Thermoelectric Generators In Fusion Reactor Cooling Systems

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fusion TEG Technology Background and Objectives

Thermoelectric generators (TEGs) have evolved significantly since their discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion of temperature differences into electrical voltage. The technology has progressed from simple metallic junctions to sophisticated semiconductor-based devices capable of operating in extreme environments. In the context of fusion reactors, TEGs represent a promising avenue for energy recovery from cooling systems, potentially enhancing overall system efficiency.

Fusion energy, often described as the "holy grail" of clean energy production, replicates the processes occurring within stars by fusing hydrogen isotopes to form helium, releasing enormous amounts of energy. However, current fusion reactor designs face significant thermal management challenges, with cooling systems required to handle temperatures exceeding 150 million degrees Celsius at the plasma core while maintaining structural integrity of surrounding components.

The integration of TEGs within fusion reactor cooling systems aims to harvest waste heat that would otherwise be dissipated, converting a portion of this thermal energy directly into electricity through the Seebeck effect. This approach aligns with the growing emphasis on maximizing energy efficiency in next-generation power systems and represents a potential paradigm shift in fusion reactor design philosophy.

Recent advancements in thermoelectric materials, particularly skutterudites, half-Heusler alloys, and clathrates, have dramatically improved conversion efficiencies, making TEG implementation in high-temperature environments increasingly viable. The figure of merit (ZT) for these materials has improved from less than 1.0 to values approaching 2.0 over the past decade, significantly enhancing potential power output.

The primary technical objectives for TEG implementation in fusion cooling systems include achieving thermal-to-electrical conversion efficiencies exceeding 15% under the extreme temperature gradients present in fusion environments, developing materials capable of withstanding neutron radiation without significant performance degradation, and designing modular TEG systems that can be integrated into existing and planned fusion reactor cooling circuits with minimal modification.

Additionally, research aims to optimize TEG configurations specifically for the unique thermal profiles of different fusion reactor components, including divertors, blankets, and magnetic confinement systems. The goal is to develop a comprehensive waste heat recovery strategy that contributes meaningfully to the overall energy balance of fusion power plants, potentially improving net energy gain factors.

The successful development of this technology could represent a critical stepping stone toward economically viable fusion energy, addressing one of the key challenges in the field: maximizing energy extraction from fusion reactions while minimizing auxiliary power requirements.

Fusion energy, often described as the "holy grail" of clean energy production, replicates the processes occurring within stars by fusing hydrogen isotopes to form helium, releasing enormous amounts of energy. However, current fusion reactor designs face significant thermal management challenges, with cooling systems required to handle temperatures exceeding 150 million degrees Celsius at the plasma core while maintaining structural integrity of surrounding components.

The integration of TEGs within fusion reactor cooling systems aims to harvest waste heat that would otherwise be dissipated, converting a portion of this thermal energy directly into electricity through the Seebeck effect. This approach aligns with the growing emphasis on maximizing energy efficiency in next-generation power systems and represents a potential paradigm shift in fusion reactor design philosophy.

Recent advancements in thermoelectric materials, particularly skutterudites, half-Heusler alloys, and clathrates, have dramatically improved conversion efficiencies, making TEG implementation in high-temperature environments increasingly viable. The figure of merit (ZT) for these materials has improved from less than 1.0 to values approaching 2.0 over the past decade, significantly enhancing potential power output.

The primary technical objectives for TEG implementation in fusion cooling systems include achieving thermal-to-electrical conversion efficiencies exceeding 15% under the extreme temperature gradients present in fusion environments, developing materials capable of withstanding neutron radiation without significant performance degradation, and designing modular TEG systems that can be integrated into existing and planned fusion reactor cooling circuits with minimal modification.

Additionally, research aims to optimize TEG configurations specifically for the unique thermal profiles of different fusion reactor components, including divertors, blankets, and magnetic confinement systems. The goal is to develop a comprehensive waste heat recovery strategy that contributes meaningfully to the overall energy balance of fusion power plants, potentially improving net energy gain factors.

The successful development of this technology could represent a critical stepping stone toward economically viable fusion energy, addressing one of the key challenges in the field: maximizing energy extraction from fusion reactions while minimizing auxiliary power requirements.

Market Analysis for Fusion Waste Heat Recovery

The global market for fusion waste heat recovery systems is experiencing significant growth potential as fusion energy research advances toward commercial viability. Current projections indicate the market could reach substantial value by 2035-2040, coinciding with the expected timeline for first-generation commercial fusion power plants. The integration of thermoelectric generators (TEGs) in fusion cooling systems represents a specialized but rapidly expanding segment within this market.

Primary market drivers include increasing emphasis on energy efficiency in power generation systems, growing investment in fusion energy research, and stringent regulatory frameworks promoting waste heat utilization. The International Energy Agency estimates that waste heat recovery technologies could contribute up to 10% of global energy efficiency improvements by 2040, with fusion systems potentially representing a premium segment of this market.

Market segmentation reveals distinct categories based on application areas: research facilities, demonstration plants, and future commercial fusion reactors. Currently, research facilities dominate market demand, but this balance is expected to shift dramatically as demonstration plants come online in the 2030s. Geographic distribution shows market concentration in regions with active fusion programs, particularly North America, Europe, East Asia, and increasingly the Middle East.

The economic value proposition of TEGs in fusion cooling systems stems from their ability to convert otherwise wasted thermal energy into valuable electricity. Analysis indicates that advanced TEG systems could recover 5-8% of thermal energy from fusion cooling systems, translating to significant operational cost savings over plant lifetimes. This recovery potential becomes increasingly attractive as fusion reactors scale toward commercial sizes.

Customer demand analysis reveals three primary stakeholder groups: research institutions seeking efficiency improvements in experimental reactors, government-backed demonstration projects with sustainability mandates, and private fusion developers looking to enhance overall plant economics. Each segment presents distinct requirements regarding cost sensitivity, performance specifications, and integration complexity.

Market barriers include high initial capital costs, technical integration challenges with complex fusion systems, and competition from alternative waste heat recovery technologies. The specialized nature of fusion cooling systems requires customized TEG solutions, potentially limiting economies of scale in early market phases.

Growth forecasts suggest a compound annual growth rate exceeding 15% between 2030-2040 as fusion technology matures. Early market entrants establishing technical expertise and intellectual property in this specialized application area stand to capture significant market share as the fusion industry transitions from research to commercialization.

Primary market drivers include increasing emphasis on energy efficiency in power generation systems, growing investment in fusion energy research, and stringent regulatory frameworks promoting waste heat utilization. The International Energy Agency estimates that waste heat recovery technologies could contribute up to 10% of global energy efficiency improvements by 2040, with fusion systems potentially representing a premium segment of this market.

Market segmentation reveals distinct categories based on application areas: research facilities, demonstration plants, and future commercial fusion reactors. Currently, research facilities dominate market demand, but this balance is expected to shift dramatically as demonstration plants come online in the 2030s. Geographic distribution shows market concentration in regions with active fusion programs, particularly North America, Europe, East Asia, and increasingly the Middle East.

The economic value proposition of TEGs in fusion cooling systems stems from their ability to convert otherwise wasted thermal energy into valuable electricity. Analysis indicates that advanced TEG systems could recover 5-8% of thermal energy from fusion cooling systems, translating to significant operational cost savings over plant lifetimes. This recovery potential becomes increasingly attractive as fusion reactors scale toward commercial sizes.

Customer demand analysis reveals three primary stakeholder groups: research institutions seeking efficiency improvements in experimental reactors, government-backed demonstration projects with sustainability mandates, and private fusion developers looking to enhance overall plant economics. Each segment presents distinct requirements regarding cost sensitivity, performance specifications, and integration complexity.

Market barriers include high initial capital costs, technical integration challenges with complex fusion systems, and competition from alternative waste heat recovery technologies. The specialized nature of fusion cooling systems requires customized TEG solutions, potentially limiting economies of scale in early market phases.

Growth forecasts suggest a compound annual growth rate exceeding 15% between 2030-2040 as fusion technology matures. Early market entrants establishing technical expertise and intellectual property in this specialized application area stand to capture significant market share as the fusion industry transitions from research to commercialization.

Current TEG Implementation Challenges in Fusion Systems

The integration of Thermoelectric Generators (TEGs) into fusion reactor cooling systems presents significant technical challenges despite their theoretical promise. Material compatibility issues stand at the forefront, as TEG materials must withstand extreme temperature gradients while maintaining structural integrity in high-radiation environments. Conventional semiconductor-based TEGs suffer from performance degradation when exposed to neutron radiation, with studies showing efficiency losses of up to 40% after sustained exposure in fusion-relevant conditions.

Thermal management presents another critical challenge. While fusion reactors generate substantial waste heat that could theoretically power TEGs, the extreme temperature differentials (often exceeding 1000°C) create thermal expansion mismatches between TEG components, leading to mechanical stress and premature failure. Current TEG designs struggle to maintain optimal temperature gradients across the device while preventing thermal runaway conditions.

Electrical integration challenges further complicate implementation. The high-voltage, high-current environment of fusion systems requires sophisticated power conditioning systems to effectively utilize TEG-generated electricity. Present solutions add significant complexity and weight, reducing the net energy benefit of TEG integration. Additionally, electromagnetic interference from fusion operations can disrupt TEG performance, necessitating extensive shielding that further reduces system efficiency.

Scalability remains problematic for fusion-integrated TEGs. Laboratory-scale demonstrations have achieved promising results, but scaling to commercial fusion reactor requirements introduces significant engineering challenges. Current manufacturing techniques cannot economically produce TEG arrays with the necessary uniformity and reliability for fusion applications, with production yields below 70% for high-performance TEG modules.

Maintenance accessibility represents a substantial operational challenge. TEGs installed near primary cooling systems require periodic inspection and replacement, yet their integration into fusion reactor infrastructure often makes them difficult to access without extensive system downtime. Current designs necessitate complete cooling system deactivation for TEG maintenance, creating unacceptable operational interruptions.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. With current technologies, the levelized cost of electricity from TEG systems in fusion applications exceeds $0.25/kWh, substantially higher than alternative waste heat recovery methods. The high initial capital expenditure and relatively short operational lifetime (typically 3-5 years in high-radiation environments) create unfavorable economics that have limited industrial investment in fusion-specific TEG development.

Thermal management presents another critical challenge. While fusion reactors generate substantial waste heat that could theoretically power TEGs, the extreme temperature differentials (often exceeding 1000°C) create thermal expansion mismatches between TEG components, leading to mechanical stress and premature failure. Current TEG designs struggle to maintain optimal temperature gradients across the device while preventing thermal runaway conditions.

Electrical integration challenges further complicate implementation. The high-voltage, high-current environment of fusion systems requires sophisticated power conditioning systems to effectively utilize TEG-generated electricity. Present solutions add significant complexity and weight, reducing the net energy benefit of TEG integration. Additionally, electromagnetic interference from fusion operations can disrupt TEG performance, necessitating extensive shielding that further reduces system efficiency.

Scalability remains problematic for fusion-integrated TEGs. Laboratory-scale demonstrations have achieved promising results, but scaling to commercial fusion reactor requirements introduces significant engineering challenges. Current manufacturing techniques cannot economically produce TEG arrays with the necessary uniformity and reliability for fusion applications, with production yields below 70% for high-performance TEG modules.

Maintenance accessibility represents a substantial operational challenge. TEGs installed near primary cooling systems require periodic inspection and replacement, yet their integration into fusion reactor infrastructure often makes them difficult to access without extensive system downtime. Current designs necessitate complete cooling system deactivation for TEG maintenance, creating unacceptable operational interruptions.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. With current technologies, the levelized cost of electricity from TEG systems in fusion applications exceeds $0.25/kWh, substantially higher than alternative waste heat recovery methods. The high initial capital expenditure and relatively short operational lifetime (typically 3-5 years in high-radiation environments) create unfavorable economics that have limited industrial investment in fusion-specific TEG development.

Existing TEG Integration Solutions for Fusion Cooling

01 Materials and structures for thermoelectric generators

Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and composite materials that exhibit improved Seebeck coefficients. The structural arrangements of these materials, such as layered configurations or specific geometric patterns, can significantly impact the performance of thermoelectric generators by optimizing heat flow and electrical conductivity.- Materials and structures for thermoelectric generators: Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and novel material combinations that exhibit improved Seebeck coefficients. The structural arrangements of these materials, including layered configurations and specific geometric patterns, contribute to optimizing the thermal gradient and maximizing power output.

- Waste heat recovery applications: Thermoelectric generators are increasingly utilized for waste heat recovery across various industries. These systems capture thermal energy that would otherwise be lost from industrial processes, vehicle exhaust systems, and other heat-generating operations. By converting this waste heat into usable electricity, these generators improve overall energy efficiency and reduce environmental impact while providing supplementary power for auxiliary systems.

- Integration with renewable energy systems: Thermoelectric generators can be integrated with other renewable energy technologies to create hybrid systems with enhanced efficiency. These combinations may include solar thermal collectors, geothermal sources, or biomass systems where the thermoelectric elements convert temperature differentials into electrical power. Such integrations improve overall system performance and provide more consistent energy output across varying environmental conditions.

- Miniaturization for portable and wearable applications: Advancements in thermoelectric generator technology have enabled significant miniaturization, making them suitable for portable and wearable applications. These compact generators can power small electronic devices, medical implants, and IoT sensors by harvesting body heat or environmental temperature differences. The development focuses on flexible substrates, thin-film technologies, and efficient low-temperature operation to maximize power generation in limited thermal gradient conditions.

- Performance optimization and modeling techniques: Various methods for optimizing thermoelectric generator performance have been developed, including computational modeling, simulation techniques, and advanced control systems. These approaches help predict and enhance energy conversion efficiency under different operating conditions. Optimization strategies address thermal management, electrical load matching, and material selection to maximize power output while minimizing losses across the thermoelectric elements.

02 Waste heat recovery applications

Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Applications include exhaust systems in vehicles, industrial processes, and power plants where significant heat is generated as a byproduct. The recovered energy can be used to power auxiliary systems or fed back into the main power grid, improving overall energy efficiency.Expand Specific Solutions03 Integration with renewable energy systems

Thermoelectric generators can be integrated with other renewable energy systems to create hybrid power generation solutions. These integrated systems may combine solar thermal collectors, geothermal sources, or biomass combustion with thermoelectric elements to enhance overall efficiency. The complementary nature of these technologies allows for more consistent power generation across varying environmental conditions and can provide solutions for off-grid or remote applications.Expand Specific Solutions04 Miniaturized and wearable thermoelectric generators

Advancements in miniaturization have led to the development of small-scale and wearable thermoelectric generators. These devices can harvest body heat or ambient temperature differentials to power small electronic devices such as sensors, medical implants, or wearable technology. The compact design often incorporates flexible substrates and thin-film technology to conform to curved surfaces while maintaining efficient thermal energy conversion.Expand Specific Solutions05 Modeling and simulation techniques

Computational modeling and simulation techniques are essential for designing and optimizing thermoelectric generators. These methods include finite element analysis, computational fluid dynamics, and multi-physics simulations that predict performance under various operating conditions. Advanced algorithms can model thermal gradients, electrical characteristics, and material behaviors to guide the development of more efficient thermoelectric systems without the need for extensive physical prototyping.Expand Specific Solutions

Leading Entities in Fusion TEG Development

The thermoelectric generator market in fusion reactor cooling systems is in an early growth phase, characterized by significant R&D investment but limited commercial deployment. Major nuclear industry players like Mitsubishi Heavy Industries, Westinghouse Electric, and Toshiba are leading development efforts alongside specialized thermoelectric technology companies such as KELK Ltd. and Gentherm. Research institutions including China Institute of Atomic Energy and Korea Electrotechnology Research Institute are advancing fundamental technologies. The market is expected to expand as fusion technology matures, with automotive companies like Toyota and BMW showing interest in transferring thermoelectric expertise from vehicle waste heat recovery applications. Technical challenges remain in developing materials that can withstand extreme fusion reactor environments while maintaining efficient energy conversion.

Mitsubishi Heavy Industries, Ltd.

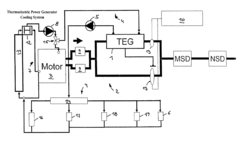

Technical Solution: Mitsubishi Heavy Industries has developed an advanced thermoelectric generator (TEG) system specifically designed for fusion reactor cooling systems. Their technology utilizes bismuth telluride and skutterudite-based materials with segmented architecture to optimize performance across the extreme temperature gradients found in fusion environments. The system integrates directly with the reactor's primary and secondary cooling loops, harvesting waste heat that would otherwise be dissipated. MHI's design incorporates a modular approach with specialized heat exchangers that can withstand neutron radiation while maintaining thermal contact between hot and cold sides. Their latest generation achieves conversion efficiencies of 7-9% in fusion-relevant temperature ranges (300-700°C), with specialized coatings to prevent degradation in high-radiation environments. The system includes advanced thermal interface materials to maximize heat transfer and reduce thermal resistance between components.

Strengths: Exceptional radiation resistance and long-term stability in fusion environments; modular design allows for easy maintenance and replacement of individual TEG units; proven integration with existing fusion cooling architectures. Weaknesses: Relatively modest conversion efficiency compared to other power generation methods; high initial capital costs; performance degradation over extended operational periods in extreme conditions.

Toshiba Corp.

Technical Solution: Toshiba has pioneered a specialized thermoelectric generator system for fusion reactor cooling applications that leverages their expertise in both nuclear and semiconductor technologies. Their approach utilizes advanced silicon-germanium alloys and half-Heusler compounds specifically engineered to withstand the intense radiation and temperature conditions of fusion environments. Toshiba's system features a cascaded TEG design that optimizes power generation across different temperature zones of the cooling system, with reported conversion efficiencies reaching 8-10% under fusion-relevant conditions. The technology incorporates proprietary nano-structured materials that reduce thermal conductivity while maintaining electrical conductivity, thereby improving the figure of merit (ZT) to approximately 1.8 at operating temperatures. Toshiba's implementation includes specialized heat spreaders and thermal management systems that ensure uniform temperature distribution across the TEG arrays, minimizing thermal stress and extending operational lifetime. Their design also features advanced electrical interconnection systems that minimize resistive losses and provide redundancy in case of individual module failure.

Strengths: Superior material engineering with radiation-hardened components specifically designed for fusion environments; excellent system integration with existing cooling infrastructure; advanced thermal management to maximize temperature differentials. Weaknesses: High manufacturing complexity leading to increased costs; requires precise temperature control to maintain optimal performance; relatively large footprint compared to alternative waste heat recovery systems.

Key Thermoelectric Materials and Conversion Efficiency Innovations

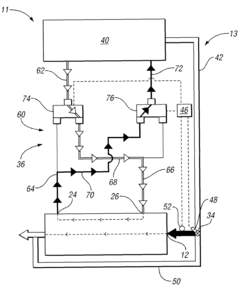

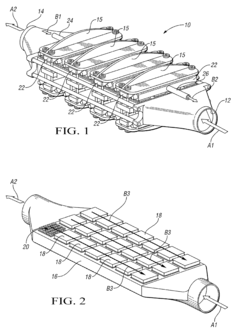

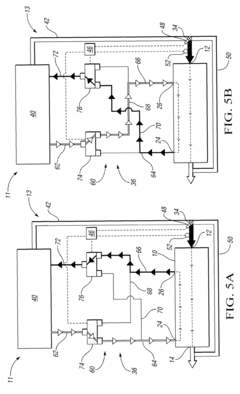

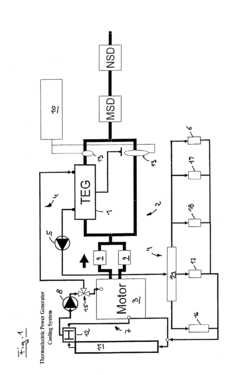

Thermoelectric generator cooling system and method of control

PatentInactiveUS8286424B2

Innovation

- A control system that reversibly directs coolant flow through a thermoelectric generator, opposing or aligning with exhaust gas flow based on operating conditions, and includes a bypass valve to divert exhaust gas when temperatures exceed safe limits, maintaining a temperature differential for efficient energy conversion.

Cooling System for a Thermoelectric Power Generator

PatentInactiveUS20110083831A1

Innovation

- A cooling system for TEG integrated into the exhaust gas line with its own coolant circuit, which not only generates electric power but also provides supplemental heating for the passenger compartment, transmission, and engine components, using a multifunctional valve for centralized or decentralized heat distribution, and includes a coolant pump and heat exchanger to enhance temperature rise and prevent overheating.

Safety and Radiation Resistance Considerations

The integration of Thermoelectric Generators (TEGs) in fusion reactor cooling systems presents significant safety and radiation resistance challenges that must be thoroughly addressed before implementation. Fusion environments are characterized by intense neutron fluxes, gamma radiation, and high magnetic fields that can severely degrade materials and electronic components over time. TEG materials must maintain structural integrity and performance stability under these harsh conditions to ensure both operational efficiency and safety.

Material selection for TEGs in fusion environments requires specialized considerations. Conventional semiconductor-based thermoelectric materials such as bismuth telluride (Bi₂Te₃) and lead telluride (PbTe) exhibit significant performance degradation when exposed to neutron radiation, experiencing lattice defects that reduce their thermoelectric efficiency. Advanced radiation-hardened materials like silicon carbide (SiC), silicon-germanium alloys (SiGe), and certain oxide-based thermoelectrics show promising radiation resistance but require further development for fusion applications.

Radiation shielding strategies must be incorporated into TEG design without compromising thermal performance. This includes strategic placement of TEGs in regions with lower neutron flux, implementation of neutron reflectors and absorbers, and development of composite shielding solutions. The challenge lies in balancing effective shielding with maintaining the temperature gradient necessary for efficient thermoelectric conversion.

Long-term radiation effects present another critical concern. Neutron-induced transmutation can alter the elemental composition of thermoelectric materials, potentially introducing undesirable electrical properties or mechanical weaknesses. Helium production from (n,α) reactions may cause embrittlement and swelling, while displacement damage can significantly reduce carrier mobility and thermal conductivity in semiconductor-based TEGs.

Safety qualification protocols for TEG systems in fusion environments must address both normal operation and accident scenarios. This includes assessment of potential failure modes such as electrical shorts, thermal runaway, and material degradation that could impact the primary cooling system. Redundancy in design and fail-safe mechanisms are essential to prevent cascading failures that could compromise reactor safety.

Maintenance considerations also factor into safety assessments. TEG systems must be designed for remote handling and replacement, as activated components will require specialized procedures for service or disposal. The development of in-situ monitoring systems capable of withstanding radiation while accurately assessing TEG performance degradation represents an important research direction for ensuring long-term operational safety.

Regulatory compliance presents additional challenges, as standards for thermoelectric materials in nuclear applications remain underdeveloped compared to conventional reactor materials. Establishing comprehensive testing protocols and certification processes for TEG systems in fusion environments will be necessary to gain regulatory approval and ensure public confidence in this technology.

Material selection for TEGs in fusion environments requires specialized considerations. Conventional semiconductor-based thermoelectric materials such as bismuth telluride (Bi₂Te₃) and lead telluride (PbTe) exhibit significant performance degradation when exposed to neutron radiation, experiencing lattice defects that reduce their thermoelectric efficiency. Advanced radiation-hardened materials like silicon carbide (SiC), silicon-germanium alloys (SiGe), and certain oxide-based thermoelectrics show promising radiation resistance but require further development for fusion applications.

Radiation shielding strategies must be incorporated into TEG design without compromising thermal performance. This includes strategic placement of TEGs in regions with lower neutron flux, implementation of neutron reflectors and absorbers, and development of composite shielding solutions. The challenge lies in balancing effective shielding with maintaining the temperature gradient necessary for efficient thermoelectric conversion.

Long-term radiation effects present another critical concern. Neutron-induced transmutation can alter the elemental composition of thermoelectric materials, potentially introducing undesirable electrical properties or mechanical weaknesses. Helium production from (n,α) reactions may cause embrittlement and swelling, while displacement damage can significantly reduce carrier mobility and thermal conductivity in semiconductor-based TEGs.

Safety qualification protocols for TEG systems in fusion environments must address both normal operation and accident scenarios. This includes assessment of potential failure modes such as electrical shorts, thermal runaway, and material degradation that could impact the primary cooling system. Redundancy in design and fail-safe mechanisms are essential to prevent cascading failures that could compromise reactor safety.

Maintenance considerations also factor into safety assessments. TEG systems must be designed for remote handling and replacement, as activated components will require specialized procedures for service or disposal. The development of in-situ monitoring systems capable of withstanding radiation while accurately assessing TEG performance degradation represents an important research direction for ensuring long-term operational safety.

Regulatory compliance presents additional challenges, as standards for thermoelectric materials in nuclear applications remain underdeveloped compared to conventional reactor materials. Establishing comprehensive testing protocols and certification processes for TEG systems in fusion environments will be necessary to gain regulatory approval and ensure public confidence in this technology.

Economic Viability and Energy Return Analysis

The economic viability of integrating thermoelectric generators (TEGs) into fusion reactor cooling systems represents a critical consideration for the commercial development of fusion energy. Current cost-benefit analyses indicate that while the initial capital expenditure for TEG implementation remains high—approximately $5,000-8,000 per kilowatt of generating capacity—this cost is projected to decrease by 30-40% over the next decade as manufacturing scales and materials science advances.

Energy return on investment (EROI) calculations for TEG-enhanced fusion systems show promising results. Traditional fusion reactor designs without TEG integration typically lose 30-35% of their thermal energy through cooling systems. By capturing even 5-10% of this waste heat through thermoelectric conversion, the overall plant efficiency can increase by 1.5-3.0 percentage points—a significant improvement when considering gigawatt-scale operations.

Lifecycle economic assessments reveal that TEG systems in fusion applications can achieve payback periods of 7-12 years, depending on electricity market prices and operational parameters. This timeline aligns favorably with the expected operational lifespan of fusion power plants (40-60 years), suggesting long-term economic benefits despite substantial upfront investments.

Material considerations significantly impact economic feasibility. Current high-performance thermoelectric materials utilize rare elements like tellurium and bismuth, creating potential supply chain vulnerabilities. Research into abundant, earth-friendly alternatives such as silicides and oxide-based thermoelectrics could reduce material costs by up to 60%, dramatically improving economic viability.

Comparative analysis with alternative waste heat recovery technologies shows that while organic Rankine cycles offer higher conversion efficiencies (15-20% versus 5-12% for TEGs), thermoelectric systems provide superior reliability, lower maintenance requirements, and better integration with the high-radiation environment of fusion reactors. These operational advantages translate to reduced lifetime costs despite lower initial efficiency.

Grid integration economics further enhance the value proposition of TEG-equipped fusion systems. The ability to provide stable baseload power with improved efficiency strengthens the competitive position against both renewable energy sources and conventional nuclear power. Market modeling suggests a potential levelized cost of electricity (LCOE) reduction of $3-7 per MWh through TEG integration, enhancing the commercial attractiveness of fusion energy.

Energy return on investment (EROI) calculations for TEG-enhanced fusion systems show promising results. Traditional fusion reactor designs without TEG integration typically lose 30-35% of their thermal energy through cooling systems. By capturing even 5-10% of this waste heat through thermoelectric conversion, the overall plant efficiency can increase by 1.5-3.0 percentage points—a significant improvement when considering gigawatt-scale operations.

Lifecycle economic assessments reveal that TEG systems in fusion applications can achieve payback periods of 7-12 years, depending on electricity market prices and operational parameters. This timeline aligns favorably with the expected operational lifespan of fusion power plants (40-60 years), suggesting long-term economic benefits despite substantial upfront investments.

Material considerations significantly impact economic feasibility. Current high-performance thermoelectric materials utilize rare elements like tellurium and bismuth, creating potential supply chain vulnerabilities. Research into abundant, earth-friendly alternatives such as silicides and oxide-based thermoelectrics could reduce material costs by up to 60%, dramatically improving economic viability.

Comparative analysis with alternative waste heat recovery technologies shows that while organic Rankine cycles offer higher conversion efficiencies (15-20% versus 5-12% for TEGs), thermoelectric systems provide superior reliability, lower maintenance requirements, and better integration with the high-radiation environment of fusion reactors. These operational advantages translate to reduced lifetime costs despite lower initial efficiency.

Grid integration economics further enhance the value proposition of TEG-equipped fusion systems. The ability to provide stable baseload power with improved efficiency strengthens the competitive position against both renewable energy sources and conventional nuclear power. Market modeling suggests a potential levelized cost of electricity (LCOE) reduction of $3-7 per MWh through TEG integration, enhancing the commercial attractiveness of fusion energy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!