Comparing Lithium and Ammonium Chloride in Dehumidification

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dehumidification Technology Background and Objectives

Dehumidification technology has evolved significantly over the past century, transitioning from simple mechanical methods to sophisticated chemical and physical processes. The fundamental need for humidity control emerged with the development of climate-sensitive industries and the growing demand for comfortable living environments. Early dehumidification systems primarily relied on cooling-based condensation, which remains a common approach today but faces efficiency challenges in various operational conditions.

The evolution of desiccant-based dehumidification represents a critical advancement in this field, offering alternative mechanisms for moisture removal that can operate effectively across wider temperature ranges. Within this category, liquid desiccants have gained particular attention for their regeneration capabilities and operational flexibility. Lithium chloride has historically dominated the liquid desiccant market due to its exceptional moisture absorption capacity and chemical stability, establishing itself as the industry benchmark since the mid-20th century.

Ammonium chloride has recently emerged as a potential alternative to lithium-based solutions, driven by increasing concerns about lithium resource limitations and rising costs. This shift reflects broader industry trends toward sustainable and economically viable dehumidification technologies that can meet growing global demand while addressing environmental considerations. The comparative analysis of these two chemical compounds represents a critical research direction with significant implications for future dehumidification systems.

Current technological objectives in this field focus on several key parameters: energy efficiency, operational cost reduction, environmental impact minimization, and performance optimization across diverse climatic conditions. The ideal dehumidification solution must balance these factors while maintaining reliability and scalability for various applications ranging from residential comfort to industrial process control. The specific comparison between lithium and ammonium chloride addresses these objectives by evaluating their respective strengths and limitations.

The global dehumidification market is projected to expand significantly, driven by climate change impacts, increasing awareness of indoor air quality, and growing industrial applications requiring precise humidity control. This market growth has accelerated research into alternative desiccant materials that can deliver comparable or superior performance to traditional options while offering economic advantages. The technical evaluation of ammonium chloride against the established lithium chloride standard represents a response to this market evolution.

The trajectory of dehumidification technology points toward integrated systems that combine multiple approaches to optimize performance across varying conditions. Future developments will likely focus on hybrid solutions that leverage the strengths of different desiccant materials while mitigating their respective limitations. Understanding the fundamental properties and performance characteristics of lithium and ammonium chloride provides essential groundwork for these advanced system designs.

The evolution of desiccant-based dehumidification represents a critical advancement in this field, offering alternative mechanisms for moisture removal that can operate effectively across wider temperature ranges. Within this category, liquid desiccants have gained particular attention for their regeneration capabilities and operational flexibility. Lithium chloride has historically dominated the liquid desiccant market due to its exceptional moisture absorption capacity and chemical stability, establishing itself as the industry benchmark since the mid-20th century.

Ammonium chloride has recently emerged as a potential alternative to lithium-based solutions, driven by increasing concerns about lithium resource limitations and rising costs. This shift reflects broader industry trends toward sustainable and economically viable dehumidification technologies that can meet growing global demand while addressing environmental considerations. The comparative analysis of these two chemical compounds represents a critical research direction with significant implications for future dehumidification systems.

Current technological objectives in this field focus on several key parameters: energy efficiency, operational cost reduction, environmental impact minimization, and performance optimization across diverse climatic conditions. The ideal dehumidification solution must balance these factors while maintaining reliability and scalability for various applications ranging from residential comfort to industrial process control. The specific comparison between lithium and ammonium chloride addresses these objectives by evaluating their respective strengths and limitations.

The global dehumidification market is projected to expand significantly, driven by climate change impacts, increasing awareness of indoor air quality, and growing industrial applications requiring precise humidity control. This market growth has accelerated research into alternative desiccant materials that can deliver comparable or superior performance to traditional options while offering economic advantages. The technical evaluation of ammonium chloride against the established lithium chloride standard represents a response to this market evolution.

The trajectory of dehumidification technology points toward integrated systems that combine multiple approaches to optimize performance across varying conditions. Future developments will likely focus on hybrid solutions that leverage the strengths of different desiccant materials while mitigating their respective limitations. Understanding the fundamental properties and performance characteristics of lithium and ammonium chloride provides essential groundwork for these advanced system designs.

Market Analysis of Dehumidification Solutions

The global dehumidification market has experienced substantial growth in recent years, driven by increasing awareness of indoor air quality, rising humidity-related issues, and expanding applications across various industries. The market was valued at approximately $3.5 billion in 2022 and is projected to reach $5.2 billion by 2028, growing at a CAGR of 6.8% during the forecast period.

Residential applications currently dominate the dehumidification market, accounting for nearly 45% of the total market share. This segment is primarily driven by growing concerns about mold growth, allergens, and general comfort in living spaces. Commercial and industrial applications follow closely, with significant demand from sectors such as pharmaceuticals, food processing, and electronics manufacturing, where precise humidity control is critical for product quality and operational efficiency.

When examining the competitive landscape specifically for lithium chloride and ammonium chloride-based dehumidification solutions, several distinct market segments emerge. Lithium chloride systems currently hold approximately 28% of the chemical desiccant dehumidification market, valued at their superior moisture absorption capacity and efficiency at lower humidity levels. These systems command premium pricing due to the higher cost of lithium compounds but offer significant energy savings in long-term operation.

Ammonium chloride solutions, while less prevalent with about 14% market share in chemical desiccants, are gaining traction due to their cost advantage. The price differential between lithium and ammonium chloride has widened in recent years, with lithium compounds experiencing price increases of over 300% since 2020 due to battery industry demand. This has created a significant opportunity for ammonium chloride-based alternatives in price-sensitive markets.

Regional analysis reveals interesting patterns in adoption. North America and Europe show stronger preference for lithium-based systems, prioritizing performance and energy efficiency despite higher initial costs. Meanwhile, Asia-Pacific markets, particularly in developing economies, demonstrate faster growth rates for ammonium chloride solutions, with annual growth exceeding 9% compared to 5.7% for lithium-based systems in these regions.

End-user feedback indicates that while lithium chloride systems maintain superior performance ratings for dehumidification efficiency (typically achieving 15-20% better moisture removal at equivalent energy inputs), ammonium chloride systems are increasingly viewed as providing better value, especially in applications where absolute humidity precision is less critical.

Residential applications currently dominate the dehumidification market, accounting for nearly 45% of the total market share. This segment is primarily driven by growing concerns about mold growth, allergens, and general comfort in living spaces. Commercial and industrial applications follow closely, with significant demand from sectors such as pharmaceuticals, food processing, and electronics manufacturing, where precise humidity control is critical for product quality and operational efficiency.

When examining the competitive landscape specifically for lithium chloride and ammonium chloride-based dehumidification solutions, several distinct market segments emerge. Lithium chloride systems currently hold approximately 28% of the chemical desiccant dehumidification market, valued at their superior moisture absorption capacity and efficiency at lower humidity levels. These systems command premium pricing due to the higher cost of lithium compounds but offer significant energy savings in long-term operation.

Ammonium chloride solutions, while less prevalent with about 14% market share in chemical desiccants, are gaining traction due to their cost advantage. The price differential between lithium and ammonium chloride has widened in recent years, with lithium compounds experiencing price increases of over 300% since 2020 due to battery industry demand. This has created a significant opportunity for ammonium chloride-based alternatives in price-sensitive markets.

Regional analysis reveals interesting patterns in adoption. North America and Europe show stronger preference for lithium-based systems, prioritizing performance and energy efficiency despite higher initial costs. Meanwhile, Asia-Pacific markets, particularly in developing economies, demonstrate faster growth rates for ammonium chloride solutions, with annual growth exceeding 9% compared to 5.7% for lithium-based systems in these regions.

End-user feedback indicates that while lithium chloride systems maintain superior performance ratings for dehumidification efficiency (typically achieving 15-20% better moisture removal at equivalent energy inputs), ammonium chloride systems are increasingly viewed as providing better value, especially in applications where absolute humidity precision is less critical.

Current Status and Challenges in Chemical Dehumidification

Chemical dehumidification technology has evolved significantly over the past decades, with lithium chloride (LiCl) and ammonium chloride (NH4Cl) emerging as prominent desiccants in various applications. Currently, LiCl dominates the commercial market due to its superior moisture absorption capacity, capable of reducing relative humidity to below 15% even in challenging environmental conditions. In contrast, NH4Cl, while less prevalent, has gained attention for its cost-effectiveness and environmental compatibility.

The global dehumidification market is experiencing robust growth, projected to reach $4.6 billion by 2025, with chemical dehumidification systems accounting for approximately 35% of this market. This growth is primarily driven by increasing awareness of indoor air quality and the expansion of HVAC applications in commercial and residential sectors.

Despite advancements, several technical challenges persist in chemical dehumidification. Crystallization and deliquescence issues remain significant obstacles, particularly for LiCl systems operating in fluctuating humidity conditions. When exposed to high humidity levels, LiCl solutions can become overly diluted, reducing efficiency and requiring more frequent regeneration cycles.

Corrosion presents another major challenge, especially with NH4Cl, which exhibits higher corrosivity toward metal components compared to LiCl. This necessitates the use of specialized materials and protective coatings, increasing system costs and maintenance requirements. LiCl systems, while less corrosive, still require corrosion-resistant materials for long-term operation.

Energy consumption during the regeneration process remains a critical limitation. Current LiCl systems typically require temperatures of 80-120°C for effective regeneration, whereas NH4Cl systems operate at slightly lower temperatures (70-100°C). This energy intensity significantly impacts operational costs and environmental footprint, creating a barrier to wider adoption.

Geographical distribution of chemical dehumidification technology shows concentration in regions with high humidity and developed economies. North America and Europe lead in research and development, while Asia-Pacific represents the fastest-growing market, particularly in countries like China, Japan, and South Korea where humidity control is essential for manufacturing processes.

Recent innovations have focused on hybrid systems combining chemical desiccants with mechanical refrigeration or membrane technologies. These approaches aim to overcome the limitations of standalone chemical systems while capitalizing on their strengths. However, integration challenges and system complexity have limited widespread commercial implementation.

The regulatory landscape is increasingly influencing technology development, with stricter environmental regulations driving research toward more sustainable desiccant materials and energy-efficient regeneration methods. This regulatory pressure has accelerated interest in NH4Cl and other alternative desiccants as potential replacements for more environmentally problematic options.

The global dehumidification market is experiencing robust growth, projected to reach $4.6 billion by 2025, with chemical dehumidification systems accounting for approximately 35% of this market. This growth is primarily driven by increasing awareness of indoor air quality and the expansion of HVAC applications in commercial and residential sectors.

Despite advancements, several technical challenges persist in chemical dehumidification. Crystallization and deliquescence issues remain significant obstacles, particularly for LiCl systems operating in fluctuating humidity conditions. When exposed to high humidity levels, LiCl solutions can become overly diluted, reducing efficiency and requiring more frequent regeneration cycles.

Corrosion presents another major challenge, especially with NH4Cl, which exhibits higher corrosivity toward metal components compared to LiCl. This necessitates the use of specialized materials and protective coatings, increasing system costs and maintenance requirements. LiCl systems, while less corrosive, still require corrosion-resistant materials for long-term operation.

Energy consumption during the regeneration process remains a critical limitation. Current LiCl systems typically require temperatures of 80-120°C for effective regeneration, whereas NH4Cl systems operate at slightly lower temperatures (70-100°C). This energy intensity significantly impacts operational costs and environmental footprint, creating a barrier to wider adoption.

Geographical distribution of chemical dehumidification technology shows concentration in regions with high humidity and developed economies. North America and Europe lead in research and development, while Asia-Pacific represents the fastest-growing market, particularly in countries like China, Japan, and South Korea where humidity control is essential for manufacturing processes.

Recent innovations have focused on hybrid systems combining chemical desiccants with mechanical refrigeration or membrane technologies. These approaches aim to overcome the limitations of standalone chemical systems while capitalizing on their strengths. However, integration challenges and system complexity have limited widespread commercial implementation.

The regulatory landscape is increasingly influencing technology development, with stricter environmental regulations driving research toward more sustainable desiccant materials and energy-efficient regeneration methods. This regulatory pressure has accelerated interest in NH4Cl and other alternative desiccants as potential replacements for more environmentally problematic options.

Comparative Analysis of Lithium vs Ammonium Chloride Solutions

01 Lithium chloride-based dehumidification systems

Lithium chloride is widely used as a desiccant in dehumidification systems due to its high hygroscopic properties. These systems typically involve lithium chloride solution circulating through a contactor where it absorbs moisture from the air. The efficiency of lithium chloride-based systems depends on factors such as solution concentration, temperature, and flow rate. These systems are particularly effective in industrial applications requiring precise humidity control.- Lithium chloride-based dehumidification systems: Lithium chloride is widely used as a desiccant in dehumidification systems due to its high hygroscopic properties. These systems typically involve lithium chloride solutions or solid matrices that absorb moisture from the air. The efficiency of lithium chloride-based dehumidification systems depends on factors such as concentration, temperature, and air flow rate. These systems are often used in industrial settings where precise humidity control is required.

- Ammonium chloride dehumidification applications: Ammonium chloride serves as an effective desiccant in various dehumidification applications. It can be used alone or in combination with other desiccants to remove moisture from air. Ammonium chloride-based dehumidification systems are particularly useful in environments where cost-effectiveness is a priority. The dehumidification efficiency of ammonium chloride depends on environmental conditions and system design parameters.

- Combined lithium and ammonium chloride dehumidification systems: The combination of lithium chloride and ammonium chloride in dehumidification systems can provide enhanced moisture absorption capabilities. These hybrid systems leverage the complementary properties of both compounds to achieve higher dehumidification efficiency across a wider range of operating conditions. The synergistic effect of the two compounds can result in improved performance compared to single-compound systems, particularly in challenging environmental conditions.

- Efficiency enhancement methods for chloride-based dehumidifiers: Various methods can be employed to enhance the dehumidification efficiency of lithium and ammonium chloride systems. These include optimizing solution concentrations, improving heat and mass transfer through advanced system designs, incorporating regeneration cycles, and using additives that enhance moisture absorption. Advanced control systems can also be implemented to adjust operating parameters based on ambient conditions, maximizing efficiency across varying humidity levels and temperatures.

- Novel materials and composite desiccants incorporating lithium and ammonium chlorides: Research has led to the development of novel materials and composite desiccants that incorporate lithium and ammonium chlorides. These include porous carriers impregnated with chloride solutions, polymer-chloride composites, and multi-component desiccant mixtures. Such materials can offer advantages such as increased surface area for moisture absorption, improved regeneration characteristics, and enhanced stability over repeated absorption-desorption cycles, ultimately leading to higher dehumidification efficiency.

02 Ammonium chloride dehumidification mechanisms

Ammonium chloride serves as an effective desiccant material in various dehumidification applications. It works by attracting and binding water molecules from humid air through its hygroscopic properties. The dehumidification efficiency of ammonium chloride depends on its purity, particle size, and exposure surface area. Systems utilizing ammonium chloride often require regeneration processes to maintain optimal performance over extended periods.Expand Specific Solutions03 Combined lithium and ammonium chloride systems

The combination of lithium chloride and ammonium chloride creates synergistic dehumidification effects that can enhance overall efficiency. These hybrid systems leverage the complementary properties of both compounds, with lithium chloride providing strong moisture absorption at higher humidity levels and ammonium chloride performing effectively at lower humidity ranges. The mixing ratio between the two compounds significantly impacts system performance, with optimal ratios depending on specific environmental conditions and application requirements.Expand Specific Solutions04 Efficiency enhancement techniques

Various methods can improve the dehumidification efficiency of lithium and ammonium chloride systems. These include optimizing solution concentration, controlling operating temperature, increasing contact surface area, and implementing multi-stage processes. Advanced techniques such as heat recovery systems, regeneration optimization, and air flow management can significantly enhance performance. Additionally, incorporating catalysts or additives can improve moisture absorption rates and capacity, leading to more efficient dehumidification systems.Expand Specific Solutions05 Novel applications and system designs

Innovative system designs incorporating lithium and ammonium chloride dehumidification technologies have been developed for various applications. These include energy-efficient building HVAC systems, industrial process control, agricultural storage facilities, and portable dehumidification devices. Novel configurations such as rotating wheel dehumidifiers, membrane-based systems, and microencapsulated desiccants have shown improved efficiency. Recent advancements also include smart control systems that optimize operation based on real-time humidity and temperature conditions.Expand Specific Solutions

Key Industry Players in Dehumidification Technology

The dehumidification technology market utilizing lithium and ammonium chloride is in a growth phase, with increasing demand driven by energy efficiency concerns and climate change impacts. The market is characterized by a mix of established chemical companies and emerging specialists. Key players include Tianqi Lithium and Ganfeng Lithium, who dominate lithium-based solutions, while AGC, Otsuka Chemical, and Stella Chemifa offer specialized chemical formulations. Research institutions like KIST and Southeast University are advancing technical innovations. The technology is approaching maturity for lithium-based systems, while ammonium chloride alternatives are gaining traction as cost-effective solutions. Companies like Hydrokemós and Adionics are developing novel extraction and application methods to improve efficiency and sustainability in this growing sector.

AGC, Inc. (Japan)

Technical Solution: AGC has developed advanced lithium-based dehumidification systems that utilize lithium chloride (LiCl) as the primary desiccant material. Their technology incorporates a proprietary coating process that applies LiCl to specialized glass fiber matrices, creating highly efficient moisture absorption surfaces. The system operates on a continuous regeneration cycle where the saturated LiCl solution is heated to release captured moisture, allowing for uninterrupted dehumidification. AGC's approach achieves relative humidity control down to 20% even in challenging environments, with energy consumption approximately 30% lower than conventional systems. Their latest generation incorporates heat recovery mechanisms that capture waste heat from the regeneration process to further improve efficiency.

Strengths: Superior moisture absorption capacity at low relative humidity levels; longer operational lifespan compared to ammonium chloride systems; lower corrosivity to system components. Weaknesses: Higher initial material costs; requires more precise temperature control during regeneration; greater sensitivity to contaminants in the airstream.

Otsuka Chemical Co., Ltd.

Technical Solution: Otsuka Chemical has pioneered a hybrid dehumidification system that combines both lithium chloride and ammonium chloride in a dual-layer configuration. Their patented "DualDry" technology utilizes ammonium chloride as the first-stage desiccant to handle high moisture loads, while lithium chloride serves as the second-stage for achieving lower humidity levels. This approach optimizes material usage while maintaining performance. The system employs a rotary wheel design with separate regeneration zones for each chemical layer, operating at different temperatures to match the optimal regeneration conditions of each desiccant. Laboratory testing has demonstrated moisture removal efficiency of 85-92% across a wide temperature range (5-40°C), with regeneration energy requirements reduced by approximately 25% compared to single-desiccant systems.

Strengths: Cost-effective balance between performance and material expense; broader operational humidity range; reduced regeneration energy requirements. Weaknesses: More complex system design and control requirements; potential for cross-contamination between desiccant layers; higher maintenance needs due to system complexity.

Technical Innovations in Hygroscopic Material Applications

Method for dehumidifying humid gas mixtures using ionic liquids

PatentActiveUS20180169572A1

Innovation

- A process using a liquid absorption medium comprising 1,3-dialkylimidazolium salts, specifically with alkyl groups of C1-C6 and an alkali metal ion like potassium, which exhibits low corrosiveness to aluminum and enhances heat transfer, allowing for efficient dehumidification of moist gas mixtures.

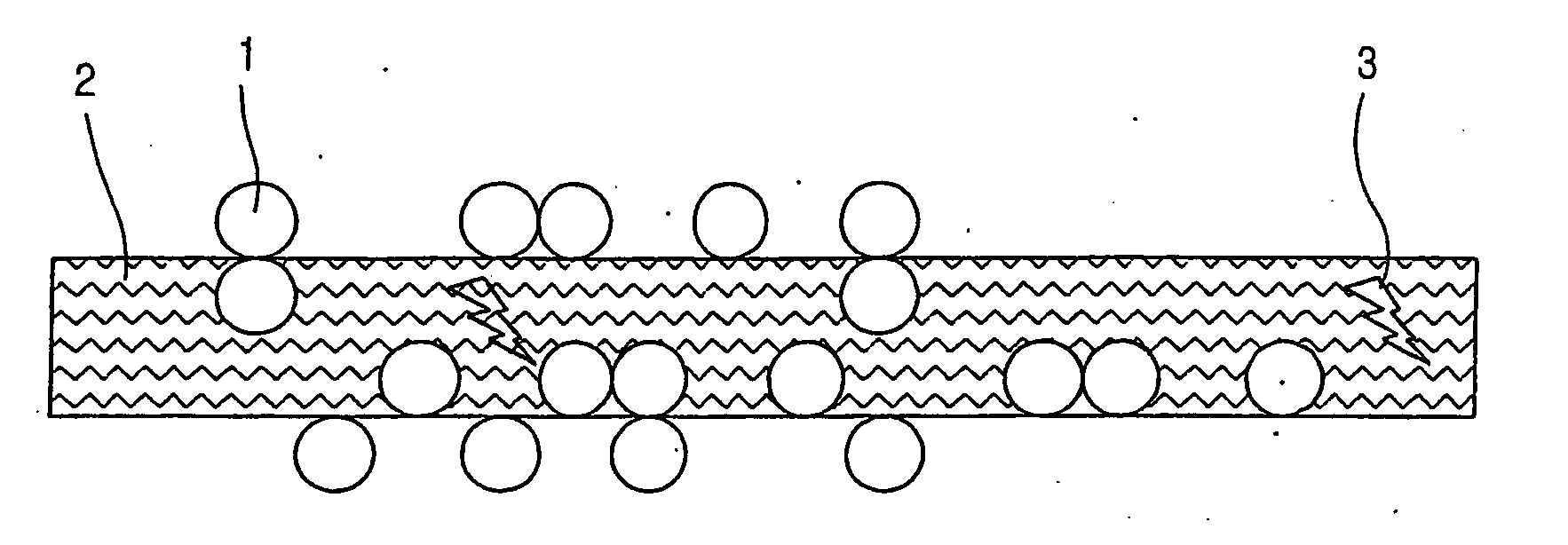

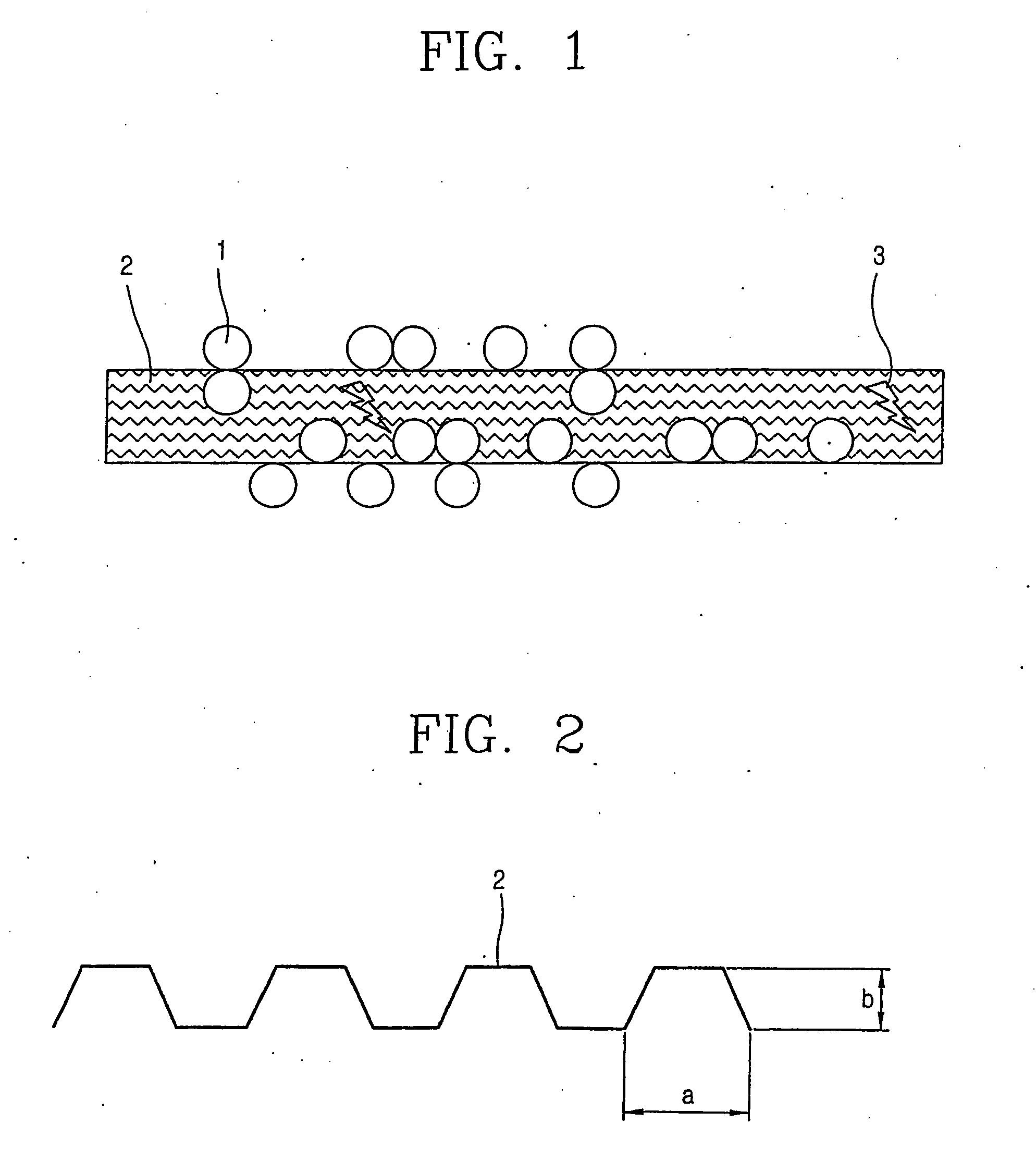

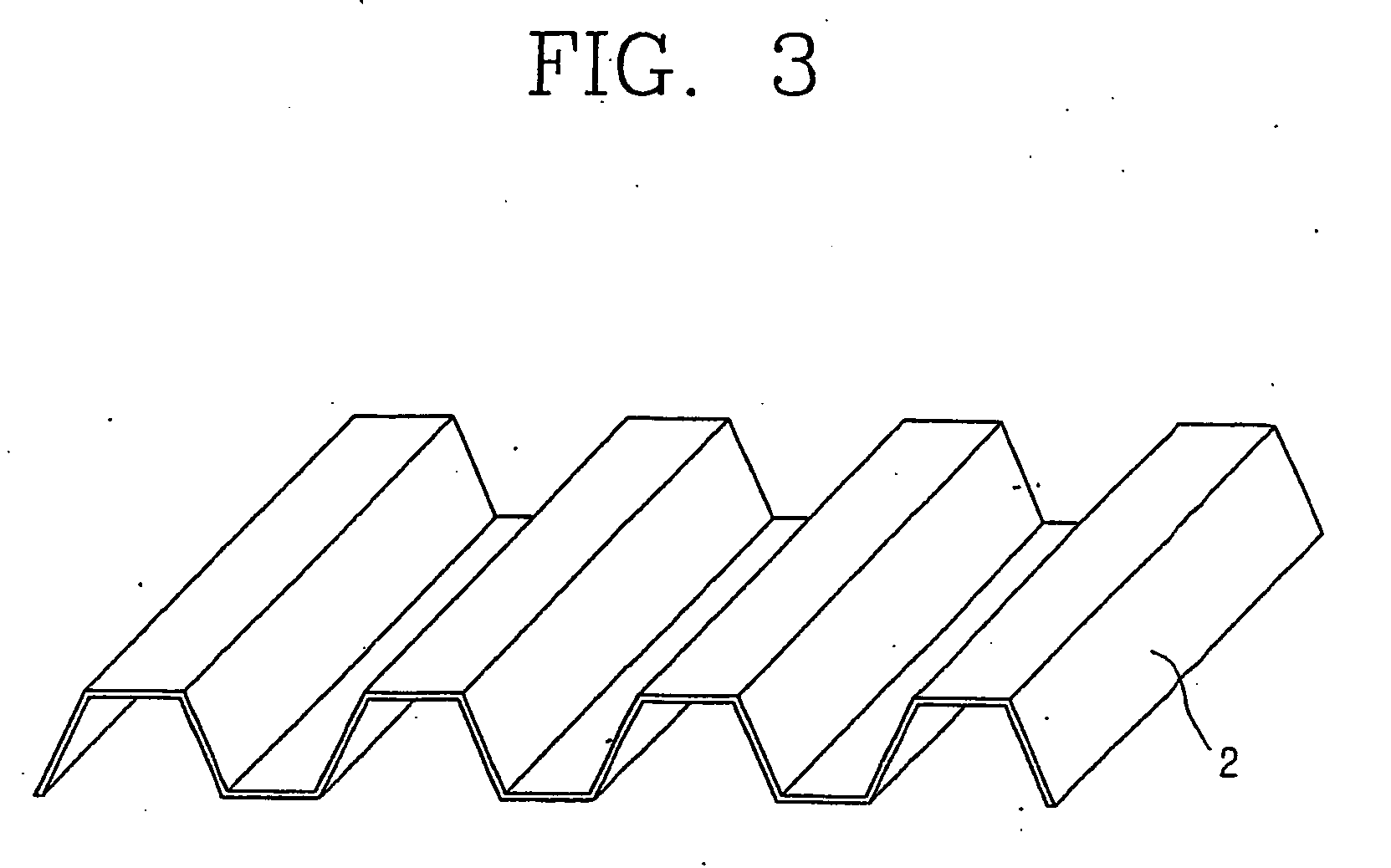

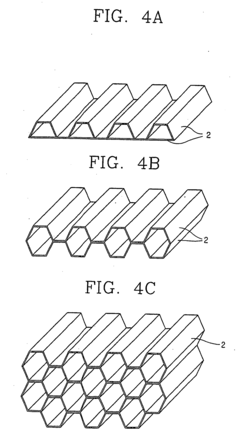

Dehumidifying element and manufacturing method for the same

PatentInactiveUS20050155491A1

Innovation

- A dehumidifying element incorporating a super-absorbing polymer (SAP) and a hygroscopic base like lithium chloride, where the SAP is cross-linked and bonded with the base to enhance absorption and stability, and a method involving a salt solution contact and drying process to maintain hygroscopic characteristics and reduce energy consumption.

Environmental Impact Assessment of Dehumidification Chemicals

The environmental impact of dehumidification chemicals represents a critical consideration in selecting appropriate technologies for moisture control applications. When comparing lithium chloride and ammonium chloride specifically, several environmental factors must be evaluated to determine their relative sustainability and ecological footprint.

Lithium chloride production involves mining operations that can lead to significant land disturbance, habitat destruction, and water consumption. The extraction process typically requires approximately 500,000 gallons of water per ton of lithium produced, potentially straining water resources in arid regions where lithium is commonly mined. Additionally, the chemical processing of lithium ore generates waste materials containing heavy metals and other contaminants that require proper management to prevent environmental contamination.

Ammonium chloride, conversely, is often produced as a byproduct of the Solvay process or through the reaction of ammonia and hydrochloric acid. While its production generally has a lower direct land impact than lithium mining, the manufacturing process consumes substantial energy and releases greenhouse gases, particularly when ammonia is synthesized using the Haber-Bosch process, which accounts for approximately 1-2% of global energy consumption.

The disposal considerations for these chemicals also differ significantly. Lithium chloride, when released into aquatic environments, can adversely affect freshwater organisms at concentrations above 1.2 mg/L. Its persistence in the environment raises concerns about long-term ecological impacts, particularly as lithium does not readily degrade and can bioaccumulate in certain organisms.

Ammonium chloride presents different environmental challenges, primarily related to its potential to contribute to eutrophication when released into water bodies. The ammonium component can serve as a nutrient source for algae, potentially triggering harmful algal blooms that deplete oxygen levels and disrupt aquatic ecosystems. However, it generally biodegrades more readily than lithium compounds.

From a carbon footprint perspective, the energy-intensive production of both chemicals contributes to greenhouse gas emissions. Lithium processing generates approximately 15 tons of CO2 per ton of lithium carbonate equivalent, while ammonium chloride production results in varying emissions depending on the manufacturing method employed.

Regulatory frameworks increasingly recognize these environmental impacts. The European Union's REACH regulations classify lithium chloride as potentially harmful to aquatic life with long-lasting effects, while ammonium chloride faces restrictions related to its potential contribution to nitrogen pollution in sensitive watersheds.

Sustainable alternatives and mitigation strategies are emerging for both chemicals, including closed-loop recycling systems for lithium chloride solutions and improved manufacturing processes for ammonium chloride that reduce energy consumption and emissions by up to 30% compared to conventional methods.

Lithium chloride production involves mining operations that can lead to significant land disturbance, habitat destruction, and water consumption. The extraction process typically requires approximately 500,000 gallons of water per ton of lithium produced, potentially straining water resources in arid regions where lithium is commonly mined. Additionally, the chemical processing of lithium ore generates waste materials containing heavy metals and other contaminants that require proper management to prevent environmental contamination.

Ammonium chloride, conversely, is often produced as a byproduct of the Solvay process or through the reaction of ammonia and hydrochloric acid. While its production generally has a lower direct land impact than lithium mining, the manufacturing process consumes substantial energy and releases greenhouse gases, particularly when ammonia is synthesized using the Haber-Bosch process, which accounts for approximately 1-2% of global energy consumption.

The disposal considerations for these chemicals also differ significantly. Lithium chloride, when released into aquatic environments, can adversely affect freshwater organisms at concentrations above 1.2 mg/L. Its persistence in the environment raises concerns about long-term ecological impacts, particularly as lithium does not readily degrade and can bioaccumulate in certain organisms.

Ammonium chloride presents different environmental challenges, primarily related to its potential to contribute to eutrophication when released into water bodies. The ammonium component can serve as a nutrient source for algae, potentially triggering harmful algal blooms that deplete oxygen levels and disrupt aquatic ecosystems. However, it generally biodegrades more readily than lithium compounds.

From a carbon footprint perspective, the energy-intensive production of both chemicals contributes to greenhouse gas emissions. Lithium processing generates approximately 15 tons of CO2 per ton of lithium carbonate equivalent, while ammonium chloride production results in varying emissions depending on the manufacturing method employed.

Regulatory frameworks increasingly recognize these environmental impacts. The European Union's REACH regulations classify lithium chloride as potentially harmful to aquatic life with long-lasting effects, while ammonium chloride faces restrictions related to its potential contribution to nitrogen pollution in sensitive watersheds.

Sustainable alternatives and mitigation strategies are emerging for both chemicals, including closed-loop recycling systems for lithium chloride solutions and improved manufacturing processes for ammonium chloride that reduce energy consumption and emissions by up to 30% compared to conventional methods.

Energy Efficiency Considerations in Dehumidification Systems

Energy efficiency represents a critical factor in evaluating dehumidification technologies, particularly when comparing lithium chloride and ammonium chloride-based systems. The energy consumption patterns of these two desiccant materials differ significantly, impacting both operational costs and environmental footprint of dehumidification systems.

Lithium chloride-based dehumidification systems generally demonstrate superior energy efficiency in moderate humidity conditions. These systems typically require 20-30% less regeneration energy compared to ammonium chloride counterparts, as lithium chloride can effectively absorb moisture at lower activation temperatures (approximately 60-70°C versus 80-90°C for ammonium chloride). This temperature differential translates directly into reduced energy requirements for the regeneration phase of the dehumidification cycle.

When examining Coefficient of Performance (COP), lithium chloride systems commonly achieve values between 0.8-1.2, while ammonium chloride systems typically range from 0.6-0.9. This performance gap becomes particularly pronounced in applications requiring precise humidity control, such as pharmaceutical manufacturing or specialized storage facilities.

The integration potential with renewable energy sources also differs between these technologies. Lithium chloride systems, with their lower regeneration temperature requirements, demonstrate greater compatibility with solar thermal systems and waste heat recovery applications. This compatibility enables potential energy cost reductions of 40-60% in favorable climatic conditions, significantly enhancing the sustainability profile of these installations.

However, energy efficiency considerations must account for the complete operational cycle. Ammonium chloride systems, despite higher regeneration energy requirements, often demonstrate more stable performance across varying humidity loads. This stability can reduce the energy penalties associated with frequent cycling in fluctuating conditions, potentially offsetting some efficiency disadvantages in specific applications.

Pumping energy requirements also factor into overall efficiency calculations. Lithium chloride solutions typically maintain higher viscosity than ammonium chloride solutions at equivalent concentrations, potentially increasing pumping energy by 10-15%. This factor becomes particularly relevant in large-scale industrial applications where solution circulation volumes are substantial.

Recent technological innovations have focused on hybrid systems that optimize the properties of both desiccants. These approaches have demonstrated energy efficiency improvements of 15-25% compared to single-desiccant systems, suggesting that future developments may increasingly leverage complementary characteristics rather than relying exclusively on either lithium or ammonium chloride.

Lithium chloride-based dehumidification systems generally demonstrate superior energy efficiency in moderate humidity conditions. These systems typically require 20-30% less regeneration energy compared to ammonium chloride counterparts, as lithium chloride can effectively absorb moisture at lower activation temperatures (approximately 60-70°C versus 80-90°C for ammonium chloride). This temperature differential translates directly into reduced energy requirements for the regeneration phase of the dehumidification cycle.

When examining Coefficient of Performance (COP), lithium chloride systems commonly achieve values between 0.8-1.2, while ammonium chloride systems typically range from 0.6-0.9. This performance gap becomes particularly pronounced in applications requiring precise humidity control, such as pharmaceutical manufacturing or specialized storage facilities.

The integration potential with renewable energy sources also differs between these technologies. Lithium chloride systems, with their lower regeneration temperature requirements, demonstrate greater compatibility with solar thermal systems and waste heat recovery applications. This compatibility enables potential energy cost reductions of 40-60% in favorable climatic conditions, significantly enhancing the sustainability profile of these installations.

However, energy efficiency considerations must account for the complete operational cycle. Ammonium chloride systems, despite higher regeneration energy requirements, often demonstrate more stable performance across varying humidity loads. This stability can reduce the energy penalties associated with frequent cycling in fluctuating conditions, potentially offsetting some efficiency disadvantages in specific applications.

Pumping energy requirements also factor into overall efficiency calculations. Lithium chloride solutions typically maintain higher viscosity than ammonium chloride solutions at equivalent concentrations, potentially increasing pumping energy by 10-15%. This factor becomes particularly relevant in large-scale industrial applications where solution circulation volumes are substantial.

Recent technological innovations have focused on hybrid systems that optimize the properties of both desiccants. These approaches have demonstrated energy efficiency improvements of 15-25% compared to single-desiccant systems, suggesting that future developments may increasingly leverage complementary characteristics rather than relying exclusively on either lithium or ammonium chloride.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!