Comparing Lithium Hydroxide Drying Methods For Maximum Yield

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Hydroxide Drying Technology Background and Objectives

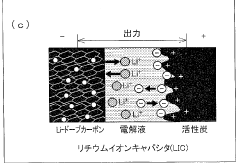

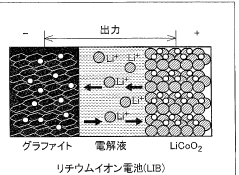

Lithium hydroxide (LiOH) has emerged as a critical material in the global energy transition, particularly for high-performance lithium-ion batteries used in electric vehicles and renewable energy storage systems. The drying process represents a crucial step in lithium hydroxide production, directly impacting product quality, energy consumption, and overall production efficiency. Over the past decade, drying technologies have evolved from conventional methods to more sophisticated approaches designed to maximize yield while minimizing energy consumption.

The evolution of lithium hydroxide drying technology can be traced through several distinct phases. Initially, simple thermal drying methods dominated the industry, characterized by high energy consumption and variable product quality. As demand for battery-grade lithium hydroxide increased in the early 2010s, vacuum drying and spray drying technologies gained prominence, offering improved control over particle morphology and moisture content.

Recent technological advancements have focused on addressing the unique challenges associated with lithium hydroxide drying, including its hygroscopic nature, thermal sensitivity, and the need for precise moisture control. Modern approaches incorporate microwave-assisted drying, fluidized bed technologies, and hybrid systems that combine multiple drying mechanisms to achieve optimal results.

The global push toward electrification has dramatically accelerated research and development in this field. Annual patent filings related to lithium hydroxide processing, including drying technologies, have increased by approximately 300% since 2015, reflecting the strategic importance of this material in the clean energy supply chain.

The primary technical objectives in lithium hydroxide drying technology development include maximizing yield through reduced material losses, achieving consistent moisture content below 0.5% while maintaining particle integrity, minimizing energy consumption, and ensuring scalability for industrial production. Additionally, there is growing emphasis on developing technologies that can accommodate varying feed qualities as lithium extraction methods diversify.

Environmental considerations have also become increasingly important, with newer drying technologies designed to reduce greenhouse gas emissions and water consumption. This trend aligns with the broader sustainability goals of the electric vehicle and renewable energy sectors that represent the primary end markets for battery-grade lithium hydroxide.

Looking forward, the technological trajectory points toward more integrated and intelligent drying systems incorporating real-time monitoring, predictive analytics, and automated control mechanisms. These advanced systems aim to optimize drying parameters dynamically based on feed characteristics and desired product specifications, potentially increasing yields by an additional 3-5% compared to current best practices.

The evolution of lithium hydroxide drying technology can be traced through several distinct phases. Initially, simple thermal drying methods dominated the industry, characterized by high energy consumption and variable product quality. As demand for battery-grade lithium hydroxide increased in the early 2010s, vacuum drying and spray drying technologies gained prominence, offering improved control over particle morphology and moisture content.

Recent technological advancements have focused on addressing the unique challenges associated with lithium hydroxide drying, including its hygroscopic nature, thermal sensitivity, and the need for precise moisture control. Modern approaches incorporate microwave-assisted drying, fluidized bed technologies, and hybrid systems that combine multiple drying mechanisms to achieve optimal results.

The global push toward electrification has dramatically accelerated research and development in this field. Annual patent filings related to lithium hydroxide processing, including drying technologies, have increased by approximately 300% since 2015, reflecting the strategic importance of this material in the clean energy supply chain.

The primary technical objectives in lithium hydroxide drying technology development include maximizing yield through reduced material losses, achieving consistent moisture content below 0.5% while maintaining particle integrity, minimizing energy consumption, and ensuring scalability for industrial production. Additionally, there is growing emphasis on developing technologies that can accommodate varying feed qualities as lithium extraction methods diversify.

Environmental considerations have also become increasingly important, with newer drying technologies designed to reduce greenhouse gas emissions and water consumption. This trend aligns with the broader sustainability goals of the electric vehicle and renewable energy sectors that represent the primary end markets for battery-grade lithium hydroxide.

Looking forward, the technological trajectory points toward more integrated and intelligent drying systems incorporating real-time monitoring, predictive analytics, and automated control mechanisms. These advanced systems aim to optimize drying parameters dynamically based on feed characteristics and desired product specifications, potentially increasing yields by an additional 3-5% compared to current best practices.

Market Demand Analysis for High-Yield Lithium Hydroxide

The global lithium hydroxide market is experiencing unprecedented growth, primarily driven by the rapid expansion of the electric vehicle (EV) industry. As of 2023, the market size has reached approximately $2.3 billion and is projected to grow at a compound annual growth rate (CAGR) of 9.2% through 2030. This surge in demand is directly linked to lithium hydroxide's critical role in manufacturing high-nickel content cathode materials for EV batteries, which offer superior energy density and longer driving ranges.

Battery manufacturers are increasingly shifting from lithium carbonate to lithium hydroxide due to its ability to enable higher performance in nickel-rich NMC (Nickel Manganese Cobalt) and NCA (Nickel Cobalt Aluminum) cathodes. These advanced cathode materials are essential for next-generation EVs that require longer range capabilities and faster charging times. Market research indicates that by 2025, lithium hydroxide demand is expected to surpass lithium carbonate in the battery sector.

The purity requirements for battery-grade lithium hydroxide have become increasingly stringent, with specifications now demanding 99.5% purity or higher. This trend has placed significant emphasis on efficient drying methods that can maintain product quality while maximizing yield. Industry surveys reveal that manufacturers are willing to invest 15-20% more in production technologies that can increase lithium hydroxide yield by at least 5% while maintaining high purity levels.

Geographically, the demand is concentrated in regions with established or rapidly growing EV and battery manufacturing capabilities. Asia Pacific, particularly China, South Korea, and Japan, accounts for approximately 65% of global lithium hydroxide consumption. However, significant growth is anticipated in Europe and North America as these regions accelerate their transition to electric mobility and establish domestic battery supply chains to reduce dependence on Asian imports.

Beyond the EV sector, high-yield lithium hydroxide is finding increasing applications in energy storage systems (ESS), consumer electronics, and specialized industrial applications. The ESS market alone is projected to create additional demand of approximately 50,000 tons annually by 2028, representing a significant secondary market for high-purity lithium hydroxide.

Supply chain security has emerged as a critical factor influencing market dynamics. Battery and EV manufacturers are increasingly seeking diversified and reliable sources of high-quality lithium hydroxide, creating opportunities for producers who can demonstrate consistent quality, high yields, and sustainable production methods. This trend is evidenced by the growing number of long-term offtake agreements being signed between lithium producers and battery manufacturers, often with price premiums for guaranteed quality and supply security.

Battery manufacturers are increasingly shifting from lithium carbonate to lithium hydroxide due to its ability to enable higher performance in nickel-rich NMC (Nickel Manganese Cobalt) and NCA (Nickel Cobalt Aluminum) cathodes. These advanced cathode materials are essential for next-generation EVs that require longer range capabilities and faster charging times. Market research indicates that by 2025, lithium hydroxide demand is expected to surpass lithium carbonate in the battery sector.

The purity requirements for battery-grade lithium hydroxide have become increasingly stringent, with specifications now demanding 99.5% purity or higher. This trend has placed significant emphasis on efficient drying methods that can maintain product quality while maximizing yield. Industry surveys reveal that manufacturers are willing to invest 15-20% more in production technologies that can increase lithium hydroxide yield by at least 5% while maintaining high purity levels.

Geographically, the demand is concentrated in regions with established or rapidly growing EV and battery manufacturing capabilities. Asia Pacific, particularly China, South Korea, and Japan, accounts for approximately 65% of global lithium hydroxide consumption. However, significant growth is anticipated in Europe and North America as these regions accelerate their transition to electric mobility and establish domestic battery supply chains to reduce dependence on Asian imports.

Beyond the EV sector, high-yield lithium hydroxide is finding increasing applications in energy storage systems (ESS), consumer electronics, and specialized industrial applications. The ESS market alone is projected to create additional demand of approximately 50,000 tons annually by 2028, representing a significant secondary market for high-purity lithium hydroxide.

Supply chain security has emerged as a critical factor influencing market dynamics. Battery and EV manufacturers are increasingly seeking diversified and reliable sources of high-quality lithium hydroxide, creating opportunities for producers who can demonstrate consistent quality, high yields, and sustainable production methods. This trend is evidenced by the growing number of long-term offtake agreements being signed between lithium producers and battery manufacturers, often with price premiums for guaranteed quality and supply security.

Current Drying Methods and Technical Challenges

The lithium hydroxide drying process represents a critical step in lithium battery production, with several established methods currently employed across the industry. Conventional thermal drying remains the most widely adopted approach, utilizing rotary kilns, fluidized bed dryers, and vacuum ovens operating at temperatures between 105-150°C. While these methods benefit from technological maturity and operational simplicity, they face significant challenges including high energy consumption, lengthy processing times (typically 6-24 hours), and potential product degradation due to thermal stress.

Spray drying has emerged as an alternative method, offering rapid moisture removal through atomization of lithium hydroxide slurry into hot gas streams. This technique achieves drying in seconds rather than hours, producing spherical particles with improved flowability. However, implementation challenges include high capital investment requirements, complex parameter optimization, and potential yield losses through material adhesion to equipment surfaces.

Microwave drying technology has gained attention for its volumetric heating capabilities, reducing drying times by 60-80% compared to conventional methods. The selective heating mechanism preserves product quality while achieving moisture content below 0.5%. Despite these advantages, the industry faces challenges with scaling microwave systems beyond laboratory or pilot scale, and concerns persist regarding uniform energy distribution in larger production volumes.

Freeze drying (lyophilization) represents a premium approach that preserves material structure through sublimation under vacuum conditions. This method produces exceptionally high purity lithium hydroxide with minimal agglomeration, but suffers from prohibitively high operational costs and extended processing cycles that limit industrial application.

Recent innovations include hybrid drying systems that combine multiple technologies to optimize efficiency. These systems typically integrate conventional thermal methods with microwave or infrared heating to reduce energy consumption while maintaining product quality. However, these complex systems require sophisticated control mechanisms and specialized expertise for operation.

A significant technical challenge across all drying methods is the hygroscopic nature of lithium hydroxide, which readily absorbs atmospheric moisture during processing and handling. This necessitates controlled atmosphere environments and immediate packaging solutions to maintain product specifications. Additionally, the industry struggles with balancing energy efficiency against product quality, as more aggressive drying parameters may improve throughput but risk particle degradation and reduced electrochemical performance in final battery applications.

Spray drying has emerged as an alternative method, offering rapid moisture removal through atomization of lithium hydroxide slurry into hot gas streams. This technique achieves drying in seconds rather than hours, producing spherical particles with improved flowability. However, implementation challenges include high capital investment requirements, complex parameter optimization, and potential yield losses through material adhesion to equipment surfaces.

Microwave drying technology has gained attention for its volumetric heating capabilities, reducing drying times by 60-80% compared to conventional methods. The selective heating mechanism preserves product quality while achieving moisture content below 0.5%. Despite these advantages, the industry faces challenges with scaling microwave systems beyond laboratory or pilot scale, and concerns persist regarding uniform energy distribution in larger production volumes.

Freeze drying (lyophilization) represents a premium approach that preserves material structure through sublimation under vacuum conditions. This method produces exceptionally high purity lithium hydroxide with minimal agglomeration, but suffers from prohibitively high operational costs and extended processing cycles that limit industrial application.

Recent innovations include hybrid drying systems that combine multiple technologies to optimize efficiency. These systems typically integrate conventional thermal methods with microwave or infrared heating to reduce energy consumption while maintaining product quality. However, these complex systems require sophisticated control mechanisms and specialized expertise for operation.

A significant technical challenge across all drying methods is the hygroscopic nature of lithium hydroxide, which readily absorbs atmospheric moisture during processing and handling. This necessitates controlled atmosphere environments and immediate packaging solutions to maintain product specifications. Additionally, the industry struggles with balancing energy efficiency against product quality, as more aggressive drying parameters may improve throughput but risk particle degradation and reduced electrochemical performance in final battery applications.

Comparative Analysis of Existing Drying Solutions

01 Vacuum drying methods for lithium hydroxide

Vacuum drying is an effective method for drying lithium hydroxide that can improve yield and product quality. By reducing pressure in the drying environment, moisture can be removed at lower temperatures, which helps preserve the chemical properties of lithium hydroxide. Vacuum drying systems often incorporate temperature control mechanisms to optimize the drying process and prevent degradation of the material. This method is particularly useful for producing high-purity lithium hydroxide required for battery applications.- Vacuum drying methods for lithium hydroxide: Vacuum drying is an effective method for drying lithium hydroxide that can improve yield and product quality. This process typically involves applying reduced pressure to lower the boiling point of water, allowing for moisture removal at lower temperatures. Vacuum drying helps prevent oxidation and contamination while ensuring uniform drying throughout the material. The method can be optimized by controlling parameters such as vacuum level, temperature, and drying time to achieve desired moisture content and particle characteristics.

- Spray drying techniques for lithium hydroxide production: Spray drying involves atomizing lithium hydroxide solution into fine droplets and exposing them to hot gas, causing rapid evaporation and formation of dry particles. This technique offers advantages such as uniform particle size distribution, improved flowability, and higher yield. The process parameters including inlet temperature, feed rate, and atomization pressure can be adjusted to control the final product characteristics. Spray drying is particularly effective for producing high-purity lithium hydroxide with consistent quality and reduced agglomeration.

- Fluidized bed drying for lithium hydroxide processing: Fluidized bed drying suspends lithium hydroxide particles in an upward-flowing gas stream while applying heat, creating efficient heat transfer and uniform drying. This method provides excellent control over particle size and moisture content, resulting in higher yields of lithium hydroxide. The technique allows for continuous processing and can be integrated with other steps in the production line. Parameters such as air velocity, bed temperature, and residence time can be optimized to achieve desired drying efficiency while maintaining product quality.

- Microwave and infrared drying methods: Advanced drying technologies utilizing microwave and infrared radiation offer efficient moisture removal from lithium hydroxide. These methods provide volumetric and selective heating, resulting in faster drying times, reduced energy consumption, and improved yield. Microwave drying penetrates the material to heat from within, while infrared radiation heats the surface effectively. These technologies can be combined or used separately depending on the specific requirements of the lithium hydroxide being processed, offering precise control over the drying process and final product characteristics.

- Multi-stage drying systems with heat recovery: Multi-stage drying systems incorporate sequential drying steps with heat recovery mechanisms to optimize energy efficiency and lithium hydroxide yield. These systems typically combine different drying technologies in series, with each stage optimized for specific moisture removal ranges. Heat recovery from later stages can be used to preheat material entering earlier stages, reducing overall energy consumption. This approach allows for precise control of drying parameters throughout the process, resulting in higher quality lithium hydroxide with consistent moisture content and improved production economics.

02 Spray drying techniques for lithium hydroxide production

Spray drying involves atomizing a lithium hydroxide solution into fine droplets and exposing them to hot gas to rapidly remove moisture. This technique allows for precise control of particle size and morphology, which can significantly impact the final yield and quality of lithium hydroxide. The process parameters such as inlet temperature, feed rate, and atomization pressure can be optimized to achieve desired particle characteristics. Spray drying is particularly advantageous for large-scale production of lithium hydroxide with consistent quality.Expand Specific Solutions03 Fluidized bed drying for lithium hydroxide

Fluidized bed drying systems provide efficient moisture removal from lithium hydroxide by suspending the particles in an upward-flowing gas stream. This method ensures uniform heat distribution and rapid drying, resulting in higher yields and consistent product quality. The fluidization process prevents agglomeration of particles and promotes even drying throughout the material. Temperature and airflow can be precisely controlled to optimize the drying conditions based on the specific requirements of the lithium hydroxide being processed.Expand Specific Solutions04 Microwave and infrared drying methods

Advanced drying technologies such as microwave and infrared heating offer advantages for lithium hydroxide drying by providing volumetric and selective heating. These methods can significantly reduce drying time and energy consumption while improving yield. Microwave drying heats the material from within, while infrared drying provides surface heating. Both methods can be precisely controlled to prevent overheating and maintain the chemical integrity of lithium hydroxide. These technologies are particularly suitable for processing heat-sensitive lithium compounds.Expand Specific Solutions05 Multi-stage drying processes and yield optimization

Multi-stage drying processes combine different drying techniques in sequence to optimize lithium hydroxide yield and quality. These processes often involve pre-drying, main drying, and final drying stages with carefully controlled temperature and humidity profiles. By implementing process monitoring and control systems, parameters can be adjusted in real-time to maximize yield while maintaining product specifications. Recovery systems can also be integrated to capture and recycle lithium-containing vapors or particles that might otherwise be lost during the drying process.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The lithium hydroxide drying market is in a growth phase, driven by increasing demand for high-purity lithium compounds for battery applications. The global market is expanding rapidly with projections exceeding $2 billion by 2025. Technologically, the field shows varying maturity levels across different drying methods, with companies pursuing both conventional and innovative approaches. Key players include established battery material producers like LG Chem, LG Energy Solution, and SK Innovation focusing on efficiency optimization, while specialized lithium producers such as Tianqi Lithium and General Lithium concentrate on yield maximization. Research institutions including Pukyong National University and Korea Institute of Geoscience & Mineral Resources are advancing novel drying technologies. BYD and Nissan represent automotive manufacturers with vertical integration interests, seeking to secure high-quality lithium hydroxide supply chains.

SK Innovation Co., Ltd.

Technical Solution: SK Innovation has developed a proprietary vacuum drying technology for lithium hydroxide production that operates at lower temperatures (around 120-150°C) compared to conventional methods. Their process incorporates a multi-stage vacuum chamber system with precise humidity and temperature controls to remove moisture content while minimizing energy consumption. The technology employs a continuous feed mechanism that allows for consistent product quality with moisture content below 0.5%. SK Innovation's method includes a pre-drying phase using fluidized bed technology to remove bulk moisture before the vacuum drying stage, which has shown to increase throughput by approximately 30% compared to traditional batch drying methods. The company has also implemented heat recovery systems that capture and reuse thermal energy from the drying process, reducing overall energy requirements by up to 25%.

Strengths: Lower energy consumption compared to conventional methods; higher throughput with continuous processing; better product consistency with uniform moisture removal; reduced carbon footprint through heat recovery systems. Weaknesses: Higher initial capital investment; requires specialized maintenance expertise; system complexity may lead to more potential failure points.

Tianqi Lithium Corp.

Technical Solution: Tianqi Lithium has pioneered an advanced spray drying technology specifically optimized for lithium hydroxide production. Their system atomizes lithium hydroxide solution into fine droplets that are dried in a controlled hot air environment at temperatures between 150-180°C. This method creates spherical particles with consistent size distribution (typically 10-50 microns) and extremely low moisture content (<0.3%). The company's proprietary process includes a multi-cyclone separation system that recovers over 99% of the product while minimizing dust formation. Tianqi has integrated real-time moisture monitoring using near-infrared spectroscopy that automatically adjusts drying parameters to maintain optimal conditions regardless of feed variations. Their technology also incorporates a two-stage heat application system that gradually removes moisture to prevent thermal degradation of the lithium hydroxide crystal structure, which has been shown to improve final product purity by reducing carbonate formation during the drying process.

Strengths: Excellent particle size control and morphology; very low final moisture content; high recovery rates; automated process control for consistent quality; reduced product degradation. Weaknesses: Higher energy consumption compared to some alternative methods; requires sophisticated control systems; atomization nozzles require regular maintenance to prevent clogging.

Critical Patents and Technical Literature Review

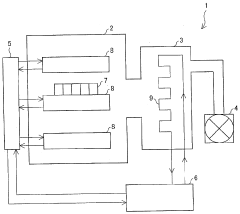

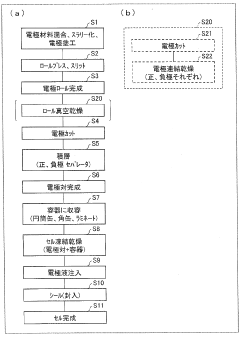

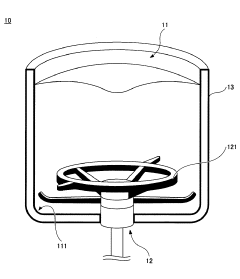

Method for drying electrode pair, method for manufacturing lithium-ion secondary battery, method for manufacturing electric double-layer capacitor, and method for manufacturing lithium-ion capacitor

PatentWO2012043398A1

Innovation

- Implementing a freeze-drying method that sublimates ice into water vapor under high vacuum, reducing drying time and temperature, thereby minimizing separator wrinkling and enhancing yield while lowering manufacturing costs.

Manufacturing method of dried lithium hydroxide

PatentActiveJP2019064911A

Innovation

- A method using a tumbling agitator with a cylindrical stirring chamber, stirring blades, and heating means to dry lithium hydroxide hydrate by maintaining a specific height of contact with the chamber's side wall and controlling the stirring blade's rotation within a defined range to enhance dehydration efficiency.

Energy Efficiency Considerations in Drying Processes

Energy efficiency represents a critical factor in the evaluation and selection of lithium hydroxide drying methods, directly impacting both operational costs and environmental sustainability. Traditional drying processes for lithium hydroxide typically consume substantial amounts of energy, with conventional thermal drying methods requiring temperatures between 105-150°C maintained over extended periods. This significant energy expenditure not only increases production costs but also contributes to the carbon footprint of lithium hydroxide manufacturing.

Comparative analysis of energy consumption across different drying technologies reveals notable variations. Conventional hot air drying systems demonstrate energy efficiencies of approximately 35-45%, with substantial heat losses through exhaust gases. In contrast, vacuum drying technologies achieve efficiencies of 55-65% by operating at lower temperatures while accelerating moisture removal through reduced pressure environments.

Microwave and infrared drying technologies offer promising alternatives with energy efficiencies potentially reaching 70-80%. These methods deliver energy directly to water molecules, minimizing heat transfer losses associated with conventional systems. Recent innovations in hybrid drying systems, combining multiple technologies such as microwave-assisted vacuum drying, have demonstrated energy savings of 25-40% compared to traditional methods while maintaining or improving lithium hydroxide quality.

Heat recovery systems represent another significant opportunity for energy optimization. Implementation of heat exchangers to capture and reuse thermal energy from exhaust streams can improve overall system efficiency by 15-25%. Advanced process control systems utilizing real-time moisture monitoring further enhance energy efficiency by optimizing drying parameters dynamically, preventing unnecessary energy expenditure through overdrying.

The economic implications of energy efficiency improvements are substantial. Industry data suggests that energy costs typically constitute 20-30% of operational expenses in lithium hydroxide production. A 20% reduction in energy consumption through improved drying technology can translate to approximately 4-6% decrease in overall production costs, representing significant savings at commercial scale.

From a sustainability perspective, energy-efficient drying technologies directly contribute to reduced greenhouse gas emissions. For facilities producing 10,000 tons of lithium hydroxide annually, implementing high-efficiency drying systems can potentially reduce carbon emissions by 1,500-2,500 tons CO₂ equivalent per year, depending on the energy source utilized.

Future developments in energy-efficient drying for lithium hydroxide production are likely to focus on renewable energy integration, advanced heat pump technologies, and artificial intelligence-driven process optimization. These innovations promise to further reduce the energy intensity of lithium hydroxide production, aligning with global sustainability goals while enhancing economic competitiveness in the rapidly expanding lithium market.

Comparative analysis of energy consumption across different drying technologies reveals notable variations. Conventional hot air drying systems demonstrate energy efficiencies of approximately 35-45%, with substantial heat losses through exhaust gases. In contrast, vacuum drying technologies achieve efficiencies of 55-65% by operating at lower temperatures while accelerating moisture removal through reduced pressure environments.

Microwave and infrared drying technologies offer promising alternatives with energy efficiencies potentially reaching 70-80%. These methods deliver energy directly to water molecules, minimizing heat transfer losses associated with conventional systems. Recent innovations in hybrid drying systems, combining multiple technologies such as microwave-assisted vacuum drying, have demonstrated energy savings of 25-40% compared to traditional methods while maintaining or improving lithium hydroxide quality.

Heat recovery systems represent another significant opportunity for energy optimization. Implementation of heat exchangers to capture and reuse thermal energy from exhaust streams can improve overall system efficiency by 15-25%. Advanced process control systems utilizing real-time moisture monitoring further enhance energy efficiency by optimizing drying parameters dynamically, preventing unnecessary energy expenditure through overdrying.

The economic implications of energy efficiency improvements are substantial. Industry data suggests that energy costs typically constitute 20-30% of operational expenses in lithium hydroxide production. A 20% reduction in energy consumption through improved drying technology can translate to approximately 4-6% decrease in overall production costs, representing significant savings at commercial scale.

From a sustainability perspective, energy-efficient drying technologies directly contribute to reduced greenhouse gas emissions. For facilities producing 10,000 tons of lithium hydroxide annually, implementing high-efficiency drying systems can potentially reduce carbon emissions by 1,500-2,500 tons CO₂ equivalent per year, depending on the energy source utilized.

Future developments in energy-efficient drying for lithium hydroxide production are likely to focus on renewable energy integration, advanced heat pump technologies, and artificial intelligence-driven process optimization. These innovations promise to further reduce the energy intensity of lithium hydroxide production, aligning with global sustainability goals while enhancing economic competitiveness in the rapidly expanding lithium market.

Environmental Impact and Sustainability Assessment

The environmental footprint of lithium hydroxide drying processes represents a critical consideration in sustainable battery material production. Conventional thermal drying methods typically consume substantial energy, with rotary kilns and flash dryers operating at temperatures between 150-300°C, resulting in significant carbon emissions. Recent life cycle assessments indicate that energy consumption during drying can account for 15-20% of the total environmental impact in lithium hydroxide production chains.

Water usage presents another environmental challenge, particularly for spray drying systems that may require additional water for operation. In water-stressed regions where lithium processing often occurs, this creates competing demands for limited resources. Vacuum drying technologies have demonstrated potential to reduce water consumption by 30-40% compared to conventional methods, offering a promising alternative in environmentally sensitive areas.

Emissions profiles vary significantly across drying technologies. Thermal methods typically generate both direct emissions from fuel combustion and indirect emissions from electricity consumption. Microwave and infrared drying systems, while more energy-efficient, still contribute to indirect emissions through electricity usage. Recent industry data suggests that transitioning from conventional to advanced drying technologies could reduce greenhouse gas emissions by 25-35% per ton of lithium hydroxide produced.

Waste generation also differs between methods. Fluidized bed dryers may produce particulate matter requiring additional filtration systems, while vacuum and freeze-drying approaches typically generate minimal solid waste. The dust collection efficiency of different systems ranges from 85% to 99%, with newer technologies incorporating advanced filtration to minimize environmental release of lithium-containing particles.

Sustainability certifications are increasingly influencing technology selection, with battery manufacturers demanding materials produced through environmentally responsible processes. The implementation of circular economy principles in drying technology design has emerged as a trend, with heat recovery systems capable of recapturing 40-60% of thermal energy for reuse in the production process.

Regulatory compliance represents another dimension of environmental impact assessment. Jurisdictions with stringent emissions standards may necessitate additional control technologies for certain drying methods, affecting both capital and operational costs. Forward-looking manufacturers are increasingly adopting technologies that exceed current regulatory requirements in anticipation of more stringent future standards.

The environmental payback period—the time required for environmental benefits to offset the impacts of manufacturing and installing new drying equipment—varies from 2-5 years depending on technology type and operational parameters. This metric has become increasingly important for companies seeking to demonstrate environmental responsibility throughout their supply chains.

Water usage presents another environmental challenge, particularly for spray drying systems that may require additional water for operation. In water-stressed regions where lithium processing often occurs, this creates competing demands for limited resources. Vacuum drying technologies have demonstrated potential to reduce water consumption by 30-40% compared to conventional methods, offering a promising alternative in environmentally sensitive areas.

Emissions profiles vary significantly across drying technologies. Thermal methods typically generate both direct emissions from fuel combustion and indirect emissions from electricity consumption. Microwave and infrared drying systems, while more energy-efficient, still contribute to indirect emissions through electricity usage. Recent industry data suggests that transitioning from conventional to advanced drying technologies could reduce greenhouse gas emissions by 25-35% per ton of lithium hydroxide produced.

Waste generation also differs between methods. Fluidized bed dryers may produce particulate matter requiring additional filtration systems, while vacuum and freeze-drying approaches typically generate minimal solid waste. The dust collection efficiency of different systems ranges from 85% to 99%, with newer technologies incorporating advanced filtration to minimize environmental release of lithium-containing particles.

Sustainability certifications are increasingly influencing technology selection, with battery manufacturers demanding materials produced through environmentally responsible processes. The implementation of circular economy principles in drying technology design has emerged as a trend, with heat recovery systems capable of recapturing 40-60% of thermal energy for reuse in the production process.

Regulatory compliance represents another dimension of environmental impact assessment. Jurisdictions with stringent emissions standards may necessitate additional control technologies for certain drying methods, affecting both capital and operational costs. Forward-looking manufacturers are increasingly adopting technologies that exceed current regulatory requirements in anticipation of more stringent future standards.

The environmental payback period—the time required for environmental benefits to offset the impacts of manufacturing and installing new drying equipment—varies from 2-5 years depending on technology type and operational parameters. This metric has become increasingly important for companies seeking to demonstrate environmental responsibility throughout their supply chains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!