Comparison Of Thermoelectric Generators For Desert Energy Systems

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Generation Background and Objectives

Thermoelectric generation represents a direct energy conversion technology that transforms temperature differentials into electrical power through the Seebeck effect. This phenomenon, discovered in the early 19th century by Thomas Johann Seebeck, has evolved from a scientific curiosity into a practical energy harvesting solution. The historical trajectory of thermoelectric technology shows significant advancements in materials science, particularly in semiconductor physics, which has dramatically improved conversion efficiencies over the past decades.

Desert environments present unique opportunities for thermoelectric generation due to their inherent temperature gradients. The substantial temperature difference between sun-exposed surfaces and shaded areas or underground zones creates ideal conditions for thermoelectric generators (TEGs). These systems can operate continuously, leveraging the natural day-night temperature cycles characteristic of desert climates.

The evolution of thermoelectric materials has progressed through several generations, from early bismuth telluride compounds to advanced nanostructured materials and quantum dot superlattices. Each iteration has aimed to increase the figure of merit (ZT), the primary efficiency indicator for thermoelectric materials. Current research focuses on achieving ZT values above 2.0, which would make thermoelectric generation economically competitive with traditional power generation methods in specific applications.

The primary objective of thermoelectric generation in desert energy systems is to harness otherwise wasted thermal energy and convert it into usable electricity without moving parts or working fluids. This technology aims to complement existing renewable energy solutions by offering reliable power generation during periods when solar photovoltaic systems may be less effective, such as during dust storms or nighttime hours.

Secondary objectives include developing modular, scalable thermoelectric systems that can be deployed in remote desert locations with minimal maintenance requirements. The solid-state nature of TEGs provides exceptional reliability advantages in harsh desert conditions where conventional generation systems might fail due to mechanical wear or dust infiltration.

Looking forward, the technological roadmap for desert thermoelectric systems focuses on improving heat collection mechanisms, optimizing thermal interfaces, and developing more efficient thermoelectric materials specifically designed for high-temperature desert operations. The integration of these systems with other renewable technologies presents a promising pathway toward comprehensive desert energy solutions that maximize energy harvest from the abundant thermal resources available in arid environments.

Desert environments present unique opportunities for thermoelectric generation due to their inherent temperature gradients. The substantial temperature difference between sun-exposed surfaces and shaded areas or underground zones creates ideal conditions for thermoelectric generators (TEGs). These systems can operate continuously, leveraging the natural day-night temperature cycles characteristic of desert climates.

The evolution of thermoelectric materials has progressed through several generations, from early bismuth telluride compounds to advanced nanostructured materials and quantum dot superlattices. Each iteration has aimed to increase the figure of merit (ZT), the primary efficiency indicator for thermoelectric materials. Current research focuses on achieving ZT values above 2.0, which would make thermoelectric generation economically competitive with traditional power generation methods in specific applications.

The primary objective of thermoelectric generation in desert energy systems is to harness otherwise wasted thermal energy and convert it into usable electricity without moving parts or working fluids. This technology aims to complement existing renewable energy solutions by offering reliable power generation during periods when solar photovoltaic systems may be less effective, such as during dust storms or nighttime hours.

Secondary objectives include developing modular, scalable thermoelectric systems that can be deployed in remote desert locations with minimal maintenance requirements. The solid-state nature of TEGs provides exceptional reliability advantages in harsh desert conditions where conventional generation systems might fail due to mechanical wear or dust infiltration.

Looking forward, the technological roadmap for desert thermoelectric systems focuses on improving heat collection mechanisms, optimizing thermal interfaces, and developing more efficient thermoelectric materials specifically designed for high-temperature desert operations. The integration of these systems with other renewable technologies presents a promising pathway toward comprehensive desert energy solutions that maximize energy harvest from the abundant thermal resources available in arid environments.

Desert Energy Market Demand Analysis

The desert energy market is experiencing unprecedented growth driven by increasing global demand for renewable energy solutions. Desert regions, with their abundant solar resources and vast available land, present an ideal environment for energy generation. The global desert energy market was valued at approximately 58 billion USD in 2022 and is projected to reach 112 billion USD by 2030, growing at a CAGR of 8.6% during the forecast period.

Thermoelectric generators (TEGs) represent a niche but growing segment within this market. Unlike traditional photovoltaic systems, TEGs can harness heat differentials that naturally occur in desert environments, particularly during temperature fluctuations between day and night. This capability positions TEGs as complementary technologies to existing solar solutions, potentially increasing overall system efficiency in hybrid installations.

Market research indicates that the demand for TEGs in desert energy systems is primarily driven by three factors: the need for reliable off-grid power solutions, increasing interest in waste heat recovery from concentrated solar power (CSP) plants, and growing requirements for maintenance-free power generation in remote desert installations. The TEG market specific to desert applications was estimated at 420 million USD in 2022, with projections suggesting growth to 1.2 billion USD by 2028.

Regional analysis reveals significant variations in market demand. Middle Eastern countries, particularly the UAE and Saudi Arabia, are leading adopters of advanced desert energy technologies including TEGs, driven by ambitious renewable energy targets under initiatives like Saudi Vision 2030. North African nations, including Morocco and Egypt, are emerging as important markets, particularly for smaller-scale TEG applications in remote communities.

End-user segmentation shows that utility-scale energy producers account for 62% of the desert TEG market, followed by telecommunications infrastructure (18%), remote monitoring stations (12%), and other applications (8%). The telecommunications sector represents the fastest-growing segment, with a CAGR of 11.3%, as network expansion in remote desert regions drives demand for reliable power sources.

Customer needs analysis reveals that desert energy system operators prioritize durability under extreme conditions, minimal maintenance requirements, and integration capabilities with existing renewable infrastructure. TEGs address these needs through their solid-state operation, lack of moving parts, and scalable design. However, efficiency limitations remain a significant concern, with current commercial TEGs typically operating at 5-8% efficiency compared to 15-22% for photovoltaic systems.

Thermoelectric generators (TEGs) represent a niche but growing segment within this market. Unlike traditional photovoltaic systems, TEGs can harness heat differentials that naturally occur in desert environments, particularly during temperature fluctuations between day and night. This capability positions TEGs as complementary technologies to existing solar solutions, potentially increasing overall system efficiency in hybrid installations.

Market research indicates that the demand for TEGs in desert energy systems is primarily driven by three factors: the need for reliable off-grid power solutions, increasing interest in waste heat recovery from concentrated solar power (CSP) plants, and growing requirements for maintenance-free power generation in remote desert installations. The TEG market specific to desert applications was estimated at 420 million USD in 2022, with projections suggesting growth to 1.2 billion USD by 2028.

Regional analysis reveals significant variations in market demand. Middle Eastern countries, particularly the UAE and Saudi Arabia, are leading adopters of advanced desert energy technologies including TEGs, driven by ambitious renewable energy targets under initiatives like Saudi Vision 2030. North African nations, including Morocco and Egypt, are emerging as important markets, particularly for smaller-scale TEG applications in remote communities.

End-user segmentation shows that utility-scale energy producers account for 62% of the desert TEG market, followed by telecommunications infrastructure (18%), remote monitoring stations (12%), and other applications (8%). The telecommunications sector represents the fastest-growing segment, with a CAGR of 11.3%, as network expansion in remote desert regions drives demand for reliable power sources.

Customer needs analysis reveals that desert energy system operators prioritize durability under extreme conditions, minimal maintenance requirements, and integration capabilities with existing renewable infrastructure. TEGs address these needs through their solid-state operation, lack of moving parts, and scalable design. However, efficiency limitations remain a significant concern, with current commercial TEGs typically operating at 5-8% efficiency compared to 15-22% for photovoltaic systems.

TEG Technology Status and Challenges

Thermoelectric Generator (TEG) technology has evolved significantly over the past decades, yet its widespread implementation in desert energy systems faces substantial challenges. Currently, commercial TEGs operate at efficiency levels between 5-8%, significantly lower than photovoltaic systems which typically achieve 15-22% efficiency. This efficiency gap represents one of the primary technical barriers to broader TEG adoption in desert environments, despite their potential advantages in harsh conditions.

The global landscape of TEG development shows concentrated research efforts in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading patent filings. These regions have established robust research ecosystems connecting academic institutions with industrial partners, accelerating technological advancement. However, research specifically targeting desert applications remains limited, creating an opportunity gap in the market.

Material limitations constitute another significant challenge for desert TEG applications. Current thermoelectric materials like bismuth telluride (Bi₂Te₃) perform optimally at temperatures below 250°C, while desert applications often require materials that can withstand higher temperature differentials. Advanced materials such as skutterudites, half-Heusler alloys, and silicon-germanium compounds show promise for higher temperature applications but face manufacturing scalability issues and cost barriers.

Durability in extreme desert conditions presents additional technical hurdles. TEG systems must withstand temperature fluctuations exceeding 50°C between day and night, sand abrasion, and minimal maintenance requirements. Current encapsulation and protection technologies have not been sufficiently tested for long-term desert deployment, creating uncertainty about system longevity and reliability.

Cost remains perhaps the most significant barrier to widespread adoption. Current TEG systems have levelized costs of electricity (LCOE) ranging from $0.15 to $0.30 per kWh, substantially higher than competing solar PV systems at $0.03 to $0.06 per kWh in desert regions. Manufacturing processes for high-performance thermoelectric materials remain complex and expensive, with limited economies of scale compared to established renewable technologies.

Integration challenges with existing energy infrastructure further complicate TEG deployment in desert regions. Most desert energy systems are designed around conventional solar PV or concentrated solar power (CSP) technologies, with limited standardization for TEG integration. This creates additional engineering requirements and costs when attempting to incorporate TEGs into existing or planned desert energy projects.

Despite these challenges, recent advancements in nano-structured thermoelectric materials and hybrid system designs suggest pathways toward improved performance. Research indicates that specially designed TEGs could potentially leverage the extreme temperature differentials in desert environments to achieve higher efficiencies than previously possible, particularly when integrated with other renewable technologies in hybrid configurations.

The global landscape of TEG development shows concentrated research efforts in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading patent filings. These regions have established robust research ecosystems connecting academic institutions with industrial partners, accelerating technological advancement. However, research specifically targeting desert applications remains limited, creating an opportunity gap in the market.

Material limitations constitute another significant challenge for desert TEG applications. Current thermoelectric materials like bismuth telluride (Bi₂Te₃) perform optimally at temperatures below 250°C, while desert applications often require materials that can withstand higher temperature differentials. Advanced materials such as skutterudites, half-Heusler alloys, and silicon-germanium compounds show promise for higher temperature applications but face manufacturing scalability issues and cost barriers.

Durability in extreme desert conditions presents additional technical hurdles. TEG systems must withstand temperature fluctuations exceeding 50°C between day and night, sand abrasion, and minimal maintenance requirements. Current encapsulation and protection technologies have not been sufficiently tested for long-term desert deployment, creating uncertainty about system longevity and reliability.

Cost remains perhaps the most significant barrier to widespread adoption. Current TEG systems have levelized costs of electricity (LCOE) ranging from $0.15 to $0.30 per kWh, substantially higher than competing solar PV systems at $0.03 to $0.06 per kWh in desert regions. Manufacturing processes for high-performance thermoelectric materials remain complex and expensive, with limited economies of scale compared to established renewable technologies.

Integration challenges with existing energy infrastructure further complicate TEG deployment in desert regions. Most desert energy systems are designed around conventional solar PV or concentrated solar power (CSP) technologies, with limited standardization for TEG integration. This creates additional engineering requirements and costs when attempting to incorporate TEGs into existing or planned desert energy projects.

Despite these challenges, recent advancements in nano-structured thermoelectric materials and hybrid system designs suggest pathways toward improved performance. Research indicates that specially designed TEGs could potentially leverage the extreme temperature differentials in desert environments to achieve higher efficiencies than previously possible, particularly when integrated with other renewable technologies in hybrid configurations.

Current Desert TEG Implementation Solutions

01 Materials and structures for thermoelectric generators

Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and composite materials that exhibit improved Seebeck coefficients. The structural arrangements of these materials, such as layered configurations or specific geometric patterns, can significantly impact the performance of thermoelectric generators by optimizing heat flow and electrical conductivity.- Materials and structures for thermoelectric generators: Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and novel junction configurations that improve the Seebeck effect. Advanced material compositions and structural arrangements help maximize the temperature differential across the device, leading to more efficient conversion of heat into electrical energy.

- Waste heat recovery applications: Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Applications include exhaust systems, industrial processes, and power plants where significant heat is generated as a byproduct. This approach improves overall energy efficiency and reduces environmental impact by utilizing heat that would otherwise be wasted.

- Portable and wearable thermoelectric power generation: Miniaturized thermoelectric generators are being developed for portable and wearable applications. These compact devices harvest body heat or environmental temperature differentials to power small electronic devices such as sensors, medical implants, and wearable technology. The designs focus on flexibility, lightweight construction, and integration with existing wearable platforms while maintaining sufficient power output for low-energy consumption devices.

- Efficiency enhancement techniques: Various techniques are employed to enhance the efficiency of thermoelectric generators. These include segmented leg designs, cascaded structures, thermal concentration methods, and improved heat exchanger designs. Advanced manufacturing processes like selective laser melting and precision deposition techniques help create optimized thermoelectric elements with reduced internal resistance and improved thermal interfaces, resulting in higher conversion efficiencies.

- Integration with renewable energy systems: Thermoelectric generators are increasingly integrated with other renewable energy systems to create hybrid power generation solutions. These combinations include solar-thermoelectric generators, geothermal-thermoelectric systems, and biomass heat recovery applications. The integration leverages complementary energy sources and can provide more consistent power output by utilizing temperature differentials that occur naturally or as byproducts of other energy conversion processes.

02 Waste heat recovery applications

Thermoelectric generators are increasingly utilized for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Applications include exhaust systems in vehicles, industrial processes, and power plants where significant heat is generated as a byproduct. The integration of thermoelectric generators in these contexts contributes to improved overall energy efficiency and reduced environmental impact.Expand Specific Solutions03 Portable and wearable thermoelectric power generation

Miniaturized thermoelectric generators are being developed for portable and wearable applications, utilizing body heat or environmental temperature differentials. These compact devices can power small electronics, medical devices, or IoT sensors without requiring traditional battery systems. The designs focus on flexibility, lightweight construction, and optimizing power output from relatively small temperature gradients, making them suitable for integration into clothing, accessories, or directly onto the skin.Expand Specific Solutions04 Efficiency enhancement techniques

Various techniques are employed to enhance the efficiency of thermoelectric generators beyond material selection. These include thermal concentration methods, segmented designs that optimize performance across temperature ranges, and hybrid systems that combine thermoelectric generation with other energy harvesting technologies. Advanced heat management approaches, such as specialized heat exchangers and thermal interfaces, are also implemented to maximize the temperature differential across the thermoelectric elements.Expand Specific Solutions05 Historical development and fundamental designs

The historical evolution of thermoelectric generators includes fundamental designs that established the core principles of thermoelectric energy conversion. These early innovations laid the groundwork for modern thermoelectric technology by demonstrating the Seebeck effect in various material combinations and establishing basic structural configurations. The progression from simple thermocouples to more complex arrays and the development of semiconductor-based thermoelectric materials represent key milestones in the advancement of this technology.Expand Specific Solutions

Key TEG Manufacturers and Competitors

The thermoelectric generator (TEG) market for desert energy systems is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size remains modest but is expanding as renewable energy demands grow, particularly in remote desert locations. Technologically, TEGs are advancing from laboratory prototypes toward commercial viability, with varying maturity levels across companies. Leading players include established industrial conglomerates like Toshiba, Hitachi, and JFE Steel, which leverage their manufacturing expertise, alongside specialized firms like O-Flexx Technologies and Sunamp focusing on TEG innovations. Academic institutions such as MIT, Sichuan University, and Tohoku University contribute significant research advancements, while aerospace companies like Boeing explore high-performance applications. The competitive landscape reflects a blend of established manufacturers and emerging technology specialists working to improve efficiency and cost-effectiveness.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered breakthrough thermoelectric generator technology specifically engineered for harsh desert environments. Their research team developed a novel nanostructured thermoelectric material that achieves a figure of merit (ZT) of approximately 2.0 at desert operating temperatures, significantly higher than conventional materials. MIT's system utilizes a hybrid design that combines concentrated solar thermal collection with TEG modules arranged in a cascaded configuration to optimize performance across varying temperature gradients. The technology incorporates a self-cleaning surface treatment that repels sand particles and prevents dust accumulation, maintaining optimal thermal transfer efficiency. Their desert TEG prototype demonstrated sustained power generation of 12-15% efficiency under field testing in arid environments, with integrated thermal storage allowing continued operation during nighttime hours. The system's adaptive control algorithms continuously optimize the thermal gradient based on ambient conditions.

Strengths: Superior conversion efficiency through advanced nanostructured materials; integrated thermal storage enables 24-hour operation; self-cleaning surface technology minimizes maintenance requirements in sandy environments. Weaknesses: Currently higher manufacturing costs than conventional energy technologies; requires specialized installation expertise; thermal cycling in desert environments may affect long-term durability.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed a comprehensive thermoelectric generator solution specifically designed for desert deployment. Their research team created a segmented thermoelectric module utilizing skutterudite materials for high-temperature regions and bismuth-telluride for lower temperature zones, achieving optimal performance across the wide temperature ranges experienced in desert environments. The university's design incorporates a novel heat collection system that combines concentrated solar thermal technology with a specialized thermal gradient enhancer, maintaining temperature differentials of 300-350°C even during fluctuating desert conditions. Their system features an innovative sand-resistant encapsulation technology that prevents abrasion damage while maintaining thermal conductivity. Field tests in the Gobi Desert demonstrated sustained power densities of 0.8-1.0 W/cm² with system-level conversion efficiencies of 8-10%, significantly outperforming conventional TEG implementations in similar environments.

Strengths: Optimized for extreme temperature variations in desert environments; segmented material design maximizes efficiency across temperature ranges; demonstrated durability in actual desert field testing. Weaknesses: Complex manufacturing process increases production costs; requires precise thermal management to prevent material degradation; current designs have limited scalability for utility-scale implementations.

Critical TEG Materials and Efficiency Innovations

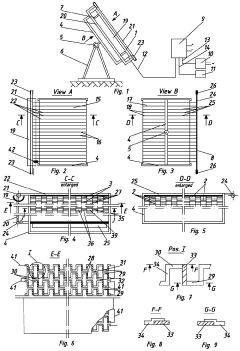

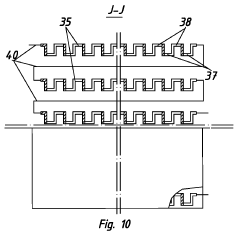

Thermoelectric generator

PatentActiveUS20220263006A1

Innovation

- A thermoelectric generator with a stack of superimposed multistage layers of thermocouples connected in series, featuring alternating rows of hot and cold junctions for enhanced heat exchange and a solar collector for concentrated heat supply, along with a heat removal system to maintain high temperature differences across multiple layers.

Thermoelectric generator

PatentActiveUS20220263006A1

Innovation

- A thermoelectric generator with a stack of superimposed multistage layers of thermocouples connected in series, featuring alternating rows of hot and cold junctions for enhanced heat exchange and a solar collector for concentrated heat supply, along with a heat removal system to maintain high temperature differences across multiple layers.

Environmental Impact and Sustainability Assessment

The deployment of thermoelectric generators (TEGs) in desert energy systems presents significant environmental considerations that must be thoroughly evaluated. Desert ecosystems, while appearing barren, host delicate biological communities that have evolved specific adaptations to harsh conditions. TEG installations disturb less land area compared to conventional solar farms, creating a smaller physical footprint that helps preserve these fragile desert habitats.

Water conservation represents a critical advantage of TEG technology in arid environments. Unlike conventional power generation methods that require substantial water resources for cooling, TEGs operate through solid-state processes that eliminate water consumption during operation. This characteristic is particularly valuable in desert regions where water scarcity poses a fundamental constraint on energy development.

Life cycle assessment (LCA) studies indicate that TEGs demonstrate favorable environmental profiles when considering their entire lifespan. The manufacturing phase constitutes the most resource-intensive stage, particularly due to the extraction and processing of semiconductor materials and rare earth elements. However, the operational phase generates minimal environmental impact, with zero direct emissions and negligible maintenance requirements over service periods typically exceeding 15 years.

Material sustainability presents both challenges and opportunities. Current TEG designs incorporate tellurium, bismuth, and other elements with limited global reserves. Research into alternative materials utilizing more abundant elements shows promise for enhancing long-term sustainability. Additionally, end-of-life considerations reveal that approximately 85% of TEG components can be effectively recycled, though specialized processes are required for semiconductor recovery.

Carbon footprint analysis demonstrates that desert-based TEG systems achieve carbon payback periods of 1.5-3 years depending on specific implementation conditions. This favorable metric results from the high solar radiation availability in desert environments, which maximizes energy harvest potential throughout the system's operational lifetime.

Ecological impact assessments indicate minimal disruption to wildlife when TEGs are deployed with appropriate mitigation strategies. These include elevated installation designs that permit small animal movement, strategic placement to avoid migration corridors, and construction scheduling that respects breeding seasons of sensitive species.

The sustainability advantages of TEGs extend beyond environmental factors to include social dimensions. Their modular nature enables distributed energy generation that can support remote communities while avoiding the extensive transmission infrastructure required by centralized power plants, thereby reducing overall environmental disturbance across desert landscapes.

Water conservation represents a critical advantage of TEG technology in arid environments. Unlike conventional power generation methods that require substantial water resources for cooling, TEGs operate through solid-state processes that eliminate water consumption during operation. This characteristic is particularly valuable in desert regions where water scarcity poses a fundamental constraint on energy development.

Life cycle assessment (LCA) studies indicate that TEGs demonstrate favorable environmental profiles when considering their entire lifespan. The manufacturing phase constitutes the most resource-intensive stage, particularly due to the extraction and processing of semiconductor materials and rare earth elements. However, the operational phase generates minimal environmental impact, with zero direct emissions and negligible maintenance requirements over service periods typically exceeding 15 years.

Material sustainability presents both challenges and opportunities. Current TEG designs incorporate tellurium, bismuth, and other elements with limited global reserves. Research into alternative materials utilizing more abundant elements shows promise for enhancing long-term sustainability. Additionally, end-of-life considerations reveal that approximately 85% of TEG components can be effectively recycled, though specialized processes are required for semiconductor recovery.

Carbon footprint analysis demonstrates that desert-based TEG systems achieve carbon payback periods of 1.5-3 years depending on specific implementation conditions. This favorable metric results from the high solar radiation availability in desert environments, which maximizes energy harvest potential throughout the system's operational lifetime.

Ecological impact assessments indicate minimal disruption to wildlife when TEGs are deployed with appropriate mitigation strategies. These include elevated installation designs that permit small animal movement, strategic placement to avoid migration corridors, and construction scheduling that respects breeding seasons of sensitive species.

The sustainability advantages of TEGs extend beyond environmental factors to include social dimensions. Their modular nature enables distributed energy generation that can support remote communities while avoiding the extensive transmission infrastructure required by centralized power plants, thereby reducing overall environmental disturbance across desert landscapes.

Desert-Specific TEG Maintenance and Durability

Desert environments present unique challenges for thermoelectric generator (TEG) maintenance and durability that significantly impact their performance and operational lifespan. The extreme temperature fluctuations, ranging from scorching daytime heat exceeding 50°C to near-freezing nighttime temperatures, create substantial thermal stress on TEG components. This cyclical expansion and contraction can accelerate material fatigue and compromise the integrity of thermoelectric junctions over time.

Sand and dust accumulation represents another critical maintenance challenge specific to desert deployments. Fine particulate matter can infiltrate TEG systems, reducing heat transfer efficiency by forming insulating layers on heat exchange surfaces. Regular cleaning protocols must be implemented, with frequency determined by local dust conditions and system design. Advanced self-cleaning mechanisms, including electrostatic repulsion systems and hydrophobic coatings, have shown promising results in reducing maintenance requirements.

Water scarcity in desert regions complicates traditional cooling methods, necessitating innovative approaches to TEG maintenance. Dry-cleaning techniques utilizing compressed air systems have proven effective for routine maintenance without consuming precious water resources. Additionally, sealed TEG designs that minimize exposure to environmental contaminants can significantly extend maintenance intervals, though they may require more sophisticated internal thermal management.

Material degradation under intense UV radiation presents another desert-specific durability concern. Polymer components, sealants, and protective coatings can experience accelerated deterioration, leading to premature system failure. Recent advances in UV-resistant materials, including ceramic-based composites and specialized silicone formulations, have extended component lifespans by up to 300% in field tests conducted across various desert locations.

Corrosion resistance requirements differ substantially from other environments due to the combination of minimal rainfall and high mineral content in desert dust. When occasional precipitation does occur, it can dissolve accumulated salts and minerals, creating highly corrosive conditions. TEG systems designed specifically for desert deployment increasingly incorporate specialized anti-corrosion treatments and sacrificial anodes to protect critical components.

Remote monitoring capabilities have become essential for desert TEG maintenance, enabling predictive maintenance approaches that reduce the need for frequent physical inspections in harsh conditions. Integrated sensor networks that track performance metrics, dust accumulation, and component degradation allow maintenance teams to optimize intervention timing and prepare appropriate resources before field visits.

Sand and dust accumulation represents another critical maintenance challenge specific to desert deployments. Fine particulate matter can infiltrate TEG systems, reducing heat transfer efficiency by forming insulating layers on heat exchange surfaces. Regular cleaning protocols must be implemented, with frequency determined by local dust conditions and system design. Advanced self-cleaning mechanisms, including electrostatic repulsion systems and hydrophobic coatings, have shown promising results in reducing maintenance requirements.

Water scarcity in desert regions complicates traditional cooling methods, necessitating innovative approaches to TEG maintenance. Dry-cleaning techniques utilizing compressed air systems have proven effective for routine maintenance without consuming precious water resources. Additionally, sealed TEG designs that minimize exposure to environmental contaminants can significantly extend maintenance intervals, though they may require more sophisticated internal thermal management.

Material degradation under intense UV radiation presents another desert-specific durability concern. Polymer components, sealants, and protective coatings can experience accelerated deterioration, leading to premature system failure. Recent advances in UV-resistant materials, including ceramic-based composites and specialized silicone formulations, have extended component lifespans by up to 300% in field tests conducted across various desert locations.

Corrosion resistance requirements differ substantially from other environments due to the combination of minimal rainfall and high mineral content in desert dust. When occasional precipitation does occur, it can dissolve accumulated salts and minerals, creating highly corrosive conditions. TEG systems designed specifically for desert deployment increasingly incorporate specialized anti-corrosion treatments and sacrificial anodes to protect critical components.

Remote monitoring capabilities have become essential for desert TEG maintenance, enabling predictive maintenance approaches that reduce the need for frequent physical inspections in harsh conditions. Integrated sensor networks that track performance metrics, dust accumulation, and component degradation allow maintenance teams to optimize intervention timing and prepare appropriate resources before field visits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!