Comparing Lithium Hydroxide Extraction Methods For Sustainability

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Hydroxide Extraction Background and Objectives

Lithium hydroxide has emerged as a critical material in the global transition towards sustainable energy systems, primarily due to its essential role in lithium-ion battery production for electric vehicles and renewable energy storage solutions. The extraction of lithium hydroxide has evolved significantly over the past several decades, transitioning from rudimentary processes to sophisticated methodologies designed to maximize yield while minimizing environmental impact.

Historically, lithium was primarily extracted from hard rock sources such as spodumene through energy-intensive thermal and chemical processes. The 1990s witnessed a paradigm shift with the development of brine-based extraction methods, which offered lower energy requirements but introduced water usage concerns. The technological trajectory has consistently moved toward more efficient and environmentally conscious extraction techniques, reflecting growing awareness of sustainability imperatives.

Current technological trends in lithium hydroxide extraction focus on reducing carbon footprints, minimizing water consumption, and decreasing chemical usage while maintaining economic viability. Direct lithium extraction (DLE) technologies represent the cutting edge of this evolution, promising significantly reduced environmental impacts compared to traditional methods. Additionally, advancements in green chemistry approaches and closed-loop systems are gaining momentum in research and development circles.

The primary objective of comparing lithium hydroxide extraction methods for sustainability is to identify and develop processes that balance economic feasibility with environmental responsibility. This involves comprehensive assessment of energy consumption, water usage, land disturbance, chemical requirements, and waste generation across different extraction methodologies. The ultimate goal is to establish extraction protocols that support the growing demand for lithium hydroxide while aligning with global sustainability targets.

Secondary objectives include quantifying the life-cycle environmental impacts of various extraction methods, identifying opportunities for process optimization, and developing standardized metrics for sustainability assessment in lithium extraction. These objectives are increasingly important as lithium demand is projected to increase by 40-fold by 2040, according to the International Energy Agency, creating urgent need for sustainable supply chains.

The technological landscape is further complicated by geographical variations in lithium resources, with South America's lithium triangle, Australia's hard rock deposits, and emerging resources in North America and Europe each requiring tailored extraction approaches. This diversity necessitates a nuanced understanding of how different extraction methods perform under varying geological and environmental conditions.

Historically, lithium was primarily extracted from hard rock sources such as spodumene through energy-intensive thermal and chemical processes. The 1990s witnessed a paradigm shift with the development of brine-based extraction methods, which offered lower energy requirements but introduced water usage concerns. The technological trajectory has consistently moved toward more efficient and environmentally conscious extraction techniques, reflecting growing awareness of sustainability imperatives.

Current technological trends in lithium hydroxide extraction focus on reducing carbon footprints, minimizing water consumption, and decreasing chemical usage while maintaining economic viability. Direct lithium extraction (DLE) technologies represent the cutting edge of this evolution, promising significantly reduced environmental impacts compared to traditional methods. Additionally, advancements in green chemistry approaches and closed-loop systems are gaining momentum in research and development circles.

The primary objective of comparing lithium hydroxide extraction methods for sustainability is to identify and develop processes that balance economic feasibility with environmental responsibility. This involves comprehensive assessment of energy consumption, water usage, land disturbance, chemical requirements, and waste generation across different extraction methodologies. The ultimate goal is to establish extraction protocols that support the growing demand for lithium hydroxide while aligning with global sustainability targets.

Secondary objectives include quantifying the life-cycle environmental impacts of various extraction methods, identifying opportunities for process optimization, and developing standardized metrics for sustainability assessment in lithium extraction. These objectives are increasingly important as lithium demand is projected to increase by 40-fold by 2040, according to the International Energy Agency, creating urgent need for sustainable supply chains.

The technological landscape is further complicated by geographical variations in lithium resources, with South America's lithium triangle, Australia's hard rock deposits, and emerging resources in North America and Europe each requiring tailored extraction approaches. This diversity necessitates a nuanced understanding of how different extraction methods perform under varying geological and environmental conditions.

Market Demand Analysis for Sustainable Lithium Hydroxide

The global lithium hydroxide market is experiencing unprecedented growth, primarily driven by the rapid expansion of the electric vehicle (EV) industry. Market research indicates that the global demand for lithium hydroxide is projected to reach 400,000 tons by 2025, with a compound annual growth rate exceeding 15% between 2021 and 2026. This surge is directly correlated with the increasing adoption of high-nickel cathode materials in EV batteries, which require high-purity lithium hydroxide rather than lithium carbonate.

Sustainability concerns are reshaping market preferences, with consumers and manufacturers increasingly prioritizing environmentally responsible production methods. A recent industry survey revealed that 78% of EV manufacturers now consider the environmental footprint of their battery supply chain as a critical factor in procurement decisions. This shift has created a premium market segment for sustainably produced lithium hydroxide, with price differentials of up to 10-15% compared to conventionally produced materials.

Regional market analysis shows varying demand patterns. Asia-Pacific, particularly China, remains the dominant consumer of lithium hydroxide, accounting for approximately 65% of global demand. However, European markets are showing the fastest growth rates as the region aggressively pursues electrification targets under the European Green Deal. North American demand is also accelerating following recent policy initiatives like the Inflation Reduction Act, which provides incentives for domestic battery production and sustainable supply chains.

The industrial application landscape for lithium hydroxide extends beyond EVs. While battery applications represent the largest market segment (approximately 80% of demand), other growing applications include lubricants, ceramics, and specialized chemical processes. These diversified applications provide market resilience and additional growth vectors for sustainable lithium hydroxide producers.

Supply chain considerations are increasingly influencing market dynamics. The COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting many regions to develop domestic lithium processing capabilities. This trend toward supply chain regionalization is creating new market opportunities for sustainable extraction technologies that can operate economically at smaller scales and with lower environmental impacts than traditional methods.

Pricing trends indicate strong market support for premium sustainable products. Lithium hydroxide produced through direct lithium extraction (DLE) methods with lower water usage and carbon footprints commands price premiums of 5-8% over conventionally produced material. This price differential is expected to widen as carbon pricing mechanisms and environmental regulations become more stringent globally.

Consumer and regulatory pressures are converging to create strong market pull for sustainable lithium hydroxide. Battery manufacturers are increasingly publishing sustainability scorecards and lifecycle assessments, creating transparency that rewards environmentally responsible production methods. This market evolution suggests that sustainability is transitioning from a differentiator to a fundamental requirement for market participation.

Sustainability concerns are reshaping market preferences, with consumers and manufacturers increasingly prioritizing environmentally responsible production methods. A recent industry survey revealed that 78% of EV manufacturers now consider the environmental footprint of their battery supply chain as a critical factor in procurement decisions. This shift has created a premium market segment for sustainably produced lithium hydroxide, with price differentials of up to 10-15% compared to conventionally produced materials.

Regional market analysis shows varying demand patterns. Asia-Pacific, particularly China, remains the dominant consumer of lithium hydroxide, accounting for approximately 65% of global demand. However, European markets are showing the fastest growth rates as the region aggressively pursues electrification targets under the European Green Deal. North American demand is also accelerating following recent policy initiatives like the Inflation Reduction Act, which provides incentives for domestic battery production and sustainable supply chains.

The industrial application landscape for lithium hydroxide extends beyond EVs. While battery applications represent the largest market segment (approximately 80% of demand), other growing applications include lubricants, ceramics, and specialized chemical processes. These diversified applications provide market resilience and additional growth vectors for sustainable lithium hydroxide producers.

Supply chain considerations are increasingly influencing market dynamics. The COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting many regions to develop domestic lithium processing capabilities. This trend toward supply chain regionalization is creating new market opportunities for sustainable extraction technologies that can operate economically at smaller scales and with lower environmental impacts than traditional methods.

Pricing trends indicate strong market support for premium sustainable products. Lithium hydroxide produced through direct lithium extraction (DLE) methods with lower water usage and carbon footprints commands price premiums of 5-8% over conventionally produced material. This price differential is expected to widen as carbon pricing mechanisms and environmental regulations become more stringent globally.

Consumer and regulatory pressures are converging to create strong market pull for sustainable lithium hydroxide. Battery manufacturers are increasingly publishing sustainability scorecards and lifecycle assessments, creating transparency that rewards environmentally responsible production methods. This market evolution suggests that sustainability is transitioning from a differentiator to a fundamental requirement for market participation.

Current Extraction Technologies and Challenges

Lithium hydroxide extraction currently employs several major technologies, each with distinct sustainability implications. The traditional method involves extracting lithium from hard rock spodumene through a process of crushing, roasting at temperatures exceeding 1000°C, acid leaching, purification, and conversion to lithium hydroxide using sodium hydroxide. This energy-intensive process generates significant carbon emissions and produces substantial solid waste, presenting major environmental challenges.

Brine-based extraction, predominantly used in South America's "Lithium Triangle," relies on solar evaporation of lithium-rich brines in large ponds over 12-18 months. While less energy-intensive than hard rock processing, this method consumes 500,000-2,000,000 liters of water per ton of lithium carbonate equivalent, creating water scarcity issues in already arid regions. The process also disrupts local ecosystems and indigenous communities' water access.

Direct lithium extraction (DLE) technologies represent emerging alternatives with promising sustainability profiles. These methods use selective adsorption, ion exchange membranes, or solvent extraction to directly capture lithium ions from brines without extensive evaporation. Early implementations suggest DLE could reduce water consumption by 50-90% while accelerating extraction timeframes to hours or days rather than months.

Recycling technologies for lithium-ion batteries are developing rapidly but face technical and economic barriers. Current hydrometallurgical and pyrometallurgical processes can recover 25-95% of lithium depending on the specific technology, though often at high energy costs and with chemical waste generation.

Key technical challenges across all extraction methods include energy intensity, water consumption, chemical usage, and waste management. The carbon footprint of lithium hydroxide production varies dramatically from 5-15 tons CO2e per ton when using renewable energy to over 15-25 tons CO2e per ton with conventional energy sources.

Geographically, extraction technologies show distinct regional patterns. Hard rock mining dominates in Australia, while brine extraction prevails in South America. North America and Europe are investing heavily in DLE technologies to reduce import dependence, while China leads in processing capacity across all extraction methods.

The industry faces increasing pressure to improve sustainability metrics as lithium demand for electric vehicles and energy storage is projected to grow 4-10 times by 2030. This has accelerated research into closed-loop systems, renewable energy integration, and more efficient extraction chemistries that could significantly reduce environmental impacts.

Brine-based extraction, predominantly used in South America's "Lithium Triangle," relies on solar evaporation of lithium-rich brines in large ponds over 12-18 months. While less energy-intensive than hard rock processing, this method consumes 500,000-2,000,000 liters of water per ton of lithium carbonate equivalent, creating water scarcity issues in already arid regions. The process also disrupts local ecosystems and indigenous communities' water access.

Direct lithium extraction (DLE) technologies represent emerging alternatives with promising sustainability profiles. These methods use selective adsorption, ion exchange membranes, or solvent extraction to directly capture lithium ions from brines without extensive evaporation. Early implementations suggest DLE could reduce water consumption by 50-90% while accelerating extraction timeframes to hours or days rather than months.

Recycling technologies for lithium-ion batteries are developing rapidly but face technical and economic barriers. Current hydrometallurgical and pyrometallurgical processes can recover 25-95% of lithium depending on the specific technology, though often at high energy costs and with chemical waste generation.

Key technical challenges across all extraction methods include energy intensity, water consumption, chemical usage, and waste management. The carbon footprint of lithium hydroxide production varies dramatically from 5-15 tons CO2e per ton when using renewable energy to over 15-25 tons CO2e per ton with conventional energy sources.

Geographically, extraction technologies show distinct regional patterns. Hard rock mining dominates in Australia, while brine extraction prevails in South America. North America and Europe are investing heavily in DLE technologies to reduce import dependence, while China leads in processing capacity across all extraction methods.

The industry faces increasing pressure to improve sustainability metrics as lithium demand for electric vehicles and energy storage is projected to grow 4-10 times by 2030. This has accelerated research into closed-loop systems, renewable energy integration, and more efficient extraction chemistries that could significantly reduce environmental impacts.

Comparative Analysis of Extraction Solutions

01 Direct lithium extraction from brines

Direct lithium extraction (DLE) methods from brines offer sustainable alternatives to traditional evaporation ponds. These techniques use selective adsorption materials or ion exchange resins to extract lithium ions directly from brine solutions with minimal environmental impact. The process reduces water consumption, processing time, and land use compared to conventional methods. Advanced DLE technologies can achieve higher lithium recovery rates while minimizing the use of chemicals and energy.- Direct lithium extraction from brines: Direct lithium extraction (DLE) methods from brines offer sustainable alternatives to traditional evaporation ponds. These techniques use selective adsorption materials, ion exchange resins, or membranes to extract lithium ions directly from brine solutions. DLE significantly reduces water consumption, processing time, and environmental footprint compared to conventional methods. The process can be optimized for different brine compositions and can achieve higher lithium recovery rates while minimizing waste generation.

- Eco-friendly extraction from clay and rock sources: Sustainable methods for extracting lithium from clay and hard rock sources involve innovative leaching techniques that minimize chemical usage and environmental impact. These processes often utilize selective acid leaching, roasting with additives, or water-based extraction systems that reduce energy consumption and waste generation. The methods focus on optimizing lithium recovery while implementing closed-loop systems for reagent recycling and water conservation, making the extraction process more environmentally responsible.

- Water and energy conservation in lithium processing: Advanced lithium hydroxide extraction methods incorporate water and energy conservation techniques to enhance sustainability. These include closed-loop water recycling systems, energy-efficient heating processes, and waste heat recovery mechanisms. By implementing these conservation strategies, operations can significantly reduce freshwater consumption, minimize wastewater discharge, and lower overall energy requirements. Some innovative approaches also utilize renewable energy sources to power extraction facilities, further reducing the carbon footprint of lithium hydroxide production.

- Waste minimization and by-product recovery: Sustainable lithium hydroxide extraction methods focus on minimizing waste generation and maximizing the recovery of valuable by-products. These approaches include selective precipitation techniques, advanced filtration systems, and integrated processing workflows that extract additional minerals such as potassium, magnesium, and boron compounds from the same source material. By converting what would traditionally be waste streams into marketable products, these methods improve the economic viability of lithium extraction while reducing environmental impact and resource consumption.

- Carbon-neutral lithium production technologies: Innovative carbon-neutral lithium production technologies aim to minimize greenhouse gas emissions throughout the extraction and processing chain. These methods incorporate carbon capture systems, utilize renewable energy sources, and implement electrification of traditionally fossil fuel-powered processes. Some approaches also explore direct lithium extraction from geothermal brines, which leverages existing geothermal energy production to power the extraction process. These technologies represent the cutting edge of sustainable lithium hydroxide production, addressing both resource efficiency and climate impact concerns.

02 Eco-friendly processing of lithium-containing minerals

Sustainable methods for processing lithium-containing minerals such as spodumene and lepidolite involve innovative techniques that reduce energy consumption and chemical usage. These processes include optimized roasting conditions, green solvents for leaching, and efficient separation technologies. By minimizing waste generation and implementing closed-loop systems, these methods significantly reduce the environmental footprint of lithium hydroxide production from hard rock sources while maintaining high extraction efficiency.Expand Specific Solutions03 Water conservation and recycling in lithium extraction

Water conservation techniques in lithium extraction processes focus on minimizing freshwater consumption and maximizing water recycling. These methods include advanced filtration systems, closed-loop water circuits, and efficient washing procedures that reduce water requirements. By implementing water recovery systems and treating process water for reuse, these sustainable approaches address one of the most significant environmental concerns in lithium production, particularly in water-scarce regions where many lithium resources are located.Expand Specific Solutions04 Energy-efficient lithium hydroxide conversion processes

Energy-efficient processes for converting lithium compounds to lithium hydroxide utilize innovative technologies that reduce carbon emissions and energy consumption. These methods include low-temperature conversion techniques, renewable energy integration, and optimized reaction conditions. By improving thermal efficiency and implementing heat recovery systems, these processes minimize the carbon footprint of lithium hydroxide production while maintaining product quality and yield, contributing to more sustainable battery supply chains.Expand Specific Solutions05 Waste minimization and by-product recovery

Advanced lithium hydroxide extraction methods focus on waste minimization and valuable by-product recovery to enhance sustainability. These approaches include selective precipitation techniques, impurity removal processes, and methods to recover valuable elements like potassium, magnesium, and boron from process streams. By transforming waste streams into marketable products and implementing circular economy principles, these technologies reduce environmental impact while improving the economic viability of lithium production operations.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The lithium hydroxide extraction market is in a growth phase, with increasing demand driven by the electric vehicle battery sector. Market size is expanding rapidly, expected to reach significant volumes by 2030 as sustainability becomes a key competitive factor. Technologically, various extraction methods show different maturity levels: POSCO Holdings and Sumitomo Metal Mining lead with commercialized direct lithium extraction technologies, while Guangdong Bangpu and General Lithium have advanced recycling processes. Academic institutions like Johns Hopkins University and Cornell University are developing novel sustainable extraction methods. Watercycle Technologies represents emerging innovation with membrane-based extraction systems. Companies like Schlumberger and Idemitsu Kosan are adapting their expertise from adjacent industries to enter this growing market with environmentally optimized processes.

Sumitomo Metal Mining Co. Ltd.

Technical Solution: Sumitomo Metal Mining has developed a sophisticated lithium extraction technology focused on sustainability and efficiency, particularly for processing lithium from diverse sources. Their approach combines solvent extraction and selective precipitation techniques to produce high-purity lithium hydroxide. The company's process begins with an innovative pre-treatment system that removes impurities such as magnesium, calcium, and boron before the main extraction phase, significantly improving the efficiency of subsequent steps[2]. Sumitomo's method employs a proprietary solvent extraction system that selectively captures lithium ions while minimizing reagent consumption. This is followed by a multi-stage purification process that achieves battery-grade lithium hydroxide with 99.9% purity. A key innovation in their technology is the implementation of a closed-loop water and reagent recovery system that recycles approximately 85% of process water and recovers valuable chemicals for reuse[6]. The company has also integrated renewable energy sources into their extraction facilities, with solar power providing up to 30% of the energy requirements at some operations, reducing the carbon footprint of the lithium hydroxide production process.

Strengths: Exceptional product purity, significant water and reagent recycling capabilities, and integration of renewable energy sources. Weaknesses: Complex multi-stage process requiring precise control systems, higher initial capital costs, and potential challenges with scaling to very large production volumes.

POSCO Holdings, Inc.

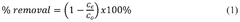

Technical Solution: POSCO Holdings has developed an innovative lithium extraction technology called "PosLX" (POSCO Lithium Extraction), which represents a significant advancement in direct lithium extraction methods. This technology employs a selective adsorption process using proprietary adsorbent materials that can extract lithium directly from various sources including brine, seawater, and recycled batteries. The PosLX process operates at ambient temperature and utilizes a continuous ion exchange system that can achieve lithium recovery rates exceeding 80% while maintaining high purity levels suitable for battery production[1]. POSCO's method dramatically reduces water consumption by over 95% compared to traditional evaporation techniques and can be completed in hours rather than months. The company has successfully demonstrated this technology at commercial scale in Argentina's lithium triangle, processing lithium chloride into battery-grade lithium hydroxide. Their integrated approach includes a closed-loop water system and energy efficiency measures that reduce the carbon footprint by approximately 70% compared to conventional methods[5]. POSCO has also developed complementary technologies for converting the extracted lithium into various forms including lithium hydroxide through an electrochemical process that avoids the use of sodium carbonate.

Strengths: Versatility in handling multiple lithium sources, minimal water consumption, rapid processing time, and significantly reduced carbon footprint. Weaknesses: Higher energy requirements for the electrochemical conversion process, potential challenges with adsorbent material longevity in continuous operations, and sensitivity to certain impurities that may require additional pre-treatment steps.

Critical Patents and Technical Innovations

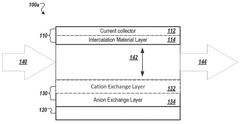

Selective recovery of li from brine solutions & coversion to LIOH in a single electrochemical cell

PatentWO2025106968A1

Innovation

- The use of a bipolar membrane capacitive deionization (BPM-CDI) device, which integrates delithiated lithium iron phosphate (LFP) intercalation electrodes with a bipolar membrane, enables the selective capture and recovery of lithium ions from brine solutions and their subsequent conversion to lithium hydroxide within a single electrochemical cell.

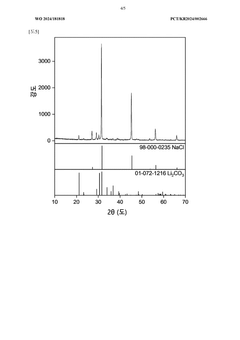

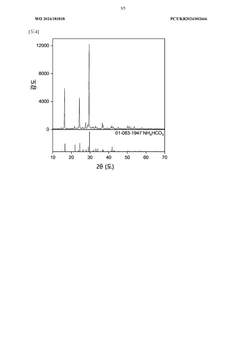

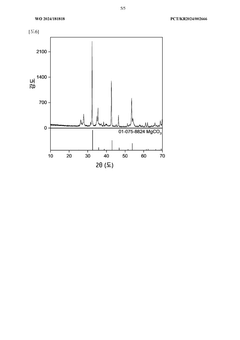

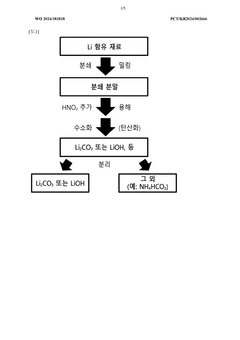

Method for extracting lithium from lithium-containing material

PatentWO2024181818A1

Innovation

- A lithium extraction method using a ruthenium oxide catalyst (HxRuO2) that catalyzes hydrogen, nitric acid, and carbon dioxide at high pressure to produce lithium carbonate or lithium hydroxide, reducing wastewater generation and allowing for the reuse of the catalyst, thereby minimizing chemical usage and environmental impact.

Environmental Impact Assessment

The environmental impact of lithium hydroxide extraction methods represents a critical dimension in evaluating their sustainability. Traditional extraction processes, particularly those involving hard rock mining and extensive brine evaporation, have demonstrated significant ecological footprints across multiple environmental domains.

Water consumption varies dramatically between extraction methods, with brine-based operations in the "Lithium Triangle" of South America consuming between 500,000 to 2 million liters of water per ton of lithium carbonate equivalent (LCE). This extensive water usage in already water-stressed regions has led to documented depletion of aquifers and disruption of local hydrological systems, affecting both ecosystems and indigenous communities.

Carbon emissions profiles differ substantially across extraction technologies. Hard rock mining and processing typically generates 15-20 tons of CO2 per ton of lithium hydroxide produced, primarily due to energy-intensive crushing, heating, and chemical processing requirements. In contrast, advanced direct lithium extraction (DLE) methods demonstrate potential for reducing carbon footprints by 30-60%, particularly when powered by renewable energy sources.

Land disturbance metrics reveal that conventional open-pit mining operations disturb approximately 2.5-3.5 hectares per 1,000 tons of annual production capacity. Brine operations, while less invasive in terms of excavation, require extensive evaporation pond networks covering 1,200-1,500 hectares for similar production volumes. Emerging DLE technologies potentially reduce this footprint by 70-90% through elimination of large evaporation ponds.

Chemical usage and waste generation present additional environmental concerns. Conventional methods typically employ strong acids, bases, and solvents, generating 5-7 tons of waste material per ton of lithium hydroxide. Advanced extraction processes utilizing selective adsorption materials or electrochemical systems demonstrate potential for reducing chemical consumption by 40-60% and waste generation by 30-50%.

Biodiversity impacts vary by extraction location and method. Hard rock mining operations have documented effects on local flora and fauna through habitat fragmentation and potential acid mine drainage. Brine operations in salt flat ecosystems have been associated with disruptions to flamingo breeding patterns and other specialized salt flat species through alteration of the delicate hydrochemical balance.

Rehabilitation potential also differs significantly between methods. While hard rock mining sites require extensive long-term reclamation efforts, newer extraction technologies designed with circular economy principles demonstrate improved potential for site restoration and reduced long-term environmental liability. This includes closed-loop water systems and regenerable extraction media that minimize permanent environmental alterations.

Water consumption varies dramatically between extraction methods, with brine-based operations in the "Lithium Triangle" of South America consuming between 500,000 to 2 million liters of water per ton of lithium carbonate equivalent (LCE). This extensive water usage in already water-stressed regions has led to documented depletion of aquifers and disruption of local hydrological systems, affecting both ecosystems and indigenous communities.

Carbon emissions profiles differ substantially across extraction technologies. Hard rock mining and processing typically generates 15-20 tons of CO2 per ton of lithium hydroxide produced, primarily due to energy-intensive crushing, heating, and chemical processing requirements. In contrast, advanced direct lithium extraction (DLE) methods demonstrate potential for reducing carbon footprints by 30-60%, particularly when powered by renewable energy sources.

Land disturbance metrics reveal that conventional open-pit mining operations disturb approximately 2.5-3.5 hectares per 1,000 tons of annual production capacity. Brine operations, while less invasive in terms of excavation, require extensive evaporation pond networks covering 1,200-1,500 hectares for similar production volumes. Emerging DLE technologies potentially reduce this footprint by 70-90% through elimination of large evaporation ponds.

Chemical usage and waste generation present additional environmental concerns. Conventional methods typically employ strong acids, bases, and solvents, generating 5-7 tons of waste material per ton of lithium hydroxide. Advanced extraction processes utilizing selective adsorption materials or electrochemical systems demonstrate potential for reducing chemical consumption by 40-60% and waste generation by 30-50%.

Biodiversity impacts vary by extraction location and method. Hard rock mining operations have documented effects on local flora and fauna through habitat fragmentation and potential acid mine drainage. Brine operations in salt flat ecosystems have been associated with disruptions to flamingo breeding patterns and other specialized salt flat species through alteration of the delicate hydrochemical balance.

Rehabilitation potential also differs significantly between methods. While hard rock mining sites require extensive long-term reclamation efforts, newer extraction technologies designed with circular economy principles demonstrate improved potential for site restoration and reduced long-term environmental liability. This includes closed-loop water systems and regenerable extraction media that minimize permanent environmental alterations.

Economic Viability of Emerging Technologies

The economic viability of emerging lithium hydroxide extraction technologies represents a critical factor in their potential for widespread adoption. Traditional extraction methods, while established, often carry significant economic burdens including high capital expenditure, substantial energy consumption, and extensive water usage. These factors directly impact operational costs and long-term profitability.

Emerging technologies such as direct lithium extraction (DLE) from brines show promising economic indicators. Initial analyses suggest potential operational cost reductions of 30-50% compared to conventional evaporation pond methods. The capital expenditure for DLE facilities, though initially higher, demonstrates better return on investment over a 5-10 year period due to significantly reduced processing times – from 18 months to potentially just days.

Adsorption-based technologies utilizing novel materials like metal-organic frameworks (MOFs) present another economically viable alternative. These systems require lower energy inputs and can operate continuously rather than batch-wise, improving throughput and reducing labor costs. Economic modeling indicates potential cost advantages of $2,000-3,500 per ton of lithium hydroxide produced compared to traditional methods.

The economic assessment must also consider scaling factors. Many emerging technologies demonstrate excellent performance in laboratory settings but face challenges in commercial-scale implementation. The cost curve typically shows that technologies requiring specialized materials or precise operating conditions may experience diminishing economic returns at larger scales, while those with simpler designs tend to benefit from economies of scale.

Market volatility presents another economic consideration. Technologies with flexible production capabilities that can adjust to market demand fluctuations offer superior economic resilience. Systems that can be temporarily scaled back during low-demand periods without significant standby costs provide strategic advantages in volatile markets.

Recovery rates significantly impact economic viability. While conventional methods typically achieve 40-60% lithium recovery, emerging technologies claim recovery rates of 80-95%. This improvement translates to substantially better resource utilization and higher revenue per extraction site, potentially offsetting higher initial technology investments.

Finally, the economic assessment must incorporate regulatory compliance costs. Technologies designed with sustainability principles from inception typically require fewer modifications to meet evolving environmental regulations, resulting in lower compliance costs over their operational lifetime and better long-term economic performance.

Emerging technologies such as direct lithium extraction (DLE) from brines show promising economic indicators. Initial analyses suggest potential operational cost reductions of 30-50% compared to conventional evaporation pond methods. The capital expenditure for DLE facilities, though initially higher, demonstrates better return on investment over a 5-10 year period due to significantly reduced processing times – from 18 months to potentially just days.

Adsorption-based technologies utilizing novel materials like metal-organic frameworks (MOFs) present another economically viable alternative. These systems require lower energy inputs and can operate continuously rather than batch-wise, improving throughput and reducing labor costs. Economic modeling indicates potential cost advantages of $2,000-3,500 per ton of lithium hydroxide produced compared to traditional methods.

The economic assessment must also consider scaling factors. Many emerging technologies demonstrate excellent performance in laboratory settings but face challenges in commercial-scale implementation. The cost curve typically shows that technologies requiring specialized materials or precise operating conditions may experience diminishing economic returns at larger scales, while those with simpler designs tend to benefit from economies of scale.

Market volatility presents another economic consideration. Technologies with flexible production capabilities that can adjust to market demand fluctuations offer superior economic resilience. Systems that can be temporarily scaled back during low-demand periods without significant standby costs provide strategic advantages in volatile markets.

Recovery rates significantly impact economic viability. While conventional methods typically achieve 40-60% lithium recovery, emerging technologies claim recovery rates of 80-95%. This improvement translates to substantially better resource utilization and higher revenue per extraction site, potentially offsetting higher initial technology investments.

Finally, the economic assessment must incorporate regulatory compliance costs. Technologies designed with sustainability principles from inception typically require fewer modifications to meet evolving environmental regulations, resulting in lower compliance costs over their operational lifetime and better long-term economic performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!