Laser Welding vs Mechanical Joining: Inspection Challenges

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Inspection Background and Objectives

Laser welding technology has evolved significantly over the past several decades, transforming from a niche manufacturing process to a mainstream joining method across multiple industries. The evolution began in the 1960s with the invention of the first working laser, followed by industrial applications in the 1970s. By the 1990s, laser welding had become established in automotive and aerospace manufacturing, with continuous advancements in beam quality, power, and control systems driving its adoption.

Today, laser welding represents a critical technology at the intersection of advanced manufacturing, materials science, and quality control. The fundamental principle involves using concentrated light energy to melt and fuse materials, creating joints with minimal heat-affected zones and superior mechanical properties compared to traditional joining methods. This technology has gained prominence due to its precision, speed, and ability to join dissimilar materials—capabilities that mechanical joining methods often cannot match.

The inspection challenges arising from laser welding versus mechanical joining stem from fundamental differences in joint characteristics. While mechanical joints (bolts, rivets, adhesives) typically offer visual confirmation of proper assembly, laser welds create internal structures that require sophisticated non-destructive testing methods to verify integrity. This inspection complexity has become increasingly significant as industries push toward lighter, stronger, and more complex assemblies.

Current technical objectives in laser welding inspection focus on developing reliable, real-time monitoring systems capable of detecting defects during the welding process rather than through post-production testing. This shift toward in-process quality assurance represents a paradigm change in manufacturing quality control, potentially eliminating costly rework and material waste while ensuring consistent joint performance.

The automotive industry has been particularly aggressive in pursuing these objectives, driven by the need for lightweight vehicle structures to improve fuel efficiency and electric vehicle range. Aerospace manufacturers similarly seek inspection technologies that can validate the integrity of critical safety components without destructive testing. Electronics manufacturers require inspection methods capable of examining microscopic welds in increasingly miniaturized devices.

Looking forward, the technical trajectory points toward integrated sensor systems combining multiple inspection modalities (thermal imaging, acoustic monitoring, spectral analysis) with artificial intelligence to provide comprehensive weld quality assessment in real-time. The ultimate goal is to develop "zero-defect" manufacturing processes where inspection is fully integrated with production, enabling adaptive control systems that can adjust welding parameters on-the-fly to prevent defect formation.

Today, laser welding represents a critical technology at the intersection of advanced manufacturing, materials science, and quality control. The fundamental principle involves using concentrated light energy to melt and fuse materials, creating joints with minimal heat-affected zones and superior mechanical properties compared to traditional joining methods. This technology has gained prominence due to its precision, speed, and ability to join dissimilar materials—capabilities that mechanical joining methods often cannot match.

The inspection challenges arising from laser welding versus mechanical joining stem from fundamental differences in joint characteristics. While mechanical joints (bolts, rivets, adhesives) typically offer visual confirmation of proper assembly, laser welds create internal structures that require sophisticated non-destructive testing methods to verify integrity. This inspection complexity has become increasingly significant as industries push toward lighter, stronger, and more complex assemblies.

Current technical objectives in laser welding inspection focus on developing reliable, real-time monitoring systems capable of detecting defects during the welding process rather than through post-production testing. This shift toward in-process quality assurance represents a paradigm change in manufacturing quality control, potentially eliminating costly rework and material waste while ensuring consistent joint performance.

The automotive industry has been particularly aggressive in pursuing these objectives, driven by the need for lightweight vehicle structures to improve fuel efficiency and electric vehicle range. Aerospace manufacturers similarly seek inspection technologies that can validate the integrity of critical safety components without destructive testing. Electronics manufacturers require inspection methods capable of examining microscopic welds in increasingly miniaturized devices.

Looking forward, the technical trajectory points toward integrated sensor systems combining multiple inspection modalities (thermal imaging, acoustic monitoring, spectral analysis) with artificial intelligence to provide comprehensive weld quality assessment in real-time. The ultimate goal is to develop "zero-defect" manufacturing processes where inspection is fully integrated with production, enabling adaptive control systems that can adjust welding parameters on-the-fly to prevent defect formation.

Market Demand Analysis for Advanced Joining Inspection

The global market for advanced joining inspection technologies is experiencing significant growth, driven by the increasing adoption of laser welding across multiple industries. Current market analysis indicates that automotive manufacturing represents the largest segment, with approximately 35% of the market share, followed by aerospace (22%), electronics (18%), and medical device manufacturing (12%). This distribution reflects the critical nature of joining quality in these high-precision industries where failure can lead to catastrophic consequences.

Market research reveals a compound annual growth rate of 7.8% for inspection technologies specifically designed for laser welded joints, outpacing the 5.2% growth rate for traditional mechanical joining inspection systems. This accelerated growth correlates directly with the transition from mechanical fastening to laser welding processes in premium manufacturing segments, particularly in lightweight vehicle construction and medical implant production.

Customer demand is increasingly focused on real-time inspection capabilities that can be integrated directly into production lines. Survey data from manufacturing executives indicates that 78% consider in-line quality assurance for joining processes a "high priority" investment area for the next three years. This represents a significant shift from the 45% reported just five years ago, demonstrating the rapidly evolving market requirements.

Regional analysis shows that Asia-Pacific currently leads in market volume, accounting for 41% of global demand, followed by Europe (32%) and North America (21%). However, European manufacturers are setting the technological standards, particularly in automotive applications where German and Scandinavian companies have established benchmark inspection protocols for laser-welded structural components.

The market is also witnessing increased demand for multi-modal inspection systems that can address the unique challenges presented by laser welding. Traditional visual inspection methods are insufficient for detecting subsurface defects common in laser welds, creating market opportunities for advanced technologies such as phased array ultrasonics, thermography, and machine learning-enhanced X-ray systems. These technologies command premium pricing, with integrated systems selling at 2.5-3 times the cost of conventional inspection equipment.

Industry forecasts predict that by 2027, over 60% of all new joining inspection installations will incorporate capabilities specifically designed for laser welding assessment, reflecting the market's recognition of the fundamental differences between mechanical and laser joining processes and their respective quality assurance requirements.

Market research reveals a compound annual growth rate of 7.8% for inspection technologies specifically designed for laser welded joints, outpacing the 5.2% growth rate for traditional mechanical joining inspection systems. This accelerated growth correlates directly with the transition from mechanical fastening to laser welding processes in premium manufacturing segments, particularly in lightweight vehicle construction and medical implant production.

Customer demand is increasingly focused on real-time inspection capabilities that can be integrated directly into production lines. Survey data from manufacturing executives indicates that 78% consider in-line quality assurance for joining processes a "high priority" investment area for the next three years. This represents a significant shift from the 45% reported just five years ago, demonstrating the rapidly evolving market requirements.

Regional analysis shows that Asia-Pacific currently leads in market volume, accounting for 41% of global demand, followed by Europe (32%) and North America (21%). However, European manufacturers are setting the technological standards, particularly in automotive applications where German and Scandinavian companies have established benchmark inspection protocols for laser-welded structural components.

The market is also witnessing increased demand for multi-modal inspection systems that can address the unique challenges presented by laser welding. Traditional visual inspection methods are insufficient for detecting subsurface defects common in laser welds, creating market opportunities for advanced technologies such as phased array ultrasonics, thermography, and machine learning-enhanced X-ray systems. These technologies command premium pricing, with integrated systems selling at 2.5-3 times the cost of conventional inspection equipment.

Industry forecasts predict that by 2027, over 60% of all new joining inspection installations will incorporate capabilities specifically designed for laser welding assessment, reflecting the market's recognition of the fundamental differences between mechanical and laser joining processes and their respective quality assurance requirements.

Technical Challenges in Laser vs Mechanical Joint Inspection

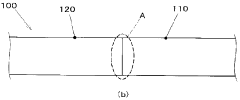

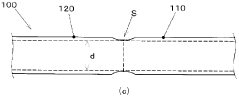

The inspection of joining methods presents significant technical challenges that vary considerably between laser welding and mechanical joining techniques. Current inspection technologies face limitations in detecting subsurface defects in laser welds, particularly in identifying micro-cracks, porosity, and incomplete fusion that may be invisible to the naked eye. Traditional non-destructive testing (NDT) methods such as ultrasonic testing struggle with the small scale and complex geometry of laser welds, while X-ray techniques, though effective, present radiation hazards and operational complexities in production environments.

For mechanical joints, inspection challenges center around detecting improper assembly, insufficient torque application, and material fatigue. The diversity of mechanical joining methods—from bolts and rivets to snap-fits and crimps—necessitates multiple inspection protocols, complicating quality assurance processes. Additionally, mechanical joints may appear satisfactory during initial inspection but fail under dynamic loading conditions, highlighting the need for both static and dynamic testing methodologies.

Real-time monitoring presents another significant challenge. While laser welding can be monitored during the process through spectroscopy and thermal imaging, interpreting this data accurately requires sophisticated algorithms and reference standards. Mechanical joining typically relies on post-process inspection, creating a time lag between production and quality verification that impacts manufacturing efficiency.

Material combinations further complicate inspection protocols. The growing trend of multi-material assemblies, particularly in automotive and aerospace applications, introduces new inspection challenges as different materials respond differently to both joining methods and inspection techniques. For instance, carbon fiber composites joined to aluminum require specialized inspection approaches that can simultaneously evaluate both materials and their interface.

Automation of inspection processes represents both a challenge and an opportunity. Vision systems and AI-based defect recognition show promise but require extensive training datasets specific to each joining method and material combination. The development of reliable automated inspection systems is hindered by the lack of standardized defect libraries and the high variability in joint appearances, especially in laser welding where surface appearance may not correlate with internal quality.

Accessibility for inspection also differs significantly between joining methods. Mechanical joints are generally more accessible for visual and tactile inspection, while laser welds may be located in hard-to-reach areas or enclosed within assemblies. This physical constraint necessitates the development of specialized inspection tools and techniques that can access confined spaces without compromising inspection accuracy.

For mechanical joints, inspection challenges center around detecting improper assembly, insufficient torque application, and material fatigue. The diversity of mechanical joining methods—from bolts and rivets to snap-fits and crimps—necessitates multiple inspection protocols, complicating quality assurance processes. Additionally, mechanical joints may appear satisfactory during initial inspection but fail under dynamic loading conditions, highlighting the need for both static and dynamic testing methodologies.

Real-time monitoring presents another significant challenge. While laser welding can be monitored during the process through spectroscopy and thermal imaging, interpreting this data accurately requires sophisticated algorithms and reference standards. Mechanical joining typically relies on post-process inspection, creating a time lag between production and quality verification that impacts manufacturing efficiency.

Material combinations further complicate inspection protocols. The growing trend of multi-material assemblies, particularly in automotive and aerospace applications, introduces new inspection challenges as different materials respond differently to both joining methods and inspection techniques. For instance, carbon fiber composites joined to aluminum require specialized inspection approaches that can simultaneously evaluate both materials and their interface.

Automation of inspection processes represents both a challenge and an opportunity. Vision systems and AI-based defect recognition show promise but require extensive training datasets specific to each joining method and material combination. The development of reliable automated inspection systems is hindered by the lack of standardized defect libraries and the high variability in joint appearances, especially in laser welding where surface appearance may not correlate with internal quality.

Accessibility for inspection also differs significantly between joining methods. Mechanical joints are generally more accessible for visual and tactile inspection, while laser welds may be located in hard-to-reach areas or enclosed within assemblies. This physical constraint necessitates the development of specialized inspection tools and techniques that can access confined spaces without compromising inspection accuracy.

Current Inspection Methodologies Comparison

01 Non-destructive inspection methods for laser welded joints

Various non-destructive testing methods can be employed to inspect laser welded joints without damaging the components. These include ultrasonic testing, radiographic inspection, thermography, and optical methods that can detect surface and subsurface defects. These techniques allow for real-time monitoring of weld quality, identification of discontinuities, and verification of joint integrity without compromising the structural integrity of the welded components.- Non-destructive inspection methods for laser welded joints: Various non-destructive testing methods can be employed to inspect laser welded joints without damaging the components. These methods include ultrasonic testing, radiographic inspection, thermography, and optical coherence tomography. These techniques allow for the detection of defects such as cracks, porosity, and incomplete fusion in laser welded joints while maintaining the integrity of the joined components.

- Real-time monitoring systems for laser welding processes: Real-time monitoring systems can be implemented during laser welding processes to detect defects as they occur. These systems utilize sensors, cameras, and advanced algorithms to analyze parameters such as temperature, plasma emissions, and weld pool dynamics. By monitoring these parameters in real-time, quality issues can be identified immediately, allowing for process adjustments and reducing inspection challenges post-welding.

- Inspection challenges for hybrid joining techniques: Hybrid joining techniques that combine laser welding with mechanical fastening present unique inspection challenges. The interface between different joining methods creates complex stress distributions and potential failure points that are difficult to assess. Specialized inspection protocols are needed to evaluate the integrity of these hybrid joints, including the assessment of both the welded areas and the mechanical fastening components.

- Automated inspection systems for high-volume production: Automated inspection systems are essential for high-volume production environments where laser welding and mechanical joining are employed. These systems incorporate machine vision, artificial intelligence, and robotics to perform rapid and consistent inspections. Automated systems can detect defects such as misalignment, insufficient penetration, and surface irregularities while maintaining production efficiency and reducing human error in the inspection process.

- Material-specific inspection considerations: Different materials present unique challenges when inspecting laser welded and mechanically joined components. For instance, reflective materials like aluminum and copper require specialized inspection techniques, while dissimilar material joints need methods that can account for varying material properties. Inspection protocols must be tailored to the specific materials being joined, considering factors such as thermal conductivity, reflectivity, and potential for intermetallic compound formation.

02 Automated vision systems for weld inspection

Advanced vision systems and image processing technologies are used for automated inspection of laser welds and mechanical joints. These systems employ cameras, sensors, and artificial intelligence algorithms to detect defects such as cracks, porosity, and incomplete fusion. Real-time monitoring during the welding process allows for immediate quality control and reduces the need for post-process inspection, improving manufacturing efficiency and ensuring consistent joint quality.Expand Specific Solutions03 Challenges in dissimilar material joining inspection

Inspecting joints between dissimilar materials presents unique challenges due to differences in thermal properties, acoustic impedance, and material structure. Conventional inspection methods may not be effective when examining joints between metals and polymers or different metal alloys. Specialized techniques are required to accurately assess bond quality, detect interface defects, and verify mechanical properties of these heterogeneous joints, particularly when laser welding is combined with mechanical joining methods.Expand Specific Solutions04 In-process monitoring systems for laser welding

In-process monitoring systems integrate sensors directly into the laser welding equipment to provide real-time feedback on weld quality. These systems monitor parameters such as temperature profiles, plasma emissions, acoustic signatures, and laser reflection patterns during the welding process. By analyzing these signals, the systems can detect anomalies immediately, allowing for process adjustments before defects form and reducing inspection requirements after welding is complete.Expand Specific Solutions05 Mechanical testing methods for joint strength verification

Destructive and semi-destructive testing methods are essential for verifying the mechanical properties and strength of laser welded and mechanically joined components. These include tensile testing, shear testing, fatigue testing, and hardness measurements. While these methods provide direct measurement of joint performance, they require sacrificial specimens and cannot be used for 100% inspection. Correlation between non-destructive inspection results and mechanical properties is crucial for developing reliable quality assurance protocols.Expand Specific Solutions

Key Industry Players in Welding Inspection Solutions

The laser welding versus mechanical joining inspection landscape is evolving rapidly, currently transitioning from early adoption to growth phase. The global market for these inspection technologies is expanding at approximately 8-10% annually, driven by automotive and aerospace applications. While mechanical joining inspection methods are mature, laser welding inspection technologies are still developing, creating significant innovation opportunities. Leading automotive manufacturers like Volkswagen, BMW, Honda, and Ford are investing heavily in advanced inspection systems, while technology providers such as IPG Photonics, Precitec, and Robert Bosch are developing specialized solutions. Research institutions including Stevens Institute of Technology and Tianjin University are contributing breakthrough inspection methodologies, creating a competitive ecosystem balancing established industrial players with emerging technology specialists.

Robert Bosch GmbH

Technical Solution: Bosch has developed an integrated laser welding inspection system that addresses the unique challenges of comparing laser welding to mechanical joining processes. Their technical solution combines multiple inspection technologies including ultrasonic testing, thermography, and machine vision systems to provide comprehensive quality assessment. The system employs high-frequency ultrasonic transducers that can detect subsurface defects in laser welds that would be impossible to identify visually, such as internal porosity or lack of fusion. Bosch's approach incorporates infrared thermography during the welding process to map heat distribution patterns and identify potential weak spots in real-time. Their system also features advanced image processing algorithms that can detect surface irregularities down to the micron level, allowing for precise comparison between laser welded and mechanically joined components. Bosch has integrated these inspection technologies with their manufacturing execution systems to provide complete traceability and statistical process control capabilities, enabling continuous improvement of both welding and joining processes.

Strengths: Comprehensive multi-method inspection approach that addresses both surface and subsurface defects; seamless integration with manufacturing systems for data-driven process optimization; applicable across diverse material combinations. Weaknesses: Higher complexity and cost compared to conventional mechanical joining inspection methods; requires significant calibration and setup time when changing between different material combinations or joint geometries.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced inspection system specifically designed to address the comparative challenges between laser welding and mechanical joining processes. Their technical solution incorporates a multi-sensor approach that combines high-resolution computed tomography (CT) scanning with acoustic emission monitoring to provide comprehensive assessment of joint integrity. GM's system employs proprietary algorithms that analyze acoustic signatures during the welding process to detect micro-fractures and inconsistencies in real-time, allowing for immediate process adjustments. Their inspection platform includes automated comparative analysis tools that quantify the structural differences between laser welded and mechanically joined components under various load conditions. GM has also integrated thermal imaging capabilities that can detect heat-affected zone anomalies specific to laser welding that wouldn't be present in mechanical joints. Their system features a digital process twin that simulates ideal weld characteristics and automatically compares them against actual inspection results, providing quantitative quality metrics for both joining methods. The platform incorporates machine learning capabilities that continuously improve defect recognition accuracy based on correlation with destructive testing results.

Strengths: Comprehensive comparison capabilities between different joining technologies; real-time process monitoring enables immediate corrective actions; integration with vehicle performance data provides long-term quality insights. Weaknesses: Complex system requires significant initial calibration for different material combinations; higher implementation cost compared to conventional inspection methods; requires specialized operator training for effective utilization.

Critical Technologies for Joint Quality Assessment

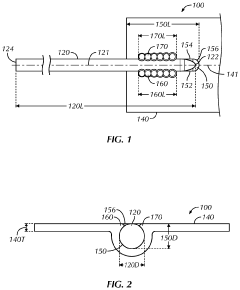

Method for manufacturing inspection probe

PatentWO2012096333A1

Innovation

- A method involving laser welding where the energy applied to the wire with the higher melting point is greater than that applied to the wire with the lower melting point, allowing for synchronized melting and preventing inadequate fusion or excessive melting, along with post-processing techniques like polishing to ensure dimensional accuracy and surface smoothness.

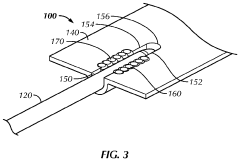

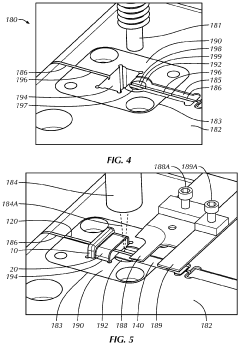

Laser brazed component and method therefor

PatentActiveUS20210299786A1

Innovation

- A method involving laser brazing is used to join molybdenum and aluminum pieces by forming a channel in the aluminum lead that aligns with the molybdenum pin, where the aluminum is melted to create a strong joint without significant mixing, using laser brazing to close the channel openings and secure the pin within the lead, thereby forming a stable and non-brittle connection.

Quality Standards and Certification Requirements

Quality standards and certification requirements play a crucial role in determining the acceptability of both laser welding and mechanical joining processes. These standards vary significantly between industries, with aerospace, automotive, and medical device manufacturing having particularly stringent requirements. The inspection challenges arise partly from the need to verify compliance with these diverse standards.

For laser welding, key international standards include ISO 13919 and ISO 12932, which define quality levels for imperfections in electron and laser beam welded joints. These standards categorize defects into severity levels and establish acceptance criteria for different applications. Additionally, AWS D17.1 specifically addresses fusion welding for aerospace applications, providing detailed requirements for laser welding inspection and quality assurance.

Mechanical joining processes are governed by standards such as ISO 12996 for mechanical joining and ISO 14589 for blind riveting. These standards define testing methods and quality requirements that necessitate different inspection approaches compared to welded joints. The fundamental difference lies in the failure modes: mechanical joints typically fail through fastener loosening or material fatigue, while laser welds may fail due to internal defects or incomplete fusion.

Certification requirements add another layer of complexity to inspection challenges. In automotive manufacturing, standards like IATF 16949 require specific quality management systems that influence how inspections must be documented and tracked. For medical devices, FDA regulations and ISO 13485 impose rigorous validation requirements for both joining methods, with particular emphasis on process consistency and traceability.

The aerospace industry presents perhaps the most demanding certification landscape, with requirements from authorities like FAA, EASA, and standards like AS9100. These often mandate 100% inspection for critical components, creating significant challenges for high-volume production using either joining method. Notably, certification for laser welding processes typically requires more extensive documentation of process parameters and operator qualifications than mechanical joining.

Environmental regulations also impact quality standards, with restrictions on certain materials used in mechanical fasteners (like hexavalent chromium coatings) driving changes in inspection protocols. Similarly, sustainability certifications increasingly require assessment of energy consumption during manufacturing, where laser welding's energy efficiency may provide advantages despite its more complex inspection requirements.

For laser welding, key international standards include ISO 13919 and ISO 12932, which define quality levels for imperfections in electron and laser beam welded joints. These standards categorize defects into severity levels and establish acceptance criteria for different applications. Additionally, AWS D17.1 specifically addresses fusion welding for aerospace applications, providing detailed requirements for laser welding inspection and quality assurance.

Mechanical joining processes are governed by standards such as ISO 12996 for mechanical joining and ISO 14589 for blind riveting. These standards define testing methods and quality requirements that necessitate different inspection approaches compared to welded joints. The fundamental difference lies in the failure modes: mechanical joints typically fail through fastener loosening or material fatigue, while laser welds may fail due to internal defects or incomplete fusion.

Certification requirements add another layer of complexity to inspection challenges. In automotive manufacturing, standards like IATF 16949 require specific quality management systems that influence how inspections must be documented and tracked. For medical devices, FDA regulations and ISO 13485 impose rigorous validation requirements for both joining methods, with particular emphasis on process consistency and traceability.

The aerospace industry presents perhaps the most demanding certification landscape, with requirements from authorities like FAA, EASA, and standards like AS9100. These often mandate 100% inspection for critical components, creating significant challenges for high-volume production using either joining method. Notably, certification for laser welding processes typically requires more extensive documentation of process parameters and operator qualifications than mechanical joining.

Environmental regulations also impact quality standards, with restrictions on certain materials used in mechanical fasteners (like hexavalent chromium coatings) driving changes in inspection protocols. Similarly, sustainability certifications increasingly require assessment of energy consumption during manufacturing, where laser welding's energy efficiency may provide advantages despite its more complex inspection requirements.

Cost-Benefit Analysis of Inspection Technologies

When evaluating inspection technologies for laser welding versus mechanical joining processes, a comprehensive cost-benefit analysis reveals significant economic implications across multiple dimensions. Initial investment costs for advanced inspection systems such as ultrasonic testing, X-ray imaging, and thermal imaging cameras typically range from $50,000 to $500,000 depending on sophistication and automation levels. While laser welding inspection technologies generally require higher upfront investment due to their precision requirements, they often deliver superior long-term value through reduced false rejection rates.

Operational costs present another critical consideration. Labor expenses for trained inspection personnel average $60,000-$80,000 annually per specialist, with laser welding inspection requiring more specialized expertise. However, automated inspection systems can reduce these costs by 40-60% over a five-year period. Energy consumption for inspection equipment varies significantly, with laser-based systems typically consuming 2-5 kW during operation compared to 1-3 kW for mechanical joining inspection systems.

Maintenance requirements constitute approximately 5-15% of the initial equipment cost annually, with laser welding inspection systems generally falling at the higher end of this range due to their optical components and calibration needs. However, these systems typically offer superior detection capabilities, identifying defects as small as 50-100 microns compared to 200-500 microns for conventional methods used with mechanical joints.

The economic impact of inspection accuracy creates substantial downstream value. False positives (rejecting acceptable parts) generate unnecessary rework costs of $20-$100 per component, while false negatives (accepting defective parts) can lead to warranty claims averaging $1,000-$10,000 per incident, not including potential liability costs. Advanced inspection technologies for laser welding typically reduce false readings by 30-50% compared to conventional methods.

Production throughput represents another significant economic factor. Modern automated inspection systems for laser welds can process 30-60 components per hour, while mechanical joining inspection may achieve 40-80 components hourly due to simpler verification requirements. However, the higher reliability of laser welding inspection reduces costly production interruptions, potentially saving $5,000-$15,000 per hour of avoided downtime.

Return on investment calculations indicate that despite higher initial costs, advanced inspection technologies for laser welding typically achieve breakeven within 18-36 months through reduced quality costs, while conventional inspection systems for mechanical joints may reach breakeven in 12-24 months but deliver less total value over their lifecycle.

Operational costs present another critical consideration. Labor expenses for trained inspection personnel average $60,000-$80,000 annually per specialist, with laser welding inspection requiring more specialized expertise. However, automated inspection systems can reduce these costs by 40-60% over a five-year period. Energy consumption for inspection equipment varies significantly, with laser-based systems typically consuming 2-5 kW during operation compared to 1-3 kW for mechanical joining inspection systems.

Maintenance requirements constitute approximately 5-15% of the initial equipment cost annually, with laser welding inspection systems generally falling at the higher end of this range due to their optical components and calibration needs. However, these systems typically offer superior detection capabilities, identifying defects as small as 50-100 microns compared to 200-500 microns for conventional methods used with mechanical joints.

The economic impact of inspection accuracy creates substantial downstream value. False positives (rejecting acceptable parts) generate unnecessary rework costs of $20-$100 per component, while false negatives (accepting defective parts) can lead to warranty claims averaging $1,000-$10,000 per incident, not including potential liability costs. Advanced inspection technologies for laser welding typically reduce false readings by 30-50% compared to conventional methods.

Production throughput represents another significant economic factor. Modern automated inspection systems for laser welds can process 30-60 components per hour, while mechanical joining inspection may achieve 40-80 components hourly due to simpler verification requirements. However, the higher reliability of laser welding inspection reduces costly production interruptions, potentially saving $5,000-$15,000 per hour of avoided downtime.

Return on investment calculations indicate that despite higher initial costs, advanced inspection technologies for laser welding typically achieve breakeven within 18-36 months through reduced quality costs, while conventional inspection systems for mechanical joints may reach breakeven in 12-24 months but deliver less total value over their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!