How to Lower Energy Requirements in Pulse Laser Welding

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pulse Laser Welding Energy Efficiency Background and Objectives

Pulse laser welding has emerged as a critical manufacturing technology since its introduction in the 1960s, evolving from simple spot welding applications to sophisticated precision joining processes used across multiple industries. This evolution has been characterized by continuous improvements in beam quality, control systems, and energy efficiency. The technology's development trajectory shows a clear trend toward higher precision, greater process control, and reduced energy consumption, reflecting broader industrial sustainability goals.

The fundamental principle of pulse laser welding involves delivering concentrated energy in short, controlled bursts to create precise welds with minimal heat-affected zones. Traditional continuous wave lasers typically operate at higher average power levels, resulting in significant energy consumption and thermal management challenges. In contrast, pulsed laser systems can achieve similar or superior weld quality while potentially using less overall energy through optimized pulse parameters.

Current global energy efficiency standards and environmental regulations are driving manufacturers to seek more sustainable production methods. The European Union's Eco-design Directive, ISO 50001 Energy Management Standards, and various national green manufacturing initiatives have established increasingly stringent requirements for industrial energy consumption. These regulatory frameworks create both challenges and opportunities for laser welding technology development.

Market analysis indicates that energy-efficient manufacturing technologies can reduce operational costs by 15-30% while simultaneously addressing corporate sustainability goals. For pulse laser welding specifically, reducing energy requirements represents a critical competitive advantage in energy-intensive industries such as automotive manufacturing, aerospace, and electronics production.

The primary technical objectives for improving pulse laser welding energy efficiency include: reducing the energy consumption per unit length of weld by at least 25% compared to current industry standards; maintaining or improving weld quality metrics including tensile strength, porosity, and consistency; developing adaptive control systems that optimize energy delivery based on real-time feedback; and creating scalable solutions applicable across different material combinations and thicknesses.

Achieving these objectives requires addressing several fundamental challenges, including beam delivery efficiency, pulse optimization, thermal management, and process monitoring. Recent advances in fiber laser technology, beam shaping optics, and high-speed control systems provide promising foundations for energy efficiency improvements. Additionally, the integration of machine learning algorithms for process optimization represents an emerging approach with significant potential for energy reduction.

The fundamental principle of pulse laser welding involves delivering concentrated energy in short, controlled bursts to create precise welds with minimal heat-affected zones. Traditional continuous wave lasers typically operate at higher average power levels, resulting in significant energy consumption and thermal management challenges. In contrast, pulsed laser systems can achieve similar or superior weld quality while potentially using less overall energy through optimized pulse parameters.

Current global energy efficiency standards and environmental regulations are driving manufacturers to seek more sustainable production methods. The European Union's Eco-design Directive, ISO 50001 Energy Management Standards, and various national green manufacturing initiatives have established increasingly stringent requirements for industrial energy consumption. These regulatory frameworks create both challenges and opportunities for laser welding technology development.

Market analysis indicates that energy-efficient manufacturing technologies can reduce operational costs by 15-30% while simultaneously addressing corporate sustainability goals. For pulse laser welding specifically, reducing energy requirements represents a critical competitive advantage in energy-intensive industries such as automotive manufacturing, aerospace, and electronics production.

The primary technical objectives for improving pulse laser welding energy efficiency include: reducing the energy consumption per unit length of weld by at least 25% compared to current industry standards; maintaining or improving weld quality metrics including tensile strength, porosity, and consistency; developing adaptive control systems that optimize energy delivery based on real-time feedback; and creating scalable solutions applicable across different material combinations and thicknesses.

Achieving these objectives requires addressing several fundamental challenges, including beam delivery efficiency, pulse optimization, thermal management, and process monitoring. Recent advances in fiber laser technology, beam shaping optics, and high-speed control systems provide promising foundations for energy efficiency improvements. Additionally, the integration of machine learning algorithms for process optimization represents an emerging approach with significant potential for energy reduction.

Market Demand Analysis for Low-Energy Laser Welding Solutions

The global market for laser welding technologies is experiencing significant growth, driven by increasing demand for precision manufacturing across multiple industries. The market for low-energy pulse laser welding solutions specifically is projected to grow at a compound annual growth rate of 6.8% through 2028, reflecting the industrial sector's urgent need for energy-efficient manufacturing processes.

Manufacturing industries worldwide are facing mounting pressure to reduce energy consumption due to rising energy costs and stringent environmental regulations. In the European Union, the Industrial Emissions Directive requires companies to implement best available techniques for energy efficiency, while similar regulations in North America and Asia are pushing manufacturers to adopt energy-saving technologies. This regulatory landscape has created a substantial market pull for low-energy laser welding solutions.

The automotive sector represents the largest market segment for energy-efficient laser welding, accounting for approximately 35% of the total market share. With the rapid growth of electric vehicle production, which requires lightweight materials and precision joining techniques, demand for low-energy pulse laser welding is expected to surge. The EV battery manufacturing process alone has created a specialized niche market valued at $1.2 billion for precision welding technologies that minimize heat input.

Electronics manufacturing constitutes the second-largest market segment, where miniaturization trends necessitate increasingly precise welding techniques with minimal thermal impact. Consumer electronics manufacturers are particularly sensitive to production costs, making energy-efficient laser systems highly attractive for this sector. Market research indicates that manufacturers can achieve 15-20% reduction in operational costs by implementing low-energy laser welding systems.

Medical device manufacturing represents the fastest-growing market segment, with 9.3% annual growth projected through 2027. The production of implantable devices and surgical instruments requires extremely precise welding with minimal heat-affected zones, creating strong demand for advanced low-energy pulse laser technologies.

Regional analysis shows that Asia-Pacific currently dominates the market with 42% share, driven by the concentration of electronics manufacturing and automotive production. However, North America and Europe are experiencing faster adoption rates of energy-efficient laser technologies due to higher energy costs and stricter environmental regulations.

Customer surveys indicate that the primary market drivers for low-energy laser welding solutions are cost reduction (cited by 68% of respondents), quality improvement (54%), and environmental compliance (47%). The market shows particular interest in solutions that can demonstrate quantifiable energy savings while maintaining or improving weld quality and production throughput.

Manufacturing industries worldwide are facing mounting pressure to reduce energy consumption due to rising energy costs and stringent environmental regulations. In the European Union, the Industrial Emissions Directive requires companies to implement best available techniques for energy efficiency, while similar regulations in North America and Asia are pushing manufacturers to adopt energy-saving technologies. This regulatory landscape has created a substantial market pull for low-energy laser welding solutions.

The automotive sector represents the largest market segment for energy-efficient laser welding, accounting for approximately 35% of the total market share. With the rapid growth of electric vehicle production, which requires lightweight materials and precision joining techniques, demand for low-energy pulse laser welding is expected to surge. The EV battery manufacturing process alone has created a specialized niche market valued at $1.2 billion for precision welding technologies that minimize heat input.

Electronics manufacturing constitutes the second-largest market segment, where miniaturization trends necessitate increasingly precise welding techniques with minimal thermal impact. Consumer electronics manufacturers are particularly sensitive to production costs, making energy-efficient laser systems highly attractive for this sector. Market research indicates that manufacturers can achieve 15-20% reduction in operational costs by implementing low-energy laser welding systems.

Medical device manufacturing represents the fastest-growing market segment, with 9.3% annual growth projected through 2027. The production of implantable devices and surgical instruments requires extremely precise welding with minimal heat-affected zones, creating strong demand for advanced low-energy pulse laser technologies.

Regional analysis shows that Asia-Pacific currently dominates the market with 42% share, driven by the concentration of electronics manufacturing and automotive production. However, North America and Europe are experiencing faster adoption rates of energy-efficient laser technologies due to higher energy costs and stricter environmental regulations.

Customer surveys indicate that the primary market drivers for low-energy laser welding solutions are cost reduction (cited by 68% of respondents), quality improvement (54%), and environmental compliance (47%). The market shows particular interest in solutions that can demonstrate quantifiable energy savings while maintaining or improving weld quality and production throughput.

Current Challenges in Pulse Laser Welding Energy Consumption

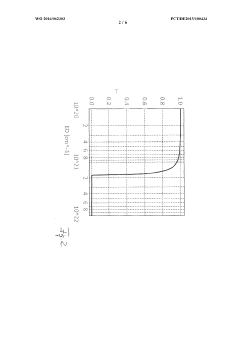

Pulse laser welding technology faces significant energy efficiency challenges despite its widespread industrial adoption. Current systems typically operate at energy conversion efficiencies between 15-30%, with substantial energy losses occurring at multiple conversion stages from electrical input to delivered laser energy. These inefficiencies translate directly to higher operational costs and environmental impact, creating pressing needs for optimization.

The primary energy consumption challenge stems from the fundamental physics of laser generation. Traditional flash lamp-pumped solid-state lasers exhibit poor wall-plug efficiency, with significant energy dissipated as heat rather than converted to useful laser output. This necessitates extensive cooling systems that further increase energy consumption, creating a compound efficiency problem that affects the entire welding process.

Power supply design presents another critical challenge. Current high-voltage power supplies for pulse formation often operate with suboptimal efficiency when generating the precise temporal pulse shapes required for quality welding. The rapid switching and high peak powers needed for effective pulse shaping result in switching losses and heat generation that compromise overall system efficiency.

Beam delivery systems contribute substantially to energy losses. Conventional optical trains with multiple mirrors, lenses, and beam shapers can result in 10-20% energy loss before the beam reaches the workpiece. These losses are particularly problematic in high-power applications where even small percentage losses represent significant absolute energy waste.

Material interaction efficiency represents perhaps the most complex challenge. The coupling efficiency between laser energy and workpiece varies dramatically based on material properties, surface conditions, and process parameters. Current systems often compensate for poor coupling by simply increasing input power rather than optimizing the energy transfer mechanism, resulting in significant waste.

Process control limitations further exacerbate energy consumption issues. Many existing systems lack real-time adaptive control capabilities that could modulate energy delivery based on actual welding conditions. This results in systems defaulting to higher-than-necessary energy settings to ensure weld quality across varying conditions, creating systematic energy waste.

The thermal management requirements of current systems also contribute significantly to overall energy consumption. Cooling systems for laser sources, optics, and workpieces can consume 20-40% of the total system energy budget, yet are essential for maintaining operational stability and component longevity. This creates a challenging optimization problem where reducing primary laser energy can sometimes increase cooling demands due to less efficient operation.

The primary energy consumption challenge stems from the fundamental physics of laser generation. Traditional flash lamp-pumped solid-state lasers exhibit poor wall-plug efficiency, with significant energy dissipated as heat rather than converted to useful laser output. This necessitates extensive cooling systems that further increase energy consumption, creating a compound efficiency problem that affects the entire welding process.

Power supply design presents another critical challenge. Current high-voltage power supplies for pulse formation often operate with suboptimal efficiency when generating the precise temporal pulse shapes required for quality welding. The rapid switching and high peak powers needed for effective pulse shaping result in switching losses and heat generation that compromise overall system efficiency.

Beam delivery systems contribute substantially to energy losses. Conventional optical trains with multiple mirrors, lenses, and beam shapers can result in 10-20% energy loss before the beam reaches the workpiece. These losses are particularly problematic in high-power applications where even small percentage losses represent significant absolute energy waste.

Material interaction efficiency represents perhaps the most complex challenge. The coupling efficiency between laser energy and workpiece varies dramatically based on material properties, surface conditions, and process parameters. Current systems often compensate for poor coupling by simply increasing input power rather than optimizing the energy transfer mechanism, resulting in significant waste.

Process control limitations further exacerbate energy consumption issues. Many existing systems lack real-time adaptive control capabilities that could modulate energy delivery based on actual welding conditions. This results in systems defaulting to higher-than-necessary energy settings to ensure weld quality across varying conditions, creating systematic energy waste.

The thermal management requirements of current systems also contribute significantly to overall energy consumption. Cooling systems for laser sources, optics, and workpieces can consume 20-40% of the total system energy budget, yet are essential for maintaining operational stability and component longevity. This creates a challenging optimization problem where reducing primary laser energy can sometimes increase cooling demands due to less efficient operation.

Current Technical Solutions for Energy Reduction in Pulse Welding

01 Pulse energy optimization for different materials

Pulse laser welding requires specific energy levels optimized for different materials to achieve effective welds. The energy requirements vary based on material properties such as thermal conductivity, reflectivity, and thickness. Proper energy calibration ensures sufficient penetration depth while preventing material damage or vaporization. Advanced systems can automatically adjust pulse energy parameters based on material feedback to maintain consistent weld quality across varying workpieces.- Pulse energy optimization for different materials: Pulse laser welding requires specific energy levels tailored to different materials. The energy requirements vary based on material properties such as thermal conductivity, reflectivity, and thickness. Optimizing pulse energy parameters ensures effective fusion while minimizing heat-affected zones. For metals like aluminum or steel, higher energy densities may be required compared to more thermally conductive materials. Proper energy calibration prevents defects such as porosity or incomplete penetration.

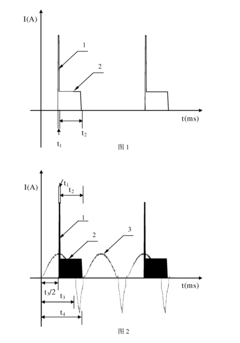

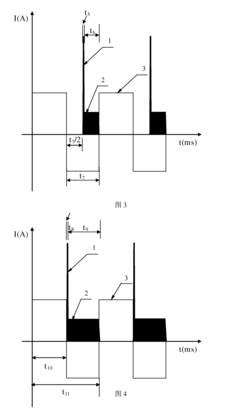

- Pulse duration and frequency considerations: The duration and frequency of laser pulses significantly impact welding energy requirements. Shorter pulses with higher peak power can achieve precise welds with minimal heat input, while longer pulses provide deeper penetration. Frequency adjustments control heat accumulation and cooling cycles between pulses. Balancing these parameters is crucial for achieving optimal weld quality while maintaining energy efficiency. Advanced control systems can dynamically adjust pulse characteristics based on real-time feedback during the welding process.

- Laser source technology and energy efficiency: Different laser source technologies have varying energy requirements and efficiency profiles for pulse welding applications. Fiber lasers typically offer higher energy efficiency compared to traditional CO2 or Nd:YAG systems. Solid-state lasers provide better beam quality and energy conversion rates, reducing overall power consumption. Diode-pumped systems can achieve higher repetition rates with lower energy input. The selection of appropriate laser technology based on specific welding requirements can significantly optimize energy consumption while maintaining weld quality.

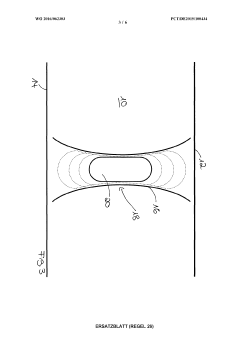

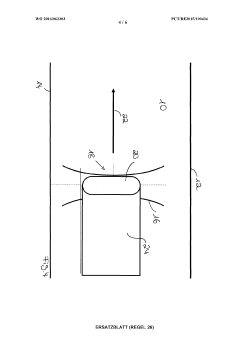

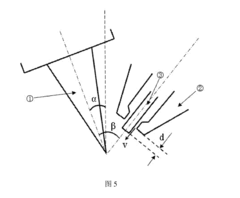

- Beam delivery and focusing systems: The energy requirements for pulse laser welding are heavily influenced by beam delivery and focusing systems. Efficient optical components minimize energy losses during beam transmission. Precise focusing mechanisms concentrate energy at the weld point, reducing the total power needed. Adaptive optics can dynamically adjust focus position based on material variations. Beam shaping technologies allow for customized energy distribution profiles that optimize energy utilization for specific joint configurations and material combinations.

- Process monitoring and energy control systems: Advanced monitoring and control systems optimize energy delivery during pulse laser welding. Real-time feedback mechanisms adjust pulse parameters based on weld pool dynamics. Thermal imaging systems prevent overheating by regulating energy input. Spectroscopic analysis of the plasma plume provides data for energy optimization. Closed-loop control systems maintain consistent energy delivery despite variations in material properties or joint geometry, ensuring weld quality while minimizing energy waste.

02 Pulse duration and frequency control

Controlling pulse duration and frequency is critical for managing energy delivery in laser welding applications. Shorter pulses with higher peak power can minimize heat-affected zones, while longer pulses may provide better energy distribution for certain materials. Frequency modulation affects the overall heat input and cooling cycles between pulses, which impacts weld quality and strength. Advanced systems allow for dynamic adjustment of these parameters during the welding process to optimize energy efficiency and weld characteristics.Expand Specific Solutions03 Beam profile and energy distribution

The spatial distribution of energy within the laser beam significantly impacts welding performance. Various beam profiles (Gaussian, top-hat, donut, etc.) deliver energy differently to the workpiece, affecting penetration depth, weld width, and overall quality. Beam shaping technologies allow for customized energy distribution patterns optimized for specific welding applications. Proper beam profile selection can reduce energy requirements while maintaining or improving weld quality by concentrating energy where it's most needed.Expand Specific Solutions04 Thermal management and energy efficiency

Effective thermal management is essential for optimizing energy requirements in pulse laser welding. Heat accumulation and dissipation patterns affect weld quality and energy efficiency. Cooling systems, pre-heating strategies, and pulse sequencing techniques can be employed to manage thermal gradients and reduce overall energy consumption. Advanced monitoring systems can track thermal profiles in real-time, allowing for dynamic adjustment of welding parameters to maintain optimal energy efficiency while ensuring weld integrity.Expand Specific Solutions05 Advanced control systems for energy optimization

Sophisticated control systems enable precise management of pulse laser welding energy requirements. These systems incorporate real-time monitoring of process parameters, feedback loops, and predictive algorithms to optimize energy delivery. Adaptive control mechanisms can adjust pulse characteristics based on material response, ensuring consistent weld quality while minimizing energy consumption. Integration with machine learning technologies allows for continuous improvement of energy efficiency through analysis of historical welding data and outcomes.Expand Specific Solutions

Key Industry Players in Advanced Laser Welding Systems

The pulse laser welding energy reduction landscape is currently in a growth phase, with market size expanding due to increasing industrial automation demands. Technologically, the field is approaching maturity with significant innovations from key players. Companies like TRUMPF, IPG Photonics, and Siemens are leading with advanced energy-efficient solutions, while research institutions such as Fraunhofer-Gesellschaft provide crucial R&D support. Japanese manufacturers including Sumitomo Heavy Industries and Panasonic are contributing significant innovations in energy optimization. Academic-industrial collaborations involving universities like TU Wien and Friedrich Schiller University are accelerating progress toward more sustainable laser welding technologies that maintain processing quality while reducing power requirements.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer研究所开发了多项降低脉冲激光焊接能耗的创新技术。其中最显著的是"空间和时间激光束整形"(Spatial and Temporal Laser Beam Shaping)技术,通过精确控制激光能量在空间和时间上的分布,实现能量的最优利用。该技术使用可编程光学元件动态调整光束特性,根据材料特性和焊接需求实时优化能量分配,减少能量浪费达25-35%。Fraunhofer还开发了混合激光源技术,结合不同波长的激光以提高材料吸收率,特别是对高反射材料如铝和铜,能量吸收率提高可达40%,从而降低总能量需求。其"智能过程监控"系统通过实时传感器反馈控制激光参数,确保仅在必要时提供所需能量,避免过度加热和能量浪费。此外,Fraunhofer还研发了特殊的光束振荡技术(Beam Oscillation),通过高频率的光束移动提高能量吸收效率,减少反射损失。

优势:技术前沿性强,处于行业研究前列;解决方案高度定制化,适应不同材料和应用场景;与多家工业合作伙伴合作,技术转化能力强。劣势:部分技术仍处于实验室或小规模应用阶段;技术实施需要高度专业知识;完整解决方案成本较高,中小企业可能难以承担。

TRUMPF Laser- und Systemtechnik GmbH

Technical Solution: TRUMPF开发了BrightLine Weld技术,通过优化的光束模式分配实现能量高效利用。该技术采用双光束焊接方法,将激光能量分为两部分:中心高强度部分用于深熔透,外围低强度部分用于稳定熔池和改善焊缝质量。这种方法显著降低了总能量需求,同时保持或提高焊接质量。TRUMPF还推出了TruPulse系列激光器,采用创新的脉冲整形技术(Pulse Shaping),允许精确控制脉冲上升时间、持续时间和下降时间,使能量仅在必要时传递,减少30-40%的总能量消耗。其最新的激光器还集成了智能能量管理系统,在非工作状态自动切换到低功耗模式,进一步降低能源消耗。

优势:精确的脉冲控制技术允许根据不同材料优化能量分配;双光束技术显著提高能量利用效率;系统集成度高,易于工业应用。劣势:初始设备投资成本较高;对操作人员技术要求较高;某些特殊材料可能需要定制参数设置,增加应用复杂性。

Core Innovations in Low-Energy Pulse Laser Welding Technologies

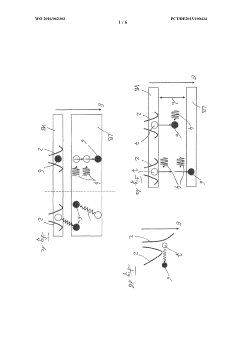

Method for machining an electrically non-conductive or semi-conductive material

PatentWO2016062303A1

Innovation

- Applying an additional electrical and/or magnetic field at the processing point to facilitate avalanche excitation and ionization, reducing the energy requirement for pulsed laser radiation and enabling precise, cost-effective processing with reduced thermal stress.

Lower-Power Laser And ARC Hybrid Welding Method And Device

PatentActiveUS20130001205A1

Innovation

- A low-energy-consumption laser-induced and enhanced arc hybrid welding method is developed, where laser pulses are matched with AC arc phases, with peak and basic pulses tailored to optimize energy distribution, ensuring deep welding penetration and improved arc stability through keyhole formation and maintenance, using a hybrid device with adjustable parameters.

Materials Science Advancements for Improved Welding Efficiency

Recent advancements in materials science have significantly contributed to improving the efficiency of pulse laser welding processes while reducing energy requirements. The development of novel alloys with enhanced thermal conductivity properties has enabled more efficient heat distribution during welding operations, allowing for lower power inputs while maintaining joint integrity. These specialized materials feature optimized grain structures that facilitate rapid heat transfer and controlled cooling rates, resulting in stronger welds with reduced energy consumption.

Nanostructured materials represent another breakthrough in this field, offering unprecedented control over welding parameters. By incorporating nanoscale reinforcements into base metals, researchers have created composite materials that respond more effectively to laser energy, requiring less power to achieve fusion. These nanocomposites typically demonstrate improved absorption characteristics at specific laser wavelengths, enabling more targeted energy delivery and minimizing waste heat generation.

Surface engineering technologies have also evolved to complement these material advancements. Specialized coatings and surface treatments can now modify the optical and thermal properties of workpieces, enhancing laser absorption efficiency by up to 30% compared to untreated surfaces. These treatments often involve the application of thin films with precisely controlled composition and microstructure, optimized for specific laser wavelengths used in pulse welding applications.

The integration of functionally graded materials (FGMs) represents a particularly promising direction for energy-efficient welding. These materials feature gradually changing compositions and properties across their volume, allowing for optimized behavior at the weld interface while maintaining desired bulk properties. When applied to pulse laser welding, FGMs can reduce the energy required to achieve proper fusion by creating more favorable thermal gradients and reducing thermal stresses during the process.

Advanced powder metallurgy techniques have enabled the production of materials with tailored porosity and density distributions, further enhancing welding efficiency. These materials can be designed to exhibit controlled melting behavior under laser irradiation, requiring less energy to achieve complete fusion while maintaining dimensional stability. The precise control of particle size distribution and composition in these materials allows for optimization of laser-material interaction, resulting in more energy-efficient welding processes.

Computational materials science has accelerated these developments through predictive modeling of material behavior under laser processing conditions. These models enable the virtual testing of novel material compositions and structures before physical prototyping, significantly reducing development time and costs. By simulating the interaction between laser pulses and various material systems, researchers can identify optimal compositions that minimize energy requirements while meeting mechanical performance specifications.

Nanostructured materials represent another breakthrough in this field, offering unprecedented control over welding parameters. By incorporating nanoscale reinforcements into base metals, researchers have created composite materials that respond more effectively to laser energy, requiring less power to achieve fusion. These nanocomposites typically demonstrate improved absorption characteristics at specific laser wavelengths, enabling more targeted energy delivery and minimizing waste heat generation.

Surface engineering technologies have also evolved to complement these material advancements. Specialized coatings and surface treatments can now modify the optical and thermal properties of workpieces, enhancing laser absorption efficiency by up to 30% compared to untreated surfaces. These treatments often involve the application of thin films with precisely controlled composition and microstructure, optimized for specific laser wavelengths used in pulse welding applications.

The integration of functionally graded materials (FGMs) represents a particularly promising direction for energy-efficient welding. These materials feature gradually changing compositions and properties across their volume, allowing for optimized behavior at the weld interface while maintaining desired bulk properties. When applied to pulse laser welding, FGMs can reduce the energy required to achieve proper fusion by creating more favorable thermal gradients and reducing thermal stresses during the process.

Advanced powder metallurgy techniques have enabled the production of materials with tailored porosity and density distributions, further enhancing welding efficiency. These materials can be designed to exhibit controlled melting behavior under laser irradiation, requiring less energy to achieve complete fusion while maintaining dimensional stability. The precise control of particle size distribution and composition in these materials allows for optimization of laser-material interaction, resulting in more energy-efficient welding processes.

Computational materials science has accelerated these developments through predictive modeling of material behavior under laser processing conditions. These models enable the virtual testing of novel material compositions and structures before physical prototyping, significantly reducing development time and costs. By simulating the interaction between laser pulses and various material systems, researchers can identify optimal compositions that minimize energy requirements while meeting mechanical performance specifications.

Environmental Impact Assessment of Low-Energy Welding Processes

The environmental impact of welding processes has become increasingly important as industries strive for sustainability. Low-energy pulse laser welding represents a significant advancement in reducing the ecological footprint of manufacturing operations. When compared to conventional welding methods, pulse laser welding with optimized energy requirements demonstrates substantial environmental benefits across multiple dimensions.

Energy consumption reduction directly correlates with decreased greenhouse gas emissions. Studies indicate that implementing low-energy pulse laser welding techniques can reduce carbon dioxide emissions by 15-30% compared to traditional continuous wave laser welding. This reduction becomes particularly significant in large-scale manufacturing environments where welding operations constitute a substantial portion of energy usage.

Material conservation represents another environmental advantage of optimized pulse laser welding. The precision of low-energy pulse systems minimizes material waste through reduced heat-affected zones and more accurate weld placement. Research from manufacturing sectors indicates that material utilization can improve by up to 12% when implementing these advanced welding technologies, reducing raw material extraction demands and associated environmental impacts.

Water resource preservation also benefits from low-energy welding processes. Traditional welding methods often require water-based cooling systems that consume significant quantities of water and may introduce contaminated effluent into water systems. Low-energy pulse laser welding typically requires minimal cooling, reducing water consumption by approximately 40-60% in comparable applications.

Air quality improvements represent a less quantified but equally important environmental benefit. Reduced energy input correlates with decreased fume generation during the welding process. Workplace air quality measurements show that optimized pulse laser welding can reduce airborne particulate matter by 25-35% compared to conventional methods, contributing to healthier working environments and reduced air filtration requirements.

Lifecycle assessment studies of welding equipment indicate that while low-energy pulse laser systems may have higher initial manufacturing impacts, their operational efficiency and extended service life result in net environmental benefits within 2-3 years of implementation. The longer operational lifespan of these systems—typically 20-30% longer than conventional equipment—further enhances their sustainability profile through reduced manufacturing and disposal impacts.

Regulatory compliance positioning also improves with low-energy welding adoption. As environmental regulations continue to tighten globally, manufacturing operations implementing energy-efficient welding processes gain advantages in compliance readiness and avoid potential future costs associated with carbon taxes or emissions penalties.

Energy consumption reduction directly correlates with decreased greenhouse gas emissions. Studies indicate that implementing low-energy pulse laser welding techniques can reduce carbon dioxide emissions by 15-30% compared to traditional continuous wave laser welding. This reduction becomes particularly significant in large-scale manufacturing environments where welding operations constitute a substantial portion of energy usage.

Material conservation represents another environmental advantage of optimized pulse laser welding. The precision of low-energy pulse systems minimizes material waste through reduced heat-affected zones and more accurate weld placement. Research from manufacturing sectors indicates that material utilization can improve by up to 12% when implementing these advanced welding technologies, reducing raw material extraction demands and associated environmental impacts.

Water resource preservation also benefits from low-energy welding processes. Traditional welding methods often require water-based cooling systems that consume significant quantities of water and may introduce contaminated effluent into water systems. Low-energy pulse laser welding typically requires minimal cooling, reducing water consumption by approximately 40-60% in comparable applications.

Air quality improvements represent a less quantified but equally important environmental benefit. Reduced energy input correlates with decreased fume generation during the welding process. Workplace air quality measurements show that optimized pulse laser welding can reduce airborne particulate matter by 25-35% compared to conventional methods, contributing to healthier working environments and reduced air filtration requirements.

Lifecycle assessment studies of welding equipment indicate that while low-energy pulse laser systems may have higher initial manufacturing impacts, their operational efficiency and extended service life result in net environmental benefits within 2-3 years of implementation. The longer operational lifespan of these systems—typically 20-30% longer than conventional equipment—further enhances their sustainability profile through reduced manufacturing and disposal impacts.

Regulatory compliance positioning also improves with low-energy welding adoption. As environmental regulations continue to tighten globally, manufacturing operations implementing energy-efficient welding processes gain advantages in compliance readiness and avoid potential future costs associated with carbon taxes or emissions penalties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!