How to Leverage Robotics for Laser Welding Innovations

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Robotics-Laser Welding Integration Background and Objectives

Laser welding technology has evolved significantly since its inception in the 1960s, transforming from experimental applications to becoming a cornerstone of modern manufacturing. The integration of robotics with laser welding represents a pivotal advancement in this evolution, enabling unprecedented precision, flexibility, and efficiency in joining processes. This technological convergence has been accelerated by Industry 4.0 initiatives, which emphasize smart manufacturing and automation to enhance productivity and quality while reducing operational costs.

The historical trajectory of robotic laser welding shows a clear progression from simple automated systems to sophisticated robotic cells capable of complex welding operations. Early implementations in the automotive industry during the 1980s demonstrated the potential for improved weld quality and production rates. By the 2000s, advancements in laser sources, particularly the shift from CO2 to fiber and disk lasers, dramatically expanded application possibilities by offering higher power density, better beam quality, and improved energy efficiency.

Current technological trends indicate a movement toward more intelligent robotic laser welding systems incorporating machine learning algorithms, real-time monitoring capabilities, and adaptive control mechanisms. These innovations enable systems to self-optimize welding parameters based on material conditions and environmental factors, significantly reducing defects and improving process stability.

The primary objective of leveraging robotics for laser welding innovations is to develop next-generation systems that overcome existing limitations in weld quality, process flexibility, and production efficiency. Specifically, this involves creating robotic solutions capable of handling complex geometries, diverse material combinations, and variable production requirements while maintaining consistent weld integrity.

Additional goals include reducing the total cost of ownership through improved energy efficiency, minimized material waste, and extended equipment lifespan. Enhanced process monitoring and quality control systems are also critical objectives, aiming to achieve zero-defect manufacturing through real-time feedback loops and predictive maintenance capabilities.

From a broader perspective, innovations in robotic laser welding seek to address emerging market demands for lightweight structures in transportation, miniaturized components in electronics, and customized products across various industries. The technology aims to enable more sustainable manufacturing practices by optimizing material usage and energy consumption while maintaining or improving product performance characteristics.

As global competition intensifies and environmental regulations become more stringent, the strategic importance of advanced robotic laser welding capabilities continues to grow, positioning this technology as a critical enabler for future manufacturing paradigms.

The historical trajectory of robotic laser welding shows a clear progression from simple automated systems to sophisticated robotic cells capable of complex welding operations. Early implementations in the automotive industry during the 1980s demonstrated the potential for improved weld quality and production rates. By the 2000s, advancements in laser sources, particularly the shift from CO2 to fiber and disk lasers, dramatically expanded application possibilities by offering higher power density, better beam quality, and improved energy efficiency.

Current technological trends indicate a movement toward more intelligent robotic laser welding systems incorporating machine learning algorithms, real-time monitoring capabilities, and adaptive control mechanisms. These innovations enable systems to self-optimize welding parameters based on material conditions and environmental factors, significantly reducing defects and improving process stability.

The primary objective of leveraging robotics for laser welding innovations is to develop next-generation systems that overcome existing limitations in weld quality, process flexibility, and production efficiency. Specifically, this involves creating robotic solutions capable of handling complex geometries, diverse material combinations, and variable production requirements while maintaining consistent weld integrity.

Additional goals include reducing the total cost of ownership through improved energy efficiency, minimized material waste, and extended equipment lifespan. Enhanced process monitoring and quality control systems are also critical objectives, aiming to achieve zero-defect manufacturing through real-time feedback loops and predictive maintenance capabilities.

From a broader perspective, innovations in robotic laser welding seek to address emerging market demands for lightweight structures in transportation, miniaturized components in electronics, and customized products across various industries. The technology aims to enable more sustainable manufacturing practices by optimizing material usage and energy consumption while maintaining or improving product performance characteristics.

As global competition intensifies and environmental regulations become more stringent, the strategic importance of advanced robotic laser welding capabilities continues to grow, positioning this technology as a critical enabler for future manufacturing paradigms.

Market Demand Analysis for Robotic Laser Welding Solutions

The global market for robotic laser welding solutions has experienced significant growth over the past decade, driven primarily by increasing automation demands across manufacturing sectors. Current market valuations indicate that the robotic laser welding segment represents approximately 18% of the overall industrial welding equipment market, with a compound annual growth rate exceeding the broader automation sector by 3-4 percentage points.

Manufacturing industries, particularly automotive and aerospace, constitute the largest demand segments for robotic laser welding technologies. The automotive sector alone accounts for nearly 40% of the total market share, as manufacturers increasingly adopt these solutions to enhance production efficiency, improve weld quality, and reduce operational costs. The aerospace industry follows with approximately 25% market share, driven by stringent quality requirements and the need for precision in critical components.

Regional analysis reveals that Asia-Pacific currently leads the market consumption, with China emerging as the primary growth engine due to its rapid industrial expansion and government initiatives promoting smart manufacturing. North America and Europe maintain substantial market shares, characterized by demand for high-precision applications and advanced integration capabilities with existing production systems.

Key market drivers include the growing emphasis on lightweight materials in transportation industries, which necessitates specialized welding techniques that robotic laser systems can effectively deliver. Additionally, the push toward Industry 4.0 implementation has accelerated demand for connected robotic welding systems capable of real-time monitoring, predictive maintenance, and integration with manufacturing execution systems.

Customer requirements are increasingly focused on flexibility and adaptability, with manufacturers seeking robotic laser welding solutions that can handle multiple material types and thicknesses without significant reconfiguration. This trend is particularly evident in industries with high product variability or frequent design changes.

Market research indicates a growing demand for collaborative robotic laser welding systems that can safely operate alongside human workers, especially among small and medium-sized enterprises seeking gradual automation implementation without complete production line overhauls.

Economic factors influencing market growth include decreasing costs of robotic systems, rising labor expenses in traditional manufacturing hubs, and increasing pressure to reduce production cycle times. The return on investment period for robotic laser welding systems has decreased from 3-5 years to 1.5-3 years for many applications, significantly enhancing their market appeal.

Future market projections suggest continued expansion, with particular growth expected in emerging economies and previously underserved sectors such as medical device manufacturing, construction, and renewable energy equipment production.

Manufacturing industries, particularly automotive and aerospace, constitute the largest demand segments for robotic laser welding technologies. The automotive sector alone accounts for nearly 40% of the total market share, as manufacturers increasingly adopt these solutions to enhance production efficiency, improve weld quality, and reduce operational costs. The aerospace industry follows with approximately 25% market share, driven by stringent quality requirements and the need for precision in critical components.

Regional analysis reveals that Asia-Pacific currently leads the market consumption, with China emerging as the primary growth engine due to its rapid industrial expansion and government initiatives promoting smart manufacturing. North America and Europe maintain substantial market shares, characterized by demand for high-precision applications and advanced integration capabilities with existing production systems.

Key market drivers include the growing emphasis on lightweight materials in transportation industries, which necessitates specialized welding techniques that robotic laser systems can effectively deliver. Additionally, the push toward Industry 4.0 implementation has accelerated demand for connected robotic welding systems capable of real-time monitoring, predictive maintenance, and integration with manufacturing execution systems.

Customer requirements are increasingly focused on flexibility and adaptability, with manufacturers seeking robotic laser welding solutions that can handle multiple material types and thicknesses without significant reconfiguration. This trend is particularly evident in industries with high product variability or frequent design changes.

Market research indicates a growing demand for collaborative robotic laser welding systems that can safely operate alongside human workers, especially among small and medium-sized enterprises seeking gradual automation implementation without complete production line overhauls.

Economic factors influencing market growth include decreasing costs of robotic systems, rising labor expenses in traditional manufacturing hubs, and increasing pressure to reduce production cycle times. The return on investment period for robotic laser welding systems has decreased from 3-5 years to 1.5-3 years for many applications, significantly enhancing their market appeal.

Future market projections suggest continued expansion, with particular growth expected in emerging economies and previously underserved sectors such as medical device manufacturing, construction, and renewable energy equipment production.

Current Technological Landscape and Challenges in Robotic Laser Welding

Robotic laser welding technology has evolved significantly over the past decade, with major advancements in both laser sources and robotic systems. Currently, fiber lasers dominate the market due to their high efficiency, beam quality, and lower maintenance requirements compared to traditional CO2 or Nd:YAG lasers. These systems typically deliver power ranges from 1kW to 20kW, with beam quality factors enabling precise focusing for various industrial applications.

The global landscape shows distinct regional specializations. European manufacturers, particularly from Germany and Switzerland, lead in high-precision robotic laser welding systems, while Japanese companies excel in automotive applications. Chinese manufacturers have rapidly expanded their market share by offering cost-effective solutions, though often with less advanced features than their Western counterparts.

Despite significant progress, several technical challenges persist in robotic laser welding. Beam positioning accuracy remains critical, with even minor deviations of 0.1-0.2mm potentially causing weld defects. Real-time seam tracking systems have improved but still struggle with highly reflective materials or complex joint geometries. The integration of vision systems with robotic controllers introduces latency issues that can compromise weld quality at higher speeds.

Material-specific challenges continue to constrain applications. Welding dissimilar metals presents metallurgical compatibility issues, while high thermal conductivity materials like aluminum and copper require precise energy management. Spatter reduction remains problematic for certain material combinations, necessitating advanced beam shaping technologies or hybrid approaches.

Process monitoring represents another significant challenge. Current in-process quality control systems can detect some defects but lack the capability to identify all potential failure modes in real-time. The correlation between sensor data and actual weld quality requires further development, particularly for complex three-dimensional parts.

Automation integration presents systemic challenges beyond the welding process itself. Robotic path planning for complex geometries requires sophisticated algorithms that balance cycle time with quality requirements. Interoperability between different manufacturers' robots, laser sources, and control systems remains limited despite efforts toward standardization.

Energy efficiency concerns are growing in importance. While modern fiber lasers offer wall-plug efficiencies of 30-40%, significant energy is still lost as heat. Cooling systems for high-power lasers consume substantial energy, and optimizing the overall energy footprint of robotic laser welding cells presents opportunities for improvement.

Human-machine interface design continues to evolve, though programming complex welding paths remains challenging for operators without specialized training. Intuitive programming interfaces and offline simulation tools have improved but still require significant expertise for optimal implementation.

The global landscape shows distinct regional specializations. European manufacturers, particularly from Germany and Switzerland, lead in high-precision robotic laser welding systems, while Japanese companies excel in automotive applications. Chinese manufacturers have rapidly expanded their market share by offering cost-effective solutions, though often with less advanced features than their Western counterparts.

Despite significant progress, several technical challenges persist in robotic laser welding. Beam positioning accuracy remains critical, with even minor deviations of 0.1-0.2mm potentially causing weld defects. Real-time seam tracking systems have improved but still struggle with highly reflective materials or complex joint geometries. The integration of vision systems with robotic controllers introduces latency issues that can compromise weld quality at higher speeds.

Material-specific challenges continue to constrain applications. Welding dissimilar metals presents metallurgical compatibility issues, while high thermal conductivity materials like aluminum and copper require precise energy management. Spatter reduction remains problematic for certain material combinations, necessitating advanced beam shaping technologies or hybrid approaches.

Process monitoring represents another significant challenge. Current in-process quality control systems can detect some defects but lack the capability to identify all potential failure modes in real-time. The correlation between sensor data and actual weld quality requires further development, particularly for complex three-dimensional parts.

Automation integration presents systemic challenges beyond the welding process itself. Robotic path planning for complex geometries requires sophisticated algorithms that balance cycle time with quality requirements. Interoperability between different manufacturers' robots, laser sources, and control systems remains limited despite efforts toward standardization.

Energy efficiency concerns are growing in importance. While modern fiber lasers offer wall-plug efficiencies of 30-40%, significant energy is still lost as heat. Cooling systems for high-power lasers consume substantial energy, and optimizing the overall energy footprint of robotic laser welding cells presents opportunities for improvement.

Human-machine interface design continues to evolve, though programming complex welding paths remains challenging for operators without specialized training. Intuitive programming interfaces and offline simulation tools have improved but still require significant expertise for optimal implementation.

Current Robotic Laser Welding Implementation Approaches

01 Robotic arm control systems for laser welding

Advanced control systems for robotic arms in laser welding applications enable precise positioning and movement during welding operations. These systems incorporate real-time feedback mechanisms, path planning algorithms, and coordination between multiple axes to ensure accurate welding trajectories. The control systems can compensate for vibrations, thermal expansion, and other physical factors that might affect welding quality, resulting in more consistent and reliable welds.- Robotic systems for precision laser welding: Advanced robotic systems designed specifically for laser welding applications that provide high precision and repeatability. These systems incorporate sophisticated motion control, positioning mechanisms, and feedback systems to ensure accurate welding paths. The robotic arms can be programmed to follow complex trajectories and maintain consistent standoff distances, which is crucial for quality laser welds in industrial applications.

- Real-time monitoring and control systems: Innovations in real-time monitoring and control systems for robotic laser welding that utilize sensors, cameras, and advanced algorithms to track weld quality during the process. These systems can detect defects, adjust parameters on-the-fly, and ensure consistent weld quality. The integration of machine vision and spectroscopic analysis allows for immediate feedback and correction, significantly reducing defects and improving overall welding efficiency.

- Collaborative robots for laser welding applications: Development of collaborative robots (cobots) specifically designed for laser welding that can safely work alongside human operators. These systems feature advanced safety mechanisms, intuitive programming interfaces, and flexible deployment options. The collaborative approach allows for human expertise to be combined with robotic precision, making them particularly valuable for small batch production and complex welding tasks that require human judgment alongside automated precision.

- Multi-axis robotic laser welding systems: Advanced multi-axis robotic systems that provide enhanced flexibility and access for laser welding complex geometries and hard-to-reach areas. These systems typically feature 6-axis or more degrees of freedom, allowing the laser head to approach the workpiece from virtually any angle. The additional axes enable welding of complex three-dimensional parts with minimal repositioning of the workpiece, increasing productivity and weld quality for automotive, aerospace, and other industries requiring intricate welding operations.

- AI and machine learning integration in robotic laser welding: Integration of artificial intelligence and machine learning algorithms into robotic laser welding systems to optimize welding parameters, predict outcomes, and continuously improve performance. These systems can analyze vast amounts of welding data to identify patterns and correlations that human operators might miss. The AI-driven approach enables adaptive control strategies that can compensate for material variations, environmental changes, and other factors that affect weld quality, resulting in more consistent and higher quality welds with reduced setup time.

02 Sensor integration for adaptive laser welding

Integration of various sensors with robotic laser welding systems allows for real-time monitoring and adaptive control of the welding process. These sensors may include vision systems, thermal cameras, and spectroscopic analyzers that can detect weld quality, seam tracking, and material properties. The sensor data is processed to make immediate adjustments to welding parameters such as laser power, focus position, and robot movement speed, ensuring optimal weld quality even when dealing with variations in material or positioning.Expand Specific Solutions03 Multi-axis robotic systems for complex welding geometries

Multi-axis robotic systems enable laser welding of complex three-dimensional components with intricate geometries. These systems typically feature six or more degrees of freedom, allowing the laser head to maintain optimal orientation relative to the welding surface regardless of its shape or position. Advanced kinematics and coordination between multiple robots can further expand capabilities, enabling welding of hard-to-reach areas and maintaining consistent standoff distance and angle of incidence for the laser beam.Expand Specific Solutions04 Collaborative robots for flexible laser welding operations

Collaborative robots (cobots) designed for laser welding applications enable flexible manufacturing setups where humans and robots can work together safely. These systems incorporate advanced safety features, intuitive programming interfaces, and quick reconfiguration capabilities to adapt to different welding tasks. The collaborative approach allows for combining human decision-making with robotic precision, particularly useful in small-batch production or complex assembly operations where full automation may not be practical.Expand Specific Solutions05 AI and machine learning for optimized laser welding

Artificial intelligence and machine learning algorithms are being integrated into robotic laser welding systems to optimize welding parameters and predict outcomes. These systems can analyze historical welding data, identify patterns, and make recommendations for optimal settings based on material properties, joint designs, and quality requirements. Machine learning models can also detect anomalies during welding, predict potential defects before they occur, and continuously improve performance through experience, leading to higher quality welds and reduced scrap rates.Expand Specific Solutions

Key Industry Players and Competitive Landscape Analysis

The robotics laser welding market is currently in a growth phase, with increasing adoption across automotive, aerospace, and manufacturing sectors. The market size is expanding rapidly, driven by demand for precision welding in complex applications. Technologically, the field is maturing with key players demonstrating varying levels of sophistication. Industry leaders like FANUC, KUKA, and Siemens have established advanced robotic welding solutions with high precision capabilities. Automotive manufacturers including Volkswagen, Honda, and Nissan are integrating these technologies into production lines. Emerging players such as IPG Photonics are advancing laser technology specifically, while companies like Comau and Wonik QnC are developing specialized end-effectors and components. Academic institutions like China Agricultural University and Xi'an Jiaotong University are contributing research innovations, indicating a collaborative ecosystem developing across industrial and academic sectors.

FANUC Corp.

Technical Solution: FANUC has pioneered robotic laser welding with their R-2000iC series robots specifically designed for high-precision laser applications. Their solution integrates proprietary motion control algorithms that achieve path accuracy within ±0.02mm, essential for critical welding applications. FANUC's laser welding package includes their Visual Seam Tracking system that uses machine vision to identify joint locations in real-time, compensating for part variations. Their robots feature hollow wrist designs that allow laser delivery systems to be routed through the arm, protecting fibers and minimizing wear. FANUC's latest innovation is their Dual Check Safety (DCS) technology, which creates virtual safety zones around the laser welding process, enabling collaborative operations while maintaining safety standards. Their systems also incorporate predictive maintenance capabilities that monitor robot performance and laser source efficiency, scheduling maintenance before failures occur.

Strengths: Industry-leading reliability with mean time between failures exceeding 80,000 hours. Comprehensive ecosystem of compatible peripherals and software tools for complete cell integration. Weaknesses: Less flexible programming interface compared to some competitors. Higher learning curve for operators transitioning from other robotic platforms.

Lincoln Global, Inc.

Technical Solution: Lincoln Electric has developed their Power Wave laser welding robotic system that integrates their advanced power source technology with specialized robotics for laser applications. Their solution features Waveform Control Technology that precisely modulates laser power during the welding process to optimize penetration and minimize heat-affected zones. Lincoln's system incorporates their CheckPoint Production Monitoring platform that collects comprehensive weld data, enabling real-time quality control and traceability. Their robotic integration includes specialized end-of-arm tooling that combines laser welding with traditional arc processes, allowing hybrid welding techniques that maximize throughput and quality. Lincoln has pioneered adaptive fill control that automatically adjusts laser parameters based on joint gap variations, compensating for part fit-up issues in production environments. Their latest innovation is their cloud-connected welding ecosystem that enables remote monitoring, parameter optimization, and predictive maintenance across multiple production facilities.

Strengths: Extensive welding process knowledge applied to laser applications, resulting in superior weld quality across diverse materials. Comprehensive training and support infrastructure with global reach. Weaknesses: More recent entry into high-power laser welding compared to some competitors. Integration with third-party laser sources can introduce complexity.

Critical Patents and Technical Innovations in Robotic Laser Welding

Welding robot and method for operating a laser welding device

PatentActiveEP3086898A1

Innovation

- A method involving a welding robot with a laser welding device that automatically moves the laser beam along a predetermined path, using a time-controlled ramp-shaped increase and decrease in welding power to ensure consistent power delivery, calculated based on current speed and distance, to achieve the target welding power at specific positions along the weld seam.

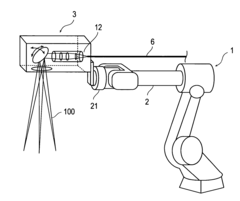

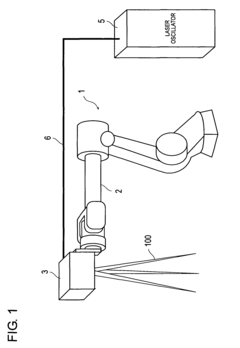

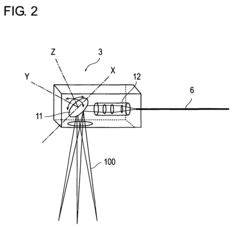

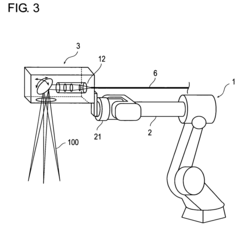

Laser welding system and laser welding control method

PatentInactiveUS8168918B2

Innovation

- A laser welding system equipped with a robot, a freely movable laser processing head, and a controller that allows for continuous motion and directional adjustment of the laser beam, enabling the laser processing head to travel at a specified speed while maintaining focus on each welding point and efficiently changing direction to the next point without stopping, thereby reducing non-welding time and arm vibration.

Safety Standards and Compliance Requirements for Industrial Robotics

The implementation of robotics in laser welding operations necessitates strict adherence to comprehensive safety standards and compliance requirements. Industrial robots used in laser welding applications must comply with ISO 10218-1 and ISO 10218-2, which outline safety requirements for industrial robots and robot systems integration. These standards establish fundamental safety principles, including risk assessment methodologies, control system safety requirements, and verification procedures.

For laser-specific applications, additional standards such as IEC 60825 (Safety of Laser Products) become essential, categorizing lasers into different classes based on their potential hazards. Class 4 lasers, commonly used in industrial welding, require stringent safety measures due to their capacity to cause severe eye damage and burn skin or materials.

The ANSI Z136.1 standard provides guidelines specifically for the safe use of lasers in North American markets, detailing requirements for protective equipment, training, and operational procedures. Similarly, in Europe, the Machinery Directive 2006/42/EC and the EN 60204-1 standard govern electrical equipment safety in machines, including robotic laser welding systems.

Risk assessment represents a critical component of compliance, with ISO 12100 providing a framework for machinery safety assessment. This process must identify potential hazards associated with robotic laser welding, including mechanical risks from robot movement, radiation exposure from the laser beam, and electrical hazards from high-power systems.

Technical protective measures must be implemented according to ISO 13849-1 and IEC 62061, which establish performance levels and safety integrity levels for safety-related control systems. These measures typically include physical safeguards like light curtains, safety fences, and interlocking devices, as well as software-based safety functions such as emergency stop systems and reduced speed operations during setup.

Collaborative robots (cobots) in laser welding environments must meet additional requirements specified in ISO/TS 15066, which addresses collaborative robot safety through power and force limiting, speed monitoring, and separation monitoring technologies.

Electromagnetic compatibility standards (IEC 61000 series) ensure that robotic laser welding systems do not generate electromagnetic interference that could affect nearby equipment or be susceptible to external electromagnetic disturbances, which is particularly important in manufacturing environments with multiple electronic systems.

Regular inspection and certification processes must be established to maintain compliance throughout the system lifecycle. This includes periodic safety audits, functional safety testing, and documentation of all safety-related modifications and maintenance activities, ensuring continuous adherence to evolving safety standards and regulations.

For laser-specific applications, additional standards such as IEC 60825 (Safety of Laser Products) become essential, categorizing lasers into different classes based on their potential hazards. Class 4 lasers, commonly used in industrial welding, require stringent safety measures due to their capacity to cause severe eye damage and burn skin or materials.

The ANSI Z136.1 standard provides guidelines specifically for the safe use of lasers in North American markets, detailing requirements for protective equipment, training, and operational procedures. Similarly, in Europe, the Machinery Directive 2006/42/EC and the EN 60204-1 standard govern electrical equipment safety in machines, including robotic laser welding systems.

Risk assessment represents a critical component of compliance, with ISO 12100 providing a framework for machinery safety assessment. This process must identify potential hazards associated with robotic laser welding, including mechanical risks from robot movement, radiation exposure from the laser beam, and electrical hazards from high-power systems.

Technical protective measures must be implemented according to ISO 13849-1 and IEC 62061, which establish performance levels and safety integrity levels for safety-related control systems. These measures typically include physical safeguards like light curtains, safety fences, and interlocking devices, as well as software-based safety functions such as emergency stop systems and reduced speed operations during setup.

Collaborative robots (cobots) in laser welding environments must meet additional requirements specified in ISO/TS 15066, which addresses collaborative robot safety through power and force limiting, speed monitoring, and separation monitoring technologies.

Electromagnetic compatibility standards (IEC 61000 series) ensure that robotic laser welding systems do not generate electromagnetic interference that could affect nearby equipment or be susceptible to external electromagnetic disturbances, which is particularly important in manufacturing environments with multiple electronic systems.

Regular inspection and certification processes must be established to maintain compliance throughout the system lifecycle. This includes periodic safety audits, functional safety testing, and documentation of all safety-related modifications and maintenance activities, ensuring continuous adherence to evolving safety standards and regulations.

Cost-Benefit Analysis of Robotic Laser Welding Adoption

The adoption of robotic laser welding systems represents a significant capital investment that must be carefully evaluated against potential returns. Initial equipment costs for industrial robotic welding systems range from $100,000 to $500,000, depending on complexity, precision requirements, and auxiliary systems integration. This substantial upfront investment often constitutes the primary barrier to adoption, particularly for small and medium-sized enterprises.

Beyond equipment acquisition, implementation costs include facility modifications, safety infrastructure, specialized training programs, and potential production downtime during installation and commissioning. These transitional expenses typically add 15-30% to the base system cost but vary significantly based on existing infrastructure and production environment.

Operating costs present a more favorable picture when compared to traditional welding methods. Robotic laser welding systems demonstrate 30-50% lower energy consumption than conventional arc welding processes, with modern fiber lasers achieving up to 40% electrical efficiency. Maintenance requirements, while specialized, generally consume only 3-7% of the total system cost annually, significantly lower than manual welding equipment maintenance.

Labor cost reductions constitute the most substantial benefit, with robotic systems capable of replacing 2-4 manual welders per shift while maintaining consistent quality. This translates to labor savings of 60-80% in high-volume production environments. Additionally, material efficiency improves by 10-15% through precise energy delivery, reduced heat-affected zones, and minimized post-weld processing requirements.

Quality improvements deliver significant but less quantifiable benefits. Rejection rates typically decrease by 30-60% after robotic laser welding implementation, while product consistency approaches Six Sigma levels. These improvements reduce warranty claims and enhance brand reputation, providing long-term competitive advantages.

Return on investment timelines vary by application and production volume. High-volume automotive applications often achieve ROI within 12-18 months, while lower-volume specialty manufacturing may require 24-36 months. The payback period shortens considerably when accounting for quality improvements, reduced rework, and enhanced production flexibility.

Sensitivity analysis reveals that production volume represents the most critical factor affecting ROI calculations. Operations running multiple shifts with consistent production demands benefit most substantially from automation, while facilities with highly variable, low-volume production may struggle to justify the investment without additional strategic considerations.

Beyond equipment acquisition, implementation costs include facility modifications, safety infrastructure, specialized training programs, and potential production downtime during installation and commissioning. These transitional expenses typically add 15-30% to the base system cost but vary significantly based on existing infrastructure and production environment.

Operating costs present a more favorable picture when compared to traditional welding methods. Robotic laser welding systems demonstrate 30-50% lower energy consumption than conventional arc welding processes, with modern fiber lasers achieving up to 40% electrical efficiency. Maintenance requirements, while specialized, generally consume only 3-7% of the total system cost annually, significantly lower than manual welding equipment maintenance.

Labor cost reductions constitute the most substantial benefit, with robotic systems capable of replacing 2-4 manual welders per shift while maintaining consistent quality. This translates to labor savings of 60-80% in high-volume production environments. Additionally, material efficiency improves by 10-15% through precise energy delivery, reduced heat-affected zones, and minimized post-weld processing requirements.

Quality improvements deliver significant but less quantifiable benefits. Rejection rates typically decrease by 30-60% after robotic laser welding implementation, while product consistency approaches Six Sigma levels. These improvements reduce warranty claims and enhance brand reputation, providing long-term competitive advantages.

Return on investment timelines vary by application and production volume. High-volume automotive applications often achieve ROI within 12-18 months, while lower-volume specialty manufacturing may require 24-36 months. The payback period shortens considerably when accounting for quality improvements, reduced rework, and enhanced production flexibility.

Sensitivity analysis reveals that production volume represents the most critical factor affecting ROI calculations. Operations running multiple shifts with consistent production demands benefit most substantially from automation, while facilities with highly variable, low-volume production may struggle to justify the investment without additional strategic considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!