damage to these fibers significantly impacts beam quality and may necessitate complete replacement, which involves substantial cost and downtime.

Power supply instability presents ongoing maintenance challenges. Fluctuations in electrical systems can cause inconsistent laser output, affecting weld quality and potentially damaging sensitive electronic components. The complex power management systems require regular inspection and calibration to maintain optimal performance.

Motion system wear constitutes a significant limitation in current laser welding equipment. The precision positioning systems that control the movement of either the laser head or the workpiece experience gradual degradation through normal operation. This wear leads to positioning errors that directly impact weld quality and repeatability.

Technical limitations also exist in monitoring and diagnostic capabilities. Many current systems lack comprehensive real-time monitoring that could predict maintenance needs before failures occur. This reactive rather than predictive approach to maintenance results in unexpected downtime and higher overall maintenance costs.

Material handling systems integrated with laser welding equipment frequently require maintenance attention. Components such as conveyors, robotic arms, and fixtures experience wear from continuous operation, affecting positioning accuracy and ultimately weld quality. These mechanical systems often represent the most maintenance-intensive aspects of the entire welding setup.

Current Maintenance Reduction Strategies and Solutions

01 Optical component maintenance and protection

Maintenance of laser welding equipment's optical components is critical for optimal performance. This includes regular cleaning and protection of lenses, mirrors, and beam delivery systems from contamination by welding spatter and fumes. Proper maintenance procedures involve using specialized cleaning solutions and techniques to remove deposits without damaging delicate optical surfaces. Protective measures such as cover glasses and shielding systems can extend the life of optical components and maintain beam quality.- Optical component maintenance and cleaning: Regular maintenance of optical components in laser welding equipment is crucial for optimal performance. This includes cleaning of lenses, mirrors, and protective windows to remove dust, spatter, and other contaminants that can affect beam quality and welding precision. Proper cleaning procedures involve using specialized solutions and techniques to avoid damaging delicate optical surfaces while ensuring maximum light transmission and beam focus.

- Cooling system maintenance: Maintenance of cooling systems is essential for laser welding equipment reliability. This includes regular inspection and cleaning of water cooling circuits, heat exchangers, and cooling fans to prevent overheating. Proper maintenance involves checking coolant levels, replacing filters, cleaning heat sinks, and ensuring proper flow rates. Well-maintained cooling systems extend the lifespan of laser components and ensure consistent welding quality by maintaining stable operating temperatures.

- Automated diagnostic and monitoring systems: Advanced laser welding equipment incorporates automated diagnostic and monitoring systems that continuously track performance parameters and detect potential issues before they cause failures. These systems monitor beam quality, power output, temperature, gas flow, and other critical variables. Real-time monitoring allows for predictive maintenance scheduling, reducing downtime and extending equipment life while ensuring consistent welding quality through early detection of performance degradation.

- Laser source maintenance and calibration: Regular maintenance of the laser source is critical for welding equipment performance. This includes calibration of power output, beam profile analysis, and replacement of consumable components such as flash lamps or diodes. Proper maintenance procedures involve checking electrical connections, gas supplies for gas lasers, and fiber integrity for fiber lasers. Scheduled maintenance of the laser source ensures consistent power delivery, beam quality, and welding results while maximizing the operational lifespan of the equipment.

- Mechanical system maintenance and alignment: Maintenance of mechanical components in laser welding equipment involves regular inspection and servicing of motion systems, fixtures, and alignment mechanisms. This includes checking for wear in linear guides, bearings, and drive systems, as well as verifying the accuracy of positioning systems. Proper alignment of beam delivery components and workpiece positioning systems is essential for welding precision. Regular lubrication, tightening of fasteners, and replacement of worn parts ensure reliable operation and consistent welding quality.

02 Cooling system maintenance

Effective maintenance of cooling systems in laser welding equipment is essential for preventing overheating and ensuring consistent performance. This includes regular inspection and cleaning of water cooling circuits, heat exchangers, and cooling fans. Maintenance procedures involve checking for leaks, replacing coolant fluids, cleaning filters, and ensuring proper flow rates. Well-maintained cooling systems help extend the lifespan of laser components and maintain stable beam parameters during operation.Expand Specific Solutions03 Automated diagnostic and monitoring systems

Advanced laser welding equipment incorporates automated diagnostic and monitoring systems that facilitate maintenance through real-time performance tracking and predictive maintenance capabilities. These systems monitor critical parameters such as beam power, focus position, gas flow rates, and component temperatures. By analyzing operational data, these systems can detect potential issues before they cause equipment failure, schedule maintenance interventions, and provide troubleshooting guidance to maintenance personnel.Expand Specific Solutions04 Gas supply system maintenance

Proper maintenance of gas supply systems is crucial for laser welding equipment performance. This includes regular inspection and cleaning of gas lines, valves, regulators, and nozzles to prevent contamination and ensure consistent gas flow. Maintenance procedures involve checking for leaks, replacing filters, cleaning nozzles, and verifying proper gas pressure and flow rates. Well-maintained gas systems ensure proper shielding of the weld area and protection of the laser beam path from contaminants.Expand Specific Solutions05 Mechanical components and alignment maintenance

Regular maintenance of mechanical components and alignment systems is essential for laser welding equipment precision. This includes checking and adjusting motion systems, beam delivery components, and workpiece positioning mechanisms. Maintenance procedures involve lubricating moving parts, tightening fasteners, checking for wear, and performing precision alignment of optical paths. Proper mechanical maintenance ensures accurate beam positioning, consistent weld quality, and reliable equipment operation.Expand Specific Solutions

Key Industry Players and Equipment Manufacturers

The laser welding equipment maintenance reduction market is in a growth phase, with increasing adoption across automotive, aerospace, and manufacturing sectors. The market size is expanding due to the cost-saving potential of reduced maintenance requirements. Technologically, the field shows varying maturity levels, with established players like TRUMPF Laser GmbH and Siemens AG offering advanced solutions with predictive maintenance capabilities. Emerging competitors include specialized firms like Wuhan Huagong Laser Engineering and Shanghai Feibo Laser Technology. Automotive manufacturers (BMW, Honda, Volkswagen) are driving innovation through in-house development, while industrial conglomerates (Honeywell, Hitachi) leverage their broader technological ecosystems to enhance maintenance efficiency in laser welding operations.

TRUMPF Laser GmbH + Co. KG

Technical Solution: TRUMPF has developed a comprehensive predictive maintenance system for their laser welding equipment that utilizes real-time monitoring and AI-based analytics. Their solution incorporates smart sensors throughout critical components that continuously collect performance data, which is then analyzed by machine learning algorithms to detect anomalies before they cause failures. The system includes their "Condition Monitoring" technology that tracks laser source parameters, beam delivery components, and cooling systems to predict maintenance needs accurately. TRUMPF's X-POINT technology enables remote diagnostics and maintenance, allowing technicians to troubleshoot and sometimes repair issues without physical presence[1]. Their Digital Maintenance Assistant provides step-by-step guidance for necessary maintenance procedures, reducing the skill level required for maintenance personnel[2].

Strengths: Industry-leading predictive maintenance algorithms with high accuracy in failure prediction; comprehensive sensor integration across all critical components; remote maintenance capabilities reducing technician visits by up to 30%. Weaknesses: Higher initial implementation cost compared to conventional systems; requires consistent connectivity for optimal performance; some advanced features may require subscription to TRUMPF's service plans.

Hitachi Ltd.

Technical Solution: Hitachi has developed an innovative maintenance reduction system for laser welding equipment centered around their "Adaptive Resonator Technology" (ART). This technology dynamically adjusts the laser resonator configuration based on operational conditions to minimize thermal stress and extend component life. Their system incorporates specialized optical coatings that resist contamination and degradation, significantly reducing the need for lens cleaning and replacement[5]. Hitachi's solution also features their proprietary "Smart Flow" cooling system that uses intelligent flow control to optimize cooling efficiency while minimizing water consumption and preventing scaling. The maintenance reduction system is supported by Hitachi's Lumada IoT platform, which provides real-time monitoring and analytics capabilities. Their predictive maintenance algorithms can detect subtle changes in beam quality, power efficiency, and thermal characteristics to identify potential issues before they affect production[6].

Strengths: Advanced optical coating technology that significantly extends component life; adaptive resonator technology that reduces thermal stress on critical components; comprehensive integration with factory management systems. Weaknesses: Higher initial cost compared to standard systems; some technologies are proprietary and require Hitachi-certified technicians for major service; full benefits require implementation of Hitachi's broader IoT ecosystem.

Critical Technologies for Maintenance Optimization

Laser welding head and process

PatentActiveEP2934811A1

Innovation

- A laser welding head design featuring an annular nozzle for protective gas injection and a transverse air flow chamber with a distance of at least 100 mm between the nozzle and the chamber, along with an air deflector and porous diffuser, minimizes aerodynamic interactions and protects the focusing lens from hot gases and dust, while a second gas nozzle provides continuous protection behind the weld line.

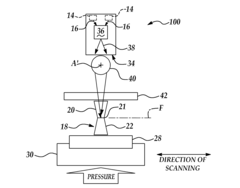

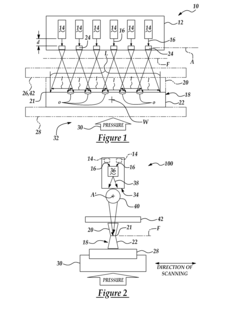

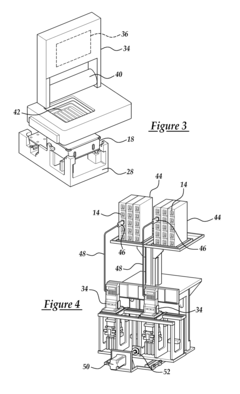

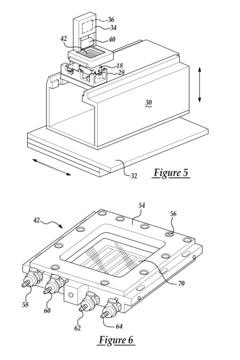

Laser welding system

PatentInactiveUS20090200278A1

Innovation

- A free-spacing beam delivery laser head with a linear array of laser diodes that generates a continuous line of focused laser energy, using transmissive and absorptive materials for the workpiece components and a water-cooled masked pressure plate to reduce maintenance needs and enhance energy efficiency.

Total Cost of Ownership Analysis for Laser Welding Equipment

When evaluating laser welding equipment investments, Total Cost of Ownership (TCO) analysis provides a comprehensive framework that extends beyond initial purchase price to include all costs throughout the equipment's lifecycle. For laser welding systems, TCO encompasses acquisition costs, operational expenses, maintenance requirements, downtime losses, and eventual disposal costs.

The acquisition phase includes not only the base equipment price but also installation costs, facility modifications, initial operator training, and software integration expenses. These upfront costs typically represent 30-40% of the total ownership cost over the equipment's lifetime.

Operational costs form a significant portion of TCO, including energy consumption, consumables, and labor. Modern fiber laser welding systems demonstrate 3-4 times greater electrical efficiency compared to traditional Nd:YAG systems, potentially saving $15,000-$25,000 annually in energy costs for high-power applications. Consumable costs vary significantly between laser types, with CO2 systems requiring regular gas replenishment while solid-state lasers eliminate this expense.

Maintenance expenses represent a critical TCO component, encompassing preventive maintenance, repairs, spare parts inventory, and technical support contracts. Industry data suggests maintenance costs typically account for 15-25% of annual TCO. Implementing condition-based maintenance strategies rather than fixed schedules can reduce these costs by 20-30% while improving equipment reliability.

Downtime costs often represent the most underestimated TCO component. When a laser welding system fails, production losses can range from $1,000-$10,000 per hour depending on the manufacturing environment. Advanced systems with predictive maintenance capabilities and redundant components demonstrate 30-40% less unplanned downtime compared to basic models.

End-of-life considerations include decommissioning, disposal, and potential resale value. Equipment with modular designs and upgrade pathways typically retains 15-25% higher residual value after 5-7 years compared to non-upgradable systems.

TCO analysis reveals that maintenance-optimized laser welding systems may command a 20-30% premium in initial price but deliver 15-40% lower lifetime ownership costs through reduced maintenance requirements, higher uptime, and extended service life. Organizations implementing comprehensive TCO modeling report 18-25% improvement in equipment investment decisions and more accurate budget forecasting.

The acquisition phase includes not only the base equipment price but also installation costs, facility modifications, initial operator training, and software integration expenses. These upfront costs typically represent 30-40% of the total ownership cost over the equipment's lifetime.

Operational costs form a significant portion of TCO, including energy consumption, consumables, and labor. Modern fiber laser welding systems demonstrate 3-4 times greater electrical efficiency compared to traditional Nd:YAG systems, potentially saving $15,000-$25,000 annually in energy costs for high-power applications. Consumable costs vary significantly between laser types, with CO2 systems requiring regular gas replenishment while solid-state lasers eliminate this expense.

Maintenance expenses represent a critical TCO component, encompassing preventive maintenance, repairs, spare parts inventory, and technical support contracts. Industry data suggests maintenance costs typically account for 15-25% of annual TCO. Implementing condition-based maintenance strategies rather than fixed schedules can reduce these costs by 20-30% while improving equipment reliability.

Downtime costs often represent the most underestimated TCO component. When a laser welding system fails, production losses can range from $1,000-$10,000 per hour depending on the manufacturing environment. Advanced systems with predictive maintenance capabilities and redundant components demonstrate 30-40% less unplanned downtime compared to basic models.

End-of-life considerations include decommissioning, disposal, and potential resale value. Equipment with modular designs and upgrade pathways typically retains 15-25% higher residual value after 5-7 years compared to non-upgradable systems.

TCO analysis reveals that maintenance-optimized laser welding systems may command a 20-30% premium in initial price but deliver 15-40% lower lifetime ownership costs through reduced maintenance requirements, higher uptime, and extended service life. Organizations implementing comprehensive TCO modeling report 18-25% improvement in equipment investment decisions and more accurate budget forecasting.

Predictive Maintenance and AI Integration Opportunities

Predictive maintenance represents a paradigm shift in laser welding equipment management, moving from reactive to proactive maintenance strategies. By leveraging advanced sensors, data analytics, and artificial intelligence, manufacturers can anticipate equipment failures before they occur, significantly reducing downtime and maintenance costs. Current predictive maintenance systems typically monitor key parameters such as laser power stability, beam quality, cooling system performance, and optical component degradation patterns to identify potential issues.

The integration of AI technologies presents particularly promising opportunities in this domain. Machine learning algorithms can analyze historical maintenance data alongside real-time sensor inputs to identify subtle patterns that precede specific failure modes. Deep learning models have demonstrated remarkable accuracy in predicting component failures up to several weeks in advance, allowing maintenance teams to schedule interventions during planned production breaks rather than emergency shutdowns.

Edge computing solutions are emerging as critical enablers for real-time predictive maintenance in laser welding environments. By processing data directly on the production floor rather than in remote cloud systems, these solutions minimize latency and enable immediate responses to detected anomalies. Several leading manufacturers have reported maintenance cost reductions of 25-30% following AI-based predictive maintenance implementation.

Digital twin technology represents another frontier in predictive maintenance for laser welding equipment. These virtual replicas simulate the physical behavior of welding systems, allowing operators to test different operational parameters and predict their impact on component wear and system performance. When combined with reinforcement learning algorithms, digital twins can even suggest optimal maintenance schedules that balance component longevity against production requirements.

The economic case for AI-integrated predictive maintenance is compelling. Industry studies indicate that predictive maintenance typically reduces machine downtime by 30-50% and extends equipment lifetime by 20-40%. For laser welding operations, where downtime costs can exceed thousands of dollars per hour, these improvements translate to substantial financial benefits. Additionally, the more precise maintenance scheduling reduces spare parts inventory requirements and optimizes technician utilization.

Implementation challenges remain, particularly regarding data quality and integration with legacy systems. Many existing laser welding installations lack sufficient sensor coverage for comprehensive predictive analytics. Retrofitting solutions are becoming more accessible, with wireless sensor networks and non-invasive monitoring technologies enabling predictive capabilities without major equipment modifications. As these technologies mature and become more affordable, their adoption across various manufacturing scales is expected to accelerate significantly.

The integration of AI technologies presents particularly promising opportunities in this domain. Machine learning algorithms can analyze historical maintenance data alongside real-time sensor inputs to identify subtle patterns that precede specific failure modes. Deep learning models have demonstrated remarkable accuracy in predicting component failures up to several weeks in advance, allowing maintenance teams to schedule interventions during planned production breaks rather than emergency shutdowns.

Edge computing solutions are emerging as critical enablers for real-time predictive maintenance in laser welding environments. By processing data directly on the production floor rather than in remote cloud systems, these solutions minimize latency and enable immediate responses to detected anomalies. Several leading manufacturers have reported maintenance cost reductions of 25-30% following AI-based predictive maintenance implementation.

Digital twin technology represents another frontier in predictive maintenance for laser welding equipment. These virtual replicas simulate the physical behavior of welding systems, allowing operators to test different operational parameters and predict their impact on component wear and system performance. When combined with reinforcement learning algorithms, digital twins can even suggest optimal maintenance schedules that balance component longevity against production requirements.

The economic case for AI-integrated predictive maintenance is compelling. Industry studies indicate that predictive maintenance typically reduces machine downtime by 30-50% and extends equipment lifetime by 20-40%. For laser welding operations, where downtime costs can exceed thousands of dollars per hour, these improvements translate to substantial financial benefits. Additionally, the more precise maintenance scheduling reduces spare parts inventory requirements and optimizes technician utilization.

Implementation challenges remain, particularly regarding data quality and integration with legacy systems. Many existing laser welding installations lack sufficient sensor coverage for comprehensive predictive analytics. Retrofitting solutions are becoming more accessible, with wireless sensor networks and non-invasive monitoring technologies enabling predictive capabilities without major equipment modifications. As these technologies mature and become more affordable, their adoption across various manufacturing scales is expected to accelerate significantly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!