Comparison Of Thermoelectric Generators For Railway Systems

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Railway TEG Technology Background and Objectives

Thermoelectric generators (TEGs) have emerged as a promising technology for energy harvesting in railway systems, converting waste heat into usable electrical energy through the Seebeck effect. The historical development of TEGs dates back to the early 19th century with Thomas Johann Seebeck's discovery, but their application in railway environments represents a relatively recent innovation aimed at enhancing energy efficiency and sustainability in transportation infrastructure.

Railway systems generate substantial amounts of waste heat during operation, particularly from braking systems, wheel-rail contact, and engine components. This thermal energy, traditionally dissipated into the environment, presents an untapped resource that could be harnessed to power various auxiliary systems, including signaling equipment, monitoring sensors, and passenger amenities. The evolution of TEG technology has been driven by advancements in semiconductor materials, manufacturing techniques, and system integration approaches.

The global push toward greener transportation solutions has accelerated research and development in railway TEG applications over the past decade. Initial implementations focused primarily on proof-of-concept demonstrations, while recent efforts have shifted toward optimizing performance, durability, and cost-effectiveness for commercial deployment. The technology has progressed from laboratory-scale prototypes to field-tested systems capable of operating under the harsh conditions typical of railway environments.

Current technical objectives for railway TEG systems center on improving conversion efficiency, which typically ranges from 3-8% in existing implementations. Research aims to achieve efficiency rates of 10-15% through advanced material development and system design optimization. Additionally, there is a focus on enhancing the robustness of TEG modules to withstand vibration, temperature fluctuations, and environmental contaminants inherent to railway operations.

Another critical objective involves reducing the cost-per-watt of TEG systems to make them economically viable alternatives to conventional power sources. This includes exploring mass production techniques, identifying alternative materials with comparable performance but lower costs, and developing standardized integration frameworks that simplify installation and maintenance procedures.

The long-term vision for railway TEG technology encompasses the development of self-powered railway infrastructure components that operate independently of external power supplies. This would significantly reduce maintenance requirements, enhance system reliability, and contribute to the overall sustainability of railway networks. As the technology matures, the integration of TEGs with other renewable energy sources and energy storage systems presents opportunities for creating comprehensive energy management solutions tailored to the unique demands of modern railway operations.

Railway systems generate substantial amounts of waste heat during operation, particularly from braking systems, wheel-rail contact, and engine components. This thermal energy, traditionally dissipated into the environment, presents an untapped resource that could be harnessed to power various auxiliary systems, including signaling equipment, monitoring sensors, and passenger amenities. The evolution of TEG technology has been driven by advancements in semiconductor materials, manufacturing techniques, and system integration approaches.

The global push toward greener transportation solutions has accelerated research and development in railway TEG applications over the past decade. Initial implementations focused primarily on proof-of-concept demonstrations, while recent efforts have shifted toward optimizing performance, durability, and cost-effectiveness for commercial deployment. The technology has progressed from laboratory-scale prototypes to field-tested systems capable of operating under the harsh conditions typical of railway environments.

Current technical objectives for railway TEG systems center on improving conversion efficiency, which typically ranges from 3-8% in existing implementations. Research aims to achieve efficiency rates of 10-15% through advanced material development and system design optimization. Additionally, there is a focus on enhancing the robustness of TEG modules to withstand vibration, temperature fluctuations, and environmental contaminants inherent to railway operations.

Another critical objective involves reducing the cost-per-watt of TEG systems to make them economically viable alternatives to conventional power sources. This includes exploring mass production techniques, identifying alternative materials with comparable performance but lower costs, and developing standardized integration frameworks that simplify installation and maintenance procedures.

The long-term vision for railway TEG technology encompasses the development of self-powered railway infrastructure components that operate independently of external power supplies. This would significantly reduce maintenance requirements, enhance system reliability, and contribute to the overall sustainability of railway networks. As the technology matures, the integration of TEGs with other renewable energy sources and energy storage systems presents opportunities for creating comprehensive energy management solutions tailored to the unique demands of modern railway operations.

Market Analysis for Railway Energy Harvesting Solutions

The railway energy harvesting market is experiencing significant growth, driven by increasing demands for sustainable power solutions in transportation infrastructure. Currently valued at approximately $87 million globally, this market is projected to reach $157 million by 2027, representing a compound annual growth rate of 6.8%. This growth trajectory is supported by the expanding railway networks worldwide, with over 1.3 million kilometers of operational rail tracks offering substantial potential for energy harvesting implementations.

Thermoelectric generators (TEGs) represent a promising segment within this market, competing with other harvesting technologies such as piezoelectric, solar, and vibration-based systems. TEGs currently account for roughly 23% of the railway energy harvesting market, with their share expected to increase to 31% by 2028 due to their reliability and maintenance-free operation characteristics.

The primary market drivers include the growing emphasis on railway electrification, increasing adoption of smart monitoring systems, and stringent environmental regulations promoting green technologies. The European Union's commitment to reduce transport emissions by 90% by 2050 has particularly accelerated interest in energy harvesting solutions across European railway networks.

Market segmentation reveals distinct application areas for TEGs in railway systems: trackside equipment powering (42% of applications), onboard systems (35%), and signaling infrastructure (23%). The trackside segment shows the highest growth potential due to the extensive deployment of sensors and monitoring equipment along railway corridors that require reliable power sources in remote locations.

Regional analysis indicates Europe leads the market with 38% share, followed by Asia-Pacific (32%), North America (21%), and other regions (9%). China and India represent the fastest-growing markets with annual growth rates exceeding 9%, driven by massive railway infrastructure expansion projects.

Key customer segments include national railway operators (53% of market demand), railway infrastructure management companies (27%), and private railway operators (20%). These stakeholders increasingly prioritize solutions that reduce operational costs and environmental impact while enhancing system reliability.

The economic benefits of implementing TEGs in railway systems are compelling, with potential energy cost savings of 15-20% for specific applications and maintenance cost reductions of up to 30% for remote equipment. The average return on investment period for railway TEG installations ranges from 3.5 to 5 years, depending on application type and scale of deployment.

Market challenges include high initial implementation costs, technical integration difficulties with existing infrastructure, and competition from alternative energy harvesting technologies. However, the increasing focus on sustainable railway operations and the development of more efficient TEG technologies are expected to overcome these barriers in the coming years.

Thermoelectric generators (TEGs) represent a promising segment within this market, competing with other harvesting technologies such as piezoelectric, solar, and vibration-based systems. TEGs currently account for roughly 23% of the railway energy harvesting market, with their share expected to increase to 31% by 2028 due to their reliability and maintenance-free operation characteristics.

The primary market drivers include the growing emphasis on railway electrification, increasing adoption of smart monitoring systems, and stringent environmental regulations promoting green technologies. The European Union's commitment to reduce transport emissions by 90% by 2050 has particularly accelerated interest in energy harvesting solutions across European railway networks.

Market segmentation reveals distinct application areas for TEGs in railway systems: trackside equipment powering (42% of applications), onboard systems (35%), and signaling infrastructure (23%). The trackside segment shows the highest growth potential due to the extensive deployment of sensors and monitoring equipment along railway corridors that require reliable power sources in remote locations.

Regional analysis indicates Europe leads the market with 38% share, followed by Asia-Pacific (32%), North America (21%), and other regions (9%). China and India represent the fastest-growing markets with annual growth rates exceeding 9%, driven by massive railway infrastructure expansion projects.

Key customer segments include national railway operators (53% of market demand), railway infrastructure management companies (27%), and private railway operators (20%). These stakeholders increasingly prioritize solutions that reduce operational costs and environmental impact while enhancing system reliability.

The economic benefits of implementing TEGs in railway systems are compelling, with potential energy cost savings of 15-20% for specific applications and maintenance cost reductions of up to 30% for remote equipment. The average return on investment period for railway TEG installations ranges from 3.5 to 5 years, depending on application type and scale of deployment.

Market challenges include high initial implementation costs, technical integration difficulties with existing infrastructure, and competition from alternative energy harvesting technologies. However, the increasing focus on sustainable railway operations and the development of more efficient TEG technologies are expected to overcome these barriers in the coming years.

Current TEG Implementation Challenges in Railway Systems

The integration of Thermoelectric Generators (TEGs) into railway systems presents several significant technical challenges that currently limit widespread adoption. One primary obstacle is the relatively low energy conversion efficiency of TEG systems, typically ranging from 3-8% under real-world operating conditions. This efficiency limitation necessitates larger TEG arrays to generate meaningful power outputs, creating spatial constraints in the already compact railway environments.

Thermal management represents another critical challenge, as railway TEG systems must handle extreme temperature fluctuations ranging from -40°C to over 600°C depending on the heat source location. The thermal cycling that occurs during normal railway operations—with frequent starts, stops, and variable speeds—creates thermal stress that can accelerate material degradation and reduce system lifespan.

Mechanical durability concerns are particularly pronounced in railway applications due to constant vibration, shock loads, and exposure to harsh environmental conditions. TEG modules must withstand these mechanical stresses while maintaining reliable electrical connections and thermal interfaces, which often leads to premature failure of conventional TEG designs not specifically engineered for high-vibration environments.

Integration complexity presents additional hurdles, as retrofitting existing railway systems with TEGs requires careful consideration of available space, access to suitable heat sources, and compatibility with existing electrical systems. The heterogeneous nature of global railway fleets, with varying designs and operational parameters, makes standardized TEG solutions difficult to implement across different railway systems.

Cost-effectiveness remains a significant barrier, with current high-quality TEG materials like bismuth telluride being expensive and sometimes containing rare or strategic elements. The initial capital expenditure for railway TEG systems often exceeds that of conventional power generation alternatives, creating financial disincentives despite potential long-term operational benefits.

Regulatory compliance adds another layer of complexity, as railway systems are subject to stringent safety and performance standards. TEG implementations must meet electromagnetic compatibility requirements, fire safety regulations, and reliability standards specific to the railway industry, which varies across different countries and jurisdictions.

Maintenance considerations also pose challenges, as TEG systems installed in difficult-to-access locations on trains require specialized maintenance protocols. The need for periodic inspection and potential replacement of TEG components must be balanced against the operational demands of railway systems, which prioritize minimal downtime and maintenance interventions.

Thermal management represents another critical challenge, as railway TEG systems must handle extreme temperature fluctuations ranging from -40°C to over 600°C depending on the heat source location. The thermal cycling that occurs during normal railway operations—with frequent starts, stops, and variable speeds—creates thermal stress that can accelerate material degradation and reduce system lifespan.

Mechanical durability concerns are particularly pronounced in railway applications due to constant vibration, shock loads, and exposure to harsh environmental conditions. TEG modules must withstand these mechanical stresses while maintaining reliable electrical connections and thermal interfaces, which often leads to premature failure of conventional TEG designs not specifically engineered for high-vibration environments.

Integration complexity presents additional hurdles, as retrofitting existing railway systems with TEGs requires careful consideration of available space, access to suitable heat sources, and compatibility with existing electrical systems. The heterogeneous nature of global railway fleets, with varying designs and operational parameters, makes standardized TEG solutions difficult to implement across different railway systems.

Cost-effectiveness remains a significant barrier, with current high-quality TEG materials like bismuth telluride being expensive and sometimes containing rare or strategic elements. The initial capital expenditure for railway TEG systems often exceeds that of conventional power generation alternatives, creating financial disincentives despite potential long-term operational benefits.

Regulatory compliance adds another layer of complexity, as railway systems are subject to stringent safety and performance standards. TEG implementations must meet electromagnetic compatibility requirements, fire safety regulations, and reliability standards specific to the railway industry, which varies across different countries and jurisdictions.

Maintenance considerations also pose challenges, as TEG systems installed in difficult-to-access locations on trains require specialized maintenance protocols. The need for periodic inspection and potential replacement of TEG components must be balanced against the operational demands of railway systems, which prioritize minimal downtime and maintenance interventions.

Comparative Analysis of Current TEG Solutions for Railways

01 Materials and structures for thermoelectric generators

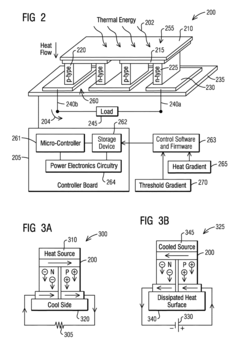

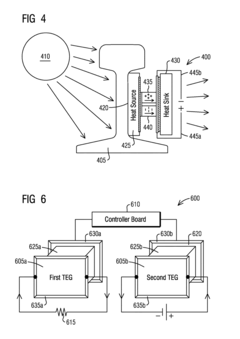

Various materials and structural designs are used to enhance the efficiency of thermoelectric generators. These include specialized semiconductor materials, nanostructured elements, and composite materials that can improve the Seebeck coefficient while reducing thermal conductivity. Advanced structural designs focus on optimizing the thermal gradient across the device and maximizing power output through improved electrical contacts and thermal interfaces.- Materials and structures for thermoelectric generators: Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and composite materials that optimize the Seebeck effect while minimizing thermal conductivity. Advanced structural designs focus on maximizing the temperature gradient across the thermoelectric elements and improving electrical contact between components.

- Waste heat recovery applications: Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Applications include exhaust heat recovery in vehicles, industrial process heat utilization, and power generation from combustion systems, contributing to improved energy efficiency and reduced environmental impact.

- Portable and wearable thermoelectric power generation: Miniaturized thermoelectric generators are being developed for portable and wearable applications, utilizing body heat or environmental temperature differences to generate electricity. These compact devices can power small electronics, medical devices, and IoT sensors without requiring battery replacement. Design considerations include flexibility, comfort, durability, and maximizing power output from relatively small temperature differentials.

- Integration with renewable energy systems: Thermoelectric generators are being integrated with other renewable energy systems to create hybrid power generation solutions. These integrated systems combine solar thermal, geothermal, or biomass heat sources with thermoelectric conversion to improve overall efficiency and provide more consistent power output. Such hybrid approaches help address intermittency issues associated with certain renewable energy sources.

- Modeling and optimization techniques: Advanced computational modeling and optimization techniques are being applied to thermoelectric generator design to maximize performance. These include thermal and electrical simulation, multi-physics modeling, and machine learning approaches to predict and enhance device efficiency. Optimization focuses on material selection, geometry configuration, thermal management, and electrical circuit design to achieve optimal power output under various operating conditions.

02 Waste heat recovery applications

Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Applications include exhaust heat recovery in vehicles, industrial process heat utilization, and power generation from geothermal sources, contributing to improved energy efficiency and reduced environmental impact.Expand Specific Solutions03 Wearable and portable thermoelectric devices

Miniaturized thermoelectric generators are being developed for wearable and portable applications. These devices harvest body heat or environmental temperature differences to power small electronics, medical devices, and sensors. The designs focus on flexibility, comfort, and integration with textiles or other wearable platforms while maintaining sufficient power output for low-energy consumption devices.Expand Specific Solutions04 Efficiency enhancement techniques

Various techniques are employed to enhance the efficiency of thermoelectric generators. These include segmented leg designs, cascaded structures, thermal concentration methods, and improved electrical circuit configurations. Advanced manufacturing processes like selective laser sintering and precision deposition techniques help create optimized thermoelectric junctions with reduced internal resistance and improved thermal management.Expand Specific Solutions05 Modeling and simulation approaches

Computational modeling and simulation techniques are essential for designing and optimizing thermoelectric generators. These approaches include finite element analysis, multi-physics simulations, and machine learning algorithms to predict performance under various operating conditions. Simulation tools help engineers analyze thermal flow patterns, electrical characteristics, and mechanical stresses, enabling rapid prototyping and performance optimization before physical manufacturing.Expand Specific Solutions

Leading Manufacturers and Competitors in Railway TEG Market

Thermoelectric generators (TEGs) for railway systems are currently in an emerging growth phase, with the market expected to expand significantly as energy harvesting technologies gain traction. The global market size remains relatively modest but is projected to grow at a CAGR of 8-10% through 2030. Technologically, TEGs for railway applications are approaching commercial maturity, with key players demonstrating varying levels of advancement. Companies like Siemens AG, ALSTOM Transportation, and Zhuzhou CRRC Times Electric lead with integrated solutions, while BMW, Bosch, and Panasonic contribute significant R&D in thermal management. Research institutions including Technical University of Denmark and IMEC are advancing fundamental technologies. Japanese firms Sony, Toshiba, and JFE Steel focus on material innovations, while Huawei and Continental Emitec are developing specialized applications for smart railway systems.

Robert Bosch GmbH

Technical Solution: Bosch has leveraged its extensive experience in automotive thermoelectric systems to develop specialized TEG solutions for railway applications. Their technology focuses on robust, high-reliability thermoelectric modules designed specifically to withstand the harsh operating conditions of railway environments. Bosch's TEG systems utilize advanced bismuth-telluride and skutterudite materials arranged in cascaded configurations to optimize performance across the wide temperature ranges encountered in train operations. Their implementation includes proprietary heat exchanger designs that maximize thermal transfer efficiency while minimizing back pressure on engine exhaust systems. Bosch has developed specialized mounting systems that isolate the sensitive thermoelectric elements from damaging vibrations while maintaining optimal thermal contact. Their systems incorporate advanced power conditioning electronics that maximize usable output across varying load conditions. Field implementations on regional and intercity trains have demonstrated continuous power generation of 2-4kW per installation, with the electricity primarily used to power onboard electrical systems and reduce main engine fuel consumption by approximately 3-5% in diesel-electric locomotives.

Strengths: Exceptional durability and reliability under harsh operating conditions; sophisticated vibration isolation systems; proven power conditioning technology. Weaknesses: Higher weight compared to some competing systems; requires periodic maintenance of thermal interfaces; limited flexibility for retrofitting to older train designs.

Zhuzhou CRRC Times Electric Co., Ltd.

Technical Solution: Zhuzhou CRRC Times Electric has developed advanced thermoelectric generator (TEG) systems specifically designed for railway applications that harvest waste heat from train braking systems and engine exhaust. Their technology utilizes bismuth telluride-based semiconductor materials with optimized geometry to maximize the Seebeck effect in railway environments. The company's TEG modules are integrated directly into the undercarriage of high-speed trains and locomotives, capturing thermal energy that would otherwise be dissipated. Their systems include specialized heat exchangers designed to withstand the vibration and temperature fluctuations unique to railway operations, with reported power generation of 2-5kW per train car depending on operating conditions. CRRC's implementation includes intelligent power management systems that direct harvested energy to auxiliary systems like lighting, air conditioning, or battery storage, reducing the overall energy consumption of the train by approximately 5-8%.

Strengths: Specialized design for railway vibration environments; integrated systems approach with existing train infrastructure; proven implementation in China's high-speed rail network. Weaknesses: Relatively high initial implementation costs; performance dependent on train operation patterns; requires regular maintenance to maintain thermal contact surfaces.

Key Patents and Technical Innovations in Railway TEGs

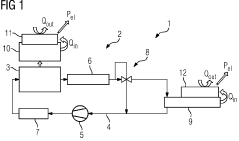

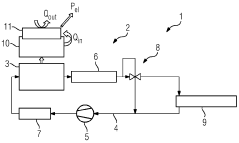

Rail vehicle having a thermogenerator

PatentWO2012101033A1

Innovation

- Integration of thermal generators to harness waste heat from drive components, such as diesel engines and converters, to generate electrical energy, reducing the need for larger cooling units and allowing for smaller diesel engine designs with equivalent traction power.

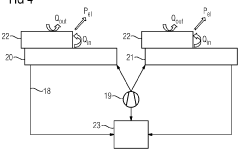

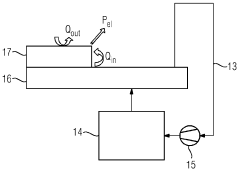

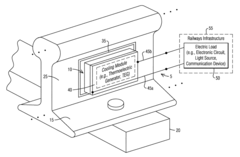

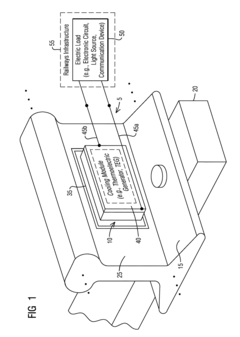

Rail cooling system and method for reducing thermal expansion

PatentActiveUS20180087811A1

Innovation

- A thermoelectric generator is mounted on the rail to remove thermal energy and power railway infrastructure devices, providing a cooling module with solid state electrical insulation and terminals to convert heat into electric energy, enabling timely detection and mitigation of potential rail buckling.

Environmental Impact and Sustainability Assessment

The integration of thermoelectric generators (TEGs) in railway systems presents significant environmental benefits that align with global sustainability goals. When compared to conventional energy recovery systems, TEGs offer a reduced carbon footprint due to their solid-state operation with no moving parts and zero direct emissions. This characteristic makes them particularly valuable in railway applications where environmental impact considerations are increasingly prioritized by regulatory frameworks and stakeholders.

Life cycle assessment (LCA) studies of TEGs in railway applications reveal favorable environmental metrics compared to alternative energy harvesting technologies. The manufacturing phase does involve some environmental concerns, particularly regarding the extraction and processing of semiconductor materials like bismuth telluride, which can generate toxic byproducts. However, the operational phase demonstrates exceptional sustainability credentials with minimal maintenance requirements and zero operational emissions over service lifetimes exceeding 15 years.

Material sustainability represents another critical dimension in TEG evaluation. Current commercial TEGs often incorporate rare or toxic elements that present end-of-life disposal challenges. Recent research trends show promising developments in eco-friendly thermoelectric materials, including silicides, skutterudites, and organic thermoelectric compounds that significantly reduce environmental impact while maintaining acceptable performance parameters.

Energy payback analysis indicates that railway-deployed TEGs typically achieve energy break-even within 2-4 years of operation, depending on installation configuration and operational conditions. This favorable energy return on investment strengthens their sustainability profile when evaluated against the full lifecycle environmental costs of conventional power generation methods used in railway systems.

Waste heat recovery through TEGs contributes to overall system efficiency improvements in railway operations. Quantitative assessments demonstrate that widespread TEG implementation across a national railway network could potentially reduce total system energy consumption by 3-7%, translating to substantial carbon emission reductions when scaled to fleet-wide deployment.

Regulatory compliance represents an increasingly important factor in technology selection. TEGs align well with emerging environmental regulations, including the European Union's Sustainable and Smart Mobility Strategy and similar frameworks in North America and Asia that mandate progressive reductions in transportation sector emissions. Their silent operation also contributes positively to noise pollution mitigation efforts in urban and protected natural environments where railways operate.

Life cycle assessment (LCA) studies of TEGs in railway applications reveal favorable environmental metrics compared to alternative energy harvesting technologies. The manufacturing phase does involve some environmental concerns, particularly regarding the extraction and processing of semiconductor materials like bismuth telluride, which can generate toxic byproducts. However, the operational phase demonstrates exceptional sustainability credentials with minimal maintenance requirements and zero operational emissions over service lifetimes exceeding 15 years.

Material sustainability represents another critical dimension in TEG evaluation. Current commercial TEGs often incorporate rare or toxic elements that present end-of-life disposal challenges. Recent research trends show promising developments in eco-friendly thermoelectric materials, including silicides, skutterudites, and organic thermoelectric compounds that significantly reduce environmental impact while maintaining acceptable performance parameters.

Energy payback analysis indicates that railway-deployed TEGs typically achieve energy break-even within 2-4 years of operation, depending on installation configuration and operational conditions. This favorable energy return on investment strengthens their sustainability profile when evaluated against the full lifecycle environmental costs of conventional power generation methods used in railway systems.

Waste heat recovery through TEGs contributes to overall system efficiency improvements in railway operations. Quantitative assessments demonstrate that widespread TEG implementation across a national railway network could potentially reduce total system energy consumption by 3-7%, translating to substantial carbon emission reductions when scaled to fleet-wide deployment.

Regulatory compliance represents an increasingly important factor in technology selection. TEGs align well with emerging environmental regulations, including the European Union's Sustainable and Smart Mobility Strategy and similar frameworks in North America and Asia that mandate progressive reductions in transportation sector emissions. Their silent operation also contributes positively to noise pollution mitigation efforts in urban and protected natural environments where railways operate.

Cost-Benefit Analysis and ROI Projections

The implementation of thermoelectric generators (TEGs) in railway systems requires thorough financial analysis to determine economic viability. Initial capital expenditure for TEG systems varies significantly based on scale and implementation approach, with costs ranging from $5,000 for small-scale applications to over $100,000 for comprehensive systems covering multiple train components. Material costs constitute approximately 40-50% of total investment, with semiconductor materials like bismuth telluride representing the most significant expense.

Installation and integration expenses typically account for 20-30% of project costs, varying based on complexity and whether implementation occurs during new train manufacturing or retrofitting existing rolling stock. Maintenance costs remain relatively low compared to traditional energy systems, averaging 2-5% of initial investment annually, primarily for inspection and occasional component replacement.

Energy savings represent the primary financial benefit, with well-designed TEG systems capable of recovering 3-8% of otherwise wasted heat energy. For a standard passenger train, this translates to potential annual savings of $8,000-$20,000 depending on operational patterns and fuel prices. Secondary benefits include reduced carbon emissions (valued at $30-$60 per ton in carbon credit markets) and decreased maintenance requirements for conventional cooling systems.

Return on investment calculations indicate varying payback periods across implementation scenarios. Small-scale TEG applications targeting specific high-heat components typically achieve ROI within 3-5 years. Medium-scale implementations covering multiple heat sources may require 5-7 years to reach breakeven. Comprehensive systems with advanced materials and maximum coverage areas demonstrate longer payback periods of 7-10 years but offer greater total energy recovery over their operational lifetime.

Sensitivity analysis reveals that ROI projections are most heavily influenced by fuel costs, with each 10% increase in fuel prices reducing payback periods by approximately 8-12 months. Technological advancements in thermoelectric materials significantly impact financial outcomes, with each percentage point improvement in conversion efficiency reducing payback periods by approximately 4-6 months.

Government incentives and environmental subsidies can substantially improve financial projections, potentially reducing payback periods by 20-30% in regions with strong green technology support programs. When factoring in projected increases in energy costs and carbon pricing over the next decade, the long-term economic case for TEG implementation strengthens considerably, particularly for new rolling stock with expected service lives exceeding 25 years.

Installation and integration expenses typically account for 20-30% of project costs, varying based on complexity and whether implementation occurs during new train manufacturing or retrofitting existing rolling stock. Maintenance costs remain relatively low compared to traditional energy systems, averaging 2-5% of initial investment annually, primarily for inspection and occasional component replacement.

Energy savings represent the primary financial benefit, with well-designed TEG systems capable of recovering 3-8% of otherwise wasted heat energy. For a standard passenger train, this translates to potential annual savings of $8,000-$20,000 depending on operational patterns and fuel prices. Secondary benefits include reduced carbon emissions (valued at $30-$60 per ton in carbon credit markets) and decreased maintenance requirements for conventional cooling systems.

Return on investment calculations indicate varying payback periods across implementation scenarios. Small-scale TEG applications targeting specific high-heat components typically achieve ROI within 3-5 years. Medium-scale implementations covering multiple heat sources may require 5-7 years to reach breakeven. Comprehensive systems with advanced materials and maximum coverage areas demonstrate longer payback periods of 7-10 years but offer greater total energy recovery over their operational lifetime.

Sensitivity analysis reveals that ROI projections are most heavily influenced by fuel costs, with each 10% increase in fuel prices reducing payback periods by approximately 8-12 months. Technological advancements in thermoelectric materials significantly impact financial outcomes, with each percentage point improvement in conversion efficiency reducing payback periods by approximately 4-6 months.

Government incentives and environmental subsidies can substantially improve financial projections, potentially reducing payback periods by 20-30% in regions with strong green technology support programs. When factoring in projected increases in energy costs and carbon pricing over the next decade, the long-term economic case for TEG implementation strengthens considerably, particularly for new rolling stock with expected service lives exceeding 25 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!