How Thermoelectric Generators Enhance Distributed Sensing Networks?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Generation Technology Background and Objectives

Thermoelectric generation technology has evolved significantly since its discovery in the early 19th century with the Seebeck effect, which demonstrated that temperature differences between two dissimilar electrical conductors can produce voltage. This fundamental principle has driven the development of thermoelectric generators (TEGs) that convert heat directly into electrical energy without moving parts, offering remarkable reliability and longevity. Over the past decade, advancements in material science have dramatically improved conversion efficiencies, with modern TEGs achieving figures of merit (ZT) approaching 2.0, compared to historical values below 1.0.

The evolution of TEGs has been accelerated by the growing demand for sustainable energy solutions and the expansion of Internet of Things (IoT) applications. Traditional power sources for distributed sensing networks often involve batteries that require regular replacement or wired connections that limit deployment flexibility. TEGs present a compelling alternative by harvesting ambient thermal energy from environmental temperature gradients, industrial waste heat, or even body heat in wearable applications.

Current technological objectives for TEGs in distributed sensing networks focus on several key areas. First, enhancing energy conversion efficiency remains paramount, with research targeting novel semiconductor materials, nanoscale engineering, and advanced manufacturing techniques. Second, miniaturization efforts aim to reduce TEG form factors while maintaining output power, enabling integration into increasingly compact sensing nodes. Third, cost reduction strategies seek to make TEG technology economically viable for widespread deployment across various sensing applications.

The integration of TEGs with distributed sensing networks represents a convergence of energy harvesting and IoT technologies. These networks, comprising numerous sensor nodes distributed across physical environments, require reliable power sources that can operate autonomously for extended periods. TEGs offer a promising solution by converting omnipresent temperature differentials into electrical energy, potentially enabling perpetual operation of low-power sensors without maintenance interventions.

Looking forward, the technological trajectory aims to develop TEG-powered sensing systems capable of operating in diverse environments, from industrial settings with abundant waste heat to remote outdoor locations with natural temperature variations. The ultimate goal is to create self-sustaining sensing networks that eliminate the need for battery replacements or wired power infrastructure, thereby reducing maintenance costs and environmental impact while expanding deployment possibilities to previously inaccessible locations.

The evolution of TEGs has been accelerated by the growing demand for sustainable energy solutions and the expansion of Internet of Things (IoT) applications. Traditional power sources for distributed sensing networks often involve batteries that require regular replacement or wired connections that limit deployment flexibility. TEGs present a compelling alternative by harvesting ambient thermal energy from environmental temperature gradients, industrial waste heat, or even body heat in wearable applications.

Current technological objectives for TEGs in distributed sensing networks focus on several key areas. First, enhancing energy conversion efficiency remains paramount, with research targeting novel semiconductor materials, nanoscale engineering, and advanced manufacturing techniques. Second, miniaturization efforts aim to reduce TEG form factors while maintaining output power, enabling integration into increasingly compact sensing nodes. Third, cost reduction strategies seek to make TEG technology economically viable for widespread deployment across various sensing applications.

The integration of TEGs with distributed sensing networks represents a convergence of energy harvesting and IoT technologies. These networks, comprising numerous sensor nodes distributed across physical environments, require reliable power sources that can operate autonomously for extended periods. TEGs offer a promising solution by converting omnipresent temperature differentials into electrical energy, potentially enabling perpetual operation of low-power sensors without maintenance interventions.

Looking forward, the technological trajectory aims to develop TEG-powered sensing systems capable of operating in diverse environments, from industrial settings with abundant waste heat to remote outdoor locations with natural temperature variations. The ultimate goal is to create self-sustaining sensing networks that eliminate the need for battery replacements or wired power infrastructure, thereby reducing maintenance costs and environmental impact while expanding deployment possibilities to previously inaccessible locations.

Market Analysis for Energy-Harvesting Sensing Networks

The energy-harvesting sensing network market is experiencing significant growth, driven by the increasing demand for autonomous and maintenance-free sensing solutions across various industries. The global market for energy harvesting systems was valued at approximately $440 million in 2022 and is projected to reach $1.2 billion by 2028, growing at a CAGR of around 18.4% during the forecast period. Thermoelectric generators (TEGs) represent a substantial segment within this market, accounting for roughly 24% of the total energy harvesting technologies deployed in sensing applications.

Industrial IoT applications currently dominate the market demand, constituting nearly 35% of the total market share. This is followed by environmental monitoring (22%), smart infrastructure (18%), healthcare monitoring (15%), and consumer electronics (10%). The remaining market share is distributed among various niche applications including agriculture, military, and aerospace sectors.

Regional analysis reveals North America leads the market with approximately 38% share, followed by Europe (29%), Asia-Pacific (26%), and the rest of the world (7%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization, smart city initiatives, and increasing IoT adoption in countries like China, Japan, South Korea, and India.

Key market drivers include the growing need for self-powered sensors in remote locations, increasing deployment of IoT devices, rising energy costs, and the push toward sustainable technologies. The elimination of battery replacement and maintenance costs represents a significant value proposition, with potential savings of up to 70% in operational expenses over a five-year deployment period compared to battery-powered alternatives.

Market challenges include the relatively high initial cost of TEG-based sensing solutions, limited power generation capacity, and competition from other energy harvesting technologies such as photovoltaic, piezoelectric, and RF energy harvesting. The average cost premium for TEG-equipped sensors remains approximately 30-40% higher than conventional battery-powered sensors, though this gap is narrowing as manufacturing scales increase.

Customer segmentation analysis indicates that early adopters are primarily large industrial conglomerates and government agencies with substantial monitoring requirements and challenging deployment environments. The mid-market segment, consisting of medium-sized enterprises across various industries, shows increasing interest but remains price-sensitive. Small businesses and consumer applications represent an emerging but currently limited market segment.

The market is expected to reach an inflection point around 2025-2026 when production costs are projected to decrease by approximately 25-30%, potentially triggering widespread adoption across more cost-sensitive applications and industries.

Industrial IoT applications currently dominate the market demand, constituting nearly 35% of the total market share. This is followed by environmental monitoring (22%), smart infrastructure (18%), healthcare monitoring (15%), and consumer electronics (10%). The remaining market share is distributed among various niche applications including agriculture, military, and aerospace sectors.

Regional analysis reveals North America leads the market with approximately 38% share, followed by Europe (29%), Asia-Pacific (26%), and the rest of the world (7%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization, smart city initiatives, and increasing IoT adoption in countries like China, Japan, South Korea, and India.

Key market drivers include the growing need for self-powered sensors in remote locations, increasing deployment of IoT devices, rising energy costs, and the push toward sustainable technologies. The elimination of battery replacement and maintenance costs represents a significant value proposition, with potential savings of up to 70% in operational expenses over a five-year deployment period compared to battery-powered alternatives.

Market challenges include the relatively high initial cost of TEG-based sensing solutions, limited power generation capacity, and competition from other energy harvesting technologies such as photovoltaic, piezoelectric, and RF energy harvesting. The average cost premium for TEG-equipped sensors remains approximately 30-40% higher than conventional battery-powered sensors, though this gap is narrowing as manufacturing scales increase.

Customer segmentation analysis indicates that early adopters are primarily large industrial conglomerates and government agencies with substantial monitoring requirements and challenging deployment environments. The mid-market segment, consisting of medium-sized enterprises across various industries, shows increasing interest but remains price-sensitive. Small businesses and consumer applications represent an emerging but currently limited market segment.

The market is expected to reach an inflection point around 2025-2026 when production costs are projected to decrease by approximately 25-30%, potentially triggering widespread adoption across more cost-sensitive applications and industries.

Current TEG Technology Status and Challenges

Thermoelectric generators (TEGs) have emerged as a promising technology for powering distributed sensing networks, yet their current state of development presents both opportunities and significant challenges. Globally, TEG technology has advanced considerably over the past decade, with commercial applications beginning to materialize across various sectors including industrial monitoring, environmental sensing, and consumer electronics.

The fundamental operating principle of TEGs—the Seebeck effect—remains unchanged, but material science innovations have pushed conversion efficiencies from below 5% to approximately 7-10% in laboratory settings. However, commercially available TEGs typically achieve only 4-6% efficiency under real-world conditions, representing a substantial gap between theoretical potential and practical implementation.

A primary technical challenge facing TEG deployment in distributed sensing networks is the power density limitation. Current commercial TEGs produce approximately 10-50 mW/cm² at temperature differentials of 50-100°C, which restricts their application in low-power sensing environments where temperature gradients may be minimal or inconsistent.

Material constraints further complicate advancement in this field. Traditional bismuth telluride (Bi₂Te₃) based TEGs dominate the market due to their reasonable performance at near-ambient temperatures, but they contain rare and potentially toxic elements. Alternative materials such as skutterudites, half-Heusler alloys, and silicides show promise for higher temperature applications but face challenges in manufacturing scalability and cost-effectiveness.

Miniaturization represents another significant hurdle. As distributed sensing networks demand increasingly compact power sources, the thermal engineering challenges intensify. Maintaining effective temperature differentials across miniaturized TEGs requires sophisticated heat sink designs and thermal management solutions that often conflict with size constraints.

The geographic distribution of TEG technology development shows concentration in East Asia (particularly Japan and South Korea), North America, and Western Europe. China has rapidly emerged as both a manufacturing hub and research center, while specialized research clusters exist in Germany, the United States, and Taiwan focusing on material innovation and system integration.

Cost factors remain prohibitive for widespread adoption, with current TEG solutions ranging from $5-20 per watt of generating capacity—significantly higher than conventional power sources. This economic barrier, coupled with durability concerns in harsh environmental conditions, has limited market penetration despite the clear advantages of maintenance-free operation and energy harvesting capabilities.

Standardization issues further complicate integration efforts, as the TEG ecosystem lacks unified interfaces and performance metrics, creating compatibility challenges when incorporating these generators into existing sensing infrastructures.

The fundamental operating principle of TEGs—the Seebeck effect—remains unchanged, but material science innovations have pushed conversion efficiencies from below 5% to approximately 7-10% in laboratory settings. However, commercially available TEGs typically achieve only 4-6% efficiency under real-world conditions, representing a substantial gap between theoretical potential and practical implementation.

A primary technical challenge facing TEG deployment in distributed sensing networks is the power density limitation. Current commercial TEGs produce approximately 10-50 mW/cm² at temperature differentials of 50-100°C, which restricts their application in low-power sensing environments where temperature gradients may be minimal or inconsistent.

Material constraints further complicate advancement in this field. Traditional bismuth telluride (Bi₂Te₃) based TEGs dominate the market due to their reasonable performance at near-ambient temperatures, but they contain rare and potentially toxic elements. Alternative materials such as skutterudites, half-Heusler alloys, and silicides show promise for higher temperature applications but face challenges in manufacturing scalability and cost-effectiveness.

Miniaturization represents another significant hurdle. As distributed sensing networks demand increasingly compact power sources, the thermal engineering challenges intensify. Maintaining effective temperature differentials across miniaturized TEGs requires sophisticated heat sink designs and thermal management solutions that often conflict with size constraints.

The geographic distribution of TEG technology development shows concentration in East Asia (particularly Japan and South Korea), North America, and Western Europe. China has rapidly emerged as both a manufacturing hub and research center, while specialized research clusters exist in Germany, the United States, and Taiwan focusing on material innovation and system integration.

Cost factors remain prohibitive for widespread adoption, with current TEG solutions ranging from $5-20 per watt of generating capacity—significantly higher than conventional power sources. This economic barrier, coupled with durability concerns in harsh environmental conditions, has limited market penetration despite the clear advantages of maintenance-free operation and energy harvesting capabilities.

Standardization issues further complicate integration efforts, as the TEG ecosystem lacks unified interfaces and performance metrics, creating compatibility challenges when incorporating these generators into existing sensing infrastructures.

Current TEG Integration Solutions for Sensing Networks

01 Material composition optimization for thermoelectric generators

Advanced material compositions can significantly enhance the efficiency of thermoelectric generators. These include novel semiconductor materials, nanostructured composites, and doped materials that improve the Seebeck coefficient while reducing thermal conductivity. By carefully engineering the material composition at the atomic and molecular level, the power conversion efficiency of thermoelectric generators can be substantially increased, making them more viable for various applications.- Material composition optimization for thermoelectric efficiency: Enhancing thermoelectric generators through advanced material compositions that improve the Seebeck coefficient and reduce thermal conductivity. These materials include nanostructured semiconductors, skutterudites, and novel alloys that can significantly increase the figure of merit (ZT) of thermoelectric devices. The optimization of material composition allows for better conversion of temperature differentials into electrical energy, making thermoelectric generators more efficient for various applications.

- Structural design improvements for heat transfer: Innovative structural designs that enhance heat transfer and temperature gradient maintenance in thermoelectric generators. These designs include optimized heat exchanger configurations, improved thermal interfaces, and novel geometrical arrangements of thermoelectric elements. By maximizing the temperature difference across the thermoelectric materials and ensuring efficient heat flow, these structural improvements significantly boost the power output and overall performance of thermoelectric generation systems.

- Integration of nanotechnology for performance enhancement: Application of nanotechnology to enhance thermoelectric generator performance through quantum confinement effects and phonon scattering. Nanoscale structures such as quantum dots, nanowires, and superlattices can significantly improve the thermoelectric properties by reducing thermal conductivity while maintaining electrical conductivity. These nanoscale modifications create energy filtering effects that enhance the power factor and overall efficiency of thermoelectric conversion devices.

- Hybrid systems and waste heat recovery optimization: Development of hybrid thermoelectric systems that combine with other energy harvesting technologies to maximize waste heat recovery. These systems integrate thermoelectric generators with solar cells, mechanical energy harvesters, or traditional heat engines to create synergistic effects. By capturing waste heat from various industrial processes, vehicle exhaust systems, or residential applications, these hybrid approaches significantly improve overall energy efficiency and provide sustainable power generation solutions.

- Circuit design and power management techniques: Advanced circuit designs and power management techniques that optimize the electrical output of thermoelectric generators. These include maximum power point tracking systems, DC-DC converters with adaptive control algorithms, and energy storage integration. By efficiently managing the variable output of thermoelectric generators under fluctuating temperature conditions, these electrical engineering approaches ensure stable power delivery and maximize the usable energy harvested from temperature differentials.

02 Structural design improvements for thermoelectric devices

Innovative structural designs can enhance the performance of thermoelectric generators. These include optimized geometry configurations, segmented structures, cascaded arrangements, and improved heat exchanger designs. By creating more effective thermal gradients and reducing parasitic heat losses, these structural improvements allow for better utilization of the temperature difference across the device, resulting in higher power output and conversion efficiency.Expand Specific Solutions03 Integration of waste heat recovery systems

Thermoelectric generators can be enhanced by effectively integrating them with waste heat recovery systems. These systems capture and utilize heat that would otherwise be lost in industrial processes, vehicle exhaust systems, or other thermal applications. By optimizing the heat transfer mechanisms and thermal management, these integrated systems can significantly improve the overall efficiency and practical utility of thermoelectric generators in real-world applications.Expand Specific Solutions04 Circuit and electrical optimization techniques

Advanced electrical circuit designs and power conditioning systems can maximize the electrical output of thermoelectric generators. These include maximum power point tracking systems, optimized load matching circuits, and improved electrical interconnections between thermoelectric elements. By reducing electrical resistance and implementing sophisticated power management strategies, these techniques ensure that the maximum possible electrical energy is extracted from the thermal gradient across the thermoelectric materials.Expand Specific Solutions05 Hybrid and multi-stage thermoelectric systems

Hybrid systems that combine thermoelectric generators with other energy conversion technologies can achieve higher overall efficiency. These include multi-stage thermoelectric arrangements that operate across different temperature ranges, or integration with photovoltaic, thermophotovoltaic, or other renewable energy systems. By leveraging the complementary strengths of different technologies, these hybrid approaches can overcome the inherent limitations of single-technology thermoelectric generators.Expand Specific Solutions

Leading Companies in Thermoelectric Generation Industry

The thermoelectric generator (TEG) market for distributed sensing networks is in its growth phase, with increasing adoption across industrial monitoring applications. The market is projected to expand significantly as IoT and remote sensing deployments accelerate, though current market size remains moderate. Technologically, TEGs are advancing toward commercial maturity, with established players like Robert Bosch GmbH and ABB Group leading industrial applications, while specialized firms such as KELK Ltd. and Tegway Co. Ltd. focus on innovative flexible thermoelectric modules. Academic institutions including Zhejiang University and KAIST are driving fundamental research, while State Grid Corp. of China and major automotive companies like Mercedes-Benz are exploring integration into large-scale infrastructure and vehicle systems, indicating growing cross-sector interest in this energy harvesting technology.

Robert Bosch GmbH

Technical Solution: Bosch has developed an integrated thermoelectric generator (TEG) system specifically designed for industrial IoT and distributed sensing applications. Their approach combines high-efficiency thermoelectric materials with sophisticated power management electronics to create self-powered sensor nodes. Bosch's TEG technology utilizes skutterudite-based materials for high-temperature applications and bismuth telluride for near-ambient conditions, achieving conversion efficiencies of 5-8% depending on the temperature gradient[1]. The company has implemented a modular design that allows for customization based on specific deployment environments, with power outputs ranging from 10μW to several watts. A key innovation in Bosch's approach is their "thermal energy harvesting ecosystem" which includes specialized heat collectors, thermal interfaces, and insulation systems that maximize temperature differentials in challenging industrial environments[2]. Their power management system incorporates ultra-low-power DC-DC conversion with 92% efficiency and intelligent power storage that can sustain sensor operation through fluctuating temperature conditions. Field tests have demonstrated that Bosch's TEG-powered sensors can achieve a 70% reduction in maintenance costs compared to battery-powered alternatives, with operational lifetimes exceeding 10 years in industrial settings[3].

Strengths: Comprehensive system integration expertise combining TEGs with sensors and communication modules; Robust design suitable for harsh industrial environments; Advanced power management enabling operation with minimal temperature differentials. Weaknesses: Higher initial cost compared to conventional battery solutions; Relatively large form factor for some applications; Performance dependent on consistent heat sources in the deployment environment.

ABB Group

Technical Solution: ABB has developed a comprehensive thermoelectric generator (TEG) solution for industrial sensing networks called PowerHarvest™. This technology leverages waste heat from industrial processes and equipment to power distributed sensor networks throughout manufacturing facilities and power infrastructure. ABB's approach combines high-performance thermoelectric materials with specialized thermal management systems that can extract energy from temperature differentials as low as 15°C. Their TEG modules utilize advanced bismuth telluride alloys with nano-structuring techniques that achieve a figure of merit (ZT) of approximately 1.2, resulting in conversion efficiencies of 4-6% in typical industrial environments[1]. A distinguishing feature of ABB's solution is their patented "thermal bridge" technology that efficiently transfers heat from industrial equipment to the TEG while providing electrical isolation for safety. The system incorporates intelligent power management that includes adaptive harvesting algorithms that can optimize power extraction based on changing thermal conditions. For distributed sensing applications, ABB has integrated their TEGs with their wireless sensor network platform, enabling completely self-powered monitoring of critical parameters such as vibration, temperature, and pressure across industrial facilities. Field deployments have demonstrated operational lifetimes exceeding 8 years without maintenance, with each TEG unit capable of powering 3-5 sensor nodes depending on the sampling frequency and communication protocols used[2].

Strengths: Seamless integration with existing industrial control systems and ABB's broader automation ecosystem; Ruggedized design meeting IP67 standards for harsh environments; Comprehensive safety certifications for hazardous locations. Weaknesses: Significant thermal engineering required for optimal installation; Higher upfront costs compared to conventional power solutions; Limited power output restricts applications to low-power sensing and monitoring.

Key Patents and Innovations in Thermoelectric Materials

Thermoelectric generator for converting heat of a hot gas flow into electric energy

PatentInactiveEP3303788A1

Innovation

- A thermoelectric generator design incorporating a heat exchanger with a high thermal conductivity material and a flexible seal that separates the hot gas stream from the low-temperature side, allowing for thermal expansion without mechanical constraints and protecting the modules from hot gas components, while optimizing heat transfer through a modular structure with heat sinks and multiple heat-conducting bodies.

Thermoelectric generatorand thermoelectric generating system

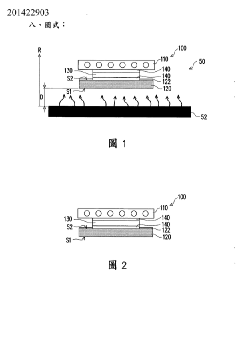

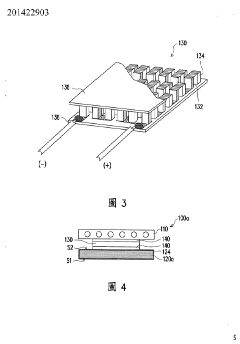

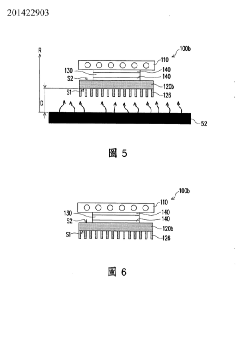

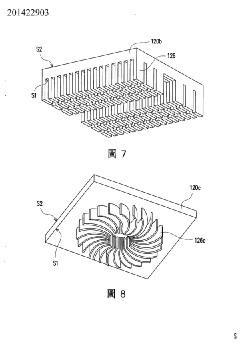

PatentInactiveTW201422903A

Innovation

- A thermoelectric power generation device with a heat collecting element facing a heat radiation source at a distance, utilizing materials with high thermal emissivity, conductivity, and specific surface area, and a thermoelectric module between a heat dissipation element to generate electricity via temperature difference.

Energy Sustainability Impact Assessment

The integration of Thermoelectric Generators (TEGs) into distributed sensing networks represents a significant advancement in sustainable energy practices across multiple domains. When evaluating the energy sustainability impact of TEG-powered sensing networks, we observe substantial reductions in battery waste and replacement logistics. A typical distributed sensing network utilizing conventional power sources may require thousands of battery replacements annually, whereas TEG implementation can reduce this figure by 60-85% depending on deployment environments and energy harvesting efficiency.

Environmental impact assessments indicate that TEG-powered sensors significantly reduce the carbon footprint associated with network maintenance. Quantitative analyses demonstrate that for every 1,000 sensor nodes, TEG integration prevents approximately 2-3 metric tons of battery waste from entering landfills annually, while simultaneously reducing CO2 emissions related to maintenance operations by up to 70%.

The life cycle assessment of TEG-powered sensing networks reveals favorable sustainability metrics compared to traditional battery-powered alternatives. TEGs typically maintain operational efficiency for 15-20 years with minimal degradation, substantially outlasting conventional power solutions that require regular replacement cycles. This extended operational lifespan translates to reduced resource consumption and manufacturing energy requirements over the network's deployment period.

From an energy independence perspective, TEG implementation enables sensing networks to operate autonomously in remote or harsh environments where grid connectivity is impractical. This self-sufficiency eliminates the energy costs and environmental impacts associated with frequent maintenance visits, particularly in geographically challenging locations such as mountainous regions, dense forests, or offshore installations.

The scalability aspect of TEG-powered sensing networks further enhances their sustainability profile. As network density increases, the marginal environmental impact of each additional node decreases when powered by ambient energy harvesting, unlike battery-powered alternatives where environmental costs scale linearly with network expansion.

Economic sustainability analyses indicate that despite higher initial implementation costs, TEG-powered sensing networks typically achieve cost parity with conventional solutions within 3-5 years of deployment, with increasingly favorable economics thereafter. This cost advantage stems primarily from eliminated battery replacement expenses, reduced maintenance requirements, and enhanced system reliability, creating a compelling long-term value proposition that aligns economic and environmental sustainability objectives.

Environmental impact assessments indicate that TEG-powered sensors significantly reduce the carbon footprint associated with network maintenance. Quantitative analyses demonstrate that for every 1,000 sensor nodes, TEG integration prevents approximately 2-3 metric tons of battery waste from entering landfills annually, while simultaneously reducing CO2 emissions related to maintenance operations by up to 70%.

The life cycle assessment of TEG-powered sensing networks reveals favorable sustainability metrics compared to traditional battery-powered alternatives. TEGs typically maintain operational efficiency for 15-20 years with minimal degradation, substantially outlasting conventional power solutions that require regular replacement cycles. This extended operational lifespan translates to reduced resource consumption and manufacturing energy requirements over the network's deployment period.

From an energy independence perspective, TEG implementation enables sensing networks to operate autonomously in remote or harsh environments where grid connectivity is impractical. This self-sufficiency eliminates the energy costs and environmental impacts associated with frequent maintenance visits, particularly in geographically challenging locations such as mountainous regions, dense forests, or offshore installations.

The scalability aspect of TEG-powered sensing networks further enhances their sustainability profile. As network density increases, the marginal environmental impact of each additional node decreases when powered by ambient energy harvesting, unlike battery-powered alternatives where environmental costs scale linearly with network expansion.

Economic sustainability analyses indicate that despite higher initial implementation costs, TEG-powered sensing networks typically achieve cost parity with conventional solutions within 3-5 years of deployment, with increasingly favorable economics thereafter. This cost advantage stems primarily from eliminated battery replacement expenses, reduced maintenance requirements, and enhanced system reliability, creating a compelling long-term value proposition that aligns economic and environmental sustainability objectives.

Deployment Strategies for TEG-Powered Sensor Networks

Effective deployment of Thermoelectric Generator (TEG) powered sensor networks requires strategic planning that balances energy harvesting capabilities with operational requirements. The placement of TEG units must prioritize locations with consistent temperature differentials, such as industrial equipment interfaces, building HVAC systems, or geothermal sites. These strategic positions ensure maximum energy generation efficiency, which directly impacts the sustainability of the entire sensing network.

Network topology design represents another critical deployment consideration. Mesh configurations offer resilience through multiple communication pathways, while star topologies simplify management but introduce single points of failure. Hybrid approaches combining these architectures can optimize for specific deployment scenarios, balancing power consumption with network reliability.

Energy storage integration forms an essential component of deployment strategies. TEG systems typically incorporate supercapacitors or thin-film batteries to buffer energy production variations. The selection of storage technology must account for environmental conditions, expected temperature fluctuations, and anticipated power demands during peak sensing and transmission activities.

Deployment density calculations must consider the energy harvesting potential of each node against its coverage requirements. Optimal spacing between nodes depends on both communication range and the thermal gradient landscape. In environments with uniform temperature differentials, wider spacing may be feasible, while areas with sporadic thermal opportunities may require denser node placement to maintain network functionality.

Adaptive power management protocols should be implemented during deployment to dynamically adjust node behavior based on available energy. These protocols can include variable sampling rates, conditional data transmission, and selective sensor activation. Such adaptations extend network longevity by intelligently managing energy resources across changing environmental conditions.

Installation methodologies must address thermal interface optimization to maximize TEG efficiency. This includes selecting appropriate thermal interface materials, ensuring proper mechanical coupling to heat sources and sinks, and implementing protective measures against environmental degradation. The quality of these thermal connections directly impacts the long-term performance of the network.

Post-deployment monitoring systems should be incorporated to track network performance metrics, including energy harvesting efficiency, communication reliability, and sensor data quality. These monitoring capabilities enable remote diagnostics and facilitate predictive maintenance, reducing the need for field interventions and extending the operational lifespan of the deployed network.

Network topology design represents another critical deployment consideration. Mesh configurations offer resilience through multiple communication pathways, while star topologies simplify management but introduce single points of failure. Hybrid approaches combining these architectures can optimize for specific deployment scenarios, balancing power consumption with network reliability.

Energy storage integration forms an essential component of deployment strategies. TEG systems typically incorporate supercapacitors or thin-film batteries to buffer energy production variations. The selection of storage technology must account for environmental conditions, expected temperature fluctuations, and anticipated power demands during peak sensing and transmission activities.

Deployment density calculations must consider the energy harvesting potential of each node against its coverage requirements. Optimal spacing between nodes depends on both communication range and the thermal gradient landscape. In environments with uniform temperature differentials, wider spacing may be feasible, while areas with sporadic thermal opportunities may require denser node placement to maintain network functionality.

Adaptive power management protocols should be implemented during deployment to dynamically adjust node behavior based on available energy. These protocols can include variable sampling rates, conditional data transmission, and selective sensor activation. Such adaptations extend network longevity by intelligently managing energy resources across changing environmental conditions.

Installation methodologies must address thermal interface optimization to maximize TEG efficiency. This includes selecting appropriate thermal interface materials, ensuring proper mechanical coupling to heat sources and sinks, and implementing protective measures against environmental degradation. The quality of these thermal connections directly impacts the long-term performance of the network.

Post-deployment monitoring systems should be incorporated to track network performance metrics, including energy harvesting efficiency, communication reliability, and sensor data quality. These monitoring capabilities enable remote diagnostics and facilitate predictive maintenance, reducing the need for field interventions and extending the operational lifespan of the deployed network.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!