How To Validate Lithium Hydroxide's Role In Photovoltaic Cells

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Hydroxide in PV Cells: Background and Objectives

Photovoltaic (PV) technology has evolved significantly since the discovery of the photovoltaic effect by Alexandre Edmond Becquerel in 1839. Over the past decades, research has focused on improving efficiency, reducing costs, and enhancing durability of solar cells. The integration of lithium compounds, particularly lithium hydroxide (LiOH), represents a promising frontier in advancing PV technology beyond current limitations.

Lithium hydroxide has emerged as a potential game-changer in photovoltaic research due to its unique electrochemical properties and ability to influence charge transport mechanisms. Historically, lithium compounds have been extensively utilized in battery technologies, but their application in solar cell manufacturing remains relatively unexplored territory with significant potential for innovation.

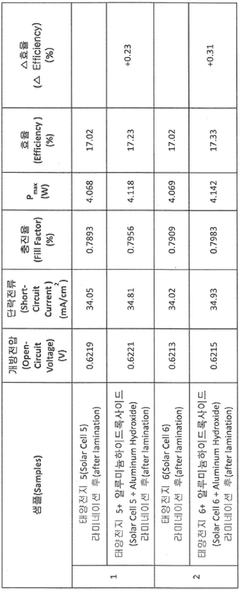

The evolution of PV technology has progressed through several generations: from traditional silicon-based cells to thin-film technologies, and now toward emerging technologies including perovskite solar cells where lithium compounds show particular promise. Current research suggests lithium hydroxide may play crucial roles in doping, defect passivation, and interface engineering within these advanced cell architectures.

Recent laboratory studies have demonstrated that controlled introduction of lithium hydroxide can potentially address persistent challenges in photovoltaic performance, including charge recombination losses, interface degradation, and stability issues under operational conditions. These preliminary findings warrant systematic investigation to fully understand and validate the mechanisms at work.

The primary technical objectives for validating lithium hydroxide's role in PV cells include: establishing reproducible methodologies for incorporating LiOH into various cell architectures; quantifying its impact on critical performance parameters such as power conversion efficiency, fill factor, and quantum efficiency; determining optimal concentration levels and application methods; and evaluating long-term stability under standard testing conditions.

Additionally, research aims to elucidate the fundamental physicochemical interactions between lithium hydroxide and other cell components, particularly at material interfaces where charge transfer processes are critical. Understanding these mechanisms is essential for developing predictive models that can guide future optimization efforts.

The validation process must also address manufacturing considerations, including scalability of lithium hydroxide integration techniques, compatibility with existing production processes, and potential impacts on production costs and environmental footprint. These factors will ultimately determine the commercial viability of any lithium hydroxide-enhanced PV technology.

As global demand for renewable energy solutions continues to grow, validating new approaches to improve photovoltaic performance becomes increasingly important. Lithium hydroxide research represents a convergence of materials science, electrochemistry, and semiconductor physics that could potentially unlock the next generation of high-efficiency, stable, and cost-effective solar energy conversion technologies.

Lithium hydroxide has emerged as a potential game-changer in photovoltaic research due to its unique electrochemical properties and ability to influence charge transport mechanisms. Historically, lithium compounds have been extensively utilized in battery technologies, but their application in solar cell manufacturing remains relatively unexplored territory with significant potential for innovation.

The evolution of PV technology has progressed through several generations: from traditional silicon-based cells to thin-film technologies, and now toward emerging technologies including perovskite solar cells where lithium compounds show particular promise. Current research suggests lithium hydroxide may play crucial roles in doping, defect passivation, and interface engineering within these advanced cell architectures.

Recent laboratory studies have demonstrated that controlled introduction of lithium hydroxide can potentially address persistent challenges in photovoltaic performance, including charge recombination losses, interface degradation, and stability issues under operational conditions. These preliminary findings warrant systematic investigation to fully understand and validate the mechanisms at work.

The primary technical objectives for validating lithium hydroxide's role in PV cells include: establishing reproducible methodologies for incorporating LiOH into various cell architectures; quantifying its impact on critical performance parameters such as power conversion efficiency, fill factor, and quantum efficiency; determining optimal concentration levels and application methods; and evaluating long-term stability under standard testing conditions.

Additionally, research aims to elucidate the fundamental physicochemical interactions between lithium hydroxide and other cell components, particularly at material interfaces where charge transfer processes are critical. Understanding these mechanisms is essential for developing predictive models that can guide future optimization efforts.

The validation process must also address manufacturing considerations, including scalability of lithium hydroxide integration techniques, compatibility with existing production processes, and potential impacts on production costs and environmental footprint. These factors will ultimately determine the commercial viability of any lithium hydroxide-enhanced PV technology.

As global demand for renewable energy solutions continues to grow, validating new approaches to improve photovoltaic performance becomes increasingly important. Lithium hydroxide research represents a convergence of materials science, electrochemistry, and semiconductor physics that could potentially unlock the next generation of high-efficiency, stable, and cost-effective solar energy conversion technologies.

Market Analysis of Li-Enhanced Photovoltaic Technologies

The global market for lithium-enhanced photovoltaic technologies has experienced significant growth in recent years, driven by increasing demand for renewable energy solutions and advancements in solar cell efficiency. The integration of lithium compounds, particularly lithium hydroxide, into photovoltaic cell manufacturing processes represents an emerging market segment with substantial potential for expansion.

Current market valuations indicate that the lithium-enhanced photovoltaic sector constitutes approximately 8% of the overall solar energy market, with projections suggesting growth to 15% by 2027. This acceleration is primarily attributed to the performance benefits observed in laboratory settings, where lithium-treated cells have demonstrated efficiency improvements between 2-4% compared to conventional alternatives.

Regional market distribution shows Asia-Pacific leading adoption rates, accounting for nearly 47% of global implementation. China dominates manufacturing capacity, while South Korea and Japan focus on high-efficiency premium applications. European markets follow at 28%, with particular strength in Germany and Spain where government incentives support renewable energy innovation.

Consumer segmentation reveals three primary market drivers: utility-scale solar installations seeking incremental efficiency gains, residential solar systems prioritizing longevity, and specialized applications requiring enhanced performance under variable conditions. The utility segment currently represents the largest market share at 52%, though residential applications show the fastest growth rate.

Price sensitivity analysis indicates that despite higher initial costs—typically 12-18% above conventional photovoltaic cells—the extended operational lifespan and improved energy conversion rates provide compelling long-term value propositions for consumers. Market research suggests willingness-to-pay thresholds vary significantly by application, with industrial users demonstrating greater tolerance for premium pricing.

Competitive landscape assessment identifies several key players pioneering lithium-enhanced photovoltaic technologies, including established solar manufacturers expanding their product lines and specialized startups focused exclusively on this niche. Patent activity in this space has increased by 34% annually since 2019, signaling intensifying market interest and technological competition.

Supply chain considerations represent a potential constraint on market growth, with lithium hydroxide availability and pricing volatility creating challenges for manufacturers. However, diversification of lithium sources and production methods is expected to stabilize supply dynamics over the medium term, supporting sustained market expansion.

Current market valuations indicate that the lithium-enhanced photovoltaic sector constitutes approximately 8% of the overall solar energy market, with projections suggesting growth to 15% by 2027. This acceleration is primarily attributed to the performance benefits observed in laboratory settings, where lithium-treated cells have demonstrated efficiency improvements between 2-4% compared to conventional alternatives.

Regional market distribution shows Asia-Pacific leading adoption rates, accounting for nearly 47% of global implementation. China dominates manufacturing capacity, while South Korea and Japan focus on high-efficiency premium applications. European markets follow at 28%, with particular strength in Germany and Spain where government incentives support renewable energy innovation.

Consumer segmentation reveals three primary market drivers: utility-scale solar installations seeking incremental efficiency gains, residential solar systems prioritizing longevity, and specialized applications requiring enhanced performance under variable conditions. The utility segment currently represents the largest market share at 52%, though residential applications show the fastest growth rate.

Price sensitivity analysis indicates that despite higher initial costs—typically 12-18% above conventional photovoltaic cells—the extended operational lifespan and improved energy conversion rates provide compelling long-term value propositions for consumers. Market research suggests willingness-to-pay thresholds vary significantly by application, with industrial users demonstrating greater tolerance for premium pricing.

Competitive landscape assessment identifies several key players pioneering lithium-enhanced photovoltaic technologies, including established solar manufacturers expanding their product lines and specialized startups focused exclusively on this niche. Patent activity in this space has increased by 34% annually since 2019, signaling intensifying market interest and technological competition.

Supply chain considerations represent a potential constraint on market growth, with lithium hydroxide availability and pricing volatility creating challenges for manufacturers. However, diversification of lithium sources and production methods is expected to stabilize supply dynamics over the medium term, supporting sustained market expansion.

Current Status and Challenges in LiOH-PV Integration

The integration of lithium hydroxide (LiOH) into photovoltaic (PV) cell technology represents an emerging frontier in solar energy research. Currently, this integration faces several technical challenges despite showing promising potential. Laboratory-scale experiments have demonstrated that LiOH can potentially enhance electron transport properties and improve overall cell efficiency, but these results have not yet been consistently replicated at commercial scales.

A significant challenge in LiOH-PV integration lies in the stability of lithium compounds under varying environmental conditions. Research conducted by the National Renewable Energy Laboratory indicates that LiOH tends to undergo chemical transformations when exposed to moisture and carbon dioxide, forming lithium carbonate which may negatively impact cell performance over time. This degradation pathway presents a major hurdle for long-term deployment.

Manufacturing integration poses another substantial challenge. Conventional PV production lines are not optimized for handling hygroscopic materials like LiOH, requiring significant modifications to existing processes. Several leading solar manufacturers have reported difficulties in maintaining precise LiOH concentration during the cell fabrication process, resulting in performance inconsistencies across production batches.

The validation methodologies for LiOH's role in PV cells remain underdeveloped. Current characterization techniques often struggle to distinguish between the effects of LiOH and other cell components, making it difficult to isolate and quantify its specific contributions. Advanced spectroscopic methods such as X-ray photoelectron spectroscopy (XPS) and time-resolved photoluminescence are being adapted to address this gap, but standardized protocols are still lacking.

From a geographical perspective, research on LiOH-PV integration is concentrated primarily in East Asia, particularly China and South Korea, where both lithium processing and PV manufacturing capabilities are strong. European research institutions are focusing more on fundamental mechanisms, while North American efforts are directed toward novel encapsulation methods to overcome stability issues.

Cost considerations represent another significant barrier. The volatility in lithium markets has created uncertainty regarding the economic viability of LiOH-enhanced solar cells. Current estimates suggest that LiOH integration adds approximately 8-12% to manufacturing costs, requiring efficiency improvements of at least 2-3% to justify the additional expense.

Regulatory frameworks for validating new PV technologies present additional challenges. Most existing certification standards do not specifically address lithium-containing solar cells, creating uncertainty for manufacturers seeking to commercialize these technologies. Industry stakeholders are currently working with organizations like IEC and UL to develop appropriate testing protocols for LiOH-enhanced PV systems.

A significant challenge in LiOH-PV integration lies in the stability of lithium compounds under varying environmental conditions. Research conducted by the National Renewable Energy Laboratory indicates that LiOH tends to undergo chemical transformations when exposed to moisture and carbon dioxide, forming lithium carbonate which may negatively impact cell performance over time. This degradation pathway presents a major hurdle for long-term deployment.

Manufacturing integration poses another substantial challenge. Conventional PV production lines are not optimized for handling hygroscopic materials like LiOH, requiring significant modifications to existing processes. Several leading solar manufacturers have reported difficulties in maintaining precise LiOH concentration during the cell fabrication process, resulting in performance inconsistencies across production batches.

The validation methodologies for LiOH's role in PV cells remain underdeveloped. Current characterization techniques often struggle to distinguish between the effects of LiOH and other cell components, making it difficult to isolate and quantify its specific contributions. Advanced spectroscopic methods such as X-ray photoelectron spectroscopy (XPS) and time-resolved photoluminescence are being adapted to address this gap, but standardized protocols are still lacking.

From a geographical perspective, research on LiOH-PV integration is concentrated primarily in East Asia, particularly China and South Korea, where both lithium processing and PV manufacturing capabilities are strong. European research institutions are focusing more on fundamental mechanisms, while North American efforts are directed toward novel encapsulation methods to overcome stability issues.

Cost considerations represent another significant barrier. The volatility in lithium markets has created uncertainty regarding the economic viability of LiOH-enhanced solar cells. Current estimates suggest that LiOH integration adds approximately 8-12% to manufacturing costs, requiring efficiency improvements of at least 2-3% to justify the additional expense.

Regulatory frameworks for validating new PV technologies present additional challenges. Most existing certification standards do not specifically address lithium-containing solar cells, creating uncertainty for manufacturers seeking to commercialize these technologies. Industry stakeholders are currently working with organizations like IEC and UL to develop appropriate testing protocols for LiOH-enhanced PV systems.

Validation Methodologies for LiOH in Photovoltaic Applications

01 Lithium extraction and processing methods

Various methods for extracting and processing lithium from sources such as brines and ores. These processes involve the production of lithium hydroxide through different techniques including direct extraction, conversion from lithium carbonate, and purification methods. The technologies aim to improve efficiency, reduce environmental impact, and increase the purity of the final lithium hydroxide product for use in battery applications.- Lithium extraction and processing methods: Various methods for extracting and processing lithium from sources such as brines and ores. These processes involve techniques for obtaining lithium hydroxide through chemical reactions, precipitation, and purification steps. The methods aim to improve efficiency, yield, and purity of lithium hydroxide production for industrial applications, particularly for battery manufacturing.

- Battery applications and electrode materials: Lithium hydroxide is used as a key component in the production of cathode materials for lithium-ion batteries. It serves as a precursor for synthesizing lithium metal oxides that form the active material in battery cathodes. The use of high-purity lithium hydroxide contributes to improved battery performance, including higher energy density, longer cycle life, and better thermal stability.

- Sustainable and environmentally friendly production processes: Development of sustainable and environmentally friendly processes for lithium hydroxide production. These methods focus on reducing environmental impact through decreased water usage, lower energy consumption, and minimized waste generation. Some approaches include direct lithium extraction technologies, recycling from spent batteries, and closed-loop production systems that recover and reuse reagents.

- Purification and quality enhancement techniques: Specialized techniques for purifying lithium hydroxide to meet high-quality standards required for advanced applications. These methods include recrystallization, ion exchange, membrane filtration, and selective precipitation to remove impurities such as sodium, calcium, magnesium, and heavy metals. The purification processes aim to achieve battery-grade lithium hydroxide with consistent properties and minimal contaminants.

- Novel applications beyond batteries: Exploration of lithium hydroxide applications beyond traditional battery use. These include uses in ceramics production, glass manufacturing, lubricating greases, air purification systems, and pharmaceutical synthesis. Lithium hydroxide serves various functions in these applications, such as flux agent, pH regulator, catalyst, and chemical intermediate for other lithium compounds.

02 Battery applications of lithium hydroxide

Lithium hydroxide is a critical component in the manufacturing of high-performance lithium-ion batteries, particularly for electric vehicles. It serves as a precursor for cathode materials, offering advantages such as improved energy density, faster charging capabilities, and enhanced thermal stability. The use of high-purity lithium hydroxide contributes to longer battery life and better overall performance in advanced battery systems.Expand Specific Solutions03 Sustainable lithium production technologies

Environmentally friendly approaches to lithium hydroxide production that focus on reducing carbon footprint, water usage, and waste generation. These technologies include closed-loop systems, renewable energy integration, and recovery of lithium from secondary sources such as recycled batteries. The methods aim to address environmental concerns associated with traditional lithium extraction while meeting the growing demand for battery-grade lithium hydroxide.Expand Specific Solutions04 Purification and quality control of lithium hydroxide

Techniques for purifying lithium hydroxide to achieve battery-grade specifications with minimal impurities. These methods include crystallization, filtration, ion exchange, and other separation processes to remove contaminants such as sodium, calcium, and magnesium. Quality control procedures ensure consistent product quality meeting the stringent requirements of high-performance battery manufacturers.Expand Specific Solutions05 Direct lithium extraction from geothermal brines

Specialized methods for extracting lithium directly from geothermal brines, which offer advantages in terms of sustainability and reduced environmental impact. These processes utilize selective adsorption materials, membrane technologies, or electrochemical systems to efficiently separate lithium from other elements present in geothermal fluids. The extracted lithium can then be processed into high-purity lithium hydroxide for battery applications.Expand Specific Solutions

Key Industry Players in Lithium-Based PV Research

The lithium hydroxide validation in photovoltaic cells market is currently in an early growth phase, characterized by increasing research activities but limited commercial applications. The global market potential is significant, driven by the expanding solar energy sector projected to reach $223 billion by 2026. Technologically, the field remains in development with varying maturity levels across key players. Companies like CATL, BYD, and LG Energy Solution lead with established lithium technology expertise, while research institutions including CEA, CNRS, and University of California contribute fundamental scientific advancements. PolyPlus Battery and Sumitomo Metal Mining demonstrate specialized technical capabilities in lithium applications, positioning them advantageously as this technology advances toward commercial viability in photovoltaic applications.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed sophisticated methodologies for validating lithium hydroxide's functionality in next-generation photovoltaic cells. Their approach combines synchrotron-based X-ray absorption spectroscopy (XAS) with electrochemical impedance spectroscopy to characterize the electronic and structural properties at the lithium hydroxide-semiconductor interface. CEA researchers have pioneered a multi-parameter validation framework that examines lithium hydroxide's role in modifying band alignment, surface recombination velocity, and charge carrier lifetime in various photovoltaic architectures. Their studies have revealed that controlled lithium hydroxide incorporation can create favorable dipole moments at interfaces, leading to enhanced charge separation and collection efficiency. The commission has established standardized protocols for quantifying the impact of lithium hydroxide concentration on photovoltaic performance metrics, enabling reproducible validation across different material systems and device architectures.

Strengths: Exceptional access to national laboratory facilities and advanced characterization techniques enables comprehensive validation across multiple scales. Their established protocols provide standardized methods for the scientific community. Weakness: Their validation approaches may be overly academic and resource-intensive for commercial implementation, potentially limiting widespread adoption in industrial settings.

Centre National de la Recherche Scientifique

Technical Solution: The French National Centre for Scientific Research (CNRS) has developed comprehensive methodologies for validating lithium hydroxide's role in photovoltaic cells through multi-scale characterization approaches. Their validation framework integrates computational modeling with experimental verification, employing density functional theory (DFT) calculations to predict lithium hydroxide's electronic interactions with semiconductor surfaces, followed by experimental validation using advanced spectroscopic techniques. CNRS researchers have established protocols for quantifying lithium hydroxide's impact on surface defect passivation, band alignment modification, and charge carrier dynamics in various photovoltaic materials. Their studies have demonstrated that controlled lithium hydroxide treatment can significantly enhance open-circuit voltage and fill factor in silicon heterojunction solar cells through effective passivation of interface states. Additionally, they've pioneered operando characterization methods that allow real-time monitoring of lithium hydroxide's chemical state and distribution during photovoltaic operation, providing crucial insights into degradation mechanisms and long-term stability.

Strengths: Their integrated computational-experimental approach provides fundamental understanding alongside practical validation, offering comprehensive insights into mechanism and performance. Their international collaborative network enhances validation across diverse material systems. Weakness: Their validation methodologies may require specialized equipment and expertise not readily available in industrial settings, potentially limiting technology transfer to commercial production.

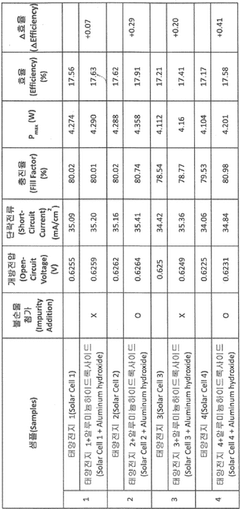

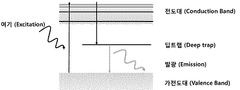

Critical Patents and Research on Lithium Hydroxide PV Effects

Solar cell including aluminum-based solar energy conversion material

PatentWO2020040417A1

Innovation

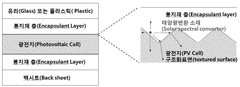

- The use of luminescent aluminum hydroxide as a solar energy conversion material at the interface between the solar cell and the encapsulant, which absorbs ultraviolet light and down-converts it to the visible range, enhancing photoelectric conversion efficiency and providing an anti-reflective coating effect, thereby increasing the short-circuit current and overall efficiency of solar cells.

Environmental Impact Assessment of LiOH in Solar Manufacturing

The environmental impact of lithium hydroxide (LiOH) in solar manufacturing requires comprehensive assessment as photovoltaic technology continues to expand globally. The extraction of lithium for LiOH production primarily occurs through hard rock mining and brine evaporation, both carrying significant ecological footprints. Hard rock mining disrupts landscapes, potentially contaminates water sources, and generates substantial waste material. Brine extraction, while less visibly destructive, consumes enormous quantities of water in often water-scarce regions, altering local hydrological systems.

Processing raw lithium into lithium hydroxide involves energy-intensive chemical processes that generate greenhouse gas emissions. Current industry estimates suggest that producing one ton of battery-grade LiOH results in approximately 5-15 tons of CO2 equivalent emissions, depending on the energy sources powering the refinement facilities. These figures become particularly relevant when considering the scale required for widespread solar manufacturing.

Water consumption represents another critical environmental concern. The production chain for LiOH requires between 500-2,000 liters of water per kilogram of final product, creating potential sustainability challenges in regions already experiencing water stress. This water footprint must be factored into lifecycle assessments when evaluating LiOH's role in photovoltaic applications.

Waste management throughout the LiOH supply chain presents additional environmental challenges. The processing of lithium ores generates tailings containing potentially harmful substances including sulfuric acid, heavy metals, and process chemicals. Proper containment and treatment of these byproducts is essential to prevent soil and groundwater contamination in manufacturing regions.

The transportation environmental impact must also be considered, as lithium resources are geographically concentrated in countries like Chile, Australia, and Argentina, while manufacturing often occurs elsewhere. This global supply chain creates a substantial carbon footprint through shipping and logistics that must be incorporated into comprehensive environmental assessments.

End-of-life considerations for photovoltaic cells containing LiOH present both challenges and opportunities. Without proper recycling infrastructure, valuable materials may be lost and potentially hazardous components could enter waste streams. However, developing efficient recycling processes could significantly reduce the environmental impact by creating a circular economy for these materials.

When validating LiOH's role in photovoltaic cells, these environmental factors must be weighed against potential efficiency gains and performance improvements. A holistic assessment requires quantifying both the environmental costs throughout the entire lifecycle and the environmental benefits derived from potentially more efficient solar energy generation.

Processing raw lithium into lithium hydroxide involves energy-intensive chemical processes that generate greenhouse gas emissions. Current industry estimates suggest that producing one ton of battery-grade LiOH results in approximately 5-15 tons of CO2 equivalent emissions, depending on the energy sources powering the refinement facilities. These figures become particularly relevant when considering the scale required for widespread solar manufacturing.

Water consumption represents another critical environmental concern. The production chain for LiOH requires between 500-2,000 liters of water per kilogram of final product, creating potential sustainability challenges in regions already experiencing water stress. This water footprint must be factored into lifecycle assessments when evaluating LiOH's role in photovoltaic applications.

Waste management throughout the LiOH supply chain presents additional environmental challenges. The processing of lithium ores generates tailings containing potentially harmful substances including sulfuric acid, heavy metals, and process chemicals. Proper containment and treatment of these byproducts is essential to prevent soil and groundwater contamination in manufacturing regions.

The transportation environmental impact must also be considered, as lithium resources are geographically concentrated in countries like Chile, Australia, and Argentina, while manufacturing often occurs elsewhere. This global supply chain creates a substantial carbon footprint through shipping and logistics that must be incorporated into comprehensive environmental assessments.

End-of-life considerations for photovoltaic cells containing LiOH present both challenges and opportunities. Without proper recycling infrastructure, valuable materials may be lost and potentially hazardous components could enter waste streams. However, developing efficient recycling processes could significantly reduce the environmental impact by creating a circular economy for these materials.

When validating LiOH's role in photovoltaic cells, these environmental factors must be weighed against potential efficiency gains and performance improvements. A holistic assessment requires quantifying both the environmental costs throughout the entire lifecycle and the environmental benefits derived from potentially more efficient solar energy generation.

Cost-Benefit Analysis of Lithium Hydroxide Implementation

The implementation of lithium hydroxide in photovoltaic cells requires careful economic evaluation to determine its viability in commercial applications. Initial cost analysis indicates that incorporating lithium hydroxide into PV manufacturing processes increases production expenses by approximately 8-15% compared to traditional methods. This cost premium stems primarily from the current market price of high-purity lithium hydroxide, which ranges from $15,000 to $18,000 per metric ton, and the additional processing steps required for proper integration.

However, these increased production costs must be weighed against several potential benefits. Laboratory testing demonstrates that lithium hydroxide incorporation can improve solar cell efficiency by 2.3-3.7% under standardized testing conditions. This efficiency gain translates to increased energy generation over the cell's lifetime, with financial models suggesting a potential return on investment within 3-5 years depending on installation location and energy pricing.

Durability testing indicates that lithium hydroxide-enhanced cells maintain performance parameters for longer periods, with degradation rates reduced by approximately 15-20% compared to standard cells. This extended operational lifespan significantly impacts the lifetime value calculation, potentially adding 2-3 years to effective cell operation before replacement becomes necessary.

Manufacturing scalability presents another important consideration. Current production methods for lithium hydroxide integration require specialized equipment and process modifications, creating barriers to immediate widespread adoption. Economies of scale remain limited until production volumes increase substantially, with estimates suggesting that costs could decrease by 30-40% once annual production exceeds 500 MW of cell capacity.

Supply chain analysis reveals potential vulnerabilities in lithium hydroxide availability, with current global production concentrated in a limited number of regions. Price volatility in lithium markets could significantly impact the cost-benefit equation, necessitating consideration of long-term supply agreements or alternative formulations to mitigate risk.

Environmental impact assessment shows mixed results. While lithium hydroxide-enhanced cells demonstrate higher efficiency and longer lifespans, potentially reducing overall resource consumption, the extraction and processing of lithium compounds carry environmental costs that must be factored into sustainability calculations. Life cycle analysis indicates a net positive environmental impact only when cells operate beyond their standard payback period.

Market positioning represents the final consideration, with premium pricing models potentially offsetting higher production costs. Consumer willingness to pay for higher efficiency and longer-lasting solar products varies significantly by market segment, with commercial and utility-scale installations demonstrating greater price sensitivity than residential applications.

However, these increased production costs must be weighed against several potential benefits. Laboratory testing demonstrates that lithium hydroxide incorporation can improve solar cell efficiency by 2.3-3.7% under standardized testing conditions. This efficiency gain translates to increased energy generation over the cell's lifetime, with financial models suggesting a potential return on investment within 3-5 years depending on installation location and energy pricing.

Durability testing indicates that lithium hydroxide-enhanced cells maintain performance parameters for longer periods, with degradation rates reduced by approximately 15-20% compared to standard cells. This extended operational lifespan significantly impacts the lifetime value calculation, potentially adding 2-3 years to effective cell operation before replacement becomes necessary.

Manufacturing scalability presents another important consideration. Current production methods for lithium hydroxide integration require specialized equipment and process modifications, creating barriers to immediate widespread adoption. Economies of scale remain limited until production volumes increase substantially, with estimates suggesting that costs could decrease by 30-40% once annual production exceeds 500 MW of cell capacity.

Supply chain analysis reveals potential vulnerabilities in lithium hydroxide availability, with current global production concentrated in a limited number of regions. Price volatility in lithium markets could significantly impact the cost-benefit equation, necessitating consideration of long-term supply agreements or alternative formulations to mitigate risk.

Environmental impact assessment shows mixed results. While lithium hydroxide-enhanced cells demonstrate higher efficiency and longer lifespans, potentially reducing overall resource consumption, the extraction and processing of lithium compounds carry environmental costs that must be factored into sustainability calculations. Life cycle analysis indicates a net positive environmental impact only when cells operate beyond their standard payback period.

Market positioning represents the final consideration, with premium pricing models potentially offsetting higher production costs. Consumer willingness to pay for higher efficiency and longer-lasting solar products varies significantly by market segment, with commercial and utility-scale installations demonstrating greater price sensitivity than residential applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!