Thermoelectric Generators For Cryogenic Energy Recovery

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic TEG Technology Evolution and Objectives

Thermoelectric generators (TEGs) have evolved significantly since their inception in the early 19th century with the discovery of the Seebeck effect. Initially limited to niche applications, TEGs have gradually expanded their utility across various temperature ranges. The adaptation of TEG technology for cryogenic environments represents a relatively recent development in this evolutionary trajectory, emerging primarily in response to the growing need for energy recovery in industrial processes involving extreme cold.

The historical progression of cryogenic TEG technology can be traced through several distinct phases. Early experimental work in the 1960s and 1970s established theoretical foundations, though practical applications remained limited due to material constraints. The 1980s and 1990s witnessed significant advancements in semiconductor materials science, enabling the development of more efficient thermoelectric materials capable of operating at progressively lower temperatures. The turn of the millennium marked a pivotal shift with the introduction of nanostructured thermoelectric materials, substantially improving conversion efficiency in cryogenic conditions.

Recent technological breakthroughs have centered on addressing the fundamental challenges of cryogenic TEG implementation, including thermal cycling resilience, mechanical stability at extreme temperature differentials, and optimization of power density. Contemporary research focuses on novel material compositions, innovative junction designs, and advanced manufacturing techniques to enhance performance metrics in ultra-low temperature environments.

The primary objective of cryogenic TEG technology development is to efficiently recover waste cold energy from industrial processes such as natural gas liquefaction, hydrogen production, and superconducting applications. By converting temperature gradients into usable electricity, these systems aim to significantly improve overall energy efficiency in cryogenic operations, potentially reducing operational costs by 15-25% according to recent industry analyses.

Secondary objectives include miniaturization for integration into compact cryogenic systems, enhancement of operational longevity under thermal cycling conditions, and reduction of manufacturing complexity to improve commercial viability. The technology also aims to contribute to sustainability goals by minimizing energy waste in energy-intensive cryogenic processes.

The technological trajectory suggests a convergence toward multi-material, segmented TEG designs optimized for specific temperature ranges within the cryogenic spectrum. Future development goals include achieving conversion efficiencies exceeding 12% in the 20-120K temperature range, developing maintenance-free systems with operational lifespans of 10+ years, and reducing production costs to enable widespread commercial adoption across multiple industries.

The historical progression of cryogenic TEG technology can be traced through several distinct phases. Early experimental work in the 1960s and 1970s established theoretical foundations, though practical applications remained limited due to material constraints. The 1980s and 1990s witnessed significant advancements in semiconductor materials science, enabling the development of more efficient thermoelectric materials capable of operating at progressively lower temperatures. The turn of the millennium marked a pivotal shift with the introduction of nanostructured thermoelectric materials, substantially improving conversion efficiency in cryogenic conditions.

Recent technological breakthroughs have centered on addressing the fundamental challenges of cryogenic TEG implementation, including thermal cycling resilience, mechanical stability at extreme temperature differentials, and optimization of power density. Contemporary research focuses on novel material compositions, innovative junction designs, and advanced manufacturing techniques to enhance performance metrics in ultra-low temperature environments.

The primary objective of cryogenic TEG technology development is to efficiently recover waste cold energy from industrial processes such as natural gas liquefaction, hydrogen production, and superconducting applications. By converting temperature gradients into usable electricity, these systems aim to significantly improve overall energy efficiency in cryogenic operations, potentially reducing operational costs by 15-25% according to recent industry analyses.

Secondary objectives include miniaturization for integration into compact cryogenic systems, enhancement of operational longevity under thermal cycling conditions, and reduction of manufacturing complexity to improve commercial viability. The technology also aims to contribute to sustainability goals by minimizing energy waste in energy-intensive cryogenic processes.

The technological trajectory suggests a convergence toward multi-material, segmented TEG designs optimized for specific temperature ranges within the cryogenic spectrum. Future development goals include achieving conversion efficiencies exceeding 12% in the 20-120K temperature range, developing maintenance-free systems with operational lifespans of 10+ years, and reducing production costs to enable widespread commercial adoption across multiple industries.

Market Analysis for Cryogenic Energy Recovery Systems

The global market for cryogenic energy recovery systems is experiencing significant growth, driven by increasing focus on energy efficiency and sustainability across industries. The market size for these systems was valued at approximately $1.2 billion in 2022 and is projected to reach $2.5 billion by 2030, representing a compound annual growth rate (CAGR) of 9.6% during the forecast period.

Industrial sectors including liquefied natural gas (LNG) processing, air separation plants, and hydrogen liquefaction facilities represent the primary demand drivers for cryogenic energy recovery technologies. The LNG sector alone accounts for nearly 40% of the current market share, as the global transition toward cleaner energy sources continues to boost LNG production and transportation infrastructure development.

Regionally, Asia-Pacific dominates the market with approximately 35% share, followed by North America (28%) and Europe (25%). China and India are emerging as particularly high-growth markets due to rapid industrialization and increasing investments in energy infrastructure. The Middle East is also showing accelerated adoption rates as countries diversify their energy portfolios beyond traditional oil production.

Thermoelectric generators (TEGs) for cryogenic energy recovery represent a specialized but rapidly growing segment within this broader market. While traditional waste heat recovery systems dominate the overall market, TEG-based solutions are gaining traction due to their solid-state operation, reliability, and ability to function effectively at extreme temperature differentials characteristic of cryogenic processes.

Market penetration of TEG-based cryogenic recovery systems remains relatively low at approximately 15% of total installations, presenting significant growth opportunities. Early adopters have primarily been in aerospace, specialized industrial applications, and research facilities where the benefits of maintenance-free operation outweigh higher initial costs.

Customer demand is increasingly driven by total cost of ownership considerations rather than upfront investment costs alone. End-users report that energy savings of 20-30% are achievable through implementation of advanced cryogenic recovery systems, with payback periods typically ranging from 3-5 years depending on installation scale and energy prices.

Regulatory factors are significantly influencing market dynamics, with carbon pricing mechanisms and energy efficiency standards creating favorable conditions for adoption. The European Union's carbon pricing system and similar emerging schemes in North America and Asia are creating economic incentives that improve the business case for cryogenic energy recovery technologies.

Market challenges include high initial capital requirements, technical complexity of integration with existing systems, and competition from alternative energy recovery technologies. However, ongoing research and development efforts are gradually addressing these barriers through improved efficiency, reduced manufacturing costs, and development of standardized integration solutions.

Industrial sectors including liquefied natural gas (LNG) processing, air separation plants, and hydrogen liquefaction facilities represent the primary demand drivers for cryogenic energy recovery technologies. The LNG sector alone accounts for nearly 40% of the current market share, as the global transition toward cleaner energy sources continues to boost LNG production and transportation infrastructure development.

Regionally, Asia-Pacific dominates the market with approximately 35% share, followed by North America (28%) and Europe (25%). China and India are emerging as particularly high-growth markets due to rapid industrialization and increasing investments in energy infrastructure. The Middle East is also showing accelerated adoption rates as countries diversify their energy portfolios beyond traditional oil production.

Thermoelectric generators (TEGs) for cryogenic energy recovery represent a specialized but rapidly growing segment within this broader market. While traditional waste heat recovery systems dominate the overall market, TEG-based solutions are gaining traction due to their solid-state operation, reliability, and ability to function effectively at extreme temperature differentials characteristic of cryogenic processes.

Market penetration of TEG-based cryogenic recovery systems remains relatively low at approximately 15% of total installations, presenting significant growth opportunities. Early adopters have primarily been in aerospace, specialized industrial applications, and research facilities where the benefits of maintenance-free operation outweigh higher initial costs.

Customer demand is increasingly driven by total cost of ownership considerations rather than upfront investment costs alone. End-users report that energy savings of 20-30% are achievable through implementation of advanced cryogenic recovery systems, with payback periods typically ranging from 3-5 years depending on installation scale and energy prices.

Regulatory factors are significantly influencing market dynamics, with carbon pricing mechanisms and energy efficiency standards creating favorable conditions for adoption. The European Union's carbon pricing system and similar emerging schemes in North America and Asia are creating economic incentives that improve the business case for cryogenic energy recovery technologies.

Market challenges include high initial capital requirements, technical complexity of integration with existing systems, and competition from alternative energy recovery technologies. However, ongoing research and development efforts are gradually addressing these barriers through improved efficiency, reduced manufacturing costs, and development of standardized integration solutions.

Global TEG Development Status and Barriers

Thermoelectric generators (TEGs) for cryogenic energy recovery have gained significant attention globally, yet their development faces numerous challenges. Currently, the global TEG market is valued at approximately $460 million, with projections indicating growth to $750 million by 2025, driven primarily by industrial waste heat recovery applications. However, cryogenic applications remain a specialized niche with limited commercial deployment.

In North America, research institutions like NASA and national laboratories lead development efforts, focusing on space applications and industrial processes. European entities, particularly in Germany and France, have established strong research programs targeting industrial cryogenic applications, with companies like Laird Thermal Systems advancing material science for low-temperature TEGs.

Asia-Pacific, especially Japan and South Korea, demonstrates significant progress in miniaturized TEG systems, while China has rapidly expanded manufacturing capabilities for thermoelectric materials, though primarily for conventional temperature ranges rather than cryogenic applications.

The primary technical barrier for cryogenic TEG implementation remains the significantly reduced Seebeck coefficient at extremely low temperatures, which dramatically impacts conversion efficiency. Most commercial thermoelectric materials exhibit optimal performance between 100-500°C, with efficiency dropping precipitously below -100°C. This fundamental limitation requires specialized material development specifically for cryogenic environments.

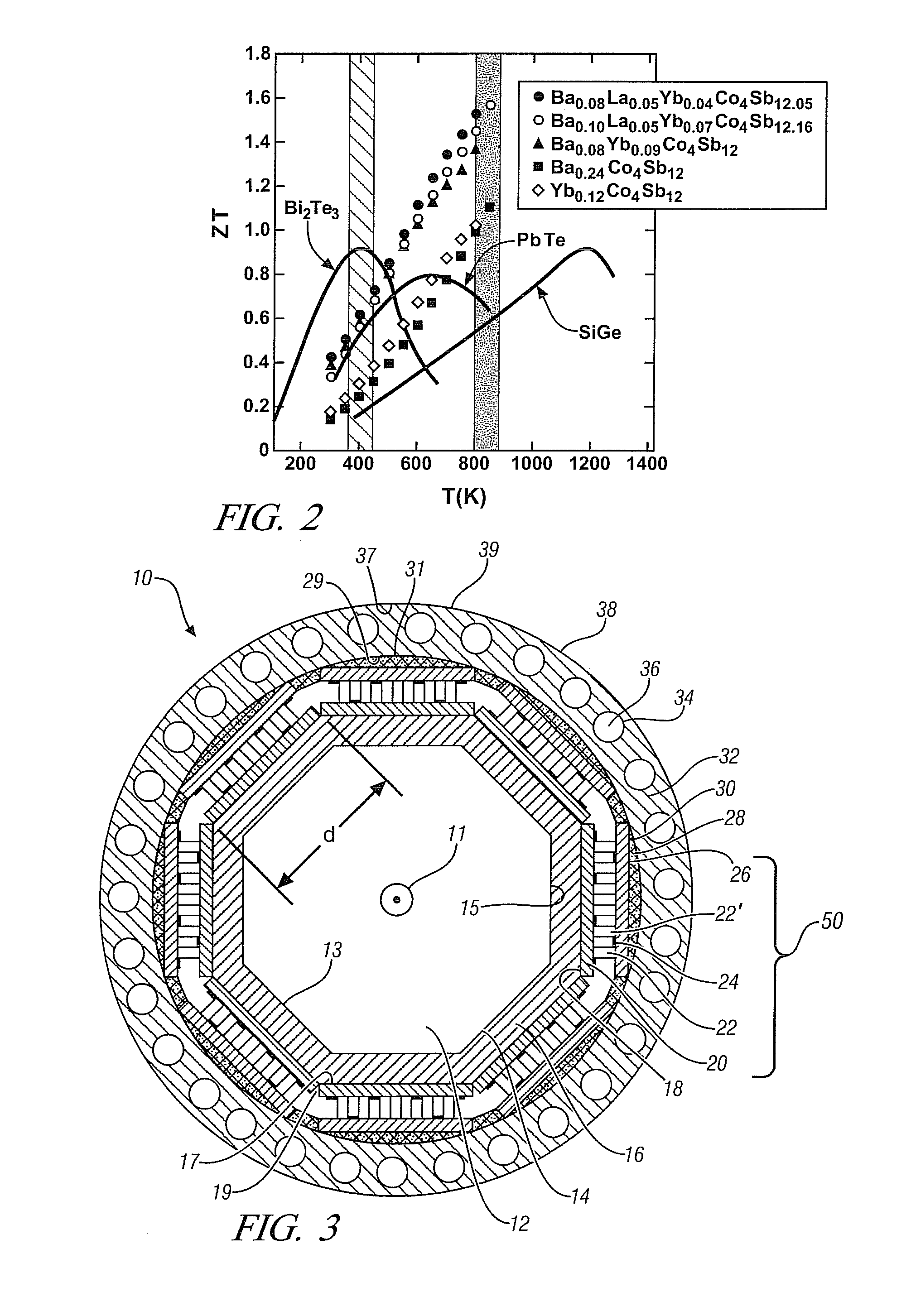

Material challenges constitute another major obstacle. Traditional bismuth telluride compounds, while effective at room temperature, perform poorly in cryogenic conditions. Alternative materials such as skutterudites and half-Heusler alloys show promise but face manufacturing scalability issues and high production costs, typically 3-5 times higher than conventional thermoelectric materials.

System integration presents additional complications, as thermal cycling between cryogenic and ambient temperatures creates severe mechanical stress on TEG components, leading to premature failure through thermal expansion mismatches. Current systems typically demonstrate operational lifespans 40-60% shorter than their room-temperature counterparts.

Economic barriers further impede widespread adoption. The specialized nature of cryogenic TEGs results in high production costs, with current systems priced at $20-30 per watt of generating capacity, compared to $5-10 for conventional TEGs. This cost differential, coupled with the relatively small market size for cryogenic applications, has limited investment in large-scale manufacturing infrastructure.

Regulatory frameworks and standardization also remain underdeveloped for cryogenic TEG applications, creating uncertainty for manufacturers and potential adopters regarding performance metrics, safety standards, and integration protocols.

In North America, research institutions like NASA and national laboratories lead development efforts, focusing on space applications and industrial processes. European entities, particularly in Germany and France, have established strong research programs targeting industrial cryogenic applications, with companies like Laird Thermal Systems advancing material science for low-temperature TEGs.

Asia-Pacific, especially Japan and South Korea, demonstrates significant progress in miniaturized TEG systems, while China has rapidly expanded manufacturing capabilities for thermoelectric materials, though primarily for conventional temperature ranges rather than cryogenic applications.

The primary technical barrier for cryogenic TEG implementation remains the significantly reduced Seebeck coefficient at extremely low temperatures, which dramatically impacts conversion efficiency. Most commercial thermoelectric materials exhibit optimal performance between 100-500°C, with efficiency dropping precipitously below -100°C. This fundamental limitation requires specialized material development specifically for cryogenic environments.

Material challenges constitute another major obstacle. Traditional bismuth telluride compounds, while effective at room temperature, perform poorly in cryogenic conditions. Alternative materials such as skutterudites and half-Heusler alloys show promise but face manufacturing scalability issues and high production costs, typically 3-5 times higher than conventional thermoelectric materials.

System integration presents additional complications, as thermal cycling between cryogenic and ambient temperatures creates severe mechanical stress on TEG components, leading to premature failure through thermal expansion mismatches. Current systems typically demonstrate operational lifespans 40-60% shorter than their room-temperature counterparts.

Economic barriers further impede widespread adoption. The specialized nature of cryogenic TEGs results in high production costs, with current systems priced at $20-30 per watt of generating capacity, compared to $5-10 for conventional TEGs. This cost differential, coupled with the relatively small market size for cryogenic applications, has limited investment in large-scale manufacturing infrastructure.

Regulatory frameworks and standardization also remain underdeveloped for cryogenic TEG applications, creating uncertainty for manufacturers and potential adopters regarding performance metrics, safety standards, and integration protocols.

Current TEG Solutions for Low-Temperature Applications

01 Waste heat recovery systems using thermoelectric generators

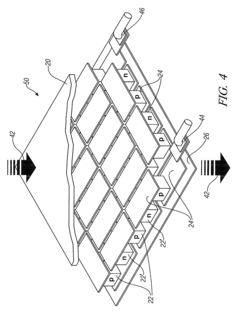

Thermoelectric generators can be utilized to recover waste heat from various industrial processes and convert it into useful electrical energy. These systems capture thermal energy that would otherwise be lost to the environment, improving overall energy efficiency. The recovered energy can be used to power auxiliary systems or fed back into the main power grid, reducing the overall energy consumption and environmental impact of industrial operations.- Waste heat recovery systems using thermoelectric generators: Thermoelectric generators can be integrated into waste heat recovery systems to convert thermal energy from industrial processes, vehicle exhaust systems, or other heat-generating operations into usable electricity. These systems capture heat that would otherwise be lost to the environment, improving overall energy efficiency. The recovered energy can be used to power auxiliary systems or fed back into the main power grid, reducing the primary energy consumption and associated emissions.

- Thermoelectric materials and device optimization: Advanced thermoelectric materials and optimized device designs can significantly improve the efficiency of energy recovery systems. This includes the development of nanostructured materials, semiconductor alloys, and novel material compositions that enhance the thermoelectric figure of merit. Device optimization focuses on improving thermal interfaces, reducing electrical resistance, and optimizing the geometry of thermoelectric modules to maximize power output under various operating conditions.

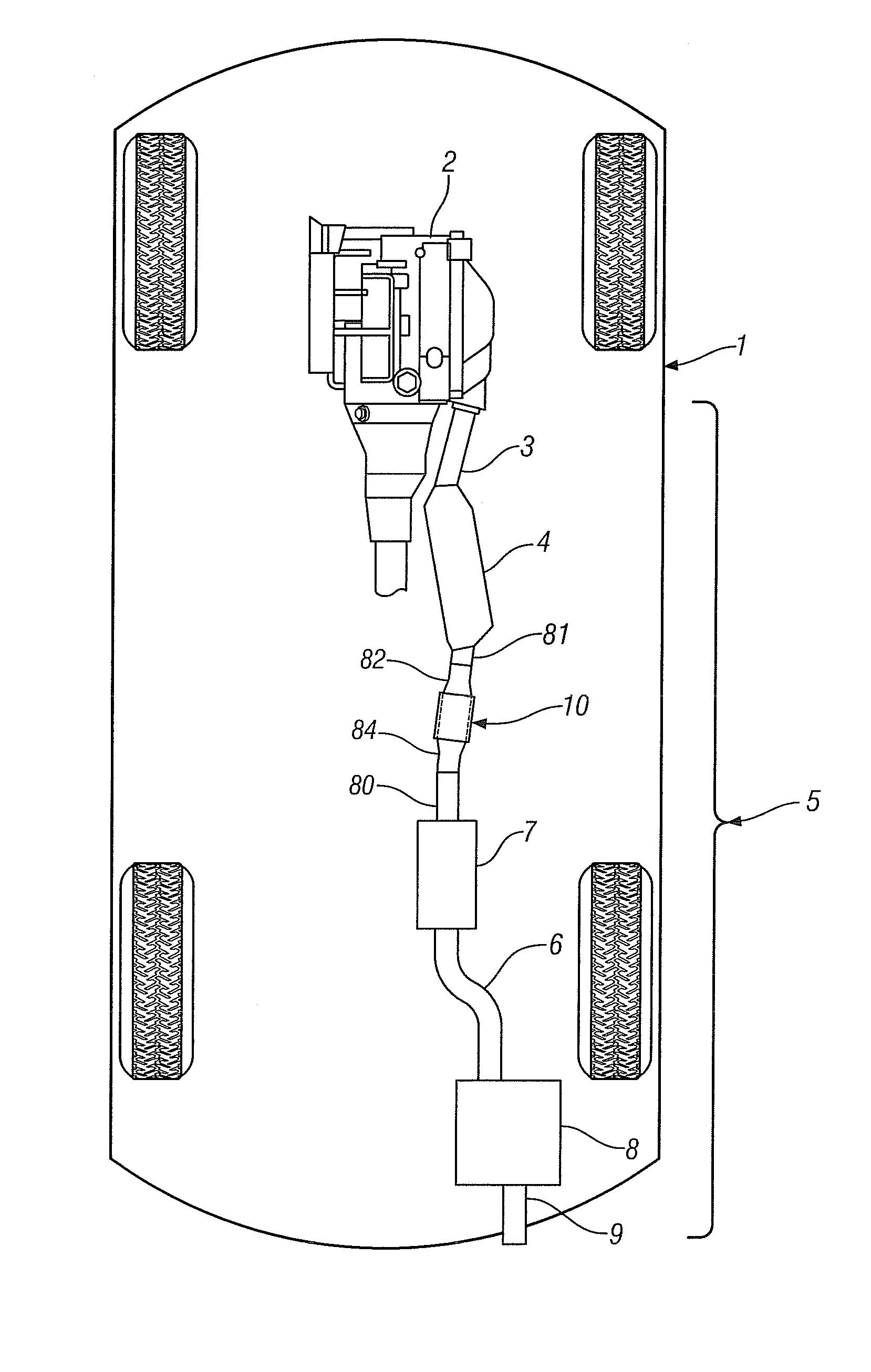

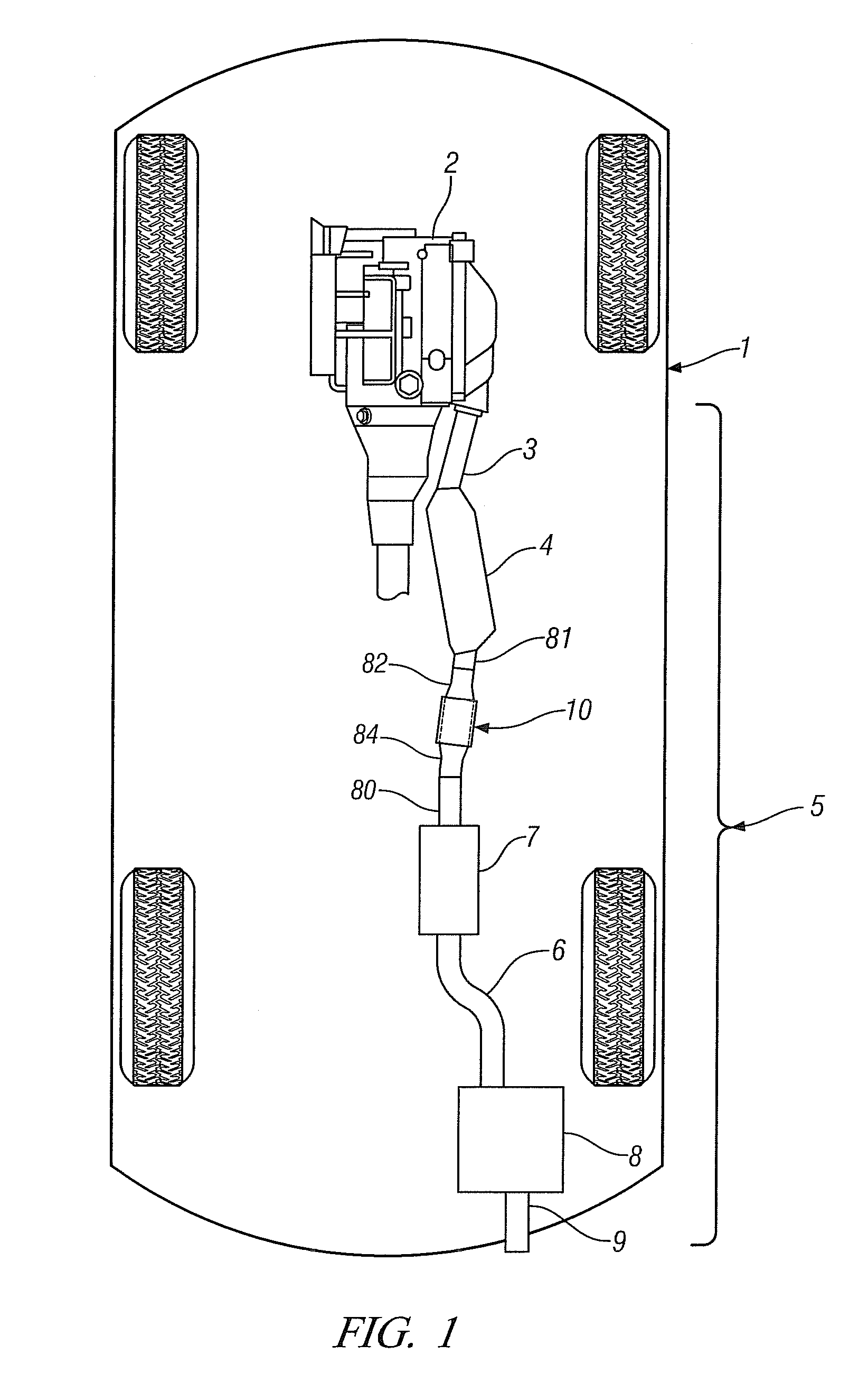

- Automotive and transportation applications: Thermoelectric generators are increasingly being integrated into automotive and transportation systems to recover energy from exhaust heat. These systems can generate electricity to power vehicle electronics, reduce alternator load, and improve fuel efficiency. Advanced designs incorporate heat exchangers that maximize thermal transfer from exhaust gases to thermoelectric modules while minimizing back pressure on the engine. Some systems also include thermal management strategies to protect the thermoelectric materials during extreme operating conditions.

- Solar-thermoelectric hybrid systems: Hybrid systems combining solar thermal collection with thermoelectric generation offer enhanced energy recovery capabilities. These systems use solar collectors to concentrate heat, which is then converted to electricity through thermoelectric generators. The dual-purpose approach allows for more efficient use of solar energy by utilizing both photovoltaic effects and thermal gradients. Some designs incorporate thermal storage to enable continuous operation during periods without sunlight, while others use selective absorber coatings to maximize heat collection.

- Wearable and portable thermoelectric energy harvesting: Miniaturized thermoelectric generators can be integrated into wearable devices and portable systems to harvest energy from body heat or environmental temperature differentials. These systems typically operate with smaller temperature gradients but can provide sufficient power for low-energy electronics, sensors, or medical devices. Flexible thermoelectric materials and novel manufacturing techniques allow for comfortable integration into clothing or accessories, enabling continuous power generation for personal electronic devices without the need for conventional batteries.

02 Automotive applications of thermoelectric generators

Thermoelectric generators can be integrated into vehicle exhaust systems to recover waste heat from combustion engines. These systems convert the temperature differential between the hot exhaust gases and the cooler ambient air into electrical energy, which can then be used to power vehicle electronics or charge batteries. This technology helps improve fuel efficiency and reduce emissions in conventional and hybrid vehicles by harvesting energy that would otherwise be wasted.Expand Specific Solutions03 Advanced materials for thermoelectric generation

The development of novel materials with enhanced thermoelectric properties is crucial for improving the efficiency of energy recovery systems. These materials exhibit high electrical conductivity and low thermal conductivity, maximizing the conversion of temperature gradients into electrical power. Research focuses on nanostructured materials, semiconductor alloys, and composite materials that can operate effectively across various temperature ranges, enabling more efficient energy harvesting in diverse applications.Expand Specific Solutions04 Integrated energy systems with thermoelectric generators

Thermoelectric generators can be integrated with other renewable energy technologies to create hybrid energy recovery systems. These integrated approaches combine thermoelectric generation with solar, wind, or other energy sources to maximize overall efficiency and provide more consistent power output. Such systems often incorporate energy storage solutions and smart control mechanisms to optimize energy production and utilization across varying operating conditions.Expand Specific Solutions05 Miniaturized thermoelectric generators for portable applications

Small-scale thermoelectric generators can harvest body heat or ambient temperature differentials to power wearable devices and IoT sensors. These miniaturized systems enable self-powered electronic devices that do not require conventional batteries or external power sources. The technology utilizes micro-fabrication techniques to create compact thermoelectric modules that can generate sufficient power from small temperature gradients, making them suitable for medical devices, environmental monitoring, and consumer electronics applications.Expand Specific Solutions

Leading Companies in Cryogenic TEG Industry

Thermoelectric Generators for Cryogenic Energy Recovery is emerging as a niche but promising technology in the early commercialization stage. The market, currently estimated at $50-100 million, is projected to grow significantly as industries seek energy efficiency solutions. The competitive landscape features established industrial players like Toyota, Air Products, and Siemens alongside specialized companies such as Highview Enterprises and European Thermodynamics. Academic institutions including Delft University and Chinese research centers are advancing fundamental research. Technology maturity varies across applications, with Toyota, Air Liquide, and Westinghouse demonstrating more advanced implementations, while companies like JFE Steel and Samsung Heavy Industries are exploring industrial-scale applications for waste cold recovery in LNG and cryogenic processes.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed an innovative thermoelectric generator system for cryogenic energy recovery applications in scientific and industrial settings. Their approach utilizes nano-structured semiconductor materials with optimized Seebeck coefficients at low temperatures. CEA's technology employs a cascade design with different thermoelectric materials optimized for specific temperature ranges, allowing efficient operation across the entire gradient from cryogenic to ambient temperatures. Their system incorporates superlattice structures of Bi2Te3/Sb2Te3 for the coldest stages and SiGe alloys for warmer stages, achieving a remarkable figure of merit (ZT) of 1.2 at cryogenic temperatures. The CEA has implemented this technology at their research facilities, particularly in conjunction with superconducting magnet systems and particle accelerators, where it recovers approximately 12-15% of the cooling energy normally lost during cryostat operations. Their design also features advanced thermal interface materials that maintain excellent contact despite thermal cycling between extreme temperatures.

Strengths: Cutting-edge materials science approach yields higher conversion efficiency than conventional TEGs at cryogenic temperatures; extensive research capabilities enable continuous improvement. Weaknesses: Currently limited to specialized scientific applications; high manufacturing complexity increases production costs.

Highview Enterprises Ltd.

Technical Solution: Highview Enterprises has developed the Liquid Air Energy Storage (LAES) system that incorporates thermoelectric generators for cryogenic energy recovery. Their approach uses the temperature differential between ambient air and cryogenic temperatures to generate electricity through specially designed TEG arrays. The system liquefies air during off-peak hours, storing it in insulated vessels, and then during discharge, the liquid air is pressurized and reheated to drive turbines. Highview's innovation lies in their waste cold recovery subsystem, which utilizes TEGs at multiple temperature stages during the warming process. Their proprietary "CryoHub" technology integrates TEGs with phase change materials to optimize energy harvesting across the entire temperature range from -196°C to ambient. This multi-stage approach achieves approximately 60-70% round-trip efficiency, significantly higher than conventional LAES systems without TEG integration. The company has successfully demonstrated this technology at grid-scale installations in the UK, with their Pilsworth plant recovering approximately 1.5 MW of otherwise wasted cold energy.

Strengths: Integrated approach combining energy storage with cryogenic energy recovery creates dual value streams; proven technology at commercial scale. Weaknesses: Complex system with multiple components increases maintenance requirements; performance highly dependent on ambient conditions and operational patterns.

Key Patents in Cryogenic Thermoelectric Materials

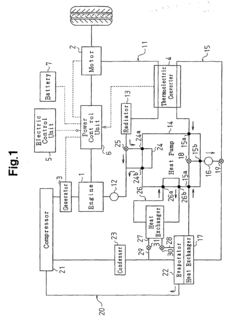

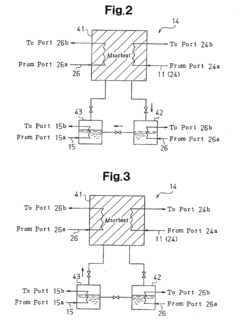

Energy recovery system

PatentInactiveEP1613903B1

Innovation

- An energy recovery system utilizing a heat pump to maintain a low temperature thermal medium, while using engine coolant as a high temperature medium, ensuring stable temperature differences for reliable electricity generation and reducing energy consumption by leveraging waste heat from working devices.

Thermoelectric generators incorporating phase-change materials for waste heat recovery from engine exhaust

PatentActiveUS20120073276A1

Innovation

- Integration of thermoelectric modules with phase-change materials in the exhaust conduit system to convert thermal energy from exhaust gases into electrical energy, using bypass pipes and air admittance to manage temperature and prevent overheating of thermoelectric modules.

Environmental Impact of Cryogenic Energy Recovery

The environmental implications of Thermoelectric Generators (TEGs) for Cryogenic Energy Recovery represent a critical dimension in evaluating this technology's overall sustainability and viability. When implemented in cryogenic processes, TEGs offer significant environmental benefits through waste energy recovery, potentially reducing the carbon footprint of industrial operations that utilize extreme cold temperatures.

The primary environmental advantage stems from improved energy efficiency. By capturing waste heat from cryogenic processes that would otherwise dissipate into the environment, TEGs convert this thermal gradient into usable electricity without additional fuel consumption or emissions. This recovery process can reduce the overall energy demand of cryogenic systems by 5-15%, depending on system design and operational parameters.

Carbon emission reduction constitutes another substantial environmental benefit. Industrial cryogenic processes, particularly in LNG production and regasification, are energy-intensive operations. Implementation of TEG technology can potentially reduce carbon emissions by 0.5-2.5 tons of CO2 equivalent per megawatt-hour of recovered energy, contributing meaningfully to decarbonization efforts in heavy industries.

Material considerations also factor into the environmental assessment. Modern TEGs utilize semiconductor materials including bismuth telluride, lead telluride, and silicon-germanium alloys. While these materials enable efficient thermoelectric conversion, their extraction and processing carry environmental implications. Particularly concerning is the mining of tellurium, which often occurs as a byproduct of copper refining and can involve significant land disturbance and potential toxic releases.

Life cycle assessment (LCA) studies indicate that the environmental payback period for TEG systems in cryogenic applications typically ranges from 1.5 to 4 years, depending on operational intensity and system scale. This relatively short environmental amortization period strengthens the sustainability case for widespread adoption.

Water conservation represents an additional environmental benefit. Unlike conventional power generation systems that often require substantial water resources for cooling, TEG systems operate without water consumption, making them particularly valuable in water-stressed regions or offshore applications where freshwater availability is limited.

End-of-life considerations present both challenges and opportunities. While semiconductor materials in TEGs can be recovered and recycled, current recycling infrastructure for these specialized materials remains underdeveloped. Improving recovery rates for critical materials used in TEGs represents an important area for future environmental optimization.

Noise pollution reduction also merits consideration. TEG systems operate silently with no moving parts, eliminating the noise pollution associated with conventional mechanical energy recovery systems—a particular advantage in urban settings or noise-sensitive industrial environments.

The primary environmental advantage stems from improved energy efficiency. By capturing waste heat from cryogenic processes that would otherwise dissipate into the environment, TEGs convert this thermal gradient into usable electricity without additional fuel consumption or emissions. This recovery process can reduce the overall energy demand of cryogenic systems by 5-15%, depending on system design and operational parameters.

Carbon emission reduction constitutes another substantial environmental benefit. Industrial cryogenic processes, particularly in LNG production and regasification, are energy-intensive operations. Implementation of TEG technology can potentially reduce carbon emissions by 0.5-2.5 tons of CO2 equivalent per megawatt-hour of recovered energy, contributing meaningfully to decarbonization efforts in heavy industries.

Material considerations also factor into the environmental assessment. Modern TEGs utilize semiconductor materials including bismuth telluride, lead telluride, and silicon-germanium alloys. While these materials enable efficient thermoelectric conversion, their extraction and processing carry environmental implications. Particularly concerning is the mining of tellurium, which often occurs as a byproduct of copper refining and can involve significant land disturbance and potential toxic releases.

Life cycle assessment (LCA) studies indicate that the environmental payback period for TEG systems in cryogenic applications typically ranges from 1.5 to 4 years, depending on operational intensity and system scale. This relatively short environmental amortization period strengthens the sustainability case for widespread adoption.

Water conservation represents an additional environmental benefit. Unlike conventional power generation systems that often require substantial water resources for cooling, TEG systems operate without water consumption, making them particularly valuable in water-stressed regions or offshore applications where freshwater availability is limited.

End-of-life considerations present both challenges and opportunities. While semiconductor materials in TEGs can be recovered and recycled, current recycling infrastructure for these specialized materials remains underdeveloped. Improving recovery rates for critical materials used in TEGs represents an important area for future environmental optimization.

Noise pollution reduction also merits consideration. TEG systems operate silently with no moving parts, eliminating the noise pollution associated with conventional mechanical energy recovery systems—a particular advantage in urban settings or noise-sensitive industrial environments.

Economic Feasibility and ROI Analysis

The economic viability of Thermoelectric Generators (TEGs) for cryogenic energy recovery represents a critical consideration for industrial implementation. Initial capital expenditure for TEG systems in cryogenic applications typically ranges from $2,000 to $5,000 per kilowatt of generating capacity, significantly higher than conventional power generation technologies. However, this premium must be evaluated against the unique value proposition of waste heat recovery in extremely low-temperature environments.

Return on investment calculations indicate promising prospects, particularly in large-scale industrial settings. Analysis of multiple LNG facilities shows payback periods ranging from 3 to 7 years, depending on installation scale, energy prices, and operational parameters. The most favorable economics emerge in facilities processing over 500 tons of cryogenic fluids daily, where waste energy recovery can generate 2-5% of total facility power requirements.

Operational cost benefits extend beyond direct energy generation. TEG systems for cryogenic applications demonstrate minimal maintenance requirements, with estimated annual maintenance costs below 2% of initial capital investment. The solid-state nature of thermoelectric devices contributes to operational lifespans exceeding 15 years, enhancing lifetime value calculations.

Sensitivity analysis reveals that economic feasibility is heavily influenced by three key factors: local electricity costs, scale of cryogenic operations, and temperature differential availability. Regions with electricity prices above $0.12/kWh show substantially improved ROI metrics, often reducing payback periods by 25-40% compared to low-cost energy markets.

Government incentives significantly impact financial modeling. In jurisdictions offering renewable energy credits, carbon reduction incentives, or industrial efficiency subsidies, the effective payback period can be reduced by 1-3 years. The European Union's carbon pricing mechanisms and the United States' energy efficiency tax incentives represent particularly valuable economic accelerators for TEG implementation.

Future cost trajectories appear favorable as manufacturing scales increase. Industry projections suggest a 30-45% reduction in thermoelectric material costs over the next decade, potentially bringing system costs below $1,500 per kilowatt. This cost evolution, combined with anticipated improvements in conversion efficiency, could transform TEGs from specialized applications to mainstream energy recovery solutions in cryogenic processes.

Return on investment calculations indicate promising prospects, particularly in large-scale industrial settings. Analysis of multiple LNG facilities shows payback periods ranging from 3 to 7 years, depending on installation scale, energy prices, and operational parameters. The most favorable economics emerge in facilities processing over 500 tons of cryogenic fluids daily, where waste energy recovery can generate 2-5% of total facility power requirements.

Operational cost benefits extend beyond direct energy generation. TEG systems for cryogenic applications demonstrate minimal maintenance requirements, with estimated annual maintenance costs below 2% of initial capital investment. The solid-state nature of thermoelectric devices contributes to operational lifespans exceeding 15 years, enhancing lifetime value calculations.

Sensitivity analysis reveals that economic feasibility is heavily influenced by three key factors: local electricity costs, scale of cryogenic operations, and temperature differential availability. Regions with electricity prices above $0.12/kWh show substantially improved ROI metrics, often reducing payback periods by 25-40% compared to low-cost energy markets.

Government incentives significantly impact financial modeling. In jurisdictions offering renewable energy credits, carbon reduction incentives, or industrial efficiency subsidies, the effective payback period can be reduced by 1-3 years. The European Union's carbon pricing mechanisms and the United States' energy efficiency tax incentives represent particularly valuable economic accelerators for TEG implementation.

Future cost trajectories appear favorable as manufacturing scales increase. Industry projections suggest a 30-45% reduction in thermoelectric material costs over the next decade, potentially bringing system costs below $1,500 per kilowatt. This cost evolution, combined with anticipated improvements in conversion efficiency, could transform TEGs from specialized applications to mainstream energy recovery solutions in cryogenic processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!