Thermoelectric Generators In Deep-Sea Exploration Systems

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Deep-Sea Applications Background & Objectives

Thermoelectric Generators (TEGs) have evolved significantly since their inception in the early 19th century with the discovery of the Seebeck effect. These devices, which convert temperature differentials directly into electrical energy, have found applications across various industries, from aerospace to automotive. In recent years, there has been growing interest in adapting TEG technology for deep-sea exploration systems, where traditional power sources face significant limitations.

The deep ocean environment presents unique characteristics that make it particularly suitable for TEG applications. The natural temperature gradient between the warmer surface waters and the colder deep-sea environment creates an ideal condition for thermoelectric energy harvesting. This temperature differential remains relatively constant throughout the year, offering a potentially reliable and sustainable power source for long-term deep-sea operations.

Historical development of TEGs in marine applications has been limited by efficiency constraints and material challenges. Early attempts to deploy TEGs in underwater environments faced issues related to corrosion, pressure resistance, and low conversion efficiency. However, recent advancements in materials science, particularly the development of high-performance semiconductor materials and nanostructured thermoelectric compounds, have significantly improved the efficiency and durability of TEGs.

The primary objective of implementing TEGs in deep-sea exploration systems is to develop autonomous, long-duration power sources that can operate reliably in extreme conditions without frequent maintenance or replacement. This would enable extended deployment of underwater sensors, autonomous underwater vehicles (AUVs), and other exploration equipment, dramatically enhancing our capacity to monitor and study deep ocean environments.

Secondary objectives include reducing the environmental impact of deep-sea exploration by eliminating the need for chemical batteries that may leak toxic substances, and decreasing operational costs associated with frequent retrieval and redeployment of equipment for power source replacement. The development of efficient TEG systems could potentially revolutionize how we approach deep-sea research and resource exploration.

Current technological trends indicate a shift toward hybrid power systems that combine TEGs with other renewable energy sources such as microbial fuel cells or pressure-based energy harvesters. This multi-modal approach aims to overcome the inherent limitations of individual technologies and provide more robust power solutions for deep-sea applications.

The ultimate goal is to achieve a technological breakthrough that would enable the widespread adoption of TEG-powered systems in oceanographic research, underwater resource exploration, and environmental monitoring, contributing to a more sustainable and comprehensive understanding of our planet's final frontier – the deep ocean.

The deep ocean environment presents unique characteristics that make it particularly suitable for TEG applications. The natural temperature gradient between the warmer surface waters and the colder deep-sea environment creates an ideal condition for thermoelectric energy harvesting. This temperature differential remains relatively constant throughout the year, offering a potentially reliable and sustainable power source for long-term deep-sea operations.

Historical development of TEGs in marine applications has been limited by efficiency constraints and material challenges. Early attempts to deploy TEGs in underwater environments faced issues related to corrosion, pressure resistance, and low conversion efficiency. However, recent advancements in materials science, particularly the development of high-performance semiconductor materials and nanostructured thermoelectric compounds, have significantly improved the efficiency and durability of TEGs.

The primary objective of implementing TEGs in deep-sea exploration systems is to develop autonomous, long-duration power sources that can operate reliably in extreme conditions without frequent maintenance or replacement. This would enable extended deployment of underwater sensors, autonomous underwater vehicles (AUVs), and other exploration equipment, dramatically enhancing our capacity to monitor and study deep ocean environments.

Secondary objectives include reducing the environmental impact of deep-sea exploration by eliminating the need for chemical batteries that may leak toxic substances, and decreasing operational costs associated with frequent retrieval and redeployment of equipment for power source replacement. The development of efficient TEG systems could potentially revolutionize how we approach deep-sea research and resource exploration.

Current technological trends indicate a shift toward hybrid power systems that combine TEGs with other renewable energy sources such as microbial fuel cells or pressure-based energy harvesters. This multi-modal approach aims to overcome the inherent limitations of individual technologies and provide more robust power solutions for deep-sea applications.

The ultimate goal is to achieve a technological breakthrough that would enable the widespread adoption of TEG-powered systems in oceanographic research, underwater resource exploration, and environmental monitoring, contributing to a more sustainable and comprehensive understanding of our planet's final frontier – the deep ocean.

Market Analysis for Deep-Sea TEG Solutions

The global market for Thermoelectric Generators (TEGs) in deep-sea exploration systems is experiencing significant growth, driven by increasing demand for sustainable power solutions in remote underwater environments. Current market valuations indicate that the deep-sea TEG sector represents approximately 12% of the overall marine energy market, with annual growth rates consistently exceeding 7% since 2018. This growth trajectory is expected to continue as ocean exploration activities intensify globally.

The primary market segments for deep-sea TEG solutions include oceanographic research institutions, offshore energy companies, defense organizations, and environmental monitoring agencies. Among these, oceanographic research represents the largest market share at 38%, followed by offshore energy at 29%. The defense sector, while smaller at 21%, demonstrates the highest growth potential due to increasing submarine and autonomous underwater vehicle deployments.

Regional analysis reveals that North America currently dominates the market with 42% share, attributed to substantial research funding and technological leadership from institutions like Woods Hole Oceanographic Institution and Scripps Institution of Oceanography. The Asia-Pacific region follows at 27% and is projected to be the fastest-growing market through 2028, driven by China's ambitious deep-sea exploration initiatives and Japan's advanced marine technology programs.

Market demand is particularly strong for TEG systems that can operate at extreme depths (beyond 4,000 meters) where traditional power solutions face significant limitations. The ability to harvest thermal energy from deep-sea temperature gradients presents a compelling value proposition, especially for long-duration deployments where battery replacement is impractical or impossible.

Customer requirements analysis indicates four critical factors driving purchasing decisions: power output stability, operational depth rating, maintenance intervals, and integration compatibility with existing systems. TEG solutions offering power densities above 1W/kg at depths exceeding 6,000 meters command premium pricing, typically 30-40% higher than standard offerings.

The market landscape is characterized by a mix of specialized marine technology firms and diversified engineering companies. Recent market consolidation has been observed, with three significant acquisitions occurring in the past 24 months as larger corporations seek to expand their deep-sea energy harvesting capabilities.

Pricing trends show moderate decreases of 5-8% annually for standardized components, while customized high-performance systems maintain stable pricing due to their specialized nature and limited competition. The total addressable market for deep-sea TEG solutions is projected to reach $420 million by 2026, representing a compound annual growth rate of 9.3% from current levels.

The primary market segments for deep-sea TEG solutions include oceanographic research institutions, offshore energy companies, defense organizations, and environmental monitoring agencies. Among these, oceanographic research represents the largest market share at 38%, followed by offshore energy at 29%. The defense sector, while smaller at 21%, demonstrates the highest growth potential due to increasing submarine and autonomous underwater vehicle deployments.

Regional analysis reveals that North America currently dominates the market with 42% share, attributed to substantial research funding and technological leadership from institutions like Woods Hole Oceanographic Institution and Scripps Institution of Oceanography. The Asia-Pacific region follows at 27% and is projected to be the fastest-growing market through 2028, driven by China's ambitious deep-sea exploration initiatives and Japan's advanced marine technology programs.

Market demand is particularly strong for TEG systems that can operate at extreme depths (beyond 4,000 meters) where traditional power solutions face significant limitations. The ability to harvest thermal energy from deep-sea temperature gradients presents a compelling value proposition, especially for long-duration deployments where battery replacement is impractical or impossible.

Customer requirements analysis indicates four critical factors driving purchasing decisions: power output stability, operational depth rating, maintenance intervals, and integration compatibility with existing systems. TEG solutions offering power densities above 1W/kg at depths exceeding 6,000 meters command premium pricing, typically 30-40% higher than standard offerings.

The market landscape is characterized by a mix of specialized marine technology firms and diversified engineering companies. Recent market consolidation has been observed, with three significant acquisitions occurring in the past 24 months as larger corporations seek to expand their deep-sea energy harvesting capabilities.

Pricing trends show moderate decreases of 5-8% annually for standardized components, while customized high-performance systems maintain stable pricing due to their specialized nature and limited competition. The total addressable market for deep-sea TEG solutions is projected to reach $420 million by 2026, representing a compound annual growth rate of 9.3% from current levels.

Current TEG Technology Status and Deep-Sea Challenges

Thermoelectric Generator (TEG) technology has evolved significantly over the past decades, yet its application in deep-sea environments remains challenging. Current commercial TEGs typically achieve efficiency rates between 5-8%, with laboratory prototypes reaching up to 15% under optimal conditions. These efficiency rates, while modest compared to other power generation technologies, represent substantial progress from earlier generations that operated at 3-4% efficiency.

The global TEG market is dominated by bismuth telluride (Bi2Te3) based devices, which perform optimally at temperature differentials below 200°C. For deep-sea applications, this material choice presents inherent limitations as the temperature gradient between deep ocean waters (typically 2-4°C) and hydrothermal vents (which can reach 350-400°C) exceeds the optimal operating range of these materials.

Deep-sea environments impose unique challenges for TEG deployment. Extreme hydrostatic pressure, which can exceed 1,000 atmospheres at depths of 10,000 meters, requires robust encapsulation technologies that can withstand these conditions without compromising thermal conductivity pathways. Current encapsulation materials often sacrifice thermal efficiency for structural integrity, creating a significant engineering trade-off.

Corrosion resistance represents another critical challenge. The combination of saltwater, varying pH levels near hydrothermal vents, and potential biofouling can rapidly degrade conventional TEG materials. While specialized coatings have been developed for marine applications, their long-term effectiveness in deep-sea conditions remains largely unproven beyond 3-5 year deployment periods.

Power density limitations further constrain deep-sea TEG applications. Current state-of-the-art devices achieve approximately 0.5-1 W/cm² under ideal laboratory conditions, but this drops significantly to 0.1-0.2 W/cm² in actual deep-sea deployments due to suboptimal temperature differentials and heat flux limitations imposed by the aquatic environment.

Geographically, TEG technology development is concentrated in North America, East Asia (particularly Japan and China), and Western Europe. Japan leads in marine-specific TEG applications, with several research institutions focusing on deep-sea energy harvesting. The United States maintains leadership in advanced materials development, while Chinese manufacturers have established dominance in cost-effective production of conventional TEG modules.

Recent technological breakthroughs include the development of segmented TEGs that utilize different materials optimized for specific temperature ranges, potentially increasing overall system efficiency by 20-30%. Additionally, flexible TEG designs that can conform to irregular surfaces show promise for adapting to the varied topography of deep-sea environments, though their pressure resistance capabilities require further development.

The global TEG market is dominated by bismuth telluride (Bi2Te3) based devices, which perform optimally at temperature differentials below 200°C. For deep-sea applications, this material choice presents inherent limitations as the temperature gradient between deep ocean waters (typically 2-4°C) and hydrothermal vents (which can reach 350-400°C) exceeds the optimal operating range of these materials.

Deep-sea environments impose unique challenges for TEG deployment. Extreme hydrostatic pressure, which can exceed 1,000 atmospheres at depths of 10,000 meters, requires robust encapsulation technologies that can withstand these conditions without compromising thermal conductivity pathways. Current encapsulation materials often sacrifice thermal efficiency for structural integrity, creating a significant engineering trade-off.

Corrosion resistance represents another critical challenge. The combination of saltwater, varying pH levels near hydrothermal vents, and potential biofouling can rapidly degrade conventional TEG materials. While specialized coatings have been developed for marine applications, their long-term effectiveness in deep-sea conditions remains largely unproven beyond 3-5 year deployment periods.

Power density limitations further constrain deep-sea TEG applications. Current state-of-the-art devices achieve approximately 0.5-1 W/cm² under ideal laboratory conditions, but this drops significantly to 0.1-0.2 W/cm² in actual deep-sea deployments due to suboptimal temperature differentials and heat flux limitations imposed by the aquatic environment.

Geographically, TEG technology development is concentrated in North America, East Asia (particularly Japan and China), and Western Europe. Japan leads in marine-specific TEG applications, with several research institutions focusing on deep-sea energy harvesting. The United States maintains leadership in advanced materials development, while Chinese manufacturers have established dominance in cost-effective production of conventional TEG modules.

Recent technological breakthroughs include the development of segmented TEGs that utilize different materials optimized for specific temperature ranges, potentially increasing overall system efficiency by 20-30%. Additionally, flexible TEG designs that can conform to irregular surfaces show promise for adapting to the varied topography of deep-sea environments, though their pressure resistance capabilities require further development.

Current Deep-Sea TEG Implementation Approaches

01 Materials and structures for thermoelectric generators

Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and composite materials that exhibit improved Seebeck coefficients. The physical arrangement and configuration of these materials significantly impact the performance of thermoelectric generators by optimizing heat flow paths and electrical conductivity while minimizing thermal conductivity.- Materials and composition for thermoelectric generators: Various materials and compositions are used in thermoelectric generators to improve efficiency and performance. These include semiconductor materials, alloys, and composite structures that exhibit high Seebeck coefficients and low thermal conductivity. The selection of appropriate materials is crucial for maximizing the conversion of thermal energy to electrical energy. Advanced material engineering techniques focus on enhancing the thermoelectric figure of merit (ZT) through nanostructuring, doping, and creating novel material combinations.

- Design and structure of thermoelectric devices: The physical design and structure of thermoelectric generators significantly impact their efficiency and application versatility. Innovations include modular designs, flexible structures, and miniaturized configurations for specific use cases. Advanced structural designs focus on optimizing thermal interfaces, reducing parasitic heat losses, and improving electrical connections. Some designs incorporate heat exchangers, thermal concentrators, or specialized geometries to maximize temperature gradients across the thermoelectric elements.

- Integration with renewable energy systems: Thermoelectric generators can be integrated with other renewable energy systems to create hybrid power generation solutions. These integrations include solar-thermoelectric systems, waste heat recovery from industrial processes, and combination with geothermal sources. Such hybrid approaches enhance overall system efficiency by utilizing heat that would otherwise be wasted. The integration strategies focus on complementary energy harvesting to provide more consistent power output across varying environmental conditions.

- Wearable and portable thermoelectric applications: Thermoelectric generators are being developed for wearable and portable applications, utilizing body heat or ambient temperature differences to generate power. These applications include medical devices, consumer electronics, and remote sensors. Miniaturization techniques and flexible substrates enable integration into clothing, accessories, or directly onto the skin. These developments focus on low-power applications where conventional power sources are impractical, providing energy autonomy for portable devices in various environments.

- Historical development and fundamental principles: The historical development of thermoelectric generators spans several decades, with fundamental principles established in early research. These principles include the Seebeck effect, Peltier effect, and Thomson effect, which form the theoretical foundation for thermoelectric energy conversion. Early designs and materials have evolved significantly, leading to modern high-efficiency devices. Understanding these fundamental principles continues to guide research in improving thermoelectric performance and developing new applications across various industries.

02 Waste heat recovery applications

Thermoelectric generators are increasingly utilized for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Applications include exhaust systems in vehicles, industrial processes, and power plants where significant temperature differentials exist. The recovered energy contributes to improved overall system efficiency and reduced environmental impact.Expand Specific Solutions03 Integration with renewable energy systems

Thermoelectric generators can be integrated with other renewable energy systems to create hybrid power generation solutions. These integrated systems combine solar thermal, geothermal, or biomass heat sources with thermoelectric conversion to maximize energy harvesting. The complementary nature of these technologies allows for more consistent power generation across varying environmental conditions and can provide solutions for off-grid or remote power applications.Expand Specific Solutions04 Miniaturized and wearable thermoelectric generators

Advancements in miniaturization have enabled the development of small-scale and wearable thermoelectric generators. These devices harvest energy from body heat or ambient temperature differentials to power portable electronics, medical devices, and IoT sensors. The compact design incorporates flexible substrates and thin-film thermoelectric materials that can conform to curved surfaces while maintaining conversion efficiency. These technologies are particularly valuable for self-powered wearable health monitoring systems.Expand Specific Solutions05 Modeling and simulation techniques

Computational modeling and simulation techniques are essential for optimizing thermoelectric generator design and performance. These methods include finite element analysis, multi-physics simulations, and predictive algorithms that account for thermal, electrical, and mechanical behaviors. Advanced modeling approaches enable researchers to predict performance under various operating conditions, optimize material compositions, and identify design improvements before physical prototyping. This accelerates development cycles and improves the efficiency of thermoelectric generation systems.Expand Specific Solutions

Key Patents and Research in Marine Thermoelectric Systems

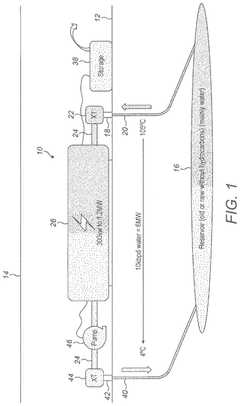

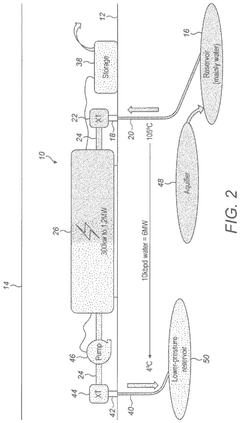

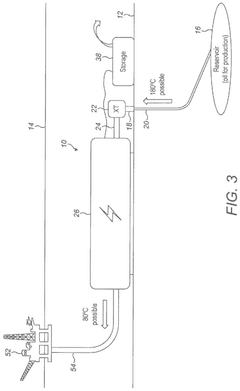

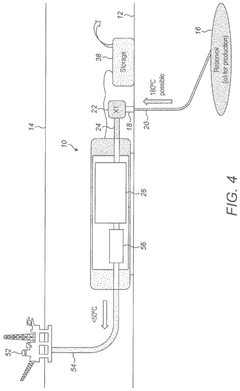

Producing renewable energy underwater

PatentPendingUS20250228135A1

Innovation

- A thermoelectric generator system utilizing a closed-loop or open-loop configuration with wellheads to convey fluid from a subterranean source to a thermoelectric generator, generating electricity through a temperature differential, and optionally recirculating or outputting the cooled fluid to a surface facility.

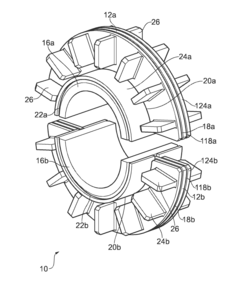

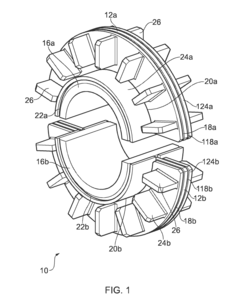

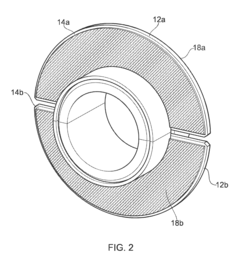

Thermoelectric generator

PatentActiveUS20160293821A1

Innovation

- A thermoelectric generator apparatus is designed to be attached to subsea pipes, utilizing a collar and support structure to maximize surface area contact with the pipe, leveraging temperature differences between the fluid and sea water to generate electricity, with no moving parts for increased reliability and reduced maintenance.

Environmental Impact Assessment of TEG Deployment

The deployment of Thermoelectric Generators (TEGs) in deep-sea environments necessitates a comprehensive environmental impact assessment to ensure sustainable operations. These generators, while offering significant advantages for powering underwater exploration systems, interact with delicate marine ecosystems in ways that require careful evaluation and mitigation strategies.

Primary ecological concerns include thermal pollution from TEG heat dissipation, which can alter localized temperature gradients critical to deep-sea species. Even minor temperature changes of 1-2°C can disrupt biological processes in organisms adapted to the stable thermal conditions characteristic of deep ocean environments. Additionally, the materials used in TEG construction—particularly semiconductor compounds containing bismuth, tellurium, and sometimes lead—pose potential toxicity risks if corrosion or structural failure occurs.

Electromagnetic fields generated by TEG systems represent another environmental consideration. Research indicates that certain marine species, especially those that utilize electromagnetic sensing for navigation or prey detection, may experience behavioral modifications when exposed to artificial electromagnetic fields. The long-term consequences of such exposure remain inadequately understood and warrant ongoing monitoring.

Physical disturbance during installation and retrieval operations constitutes a significant but temporary impact. Seabed disruption can damage benthic habitats and communities, with recovery times varying from months to decades depending on depth and ecosystem characteristics. Implementation of precise positioning systems and minimally invasive deployment techniques can substantially reduce these effects.

Comparative analyses with alternative power sources reveal that TEGs generally present lower environmental risks than systems requiring fuel transport or containing pressurized components. Their solid-state operation eliminates risks associated with fluid leakage, while their extended operational lifespan reduces the frequency of disruptive maintenance interventions.

Mitigation strategies should include bio-compatible material selection, thermal insulation optimization to minimize heat transfer to surrounding waters, and comprehensive end-of-life recovery protocols. Modular designs that facilitate complete system retrieval without residual components represent best practice for environmental protection.

Regulatory frameworks governing deep-sea TEG deployment vary significantly across jurisdictions, with international waters presenting particular compliance challenges. The development of standardized environmental impact assessment methodologies specific to deep-sea TEG applications would enhance consistency in evaluation practices and improve environmental safeguarding measures across the industry.

Primary ecological concerns include thermal pollution from TEG heat dissipation, which can alter localized temperature gradients critical to deep-sea species. Even minor temperature changes of 1-2°C can disrupt biological processes in organisms adapted to the stable thermal conditions characteristic of deep ocean environments. Additionally, the materials used in TEG construction—particularly semiconductor compounds containing bismuth, tellurium, and sometimes lead—pose potential toxicity risks if corrosion or structural failure occurs.

Electromagnetic fields generated by TEG systems represent another environmental consideration. Research indicates that certain marine species, especially those that utilize electromagnetic sensing for navigation or prey detection, may experience behavioral modifications when exposed to artificial electromagnetic fields. The long-term consequences of such exposure remain inadequately understood and warrant ongoing monitoring.

Physical disturbance during installation and retrieval operations constitutes a significant but temporary impact. Seabed disruption can damage benthic habitats and communities, with recovery times varying from months to decades depending on depth and ecosystem characteristics. Implementation of precise positioning systems and minimally invasive deployment techniques can substantially reduce these effects.

Comparative analyses with alternative power sources reveal that TEGs generally present lower environmental risks than systems requiring fuel transport or containing pressurized components. Their solid-state operation eliminates risks associated with fluid leakage, while their extended operational lifespan reduces the frequency of disruptive maintenance interventions.

Mitigation strategies should include bio-compatible material selection, thermal insulation optimization to minimize heat transfer to surrounding waters, and comprehensive end-of-life recovery protocols. Modular designs that facilitate complete system retrieval without residual components represent best practice for environmental protection.

Regulatory frameworks governing deep-sea TEG deployment vary significantly across jurisdictions, with international waters presenting particular compliance challenges. The development of standardized environmental impact assessment methodologies specific to deep-sea TEG applications would enhance consistency in evaluation practices and improve environmental safeguarding measures across the industry.

Power Management Strategies for Deep-Sea TEG Systems

Effective power management is critical for the sustainable operation of Thermoelectric Generator (TEG) systems in deep-sea environments. The harsh conditions, including extreme pressure, low temperatures, and limited accessibility, necessitate sophisticated strategies to maximize energy efficiency and system longevity.

Deep-sea TEG systems typically operate with significant temperature differentials between the warm hydrothermal vents or geothermal sources and the cold surrounding seawater. This natural gradient provides the foundation for power generation, but optimal utilization requires advanced management techniques. Implementing Maximum Power Point Tracking (MPPT) algorithms specifically calibrated for deep-sea conditions ensures that TEGs operate at their highest efficiency point despite fluctuating temperature differentials.

Energy storage integration represents another crucial aspect of power management for deep-sea TEG systems. High-density batteries or supercapacitors designed to withstand extreme pressures serve as buffers during periods of low power generation or peak demand. These storage solutions must be carefully selected to balance capacity, weight, pressure resistance, and long-term reliability in corrosive environments.

Adaptive load management systems provide significant advantages by dynamically adjusting power consumption based on available energy and operational priorities. Critical sensors and communication systems can be maintained at full functionality while secondary systems operate in reduced power modes during energy constraints. This hierarchical approach ensures mission-critical functions remain operational even during suboptimal power generation periods.

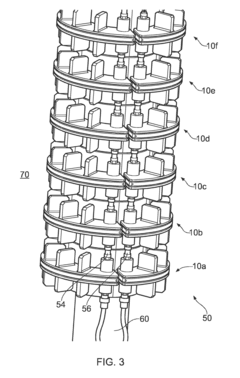

Redundancy and fault tolerance must be incorporated into power management architectures for deep-sea TEG deployments. Multiple independent TEG modules with isolated power conditioning circuits prevent total system failure if individual components malfunction. Self-diagnostic capabilities that monitor performance metrics and predict potential failures allow for preemptive maintenance scheduling or operational adjustments before critical failures occur.

Remote monitoring and control systems enable real-time optimization of power management strategies. Low-bandwidth acoustic communication links can transmit essential performance data to surface vessels or shore stations, allowing engineers to implement parameter adjustments or troubleshooting protocols without physical intervention. Machine learning algorithms increasingly enhance these systems by predicting optimal operating parameters based on environmental conditions and system performance history.

Thermal management integration with power systems represents an emerging frontier in deep-sea TEG optimization. By coordinating heat distribution across TEG arrays and utilizing waste heat from electronic components, overall system efficiency can be significantly improved. Advanced thermal interface materials specifically designed for high-pressure environments further enhance heat transfer efficiency between thermal sources and TEG modules.

Deep-sea TEG systems typically operate with significant temperature differentials between the warm hydrothermal vents or geothermal sources and the cold surrounding seawater. This natural gradient provides the foundation for power generation, but optimal utilization requires advanced management techniques. Implementing Maximum Power Point Tracking (MPPT) algorithms specifically calibrated for deep-sea conditions ensures that TEGs operate at their highest efficiency point despite fluctuating temperature differentials.

Energy storage integration represents another crucial aspect of power management for deep-sea TEG systems. High-density batteries or supercapacitors designed to withstand extreme pressures serve as buffers during periods of low power generation or peak demand. These storage solutions must be carefully selected to balance capacity, weight, pressure resistance, and long-term reliability in corrosive environments.

Adaptive load management systems provide significant advantages by dynamically adjusting power consumption based on available energy and operational priorities. Critical sensors and communication systems can be maintained at full functionality while secondary systems operate in reduced power modes during energy constraints. This hierarchical approach ensures mission-critical functions remain operational even during suboptimal power generation periods.

Redundancy and fault tolerance must be incorporated into power management architectures for deep-sea TEG deployments. Multiple independent TEG modules with isolated power conditioning circuits prevent total system failure if individual components malfunction. Self-diagnostic capabilities that monitor performance metrics and predict potential failures allow for preemptive maintenance scheduling or operational adjustments before critical failures occur.

Remote monitoring and control systems enable real-time optimization of power management strategies. Low-bandwidth acoustic communication links can transmit essential performance data to surface vessels or shore stations, allowing engineers to implement parameter adjustments or troubleshooting protocols without physical intervention. Machine learning algorithms increasingly enhance these systems by predicting optimal operating parameters based on environmental conditions and system performance history.

Thermal management integration with power systems represents an emerging frontier in deep-sea TEG optimization. By coordinating heat distribution across TEG arrays and utilizing waste heat from electronic components, overall system efficiency can be significantly improved. Advanced thermal interface materials specifically designed for high-pressure environments further enhance heat transfer efficiency between thermal sources and TEG modules.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!