Laser Welding for Custom Tooling: Precision and Feasibility

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Technology Background and Objectives

Laser welding technology has evolved significantly since its inception in the 1960s, transforming from experimental applications to a cornerstone of precision manufacturing. The fundamental principle involves using concentrated light energy to create localized heat for joining materials with minimal thermal distortion. This evolution has been marked by continuous improvements in beam quality, power density, and control systems, enabling increasingly precise applications across diverse industries.

The trajectory of laser welding development shows a clear trend toward higher precision, greater energy efficiency, and enhanced adaptability to various materials. Early CO2 lasers have given way to fiber, disk, and diode lasers, each offering specific advantages in terms of beam characteristics, wavelength, and power delivery. These advancements have expanded the technology's application scope from basic metal joining to complex multi-material assemblies and micro-welding operations.

In the context of custom tooling applications, laser welding represents a transformative approach to fabrication and repair processes. Traditional tooling manufacturing often involves multiple machining steps, heat treatments, and finishing operations that can be time-consuming and costly. Laser welding offers the potential to streamline these processes by enabling direct material deposition, repair of high-value components, and creation of complex geometries that would be difficult to achieve through conventional methods.

The primary technical objectives for laser welding in custom tooling applications center around achieving submillimeter precision while maintaining structural integrity and material properties. This includes developing capabilities for joining dissimilar materials, managing thermal stresses in complex geometries, and ensuring consistent weld quality across varying production volumes. Additionally, there is a growing emphasis on process monitoring and quality control systems that can provide real-time feedback during welding operations.

Environmental and economic considerations are also shaping the technology's development trajectory. Modern laser welding systems aim to reduce energy consumption, minimize material waste, and decrease the environmental footprint of manufacturing processes. From an economic perspective, the technology seeks to balance initial investment costs against long-term operational benefits, including reduced labor requirements, decreased material consumption, and improved product quality.

Looking forward, the field is moving toward more intelligent and autonomous laser welding systems that incorporate advanced sensing, machine learning algorithms, and adaptive control mechanisms. These developments aim to further enhance precision, reliability, and accessibility of laser welding technology for custom tooling applications across diverse industrial sectors.

The trajectory of laser welding development shows a clear trend toward higher precision, greater energy efficiency, and enhanced adaptability to various materials. Early CO2 lasers have given way to fiber, disk, and diode lasers, each offering specific advantages in terms of beam characteristics, wavelength, and power delivery. These advancements have expanded the technology's application scope from basic metal joining to complex multi-material assemblies and micro-welding operations.

In the context of custom tooling applications, laser welding represents a transformative approach to fabrication and repair processes. Traditional tooling manufacturing often involves multiple machining steps, heat treatments, and finishing operations that can be time-consuming and costly. Laser welding offers the potential to streamline these processes by enabling direct material deposition, repair of high-value components, and creation of complex geometries that would be difficult to achieve through conventional methods.

The primary technical objectives for laser welding in custom tooling applications center around achieving submillimeter precision while maintaining structural integrity and material properties. This includes developing capabilities for joining dissimilar materials, managing thermal stresses in complex geometries, and ensuring consistent weld quality across varying production volumes. Additionally, there is a growing emphasis on process monitoring and quality control systems that can provide real-time feedback during welding operations.

Environmental and economic considerations are also shaping the technology's development trajectory. Modern laser welding systems aim to reduce energy consumption, minimize material waste, and decrease the environmental footprint of manufacturing processes. From an economic perspective, the technology seeks to balance initial investment costs against long-term operational benefits, including reduced labor requirements, decreased material consumption, and improved product quality.

Looking forward, the field is moving toward more intelligent and autonomous laser welding systems that incorporate advanced sensing, machine learning algorithms, and adaptive control mechanisms. These developments aim to further enhance precision, reliability, and accessibility of laser welding technology for custom tooling applications across diverse industrial sectors.

Market Demand Analysis for Precision Tooling

The global precision tooling market has witnessed significant growth in recent years, driven by increasing demand for high-precision components across various industries. The market size for precision tooling was valued at approximately $22.8 billion in 2022 and is projected to reach $30.5 billion by 2028, growing at a CAGR of 5.2%. This growth trajectory underscores the expanding need for advanced manufacturing solutions like laser welding technology.

The automotive industry represents one of the largest consumers of precision tooling, accounting for nearly 35% of the market share. With the transition toward electric vehicles and lightweight materials, demand for high-precision welding techniques has surged. Automotive manufacturers require tooling solutions that can handle complex geometries and maintain tight tolerances, making laser welding particularly attractive for this sector.

Aerospace and defense industries follow closely, contributing about 22% to the precision tooling market. These sectors demand exceptional quality standards and material integrity, which laser welding can effectively deliver. The ability to create strong, precise welds without excessive heat-affected zones makes this technology invaluable for critical aerospace components.

Medical device manufacturing has emerged as the fastest-growing segment, with a growth rate of 7.8% annually. The production of surgical instruments, implants, and diagnostic equipment requires extremely precise tooling solutions. Laser welding's capacity to join dissimilar materials while maintaining biocompatibility has positioned it as a preferred method in this sector.

Regional analysis reveals that Asia-Pacific dominates the precision tooling market with a 42% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America and Europe follow with 28% and 24% respectively, with these regions focusing on high-value, specialized tooling applications.

Customer surveys indicate that manufacturers are increasingly prioritizing tooling solutions that offer flexibility, precision, and reduced lead times. Approximately 68% of manufacturing executives cite customization capabilities as a critical factor in tooling selection, while 73% emphasize the importance of precision in maintaining competitive advantage.

The trend toward miniaturization across electronics and medical industries has further accelerated demand for high-precision tooling solutions. Components requiring sub-micron accuracy have increased by 58% over the past five years, creating substantial opportunities for advanced welding technologies like laser-based systems.

The automotive industry represents one of the largest consumers of precision tooling, accounting for nearly 35% of the market share. With the transition toward electric vehicles and lightweight materials, demand for high-precision welding techniques has surged. Automotive manufacturers require tooling solutions that can handle complex geometries and maintain tight tolerances, making laser welding particularly attractive for this sector.

Aerospace and defense industries follow closely, contributing about 22% to the precision tooling market. These sectors demand exceptional quality standards and material integrity, which laser welding can effectively deliver. The ability to create strong, precise welds without excessive heat-affected zones makes this technology invaluable for critical aerospace components.

Medical device manufacturing has emerged as the fastest-growing segment, with a growth rate of 7.8% annually. The production of surgical instruments, implants, and diagnostic equipment requires extremely precise tooling solutions. Laser welding's capacity to join dissimilar materials while maintaining biocompatibility has positioned it as a preferred method in this sector.

Regional analysis reveals that Asia-Pacific dominates the precision tooling market with a 42% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America and Europe follow with 28% and 24% respectively, with these regions focusing on high-value, specialized tooling applications.

Customer surveys indicate that manufacturers are increasingly prioritizing tooling solutions that offer flexibility, precision, and reduced lead times. Approximately 68% of manufacturing executives cite customization capabilities as a critical factor in tooling selection, while 73% emphasize the importance of precision in maintaining competitive advantage.

The trend toward miniaturization across electronics and medical industries has further accelerated demand for high-precision tooling solutions. Components requiring sub-micron accuracy have increased by 58% over the past five years, creating substantial opportunities for advanced welding technologies like laser-based systems.

Current Laser Welding Capabilities and Challenges

Laser welding technology has evolved significantly over the past decades, establishing itself as a critical process in precision manufacturing. Current capabilities include high-precision welding with spot sizes as small as 0.1mm, enabling intricate joins in custom tooling applications. Modern laser welding systems can achieve power densities exceeding 1 MW/cm², allowing for deep penetration welds with minimal heat-affected zones. This characteristic is particularly valuable for custom tooling where maintaining material properties and dimensional accuracy is paramount.

The technology now offers various modalities including continuous wave, pulsed, and quasi-continuous operations, each suited to specific tooling requirements. Fiber lasers dominate the market with wall-plug efficiencies reaching 30-40%, significantly higher than traditional Nd:YAG systems. These systems can deliver consistent beam quality with M² values below 1.2, ensuring repeatable weld characteristics across production runs.

Despite these advancements, several challenges persist in laser welding for custom tooling applications. Material compatibility remains a significant hurdle, particularly when joining dissimilar metals with varying thermal properties. The formation of brittle intermetallic compounds can compromise joint integrity, limiting the combinations of materials that can be effectively welded. This is especially problematic for multi-material custom tools that require optimal performance characteristics from each component.

Process monitoring and quality control present another major challenge. Real-time weld pool monitoring systems exist but often lack the sensitivity required for the most demanding custom tooling applications. The industry still struggles with reliable detection of sub-surface defects such as porosity and micro-cracks that can lead to premature tool failure under high-stress conditions.

Automation integration challenges also limit widespread adoption in custom tooling environments. While robotic systems offer excellent repeatability for high-volume production, they often lack the flexibility required for low-volume, high-mix custom tooling applications. Programming complexity and setup times can make laser welding economically unfeasible for smaller production runs.

Energy consumption remains a concern, with high-power laser systems requiring significant electrical input. This impacts both operational costs and environmental footprint, particularly relevant as manufacturing sustainability becomes increasingly important. Newer fiber laser technologies have improved efficiency, but further advancements are needed to optimize energy utilization.

Accessibility presents another barrier, as high-end laser welding equipment requires substantial capital investment, often beyond the reach of smaller custom tooling manufacturers. This creates a technological divide where advanced welding capabilities are concentrated among larger manufacturers, potentially limiting innovation in specialized tooling applications.

The technology now offers various modalities including continuous wave, pulsed, and quasi-continuous operations, each suited to specific tooling requirements. Fiber lasers dominate the market with wall-plug efficiencies reaching 30-40%, significantly higher than traditional Nd:YAG systems. These systems can deliver consistent beam quality with M² values below 1.2, ensuring repeatable weld characteristics across production runs.

Despite these advancements, several challenges persist in laser welding for custom tooling applications. Material compatibility remains a significant hurdle, particularly when joining dissimilar metals with varying thermal properties. The formation of brittle intermetallic compounds can compromise joint integrity, limiting the combinations of materials that can be effectively welded. This is especially problematic for multi-material custom tools that require optimal performance characteristics from each component.

Process monitoring and quality control present another major challenge. Real-time weld pool monitoring systems exist but often lack the sensitivity required for the most demanding custom tooling applications. The industry still struggles with reliable detection of sub-surface defects such as porosity and micro-cracks that can lead to premature tool failure under high-stress conditions.

Automation integration challenges also limit widespread adoption in custom tooling environments. While robotic systems offer excellent repeatability for high-volume production, they often lack the flexibility required for low-volume, high-mix custom tooling applications. Programming complexity and setup times can make laser welding economically unfeasible for smaller production runs.

Energy consumption remains a concern, with high-power laser systems requiring significant electrical input. This impacts both operational costs and environmental footprint, particularly relevant as manufacturing sustainability becomes increasingly important. Newer fiber laser technologies have improved efficiency, but further advancements are needed to optimize energy utilization.

Accessibility presents another barrier, as high-end laser welding equipment requires substantial capital investment, often beyond the reach of smaller custom tooling manufacturers. This creates a technological divide where advanced welding capabilities are concentrated among larger manufacturers, potentially limiting innovation in specialized tooling applications.

Current Laser Welding Solutions for Custom Tooling

01 Laser beam control systems for precision welding

Advanced control systems are used to enhance laser welding precision by precisely manipulating the laser beam parameters. These systems include real-time monitoring and adjustment of beam focus, power, and trajectory to maintain consistent weld quality. The technology incorporates feedback mechanisms that can detect and correct deviations during the welding process, ensuring high precision even with complex geometries or variable material conditions.- Precision control systems for laser welding: Advanced control systems are essential for achieving high precision in laser welding operations. These systems incorporate real-time monitoring, feedback mechanisms, and precise positioning controls to maintain welding accuracy. By utilizing sophisticated algorithms and sensors, these control systems can adjust laser parameters dynamically during the welding process, compensating for any variations and ensuring consistent weld quality with minimal deviation.

- Beam focusing and positioning technologies: Precise beam focusing and positioning technologies are critical for achieving high-precision laser welding. These technologies include advanced optical systems, beam shaping components, and high-precision motion control mechanisms that enable accurate placement of the laser beam on the workpiece. By optimizing the focal point and maintaining consistent beam characteristics, these technologies minimize heat-affected zones and improve weld quality, particularly for micro-welding applications where sub-millimeter precision is required.

- Monitoring and quality assurance systems: Real-time monitoring and quality assurance systems play a crucial role in maintaining laser welding precision. These systems utilize various sensors, cameras, and spectroscopic techniques to observe the welding process, detect defects, and ensure consistent weld quality. Advanced image processing algorithms analyze the weld pool dynamics and thermal patterns, allowing for immediate adjustments to welding parameters when deviations are detected, thus ensuring high precision and repeatability in the welding process.

- Specialized fixtures and positioning equipment: Specialized fixtures and positioning equipment are designed to hold workpieces with extreme stability during laser welding operations. These fixtures minimize vibration, thermal expansion effects, and positioning errors that could compromise welding precision. Advanced designs incorporate materials with low thermal expansion coefficients, precision alignment mechanisms, and automated clamping systems that maintain consistent pressure and alignment throughout the welding process, ensuring high-precision results even for complex geometries.

- Pulse shaping and beam modulation techniques: Pulse shaping and beam modulation techniques allow for precise control over the energy delivery during laser welding. By carefully tailoring the temporal profile of laser pulses and modulating beam characteristics, these techniques enable fine control over the heat input, melt pool dynamics, and solidification behavior. This level of control is particularly important for welding thin materials, dissimilar metals, or heat-sensitive components where conventional welding approaches would cause distortion or damage, thus significantly enhancing welding precision.

02 Positioning and fixturing technologies for welding accuracy

Specialized positioning and fixturing systems are critical for achieving high precision in laser welding applications. These technologies ensure precise alignment of workpieces relative to the laser beam, minimizing gaps and misalignments that could compromise weld quality. Advanced fixtures incorporate micro-adjustment capabilities, vibration dampening features, and automated positioning systems that can achieve positioning accuracy in the micrometer range.Expand Specific Solutions03 Process monitoring and quality control methods

Real-time monitoring systems are implemented to ensure laser welding precision through continuous assessment of weld quality parameters. These systems utilize various sensors including thermal cameras, spectroscopic analyzers, and high-speed imaging to detect defects or deviations during the welding process. Advanced algorithms process this data to make immediate adjustments to welding parameters or to flag potential quality issues, enabling consistent precision across production runs.Expand Specific Solutions04 Material-specific laser welding techniques

Specialized laser welding techniques have been developed to address the unique challenges presented by different materials, enhancing precision outcomes. These techniques include tailored pulse shaping, wavelength selection, and power modulation strategies optimized for specific material properties. For challenging materials like highly reflective metals or heat-sensitive components, these approaches minimize thermal distortion and ensure consistent penetration depth, resulting in precise, high-quality welds.Expand Specific Solutions05 Automation and robotics integration for precision welding

Integration of robotics and automation systems with laser welding technology significantly enhances precision capabilities. These systems eliminate human error factors and enable consistent reproduction of complex welding paths with sub-millimeter accuracy. Advanced robotic systems incorporate multi-axis movement control, path planning algorithms, and synchronization with laser parameters to maintain optimal welding conditions throughout the process, even for intricate three-dimensional components.Expand Specific Solutions

Key Industry Players in Laser Welding Equipment

Laser welding for custom tooling is currently in a growth phase, with the market expected to reach significant expansion due to increasing demand for precision manufacturing across automotive, aerospace, and medical sectors. The global market is estimated at approximately $2.5 billion, growing at 5-7% annually. Technologically, the field shows varying maturity levels among key players. IPG Photonics and Han's Laser lead in laser source innovation, while industrial giants like Bosch, Volkswagen, and Boeing demonstrate advanced integration capabilities. Fraunhofer-Gesellschaft contributes cutting-edge research, and specialized firms like Laser Depth Dynamics offer sophisticated monitoring solutions. KUKA Systems provides automation expertise essential for industrial implementation, creating a competitive landscape where technological differentiation and application-specific solutions drive market positioning.

IPG Photonics Corp.

Technical Solution: IPG Photonics has developed advanced fiber laser technology specifically optimized for custom tooling applications. Their high-power fiber lasers (up to 20kW) utilize proprietary single-mode and multi-mode designs that deliver exceptional beam quality with M² values below 1.1 for single-mode operation. For precision tooling, IPG's QCW (Quasi-Continuous Wave) lasers provide peak powers up to 1.5kW while maintaining pulse widths from 0.2ms to continuous operation, enabling precise heat input control. Their systems incorporate real-time monitoring with closed-loop feedback that adjusts parameters within microseconds to maintain weld quality across variable material conditions. IPG's proprietary process monitoring technology uses spectral analysis of the plasma plume to detect and correct defects during welding, achieving positional accuracy of ±10μm for micro-tooling applications[1]. Their systems also feature specialized beam shaping optics that can create custom energy distributions optimized for specific alloy combinations.

Strengths: Superior beam quality enables extremely precise welds with minimal heat-affected zones. Proprietary monitoring systems provide real-time quality control. Vertical integration of component manufacturing ensures system reliability and performance consistency. Weaknesses: Higher initial capital investment compared to conventional welding systems. Requires specialized operator training and expertise for optimal utilization. Limited flexibility for extremely large tooling applications requiring mobility.

Robert Bosch GmbH

Technical Solution: Bosch has developed an integrated laser welding solution for custom tooling that combines their BOS5000 laser system with advanced process monitoring. Their approach utilizes disk laser technology operating at 1030nm wavelength with power modulation capabilities from 100W to 5kW, allowing precise energy delivery for various material thicknesses. The system incorporates Bosch's proprietary "WeldSight" monitoring technology that uses multiple sensors (thermal imaging, spectroscopy, and acoustic monitoring) to create a comprehensive real-time quality assessment. For custom tooling applications, they've implemented adaptive beam shaping technology that can dynamically adjust the laser spot geometry during welding to optimize penetration and minimize distortion. Their system achieves positioning accuracy of ±15μm with repeatability of ±5μm[2]. Bosch's solution includes specialized fixturing systems with integrated cooling channels to minimize thermal distortion during welding of precision tools. Their process database contains parameters for over 200 material combinations, enabling rapid setup for custom tooling applications with diverse material requirements.

Strengths: Comprehensive process monitoring with multi-sensor approach provides exceptional quality control. Adaptive beam shaping technology optimizes weld characteristics for different materials and joint geometries. Extensive material database accelerates setup for diverse tooling applications. Weaknesses: System complexity requires significant technical expertise for maintenance and optimization. Higher energy consumption compared to some competing technologies. Limited portability for in-field applications.

Critical Technical Innovations in Precision Laser Welding

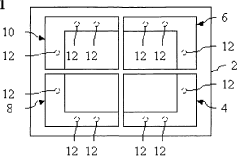

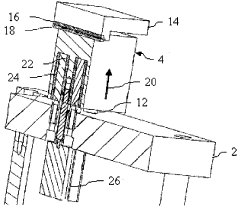

Laser welding tool, arrangement for welding two welding articles and method for operating the arrangement

PatentWO2010046089A1

Innovation

- A laser welding tool with independently movable partial elements that can apply increased pressure along segments of the weld, allowing for continuous or stepwise pressure adjustment, and a control device coupled with the laser to precisely displace these elements based on the laser position, ensuring uniform contact pressure during the welding process.

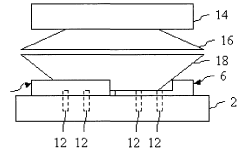

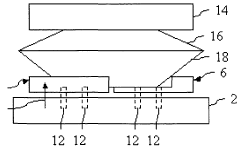

Welding and/or cutting device

PatentInactiveEP0892692A1

Innovation

- The welding device allows the laser head to move independently of the pressure roller and manipulator path, enabling transverse or oblique movements for precise seam tracking and orientation, with additional welding devices like wire feed or sealing devices that can be integrated for enhanced performance.

Material Compatibility and Metallurgical Considerations

Material compatibility represents a critical factor in laser welding applications for custom tooling manufacturing. The interaction between different metals and alloys during the welding process significantly impacts the structural integrity and performance of the final product. High-carbon steels, tool steels, and specialty alloys commonly used in tooling applications each present unique challenges when subjected to laser welding techniques. The thermal conductivity, melting point, and coefficient of thermal expansion of these materials must be carefully considered to prevent defects such as cracking, porosity, and incomplete fusion.

When dissimilar metals are joined, the formation of intermetallic compounds at the weld interface becomes a primary concern. These compounds often exhibit brittle characteristics that can compromise the mechanical properties of the welded joint. For instance, welding aluminum to steel creates Al-Fe intermetallics that significantly reduce joint strength. Advanced laser welding techniques have been developed to mitigate these effects, including controlled heat input strategies and specialized filler materials designed to create transition zones between dissimilar metals.

The metallurgical transformations occurring during laser welding also warrant careful examination. The rapid heating and cooling cycles characteristic of laser welding create unique microstructures in the heat-affected zone (HAZ) and fusion zone. In tool steels, this can lead to martensite formation, which increases hardness but may introduce brittleness if not properly controlled. Post-weld heat treatment becomes essential in many tooling applications to relieve residual stresses and optimize the microstructural properties for the intended service conditions.

Surface preparation and cleanliness significantly influence weld quality and material compatibility. Oxides, contaminants, and surface coatings can interfere with beam absorption and create inclusions or porosity in the weld. For precision tooling applications, stringent surface preparation protocols must be established to ensure consistent weld quality across different material combinations.

Recent advancements in laser technology have expanded the range of compatible materials for tooling applications. Fiber and disk lasers with precise power control capabilities allow for welding of traditionally challenging materials such as copper alloys, titanium, and refractory metals. Hybrid laser-arc welding techniques further enhance material compatibility by combining the deep penetration of laser welding with the gap-bridging capability of arc processes, particularly valuable for joining thick sections in large tooling components.

The development of tailored beam profiles and multi-beam approaches has also improved the ability to manage thermal gradients across dissimilar materials with varying thermal properties. These innovations enable more precise control over the heat-affected zone and reduce the risk of thermal distortion in precision tooling applications where dimensional accuracy is paramount.

When dissimilar metals are joined, the formation of intermetallic compounds at the weld interface becomes a primary concern. These compounds often exhibit brittle characteristics that can compromise the mechanical properties of the welded joint. For instance, welding aluminum to steel creates Al-Fe intermetallics that significantly reduce joint strength. Advanced laser welding techniques have been developed to mitigate these effects, including controlled heat input strategies and specialized filler materials designed to create transition zones between dissimilar metals.

The metallurgical transformations occurring during laser welding also warrant careful examination. The rapid heating and cooling cycles characteristic of laser welding create unique microstructures in the heat-affected zone (HAZ) and fusion zone. In tool steels, this can lead to martensite formation, which increases hardness but may introduce brittleness if not properly controlled. Post-weld heat treatment becomes essential in many tooling applications to relieve residual stresses and optimize the microstructural properties for the intended service conditions.

Surface preparation and cleanliness significantly influence weld quality and material compatibility. Oxides, contaminants, and surface coatings can interfere with beam absorption and create inclusions or porosity in the weld. For precision tooling applications, stringent surface preparation protocols must be established to ensure consistent weld quality across different material combinations.

Recent advancements in laser technology have expanded the range of compatible materials for tooling applications. Fiber and disk lasers with precise power control capabilities allow for welding of traditionally challenging materials such as copper alloys, titanium, and refractory metals. Hybrid laser-arc welding techniques further enhance material compatibility by combining the deep penetration of laser welding with the gap-bridging capability of arc processes, particularly valuable for joining thick sections in large tooling components.

The development of tailored beam profiles and multi-beam approaches has also improved the ability to manage thermal gradients across dissimilar materials with varying thermal properties. These innovations enable more precise control over the heat-affected zone and reduce the risk of thermal distortion in precision tooling applications where dimensional accuracy is paramount.

Quality Control and Process Monitoring Systems

Quality control and process monitoring systems are critical components in laser welding applications for custom tooling manufacturing. These systems ensure that the welding process meets the required specifications and maintains consistent quality throughout production. Real-time monitoring technologies have evolved significantly, now incorporating multiple sensor arrays that can detect variations in temperature, plasma emissions, and acoustic signatures during the welding process.

Advanced vision systems equipped with high-speed cameras capture the weld pool dynamics at rates exceeding 10,000 frames per second, allowing for immediate detection of defects such as porosity, cracks, or incomplete fusion. These systems often utilize artificial intelligence algorithms to analyze the captured data against predetermined quality parameters, triggering automatic adjustments to laser power, focus, or speed when deviations occur.

Spectroscopic analysis systems monitor the plasma plume generated during laser welding, providing valuable information about the material composition and potential contamination in the weld zone. Changes in the spectral signature can indicate issues with shielding gas coverage or material impurities that might compromise weld integrity. This data is particularly valuable when working with specialized alloys in custom tooling applications.

Thermal imaging technologies have become increasingly sophisticated, offering temperature mapping capabilities with precision down to ±2°C. These systems can detect heat distribution anomalies that might indicate improper energy absorption or heat-affected zone issues. For custom tooling applications, where dimensional stability is paramount, thermal monitoring helps prevent distortion and ensures that critical tolerances are maintained.

Process monitoring data integration has advanced to include comprehensive digital twins of the welding process. These virtual models compare real-time performance against simulated optimal conditions, enabling predictive quality control rather than reactive inspection. Machine learning algorithms continuously refine these models based on historical data, improving detection accuracy and reducing false positives.

Documentation and traceability systems have become integral to quality control in laser welding operations. Each weld can be digitally documented with its complete parameter set, monitoring data, and quality verification results. This creates an unbroken chain of quality evidence that is particularly valuable for custom tooling applications in regulated industries such as aerospace, medical device manufacturing, or automotive safety components.

The implementation of closed-loop feedback systems represents the cutting edge of quality control in laser welding. These systems not only detect deviations but automatically implement corrective actions within milliseconds, maintaining process stability even when material properties or environmental conditions fluctuate. This capability is essential for maintaining precision in complex custom tooling applications where manual intervention would be impractical or insufficient.

Advanced vision systems equipped with high-speed cameras capture the weld pool dynamics at rates exceeding 10,000 frames per second, allowing for immediate detection of defects such as porosity, cracks, or incomplete fusion. These systems often utilize artificial intelligence algorithms to analyze the captured data against predetermined quality parameters, triggering automatic adjustments to laser power, focus, or speed when deviations occur.

Spectroscopic analysis systems monitor the plasma plume generated during laser welding, providing valuable information about the material composition and potential contamination in the weld zone. Changes in the spectral signature can indicate issues with shielding gas coverage or material impurities that might compromise weld integrity. This data is particularly valuable when working with specialized alloys in custom tooling applications.

Thermal imaging technologies have become increasingly sophisticated, offering temperature mapping capabilities with precision down to ±2°C. These systems can detect heat distribution anomalies that might indicate improper energy absorption or heat-affected zone issues. For custom tooling applications, where dimensional stability is paramount, thermal monitoring helps prevent distortion and ensures that critical tolerances are maintained.

Process monitoring data integration has advanced to include comprehensive digital twins of the welding process. These virtual models compare real-time performance against simulated optimal conditions, enabling predictive quality control rather than reactive inspection. Machine learning algorithms continuously refine these models based on historical data, improving detection accuracy and reducing false positives.

Documentation and traceability systems have become integral to quality control in laser welding operations. Each weld can be digitally documented with its complete parameter set, monitoring data, and quality verification results. This creates an unbroken chain of quality evidence that is particularly valuable for custom tooling applications in regulated industries such as aerospace, medical device manufacturing, or automotive safety components.

The implementation of closed-loop feedback systems represents the cutting edge of quality control in laser welding. These systems not only detect deviations but automatically implement corrective actions within milliseconds, maintaining process stability even when material properties or environmental conditions fluctuate. This capability is essential for maintaining precision in complex custom tooling applications where manual intervention would be impractical or insufficient.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!