How to Optimize Energy Use in Continuous Laser Welding

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Energy Efficiency Background and Objectives

Laser welding technology has evolved significantly since its inception in the 1960s, transforming from a niche application to a mainstream manufacturing process across multiple industries. The continuous laser welding process, characterized by uninterrupted beam delivery along a seam, has become particularly valuable in automotive, aerospace, and electronics manufacturing due to its precision and efficiency. However, energy consumption remains a critical concern as industrial energy costs rise and environmental regulations tighten globally.

The evolution of laser welding efficiency has progressed through several distinct phases. Early CO2 lasers offered only 5-10% wall-plug efficiency, while modern fiber and disk lasers can achieve 30-40% efficiency. Despite these improvements, significant energy is still wasted during the welding process through reflection, heat dissipation, and beam delivery losses. Current industry benchmarks suggest that only 20-30% of input energy effectively contributes to the actual weld formation in typical applications.

Market trends indicate growing demand for energy-efficient manufacturing processes, driven by both economic pressures and sustainability initiatives. The European Union's Green Deal and similar policies worldwide are accelerating the adoption of energy-efficient technologies across manufacturing sectors. Additionally, the increasing electrification of vehicles has created unprecedented demand for high-precision, energy-efficient joining technologies for battery production and lightweight structural components.

The primary technical objective of optimizing energy use in continuous laser welding encompasses several interconnected goals. First, to increase the ratio of energy that directly contributes to weld formation versus total energy input. Second, to develop adaptive control systems that can dynamically adjust laser parameters based on real-time feedback to maintain optimal energy utilization across varying material conditions. Third, to integrate energy recovery systems that can capture and repurpose waste heat generated during the welding process.

Recent technological advancements in beam shaping, pulse modulation, and multi-beam approaches have shown promising results in laboratory settings, demonstrating potential energy savings of 15-25% compared to conventional methods. However, translating these advances to industrial-scale applications presents significant challenges related to process stability, quality assurance, and implementation costs.

The trajectory of laser welding technology suggests continued improvements in energy efficiency through the integration of artificial intelligence for process optimization, development of novel laser sources with higher wall-plug efficiency, and implementation of comprehensive energy management systems that consider the entire manufacturing ecosystem rather than isolated welding operations.

The evolution of laser welding efficiency has progressed through several distinct phases. Early CO2 lasers offered only 5-10% wall-plug efficiency, while modern fiber and disk lasers can achieve 30-40% efficiency. Despite these improvements, significant energy is still wasted during the welding process through reflection, heat dissipation, and beam delivery losses. Current industry benchmarks suggest that only 20-30% of input energy effectively contributes to the actual weld formation in typical applications.

Market trends indicate growing demand for energy-efficient manufacturing processes, driven by both economic pressures and sustainability initiatives. The European Union's Green Deal and similar policies worldwide are accelerating the adoption of energy-efficient technologies across manufacturing sectors. Additionally, the increasing electrification of vehicles has created unprecedented demand for high-precision, energy-efficient joining technologies for battery production and lightweight structural components.

The primary technical objective of optimizing energy use in continuous laser welding encompasses several interconnected goals. First, to increase the ratio of energy that directly contributes to weld formation versus total energy input. Second, to develop adaptive control systems that can dynamically adjust laser parameters based on real-time feedback to maintain optimal energy utilization across varying material conditions. Third, to integrate energy recovery systems that can capture and repurpose waste heat generated during the welding process.

Recent technological advancements in beam shaping, pulse modulation, and multi-beam approaches have shown promising results in laboratory settings, demonstrating potential energy savings of 15-25% compared to conventional methods. However, translating these advances to industrial-scale applications presents significant challenges related to process stability, quality assurance, and implementation costs.

The trajectory of laser welding technology suggests continued improvements in energy efficiency through the integration of artificial intelligence for process optimization, development of novel laser sources with higher wall-plug efficiency, and implementation of comprehensive energy management systems that consider the entire manufacturing ecosystem rather than isolated welding operations.

Market Analysis for Energy-Efficient Welding Technologies

The global market for energy-efficient welding technologies has experienced significant growth in recent years, driven by increasing industrial focus on sustainability and cost reduction. The continuous laser welding segment specifically has seen a compound annual growth rate of approximately 7.8% between 2018 and 2022, with projections indicating continued expansion through 2030. This growth trajectory is supported by stringent environmental regulations across major manufacturing regions and rising energy costs that have pushed manufacturers to seek more efficient production methods.

Market demand for energy-optimized continuous laser welding systems is particularly strong in automotive, aerospace, and electronics manufacturing sectors. These industries collectively represent over 65% of the total market share for advanced welding technologies. The automotive sector leads adoption, implementing energy-efficient laser welding for lightweight vehicle construction to meet fuel efficiency standards. Meanwhile, the aerospace industry values precision welding with minimal energy consumption for critical components.

Regional analysis reveals that Asia-Pacific currently dominates the market with approximately 40% share, followed by Europe and North America. China and South Korea have emerged as manufacturing powerhouses with substantial investments in energy-efficient production technologies. European markets, particularly Germany and Italy, demonstrate strong demand driven by strict energy consumption regulations and sustainability initiatives.

Consumer electronics manufacturers represent a rapidly growing market segment, with demand increasing at nearly 9% annually for micro-welding applications that require precise energy control. This sector values technologies that minimize heat-affected zones while maintaining high throughput rates.

Market research indicates that end-users are willing to pay a premium of 15-20% for welding systems that demonstrate energy savings of 30% or more compared to conventional technologies. The return on investment period customers expect has shortened from 3-4 years to 18-24 months, indicating heightened price sensitivity coupled with stronger value perception for energy efficiency.

Competition in this market space is intensifying, with traditional welding equipment manufacturers facing challenges from specialized laser technology companies. The market structure is transitioning from fragmented to increasingly consolidated as technology leaders acquire smaller innovative firms to expand their energy-efficient product portfolios.

Emerging economies present significant growth opportunities, with India, Brazil, and Southeast Asian nations showing increased adoption rates as their manufacturing sectors modernize and energy costs rise. These markets are expected to grow at 1.5 times the global average rate over the next five years.

Market demand for energy-optimized continuous laser welding systems is particularly strong in automotive, aerospace, and electronics manufacturing sectors. These industries collectively represent over 65% of the total market share for advanced welding technologies. The automotive sector leads adoption, implementing energy-efficient laser welding for lightweight vehicle construction to meet fuel efficiency standards. Meanwhile, the aerospace industry values precision welding with minimal energy consumption for critical components.

Regional analysis reveals that Asia-Pacific currently dominates the market with approximately 40% share, followed by Europe and North America. China and South Korea have emerged as manufacturing powerhouses with substantial investments in energy-efficient production technologies. European markets, particularly Germany and Italy, demonstrate strong demand driven by strict energy consumption regulations and sustainability initiatives.

Consumer electronics manufacturers represent a rapidly growing market segment, with demand increasing at nearly 9% annually for micro-welding applications that require precise energy control. This sector values technologies that minimize heat-affected zones while maintaining high throughput rates.

Market research indicates that end-users are willing to pay a premium of 15-20% for welding systems that demonstrate energy savings of 30% or more compared to conventional technologies. The return on investment period customers expect has shortened from 3-4 years to 18-24 months, indicating heightened price sensitivity coupled with stronger value perception for energy efficiency.

Competition in this market space is intensifying, with traditional welding equipment manufacturers facing challenges from specialized laser technology companies. The market structure is transitioning from fragmented to increasingly consolidated as technology leaders acquire smaller innovative firms to expand their energy-efficient product portfolios.

Emerging economies present significant growth opportunities, with India, Brazil, and Southeast Asian nations showing increased adoption rates as their manufacturing sectors modernize and energy costs rise. These markets are expected to grow at 1.5 times the global average rate over the next five years.

Current Challenges in Continuous Laser Welding Energy Consumption

Continuous laser welding has emerged as a critical manufacturing process across industries, yet its energy efficiency remains a significant concern. Current systems typically operate at energy conversion efficiencies between 10-30%, with substantial energy losses occurring throughout the process chain. These inefficiencies not only increase operational costs but also contribute to environmental impact through unnecessary carbon emissions.

The primary challenge lies in the laser source itself, where electrical-to-optical conversion efficiency varies widely depending on the laser type. CO2 lasers operate at approximately 10-15% efficiency, while fiber and disk lasers achieve 25-35%. This fundamental inefficiency creates a baseline energy loss that propagates throughout the entire welding system.

Beam delivery systems present another critical challenge, with losses occurring through optical components including mirrors, lenses, and fiber cables. Each reflection or transmission point can result in 0.5-2% energy loss, which compounds across complex delivery paths. Additionally, cooling systems required to maintain optimal laser operation typically consume 30-50% of the total system energy, creating a significant parasitic load.

Process parameters optimization remains largely empirical in industrial settings, with many operators using excessive power margins to ensure weld quality. Studies indicate that up to 20% of energy consumption could be reduced through precise parameter optimization without compromising weld integrity. However, the complex interdependence between parameters such as laser power, welding speed, focal position, and material properties makes systematic optimization challenging.

Real-time monitoring and adaptive control systems represent an emerging solution, but current implementations face limitations in sensor technology, data processing speed, and control algorithms. Most systems operate with fixed parameters throughout the welding process, unable to respond to dynamic changes in material conditions or joint geometry.

Energy recovery opportunities remain largely unexploited, with heat generated during the process typically dissipated as waste. Thermal management systems generally focus on maintaining operational stability rather than energy recovery, despite the potential for utilizing this waste heat for preheating materials or supporting facility heating needs.

Industry standards and regulatory frameworks for energy efficiency in laser welding processes are still evolving, creating uncertainty for manufacturers investing in new equipment. The lack of standardized energy efficiency metrics specific to laser welding makes comparative assessment difficult and hinders the adoption of more efficient technologies.

Material-specific challenges further complicate energy optimization efforts, as different alloys and material combinations require vastly different energy inputs for successful welding. This variability necessitates flexible systems capable of precise energy delivery across diverse applications, often resulting in equipment oversized for average requirements.

The primary challenge lies in the laser source itself, where electrical-to-optical conversion efficiency varies widely depending on the laser type. CO2 lasers operate at approximately 10-15% efficiency, while fiber and disk lasers achieve 25-35%. This fundamental inefficiency creates a baseline energy loss that propagates throughout the entire welding system.

Beam delivery systems present another critical challenge, with losses occurring through optical components including mirrors, lenses, and fiber cables. Each reflection or transmission point can result in 0.5-2% energy loss, which compounds across complex delivery paths. Additionally, cooling systems required to maintain optimal laser operation typically consume 30-50% of the total system energy, creating a significant parasitic load.

Process parameters optimization remains largely empirical in industrial settings, with many operators using excessive power margins to ensure weld quality. Studies indicate that up to 20% of energy consumption could be reduced through precise parameter optimization without compromising weld integrity. However, the complex interdependence between parameters such as laser power, welding speed, focal position, and material properties makes systematic optimization challenging.

Real-time monitoring and adaptive control systems represent an emerging solution, but current implementations face limitations in sensor technology, data processing speed, and control algorithms. Most systems operate with fixed parameters throughout the welding process, unable to respond to dynamic changes in material conditions or joint geometry.

Energy recovery opportunities remain largely unexploited, with heat generated during the process typically dissipated as waste. Thermal management systems generally focus on maintaining operational stability rather than energy recovery, despite the potential for utilizing this waste heat for preheating materials or supporting facility heating needs.

Industry standards and regulatory frameworks for energy efficiency in laser welding processes are still evolving, creating uncertainty for manufacturers investing in new equipment. The lack of standardized energy efficiency metrics specific to laser welding makes comparative assessment difficult and hinders the adoption of more efficient technologies.

Material-specific challenges further complicate energy optimization efforts, as different alloys and material combinations require vastly different energy inputs for successful welding. This variability necessitates flexible systems capable of precise energy delivery across diverse applications, often resulting in equipment oversized for average requirements.

Current Energy Optimization Techniques for Continuous Laser Welding

01 Energy efficiency optimization in continuous laser welding

Various methods and systems are employed to optimize energy usage during continuous laser welding processes. These include precise power control mechanisms, energy recovery systems, and adaptive power management that adjusts laser output based on material properties and welding requirements. Such optimizations reduce overall energy consumption while maintaining weld quality and production efficiency.- Energy efficiency optimization in continuous laser welding: Various methods and systems are employed to optimize energy consumption during continuous laser welding processes. These include precise power control mechanisms, energy recovery systems, and adaptive power management that adjusts laser output based on material properties and welding requirements. Such optimizations reduce overall energy consumption while maintaining weld quality and production efficiency.

- Laser power control systems for welding applications: Advanced control systems regulate laser power during continuous welding operations to ensure optimal energy use. These systems incorporate feedback mechanisms that monitor welding parameters in real-time and adjust power delivery accordingly. Features include pulse modulation, power ramping, and intelligent power distribution that minimize energy waste while ensuring consistent weld quality across varying material thicknesses and compositions.

- Thermal management in continuous laser welding processes: Effective thermal management systems are crucial for energy-efficient continuous laser welding. These include cooling systems, heat dissipation mechanisms, and thermal monitoring technologies that prevent overheating and energy waste. By maintaining optimal operating temperatures, these systems extend equipment lifespan, improve weld quality, and significantly reduce energy consumption during extended welding operations.

- Energy monitoring and analysis in laser welding systems: Sophisticated monitoring and analysis tools track energy consumption during continuous laser welding operations. These systems collect data on power usage, efficiency metrics, and process parameters to identify optimization opportunities. Real-time monitoring capabilities allow for immediate adjustments to welding parameters, while analytical tools provide insights for long-term energy efficiency improvements and cost reduction strategies.

- Novel laser technologies for energy-efficient welding: Innovative laser technologies have been developed specifically to reduce energy consumption in continuous welding applications. These include high-efficiency laser sources, beam shaping optics, and hybrid laser systems that combine different energy sources. Such technologies deliver more focused energy to the weld zone, minimize heat-affected areas, and achieve higher energy transfer efficiency compared to conventional laser welding methods.

02 Laser power control systems for energy management

Advanced control systems regulate laser power during continuous welding operations to minimize energy waste. These systems incorporate real-time monitoring of welding parameters, feedback loops, and predictive algorithms to maintain optimal energy levels. By precisely controlling power delivery based on material thickness, welding speed, and joint configuration, these systems ensure efficient energy use while achieving consistent weld quality.Expand Specific Solutions03 Thermal management techniques in laser welding

Thermal management plays a crucial role in energy efficiency during continuous laser welding. Technologies such as heat sinks, cooling systems, and thermal barriers help control heat distribution and prevent energy losses. Advanced thermal management approaches include selective cooling of critical components, heat recovery systems, and thermal profiling to optimize energy transfer to the workpiece while minimizing waste heat generation.Expand Specific Solutions04 Monitoring and feedback systems for energy optimization

Real-time monitoring and feedback systems are implemented to track energy consumption during continuous laser welding processes. These systems utilize sensors to measure parameters such as temperature, power input, beam characteristics, and material response. The collected data feeds into control algorithms that dynamically adjust welding parameters to maintain optimal energy efficiency while ensuring weld quality meets specifications.Expand Specific Solutions05 Novel laser sources and beam delivery for energy efficiency

Innovative laser sources and beam delivery systems are designed to improve energy efficiency in continuous welding applications. These include high-efficiency diode lasers, fiber lasers with improved beam quality, and hybrid laser systems. Advanced beam shaping optics, beam combining techniques, and novel resonator designs help maximize energy transfer to the workpiece while reducing losses in the beam delivery path.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Laser Welding

The continuous laser welding energy optimization landscape is currently in a growth phase, with market size expanding due to increasing automotive and electronics applications. The technology is reaching maturity, with key players demonstrating varied levels of expertise. Industry leaders like TRUMPF Laser- und Systemtechnik and Fraunhofer-Gesellschaft are driving innovation through advanced research, while automotive manufacturers Toyota, Honda, and HELLA are implementing practical applications. Electronics companies including Panasonic, Toshiba, and LG Energy Solution are developing specialized energy-efficient solutions. Academic institutions such as Beijing University of Technology and Huazhong University collaborate with industry partners to bridge theoretical research and practical implementation, creating a competitive ecosystem balancing established players and emerging specialists.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed comprehensive energy optimization solutions for continuous laser welding through their LAPRISS laser welding system series. Their approach integrates high-efficiency direct diode lasers with sophisticated power management systems that reduce energy consumption by up to 40% compared to traditional Nd:YAG lasers. Panasonic's technology features adaptive power control algorithms that continuously adjust laser output based on real-time feedback from multiple sensors monitoring weld pool dynamics and material conditions. Their systems incorporate specialized beam shaping optics that optimize energy distribution across the weld zone, reducing the total power required while maintaining weld quality. Panasonic has also pioneered the use of dual-beam technology that splits laser energy between preheating and welding functions, improving overall process efficiency. Their latest innovations include AI-driven predictive models that optimize laser parameters based on material properties and joint configurations, further reducing energy waste. Additionally, Panasonic's systems feature energy-efficient cooling solutions that minimize auxiliary power consumption, which can account for up to 30% of a laser welding system's total energy use.

Strengths: Exceptional electrical efficiency of their direct diode laser technology; comprehensive integration with factory automation systems for holistic energy management; strong presence in automotive and electronics manufacturing sectors. Weaknesses: Higher initial investment compared to conventional welding technologies; requires specialized technical support for maintenance and optimization; more complex setup procedures for achieving maximum energy efficiency.

TRUMPF Laser- und Systemtechnik GmbH

Technical Solution: TRUMPF has developed advanced energy optimization solutions for continuous laser welding through their TruLaser Cell series. Their technology incorporates real-time power modulation that adjusts laser output based on material thickness and welding speed, reducing energy consumption by up to 30% compared to conventional systems. TRUMPF's BrightLine Weld technology enables precise energy distribution across the weld seam, minimizing heat-affected zones and reducing overall power requirements. Their systems feature intelligent beam shaping that can switch between different intensity distributions to optimize energy use for different phases of the welding process. Additionally, TRUMPF has implemented predictive maintenance algorithms that monitor laser efficiency and recommend adjustments to maintain optimal energy performance over the system's lifecycle. Their latest systems incorporate energy recovery mechanisms that capture and reuse waste heat from cooling systems, further improving overall energy efficiency.

Strengths: Industry-leading beam quality control allowing precise energy delivery exactly where needed; comprehensive system integration capabilities that optimize the entire welding process rather than just the laser source; extensive experience in industrial applications. Weaknesses: Higher initial investment costs compared to conventional welding systems; requires specialized training for operators to fully utilize energy-saving features; system complexity can lead to longer setup times.

Key Patents and Innovations in Laser Welding Energy Efficiency

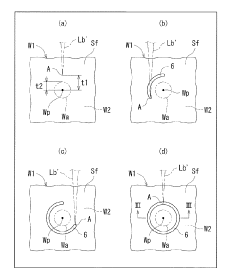

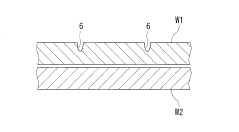

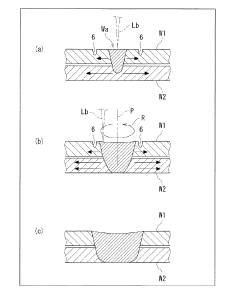

Laser welding method

PatentInactiveJP2021109184A

Innovation

- A laser welding method that creates a low thermal conductivity region near the welding position on one metal plate, suppressing heat transfer along the metal plate's extending direction by forming a concave portion with lower thermal conductivity than the metal plate, and then irradiating a laser beam to melt and join the plates.

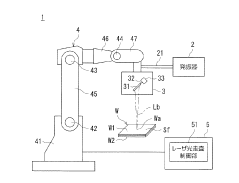

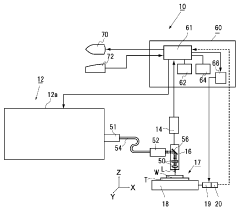

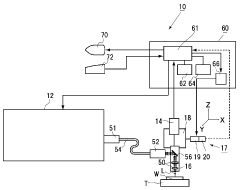

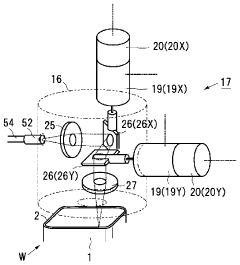

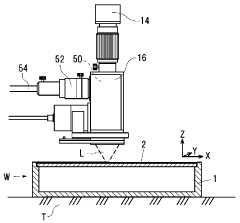

Laser welding method and apparatus therefor

PatentWO2014080442A1

Innovation

- A method and apparatus that dynamically adjust the CW laser output based on real-time calculations of the moving device's speed, ensuring the laser energy is within a predetermined range by synchronizing the laser output with the scanning speed, eliminating the need for pre-programmed output adjustments and allowing for stable energy supply during welding.

Environmental Impact Assessment of Laser Welding Processes

Laser welding processes, while offering significant advantages in manufacturing efficiency and precision, carry notable environmental implications that warrant comprehensive assessment. The environmental footprint of continuous laser welding extends across multiple dimensions, from energy consumption and resource utilization to emissions and waste generation. Primary environmental concerns include the substantial electricity consumption required to power laser systems, which contributes to indirect carbon emissions when sourced from non-renewable energy grids.

Emissions from laser welding processes present another significant environmental consideration. During operation, laser welding generates fumes containing metal particulates, gases, and volatile organic compounds (VOCs). These emissions vary based on material composition, with certain metals like zinc-coated steel producing more hazardous byproducts. Without proper extraction and filtration systems, these airborne contaminants can impact both workplace air quality and the broader environment.

Water usage represents a less obvious but important environmental factor. Cooling systems for high-powered lasers often require substantial water resources, contributing to industrial water consumption. Additionally, the production of specialized gases used in shielding processes during laser welding carries its own upstream environmental impact through extraction and processing operations.

Material efficiency presents a positive environmental aspect of laser welding. The precision of laser processes typically results in reduced material waste compared to conventional welding methods. This advantage becomes particularly significant in high-volume manufacturing operations where even small reductions in waste per unit translate to substantial resource conservation at scale.

The lifecycle environmental impact extends to the manufacturing and eventual disposal of laser equipment itself. Modern laser systems contain various specialized components and rare earth elements whose extraction and processing carry significant environmental burdens. The extended operational lifespan of quality laser systems partially offsets these impacts, but end-of-life considerations remain important for comprehensive environmental assessment.

Regulatory frameworks increasingly address these environmental aspects of industrial processes including laser welding. Compliance with emissions standards, energy efficiency requirements, and waste management regulations varies significantly across regions, creating a complex landscape for manufacturers operating globally. Forward-thinking organizations are implementing environmental management systems specifically tailored to laser processing operations, establishing monitoring protocols and continuous improvement mechanisms.

Emissions from laser welding processes present another significant environmental consideration. During operation, laser welding generates fumes containing metal particulates, gases, and volatile organic compounds (VOCs). These emissions vary based on material composition, with certain metals like zinc-coated steel producing more hazardous byproducts. Without proper extraction and filtration systems, these airborne contaminants can impact both workplace air quality and the broader environment.

Water usage represents a less obvious but important environmental factor. Cooling systems for high-powered lasers often require substantial water resources, contributing to industrial water consumption. Additionally, the production of specialized gases used in shielding processes during laser welding carries its own upstream environmental impact through extraction and processing operations.

Material efficiency presents a positive environmental aspect of laser welding. The precision of laser processes typically results in reduced material waste compared to conventional welding methods. This advantage becomes particularly significant in high-volume manufacturing operations where even small reductions in waste per unit translate to substantial resource conservation at scale.

The lifecycle environmental impact extends to the manufacturing and eventual disposal of laser equipment itself. Modern laser systems contain various specialized components and rare earth elements whose extraction and processing carry significant environmental burdens. The extended operational lifespan of quality laser systems partially offsets these impacts, but end-of-life considerations remain important for comprehensive environmental assessment.

Regulatory frameworks increasingly address these environmental aspects of industrial processes including laser welding. Compliance with emissions standards, energy efficiency requirements, and waste management regulations varies significantly across regions, creating a complex landscape for manufacturers operating globally. Forward-thinking organizations are implementing environmental management systems specifically tailored to laser processing operations, establishing monitoring protocols and continuous improvement mechanisms.

Cost-Benefit Analysis of Energy-Efficient Laser Welding Implementation

Implementing energy-efficient laser welding technologies requires careful financial analysis to justify the initial investment costs against long-term operational savings. The capital expenditure for upgrading to energy-optimized continuous laser welding systems typically ranges from $150,000 to $500,000, depending on the scale of operations and specific technology selected. This includes costs for new equipment, installation, system integration, and initial operator training.

Energy consumption reduction represents the primary financial benefit, with modern optimized systems demonstrating 30-45% lower energy usage compared to conventional laser welding setups. For a medium-sized manufacturing facility operating two shifts daily, this translates to approximately $25,000-$40,000 in annual energy cost savings, depending on local electricity rates and production volume.

Maintenance costs also factor significantly into the cost-benefit equation. Energy-efficient laser systems generally incorporate advanced monitoring capabilities and more durable components, reducing maintenance requirements by an estimated 15-25%. This represents additional annual savings of $8,000-$15,000 for typical industrial applications.

Production efficiency improvements provide another substantial financial benefit. Energy-optimized laser welding systems typically achieve 10-20% faster processing speeds while maintaining or improving weld quality. For manufacturers with high-volume production lines, this efficiency gain can increase throughput value by $30,000-$70,000 annually.

The return on investment (ROI) timeline varies based on implementation scale and existing infrastructure. Most companies achieve full ROI within 2.5-4 years. Smaller implementations focusing on critical production bottlenecks may see ROI in as little as 18 months, while comprehensive facility-wide upgrades typically require longer payback periods.

Government incentives and carbon reduction credits can significantly improve the financial equation. Many regions offer tax incentives, grants, or subsidies for industrial energy efficiency improvements, potentially covering 10-30% of implementation costs. Carbon credit programs provide additional financial benefits in regions with established carbon markets.

Risk factors affecting the cost-benefit analysis include potential production disruptions during implementation, which typically range from 3-10 days depending on installation complexity. Training costs for operators and maintenance personnel must also be considered, averaging $1,500-$3,000 per employee for comprehensive skill development.

Energy consumption reduction represents the primary financial benefit, with modern optimized systems demonstrating 30-45% lower energy usage compared to conventional laser welding setups. For a medium-sized manufacturing facility operating two shifts daily, this translates to approximately $25,000-$40,000 in annual energy cost savings, depending on local electricity rates and production volume.

Maintenance costs also factor significantly into the cost-benefit equation. Energy-efficient laser systems generally incorporate advanced monitoring capabilities and more durable components, reducing maintenance requirements by an estimated 15-25%. This represents additional annual savings of $8,000-$15,000 for typical industrial applications.

Production efficiency improvements provide another substantial financial benefit. Energy-optimized laser welding systems typically achieve 10-20% faster processing speeds while maintaining or improving weld quality. For manufacturers with high-volume production lines, this efficiency gain can increase throughput value by $30,000-$70,000 annually.

The return on investment (ROI) timeline varies based on implementation scale and existing infrastructure. Most companies achieve full ROI within 2.5-4 years. Smaller implementations focusing on critical production bottlenecks may see ROI in as little as 18 months, while comprehensive facility-wide upgrades typically require longer payback periods.

Government incentives and carbon reduction credits can significantly improve the financial equation. Many regions offer tax incentives, grants, or subsidies for industrial energy efficiency improvements, potentially covering 10-30% of implementation costs. Carbon credit programs provide additional financial benefits in regions with established carbon markets.

Risk factors affecting the cost-benefit analysis include potential production disruptions during implementation, which typically range from 3-10 days depending on installation complexity. Training costs for operators and maintenance personnel must also be considered, averaging $1,500-$3,000 per employee for comprehensive skill development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!