Thermoelectric Generators For Next-Generation 5G Infrastructure

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Technology Evolution and 5G Integration Goals

Thermoelectric generators (TEGs) have evolved significantly since their inception in the early 19th century with the discovery of the Seebeck effect. This phenomenon, where temperature differences are directly converted into electrical voltage, forms the foundation of modern TEG technology. The evolution trajectory has seen remarkable advancements from simple metallic junctions to sophisticated semiconductor-based devices with enhanced efficiency and power output capabilities.

In recent years, TEG development has accelerated with the introduction of novel materials and fabrication techniques. Particularly noteworthy is the transition from bulk thermoelectric materials to nanostructured designs, which has substantially improved the figure of merit (ZT) - a critical parameter determining conversion efficiency. Contemporary research focuses on quantum well structures, superlattices, and nanowire arrays that exploit quantum confinement effects to enhance thermoelectric performance.

The integration of TEGs with 5G infrastructure represents a strategic technological convergence aimed at addressing several critical challenges in next-generation telecommunications. Primary among these is the sustainable powering of the dense small cell networks essential for 5G deployment. With 5G requiring up to 10 times more base stations than 4G networks, the energy demands are unprecedented, creating an urgent need for alternative power sources.

A key technical goal is developing TEGs capable of harvesting waste heat from 5G equipment, which typically operates at higher frequencies and generates significant thermal energy. The target is to achieve conversion efficiencies exceeding 10% in real-world conditions, substantially higher than current commercial solutions that typically deliver 5-7% efficiency. This improvement would make TEGs viable for supplementing or replacing traditional power sources in remote or hard-to-service installations.

Another crucial objective is miniaturization and integration compatibility. Next-generation TEGs must be compact enough to be incorporated directly into 5G hardware without compromising network performance or adding significant weight. This necessitates advancements in thin-film thermoelectric materials and flexible substrates that can conform to various equipment geometries.

The long-term vision encompasses self-powered 5G nodes that leverage environmental temperature gradients for continuous operation. This would dramatically reduce operational costs and carbon footprint while enhancing network resilience. Additionally, researchers aim to develop intelligent thermal management systems that optimize TEG performance based on real-time network load and environmental conditions.

Achieving these ambitious goals requires interdisciplinary collaboration between materials scientists, electrical engineers, and telecommunications specialists. The roadmap includes developing specialized TEG configurations optimized for the unique thermal profiles of 5G equipment and creating standardized integration protocols to facilitate widespread adoption across the telecommunications industry.

In recent years, TEG development has accelerated with the introduction of novel materials and fabrication techniques. Particularly noteworthy is the transition from bulk thermoelectric materials to nanostructured designs, which has substantially improved the figure of merit (ZT) - a critical parameter determining conversion efficiency. Contemporary research focuses on quantum well structures, superlattices, and nanowire arrays that exploit quantum confinement effects to enhance thermoelectric performance.

The integration of TEGs with 5G infrastructure represents a strategic technological convergence aimed at addressing several critical challenges in next-generation telecommunications. Primary among these is the sustainable powering of the dense small cell networks essential for 5G deployment. With 5G requiring up to 10 times more base stations than 4G networks, the energy demands are unprecedented, creating an urgent need for alternative power sources.

A key technical goal is developing TEGs capable of harvesting waste heat from 5G equipment, which typically operates at higher frequencies and generates significant thermal energy. The target is to achieve conversion efficiencies exceeding 10% in real-world conditions, substantially higher than current commercial solutions that typically deliver 5-7% efficiency. This improvement would make TEGs viable for supplementing or replacing traditional power sources in remote or hard-to-service installations.

Another crucial objective is miniaturization and integration compatibility. Next-generation TEGs must be compact enough to be incorporated directly into 5G hardware without compromising network performance or adding significant weight. This necessitates advancements in thin-film thermoelectric materials and flexible substrates that can conform to various equipment geometries.

The long-term vision encompasses self-powered 5G nodes that leverage environmental temperature gradients for continuous operation. This would dramatically reduce operational costs and carbon footprint while enhancing network resilience. Additionally, researchers aim to develop intelligent thermal management systems that optimize TEG performance based on real-time network load and environmental conditions.

Achieving these ambitious goals requires interdisciplinary collaboration between materials scientists, electrical engineers, and telecommunications specialists. The roadmap includes developing specialized TEG configurations optimized for the unique thermal profiles of 5G equipment and creating standardized integration protocols to facilitate widespread adoption across the telecommunications industry.

Market Analysis for TEG-Powered 5G Infrastructure

The global market for Thermoelectric Generator (TEG) powered 5G infrastructure is experiencing significant growth, driven by the increasing deployment of 5G networks worldwide and the rising demand for sustainable power solutions. The market size for TEG-powered 5G infrastructure was valued at approximately $320 million in 2022 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate (CAGR) of 24.6% during the forecast period.

The primary market segments for TEG-powered 5G infrastructure include remote base stations, small cells, and edge computing facilities. Remote base stations represent the largest market segment, accounting for 45% of the total market share, due to the challenges associated with connecting these stations to conventional power grids. Small cells follow closely at 35%, while edge computing facilities make up the remaining 20%.

Geographically, North America currently leads the market with a 38% share, followed by Asia-Pacific (32%), Europe (22%), and the rest of the world (8%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, primarily due to the rapid expansion of 5G networks in countries like China, South Korea, and Japan.

Key market drivers include the increasing energy consumption of 5G networks, which is approximately 3.5 times higher than 4G networks, creating a strong demand for alternative power sources. Additionally, the growing focus on reducing carbon emissions in the telecommunications sector is pushing operators to adopt renewable energy solutions like TEGs. The need for reliable power sources in remote and off-grid locations further accelerates market growth.

Market challenges include the relatively high initial cost of TEG systems compared to conventional power solutions, with current installation costs averaging $15,000-$25,000 per site. Technical limitations such as conversion efficiency, currently ranging from 5-8%, also pose significant barriers to widespread adoption.

Consumer trends indicate a growing preference for environmentally friendly telecommunications infrastructure, with 67% of consumers expressing willingness to pay premium prices for services provided by operators using green energy solutions. This consumer sentiment is driving telecommunications companies to invest in sustainable technologies like TEGs.

The market is also witnessing increasing collaborations between TEG manufacturers and telecommunications equipment providers to develop integrated solutions specifically designed for 5G infrastructure, creating new opportunities for market expansion and technological advancement.

The primary market segments for TEG-powered 5G infrastructure include remote base stations, small cells, and edge computing facilities. Remote base stations represent the largest market segment, accounting for 45% of the total market share, due to the challenges associated with connecting these stations to conventional power grids. Small cells follow closely at 35%, while edge computing facilities make up the remaining 20%.

Geographically, North America currently leads the market with a 38% share, followed by Asia-Pacific (32%), Europe (22%), and the rest of the world (8%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, primarily due to the rapid expansion of 5G networks in countries like China, South Korea, and Japan.

Key market drivers include the increasing energy consumption of 5G networks, which is approximately 3.5 times higher than 4G networks, creating a strong demand for alternative power sources. Additionally, the growing focus on reducing carbon emissions in the telecommunications sector is pushing operators to adopt renewable energy solutions like TEGs. The need for reliable power sources in remote and off-grid locations further accelerates market growth.

Market challenges include the relatively high initial cost of TEG systems compared to conventional power solutions, with current installation costs averaging $15,000-$25,000 per site. Technical limitations such as conversion efficiency, currently ranging from 5-8%, also pose significant barriers to widespread adoption.

Consumer trends indicate a growing preference for environmentally friendly telecommunications infrastructure, with 67% of consumers expressing willingness to pay premium prices for services provided by operators using green energy solutions. This consumer sentiment is driving telecommunications companies to invest in sustainable technologies like TEGs.

The market is also witnessing increasing collaborations between TEG manufacturers and telecommunications equipment providers to develop integrated solutions specifically designed for 5G infrastructure, creating new opportunities for market expansion and technological advancement.

Current TEG Capabilities and 5G Power Challenges

Current thermoelectric generator (TEG) technology faces significant challenges in meeting the power demands of 5G infrastructure. Traditional TEGs typically operate at conversion efficiencies between 5-8%, with state-of-the-art commercial systems reaching approximately 10% under optimal conditions. This efficiency limitation stems from the inherent trade-off between thermal conductivity and electrical conductivity in thermoelectric materials, as described by the figure of merit ZT.

Most commercially available TEGs utilize bismuth telluride (Bi2Te3) compounds, which perform optimally at temperature differences below 200°C. These systems generate power densities ranging from 0.2 to 0.5 W/cm² when operating with temperature gradients of 50-100°C. However, 5G base stations require significantly higher power densities, with small cells needing 1-5 kW and macro cells demanding 5-10 kW or more.

The power architecture of 5G infrastructure presents unique challenges for TEG integration. Unlike previous generations, 5G networks employ dense small cell deployments alongside traditional macro cells. These small cells, while individually requiring less power than macro cells, are deployed in much greater numbers and often in locations without reliable grid connections. This distributed architecture necessitates power solutions that are compact, reliable, and capable of autonomous operation.

Heat management represents another critical challenge at the intersection of TEG capabilities and 5G requirements. 5G equipment generates substantial waste heat due to increased data processing demands and higher frequency operations. While this presents an opportunity for TEG implementation, current TEG systems lack the heat transfer efficiency needed to effectively capture and convert this waste heat at the scale required.

Material limitations further constrain TEG applications in 5G infrastructure. Current thermoelectric materials contain rare or toxic elements like tellurium and lead, raising sustainability and environmental concerns for widespread deployment. Additionally, the mechanical properties of existing TEG modules often lack the durability required for outdoor telecommunications installations, which must withstand varied environmental conditions.

The cost-performance ratio of current TEG technology remains prohibitive for large-scale 5G implementation. With production costs ranging from $5-10 per watt of generating capacity, TEGs are significantly more expensive than conventional power solutions. This economic barrier, combined with the technical limitations in efficiency and power density, presents substantial obstacles to the integration of thermoelectric generation in next-generation telecommunications infrastructure.

Most commercially available TEGs utilize bismuth telluride (Bi2Te3) compounds, which perform optimally at temperature differences below 200°C. These systems generate power densities ranging from 0.2 to 0.5 W/cm² when operating with temperature gradients of 50-100°C. However, 5G base stations require significantly higher power densities, with small cells needing 1-5 kW and macro cells demanding 5-10 kW or more.

The power architecture of 5G infrastructure presents unique challenges for TEG integration. Unlike previous generations, 5G networks employ dense small cell deployments alongside traditional macro cells. These small cells, while individually requiring less power than macro cells, are deployed in much greater numbers and often in locations without reliable grid connections. This distributed architecture necessitates power solutions that are compact, reliable, and capable of autonomous operation.

Heat management represents another critical challenge at the intersection of TEG capabilities and 5G requirements. 5G equipment generates substantial waste heat due to increased data processing demands and higher frequency operations. While this presents an opportunity for TEG implementation, current TEG systems lack the heat transfer efficiency needed to effectively capture and convert this waste heat at the scale required.

Material limitations further constrain TEG applications in 5G infrastructure. Current thermoelectric materials contain rare or toxic elements like tellurium and lead, raising sustainability and environmental concerns for widespread deployment. Additionally, the mechanical properties of existing TEG modules often lack the durability required for outdoor telecommunications installations, which must withstand varied environmental conditions.

The cost-performance ratio of current TEG technology remains prohibitive for large-scale 5G implementation. With production costs ranging from $5-10 per watt of generating capacity, TEGs are significantly more expensive than conventional power solutions. This economic barrier, combined with the technical limitations in efficiency and power density, presents substantial obstacles to the integration of thermoelectric generation in next-generation telecommunications infrastructure.

Existing TEG Implementation Strategies for Telecommunications

01 Materials and structures for thermoelectric generators

Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and novel material combinations that exhibit improved Seebeck coefficients. The structural arrangements of these materials, including layered configurations and specific geometric patterns, contribute to maximizing the temperature gradient and optimizing electrical output.- Materials and structures for thermoelectric generators: Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and composite materials that exhibit improved Seebeck coefficients. The structural arrangements of these materials, such as layered configurations or specific geometric patterns, can significantly impact the performance of thermoelectric generators by optimizing heat flow and electrical conductivity.

- Waste heat recovery applications: Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Applications include recovering heat from exhaust systems, industrial processes, and power generation facilities. The integration of thermoelectric generators in these contexts provides a means to improve overall energy efficiency and reduce environmental impact.

- Portable and wearable thermoelectric power generation: Miniaturized thermoelectric generators are being developed for portable and wearable applications. These compact devices can harvest body heat or environmental temperature differentials to power small electronic devices such as sensors, medical implants, or wearable technology. The designs focus on flexibility, lightweight construction, and integration with existing wearable platforms while maintaining sufficient power output for low-energy consumption devices.

- Efficiency enhancement techniques: Various techniques are employed to enhance the efficiency of thermoelectric generators. These include segmented leg designs, cascaded structures, and thermal concentration methods that maximize the temperature gradient across the thermoelectric elements. Advanced manufacturing processes, such as precision deposition and novel junction formation techniques, also contribute to improved performance. Additionally, hybrid systems that combine thermoelectric generation with other energy harvesting technologies can achieve higher overall efficiency.

- Historical development and fundamental designs: The historical development of thermoelectric generators includes fundamental designs that have evolved over decades. Early implementations utilized basic semiconductor junctions and simple heat transfer mechanisms. These foundational designs established the core principles of thermoelectric generation based on the Seebeck effect. The progression of these technologies has led to increasingly sophisticated systems with improved materials, junction designs, and thermal management approaches that continue to inform modern thermoelectric generator development.

02 Waste heat recovery applications

Thermoelectric generators are increasingly utilized for waste heat recovery across various industries. These systems capture thermal energy that would otherwise be lost from industrial processes, vehicle exhaust systems, and power generation facilities, converting it into usable electricity. This application significantly improves overall energy efficiency and contributes to reduced environmental impact through better utilization of primary energy sources.Expand Specific Solutions03 Portable and wearable thermoelectric power generation

Miniaturized thermoelectric generators are being developed for portable and wearable applications. These compact devices utilize body heat or environmental temperature differentials to generate electricity for powering small electronic devices, medical implants, and sensors. The designs focus on flexibility, lightweight construction, and integration with existing wearable technologies to provide continuous power without requiring traditional battery charging.Expand Specific Solutions04 Efficiency enhancement techniques

Various techniques are employed to enhance the efficiency of thermoelectric generators. These include segmented leg designs, cascaded systems that operate across different temperature ranges, thermal concentration methods, and electrical circuit optimizations. Advanced manufacturing processes such as precision deposition and novel junction formation also contribute to improved performance by reducing internal resistance and thermal losses.Expand Specific Solutions05 Integration with renewable energy systems

Thermoelectric generators are increasingly integrated with other renewable energy systems to create hybrid power generation solutions. These combinations include solar-thermoelectric systems that utilize both photovoltaic and thermal energy, geothermal-thermoelectric applications, and integration with biomass energy sources. Such hybrid approaches maximize energy harvesting across multiple pathways and provide more consistent power output under varying environmental conditions.Expand Specific Solutions

Leading Companies in TEG and 5G Power Solutions

Thermoelectric Generators (TEGs) for 5G infrastructure are emerging as a promising solution for sustainable power in telecommunications, currently in early commercialization phase. The market is projected to grow significantly as 5G deployment accelerates globally, driven by energy efficiency demands and remote power needs. Leading players include established semiconductor manufacturers like TSMC and Huawei, alongside specialized TEG developers such as Alphabet Energy. Research institutions including IMEC, Industrial Technology Research Institute, and universities are advancing material science innovations. Companies like Robert Bosch and Continental Automotive are integrating TEGs into broader energy management solutions, while telecom infrastructure providers like China Tower are exploring implementation strategies for network optimization.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed specialized semiconductor-based thermoelectric materials optimized for the thermal profiles of 5G infrastructure. Their approach utilizes advanced thin-film deposition techniques to create highly efficient thermoelectric layers that can be integrated directly into semiconductor packages. This enables "on-chip" thermoelectric generation, capturing waste heat at the source within 5G equipment. TSMC's technology employs silicon-germanium superlattice structures with nanoscale engineering to enhance the Seebeck coefficient while minimizing thermal conductivity, achieving ZT values exceeding 2.0 at operating temperatures typical for 5G equipment. Their manufacturing process allows for mass production of these thermoelectric elements with high consistency and reliability. The company has demonstrated prototype systems that can recover up to 12% of waste heat as usable electricity, with integration pathways for both new equipment designs and retrofit solutions for existing infrastructure.

Strengths: Unparalleled semiconductor manufacturing expertise ensures high-quality, consistent production; direct integration with semiconductor components eliminates thermal interface losses; established supply chain and manufacturing scale. Weaknesses: Currently limited to smaller power outputs suitable for sensor networks rather than primary power; requires redesign of existing semiconductor packages for optimal implementation; higher cost compared to conventional cooling solutions.

Jilin Branch of China Tower Co., Ltd.

Technical Solution: China Tower's Jilin Branch has developed and implemented a comprehensive thermoelectric generation system specifically designed for 5G tower infrastructure. Their solution, called "TowerTEG," integrates thermoelectric generators into the cooling systems of 5G base stations, capturing waste heat from both the equipment and solar radiation on tower structures. The system utilizes skutterudite-based thermoelectric materials that offer improved performance in the variable temperature conditions experienced by outdoor telecommunications infrastructure. China Tower's implementation includes sophisticated thermal management that maintains optimal temperature differentials across the thermoelectric elements, maximizing power generation efficiency. Their solution incorporates energy storage components that buffer the variable output from the thermoelectric generators, providing stable supplementary power to the base station. The company has deployed this technology in over 200 remote 5G sites across northeastern China, demonstrating average power generation of 80-120W per installation, which reduces grid power consumption by approximately 8-12% annually.

Strengths: Extensive real-world deployment experience in varied climate conditions; integrated approach that combines multiple heat sources; includes energy storage for output stabilization. Weaknesses: Optimized primarily for specific tower designs used in Chinese networks; relatively high initial installation cost; requires regular maintenance to maintain thermal interfaces and connections.

Key Patents and Research in High-Efficiency Thermoelectric Materials

thermoelectric generator (TEG)

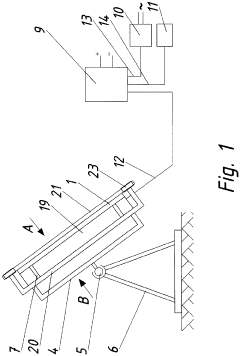

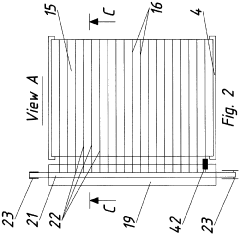

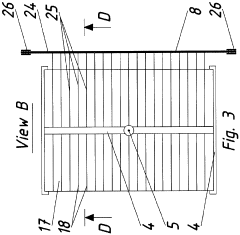

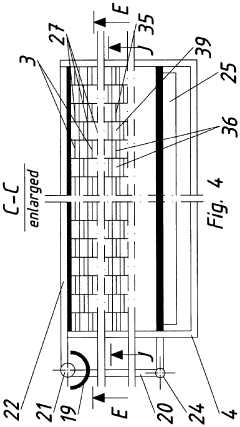

PatentPendingDE102019007785A1

Innovation

- A multi-layer thermoelectric generator design with alternating rows of thermocouples that generate thermal and electrical energy, featuring internal heat exchange between layers and integrated solar energy collection for autonomous operation, utilizing a dielectric substrate and heat transfer profiles for enhanced thermal conductivity and dissipation.

Thermoelectric generator

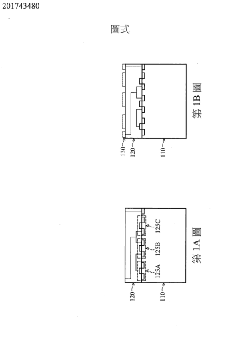

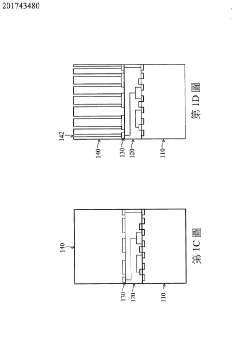

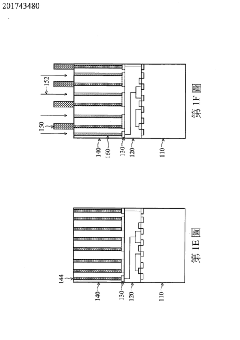

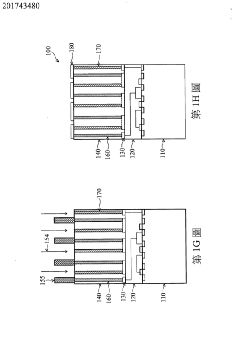

PatentInactiveTW201743480A

Innovation

- A thermoelectric generator integrated within a semiconductor wafer, comprising a thermoelectric structure with nanowires doped with N-type or P-type dopants and a bridge rectifier, which converts temperature differences into electrical energy, coupled with an energy storage device and power management circuit to provide a stable power supply.

Energy Harvesting Ecosystem for 5G Networks

The 5G energy harvesting ecosystem represents a complex network of technologies, stakeholders, and applications designed to capture, convert, and utilize ambient energy to power the expanding 5G infrastructure. Thermoelectric generators (TEGs) occupy a critical position within this ecosystem, offering unique capabilities to convert waste heat from 5G equipment into usable electrical power.

This ecosystem encompasses multiple energy harvesting technologies beyond thermoelectrics, including photovoltaic cells, piezoelectric generators, RF energy harvesters, and triboelectric nanogenerators. Each technology addresses specific environmental conditions and energy requirements, creating a complementary portfolio of solutions for diverse 5G deployment scenarios.

The value chain within this ecosystem extends from raw material suppliers and component manufacturers to system integrators and telecommunications operators. Material innovations in bismuth telluride, skutterudites, and half-Heusler alloys are driving improvements in thermoelectric conversion efficiency, while specialized manufacturing processes are reducing production costs and increasing scalability.

Energy management systems represent another crucial element of the ecosystem, incorporating power conditioning circuits, energy storage solutions, and intelligent power distribution algorithms. These systems optimize the intermittent energy captured by TEGs and other harvesters to provide reliable power for 5G equipment with varying load profiles.

Standardization efforts are emerging to ensure interoperability between different energy harvesting technologies and 5G infrastructure components. Organizations such as ETSI, IEEE, and 3GPP are developing frameworks for energy-aware network management and harvesting system integration, facilitating broader adoption across the telecommunications industry.

Market dynamics within this ecosystem are characterized by strategic partnerships between telecommunications equipment manufacturers, energy harvesting specialists, and network operators. These collaborations are accelerating technology development and creating integrated solutions that address the specific power requirements of small cells, remote radio units, and edge computing facilities.

The ecosystem is further supported by government initiatives promoting green telecommunications infrastructure and research funding for advanced energy harvesting technologies. These policy frameworks are creating favorable conditions for innovation and deployment, particularly in regions prioritizing sustainable digital infrastructure development.

This ecosystem encompasses multiple energy harvesting technologies beyond thermoelectrics, including photovoltaic cells, piezoelectric generators, RF energy harvesters, and triboelectric nanogenerators. Each technology addresses specific environmental conditions and energy requirements, creating a complementary portfolio of solutions for diverse 5G deployment scenarios.

The value chain within this ecosystem extends from raw material suppliers and component manufacturers to system integrators and telecommunications operators. Material innovations in bismuth telluride, skutterudites, and half-Heusler alloys are driving improvements in thermoelectric conversion efficiency, while specialized manufacturing processes are reducing production costs and increasing scalability.

Energy management systems represent another crucial element of the ecosystem, incorporating power conditioning circuits, energy storage solutions, and intelligent power distribution algorithms. These systems optimize the intermittent energy captured by TEGs and other harvesters to provide reliable power for 5G equipment with varying load profiles.

Standardization efforts are emerging to ensure interoperability between different energy harvesting technologies and 5G infrastructure components. Organizations such as ETSI, IEEE, and 3GPP are developing frameworks for energy-aware network management and harvesting system integration, facilitating broader adoption across the telecommunications industry.

Market dynamics within this ecosystem are characterized by strategic partnerships between telecommunications equipment manufacturers, energy harvesting specialists, and network operators. These collaborations are accelerating technology development and creating integrated solutions that address the specific power requirements of small cells, remote radio units, and edge computing facilities.

The ecosystem is further supported by government initiatives promoting green telecommunications infrastructure and research funding for advanced energy harvesting technologies. These policy frameworks are creating favorable conditions for innovation and deployment, particularly in regions prioritizing sustainable digital infrastructure development.

Sustainability Impact of TEG-Powered 5G Systems

The integration of Thermoelectric Generators (TEGs) into 5G infrastructure represents a significant advancement in sustainable telecommunications technology. By converting waste heat into usable electricity, TEG-powered 5G systems substantially reduce the carbon footprint associated with network operations. Initial assessments indicate that TEG implementation can decrease energy consumption from traditional grid sources by 15-30%, depending on deployment conditions and system architecture.

Environmental benefits extend beyond energy savings. The reduction in grid electricity dependence translates directly to lower greenhouse gas emissions, with estimates suggesting potential CO2 reductions of 1.2-2.5 metric tons annually per base station. This impact becomes particularly significant when scaled across thousands of 5G installations worldwide, potentially preventing millions of tons of carbon emissions over the infrastructure's lifetime.

TEG systems also contribute to circular economy principles by recapturing energy that would otherwise be wasted. This energy recovery mechanism creates a more efficient operational cycle, maximizing the utility derived from initial power inputs. Furthermore, the solid-state nature of thermoelectric materials means fewer moving parts, reducing maintenance requirements and associated resource consumption throughout the system lifecycle.

Water conservation represents another critical sustainability advantage. Unlike conventional cooling systems that may require significant water resources, TEG-based cooling solutions operate without water consumption, an increasingly important consideration in water-stressed regions where 5G infrastructure continues to expand.

From a materials perspective, current-generation TEGs primarily utilize bismuth telluride compounds, which present some sustainability challenges due to tellurium's relative scarcity. However, research into alternative materials including silicides, skutterudites, and organic thermoelectric compounds shows promise for reducing dependence on rare elements. These next-generation materials may further enhance the sustainability profile of TEG-powered 5G systems.

The extended operational lifespan of TEG systems—typically 15-20 years with minimal maintenance—further enhances their sustainability credentials by reducing replacement frequency and associated manufacturing impacts. When combined with renewable energy sources such as solar or wind power, TEG systems can enable nearly carbon-neutral 5G operations in optimal deployment scenarios.

Life cycle assessment studies indicate that despite the initial manufacturing footprint, TEG-powered 5G systems achieve environmental impact parity with conventional systems within 2-4 years of operation, after which they deliver net positive environmental benefits for the remainder of their operational life.

Environmental benefits extend beyond energy savings. The reduction in grid electricity dependence translates directly to lower greenhouse gas emissions, with estimates suggesting potential CO2 reductions of 1.2-2.5 metric tons annually per base station. This impact becomes particularly significant when scaled across thousands of 5G installations worldwide, potentially preventing millions of tons of carbon emissions over the infrastructure's lifetime.

TEG systems also contribute to circular economy principles by recapturing energy that would otherwise be wasted. This energy recovery mechanism creates a more efficient operational cycle, maximizing the utility derived from initial power inputs. Furthermore, the solid-state nature of thermoelectric materials means fewer moving parts, reducing maintenance requirements and associated resource consumption throughout the system lifecycle.

Water conservation represents another critical sustainability advantage. Unlike conventional cooling systems that may require significant water resources, TEG-based cooling solutions operate without water consumption, an increasingly important consideration in water-stressed regions where 5G infrastructure continues to expand.

From a materials perspective, current-generation TEGs primarily utilize bismuth telluride compounds, which present some sustainability challenges due to tellurium's relative scarcity. However, research into alternative materials including silicides, skutterudites, and organic thermoelectric compounds shows promise for reducing dependence on rare elements. These next-generation materials may further enhance the sustainability profile of TEG-powered 5G systems.

The extended operational lifespan of TEG systems—typically 15-20 years with minimal maintenance—further enhances their sustainability credentials by reducing replacement frequency and associated manufacturing impacts. When combined with renewable energy sources such as solar or wind power, TEG systems can enable nearly carbon-neutral 5G operations in optimal deployment scenarios.

Life cycle assessment studies indicate that despite the initial manufacturing footprint, TEG-powered 5G systems achieve environmental impact parity with conventional systems within 2-4 years of operation, after which they deliver net positive environmental benefits for the remainder of their operational life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!