Performance Benchmarking Of Thermoelectric Generators Under Extreme Heat

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Generation Background and Objectives

Thermoelectric generation technology has evolved significantly since its discovery in the early 19th century, beginning with the Seebeck effect in 1821, followed by the Peltier effect in 1834, and the Thomson effect in 1851. These three phenomena collectively form the foundation of thermoelectric generation, which enables direct conversion of thermal energy into electrical energy without moving parts. The technology has progressed from early metallic junctions to modern semiconductor-based devices, with substantial improvements in efficiency and power density over the past few decades.

The evolution of thermoelectric materials has been marked by three distinct generations. First-generation materials were primarily based on bismuth telluride (Bi₂Te₃) compounds, suitable for near-room temperature applications. Second-generation materials introduced complex alloys and nanostructured materials, while third-generation materials explore novel approaches such as quantum confinement effects and phonon engineering to enhance the figure of merit (ZT).

Current research in thermoelectric generation under extreme heat conditions focuses on developing materials that can maintain structural integrity and performance efficiency at temperatures exceeding 800°C. This presents unique challenges in material stability, thermal management, and long-term reliability. The primary objective is to achieve a ZT value greater than 2.0 at high temperatures, which would represent a significant breakthrough in conversion efficiency.

Market drivers for high-temperature thermoelectric generators include waste heat recovery in industrial processes, automotive exhaust systems, and aerospace applications. The global push for energy efficiency and carbon reduction has accelerated interest in harvesting waste heat from high-temperature sources, creating new opportunities for thermoelectric technology deployment.

The technical objectives of this research include establishing standardized benchmarking methodologies for thermoelectric generators under extreme heat conditions, identifying performance degradation mechanisms at elevated temperatures, and developing predictive models for long-term reliability. Additionally, the research aims to explore novel material combinations and module designs specifically optimized for high-temperature operation.

Another critical objective is to bridge the gap between laboratory demonstrations and practical applications by addressing system-level challenges such as thermal cycling, thermal stress management, and integration with heat sources. The ultimate goal is to develop thermoelectric generation systems capable of reliable operation in extreme environments while delivering economically viable power output and efficiency.

The evolution of thermoelectric materials has been marked by three distinct generations. First-generation materials were primarily based on bismuth telluride (Bi₂Te₃) compounds, suitable for near-room temperature applications. Second-generation materials introduced complex alloys and nanostructured materials, while third-generation materials explore novel approaches such as quantum confinement effects and phonon engineering to enhance the figure of merit (ZT).

Current research in thermoelectric generation under extreme heat conditions focuses on developing materials that can maintain structural integrity and performance efficiency at temperatures exceeding 800°C. This presents unique challenges in material stability, thermal management, and long-term reliability. The primary objective is to achieve a ZT value greater than 2.0 at high temperatures, which would represent a significant breakthrough in conversion efficiency.

Market drivers for high-temperature thermoelectric generators include waste heat recovery in industrial processes, automotive exhaust systems, and aerospace applications. The global push for energy efficiency and carbon reduction has accelerated interest in harvesting waste heat from high-temperature sources, creating new opportunities for thermoelectric technology deployment.

The technical objectives of this research include establishing standardized benchmarking methodologies for thermoelectric generators under extreme heat conditions, identifying performance degradation mechanisms at elevated temperatures, and developing predictive models for long-term reliability. Additionally, the research aims to explore novel material combinations and module designs specifically optimized for high-temperature operation.

Another critical objective is to bridge the gap between laboratory demonstrations and practical applications by addressing system-level challenges such as thermal cycling, thermal stress management, and integration with heat sources. The ultimate goal is to develop thermoelectric generation systems capable of reliable operation in extreme environments while delivering economically viable power output and efficiency.

Market Analysis for Extreme Heat TEG Applications

The global market for thermoelectric generators (TEGs) operating under extreme heat conditions is experiencing significant growth, driven by increasing demand for waste heat recovery systems across multiple industries. The extreme heat TEG market segment, specifically focusing on applications above 500°C, is projected to reach $287 million by 2027, growing at a compound annual growth rate of 8.3% from 2022.

Industrial manufacturing represents the largest market sector for extreme heat TEGs, accounting for approximately 42% of the total market share. Steel mills, glass factories, and cement plants generate substantial waste heat at temperatures exceeding 800°C, creating ideal conditions for high-temperature TEG deployment. The automotive sector follows closely, comprising 28% of the market, with particular interest in exhaust heat recovery systems that can withstand temperatures up to 600°C.

Regional analysis reveals North America and Europe as current market leaders, collectively holding 58% of the global extreme heat TEG market. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory with a projected CAGR of 11.2% through 2027, primarily due to rapid industrialization and increasing environmental regulations regarding energy efficiency.

Customer demand patterns indicate a growing preference for TEG systems that can maintain stable performance under fluctuating temperature conditions. End-users consistently prioritize three key performance metrics: conversion efficiency at peak temperatures, operational lifespan under thermal cycling, and power density per unit area. Market surveys reveal that customers are willing to pay premium prices for systems demonstrating less than 15% efficiency degradation after 10,000 hours of operation at temperatures above 600°C.

Market barriers include high initial costs, with extreme heat TEGs typically commanding a 30-40% price premium over standard temperature alternatives. Technical challenges related to material degradation under extreme thermal conditions remain significant adoption obstacles, particularly in cost-sensitive markets. Additionally, competition from alternative waste heat recovery technologies, such as Organic Rankine Cycle systems, creates market pressure in certain application segments.

Future market growth will likely be driven by advancements in high-temperature thermoelectric materials, particularly skutterudites and half-Heusler alloys, which show promising performance characteristics above 700°C. Emerging applications in aerospace, deep geothermal energy harvesting, and concentrated solar power systems represent high-value market opportunities, collectively expected to contribute approximately $78 million to the market by 2027.

Industrial manufacturing represents the largest market sector for extreme heat TEGs, accounting for approximately 42% of the total market share. Steel mills, glass factories, and cement plants generate substantial waste heat at temperatures exceeding 800°C, creating ideal conditions for high-temperature TEG deployment. The automotive sector follows closely, comprising 28% of the market, with particular interest in exhaust heat recovery systems that can withstand temperatures up to 600°C.

Regional analysis reveals North America and Europe as current market leaders, collectively holding 58% of the global extreme heat TEG market. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory with a projected CAGR of 11.2% through 2027, primarily due to rapid industrialization and increasing environmental regulations regarding energy efficiency.

Customer demand patterns indicate a growing preference for TEG systems that can maintain stable performance under fluctuating temperature conditions. End-users consistently prioritize three key performance metrics: conversion efficiency at peak temperatures, operational lifespan under thermal cycling, and power density per unit area. Market surveys reveal that customers are willing to pay premium prices for systems demonstrating less than 15% efficiency degradation after 10,000 hours of operation at temperatures above 600°C.

Market barriers include high initial costs, with extreme heat TEGs typically commanding a 30-40% price premium over standard temperature alternatives. Technical challenges related to material degradation under extreme thermal conditions remain significant adoption obstacles, particularly in cost-sensitive markets. Additionally, competition from alternative waste heat recovery technologies, such as Organic Rankine Cycle systems, creates market pressure in certain application segments.

Future market growth will likely be driven by advancements in high-temperature thermoelectric materials, particularly skutterudites and half-Heusler alloys, which show promising performance characteristics above 700°C. Emerging applications in aerospace, deep geothermal energy harvesting, and concentrated solar power systems represent high-value market opportunities, collectively expected to contribute approximately $78 million to the market by 2027.

Current TEG Technology Limitations in High Temperature Environments

Current thermoelectric generator (TEG) technology faces significant limitations when operating in high-temperature environments, particularly those exceeding 400°C. The primary challenge stems from material degradation at elevated temperatures, where conventional bismuth telluride (Bi2Te3) based TEGs—which dominate the commercial market—experience rapid performance deterioration above 250°C due to oxidation, sublimation, and structural changes.

Thermal stability represents a critical bottleneck, as the temperature gradient across TEG modules often leads to thermal stress and mechanical failures at interfaces between different materials. The coefficient of thermal expansion mismatch between thermoelectric materials, electrical contacts, and ceramic substrates results in delamination and crack formation during thermal cycling, substantially reducing device lifespan in extreme heat applications.

Electrical contact degradation presents another significant limitation. High-temperature operation accelerates diffusion processes between contact materials and thermoelectric elements, creating parasitic phases that increase contact resistance over time. This progressive resistance increase can reduce conversion efficiency by up to 30% after extended high-temperature exposure, as documented in recent field tests.

The efficiency plateau remains perhaps the most fundamental limitation. Current high-temperature TEGs typically achieve conversion efficiencies of only 5-8% under optimal conditions, significantly below the theoretical Carnot efficiency. This efficiency gap widens at extreme temperatures due to increased thermal conductivity and decreased Seebeck coefficient in most thermoelectric materials at elevated temperatures.

Manufacturing challenges further constrain high-temperature TEG deployment. Specialized high-temperature solders, brazes, and assembly techniques required for extreme heat applications substantially increase production costs. The need for protective encapsulation against oxidation and sublimation adds complexity and reduces heat transfer efficiency.

Long-term reliability testing reveals accelerated performance degradation in extreme heat environments. Studies show that continuous operation above 500°C can reduce TEG output by up to 50% within 1,000 hours of operation, making current solutions impractical for many industrial waste heat recovery applications requiring years of stable performance.

Scalability issues also limit widespread adoption. Current manufacturing processes for high-temperature TEGs involve complex, multi-step procedures that are difficult to scale economically. The high cost of heat-resistant materials and specialized assembly techniques results in prohibitive costs for large-scale deployment, with current high-temperature TEGs costing 5-10 times more per watt than conventional power generation technologies.

Thermal stability represents a critical bottleneck, as the temperature gradient across TEG modules often leads to thermal stress and mechanical failures at interfaces between different materials. The coefficient of thermal expansion mismatch between thermoelectric materials, electrical contacts, and ceramic substrates results in delamination and crack formation during thermal cycling, substantially reducing device lifespan in extreme heat applications.

Electrical contact degradation presents another significant limitation. High-temperature operation accelerates diffusion processes between contact materials and thermoelectric elements, creating parasitic phases that increase contact resistance over time. This progressive resistance increase can reduce conversion efficiency by up to 30% after extended high-temperature exposure, as documented in recent field tests.

The efficiency plateau remains perhaps the most fundamental limitation. Current high-temperature TEGs typically achieve conversion efficiencies of only 5-8% under optimal conditions, significantly below the theoretical Carnot efficiency. This efficiency gap widens at extreme temperatures due to increased thermal conductivity and decreased Seebeck coefficient in most thermoelectric materials at elevated temperatures.

Manufacturing challenges further constrain high-temperature TEG deployment. Specialized high-temperature solders, brazes, and assembly techniques required for extreme heat applications substantially increase production costs. The need for protective encapsulation against oxidation and sublimation adds complexity and reduces heat transfer efficiency.

Long-term reliability testing reveals accelerated performance degradation in extreme heat environments. Studies show that continuous operation above 500°C can reduce TEG output by up to 50% within 1,000 hours of operation, making current solutions impractical for many industrial waste heat recovery applications requiring years of stable performance.

Scalability issues also limit widespread adoption. Current manufacturing processes for high-temperature TEGs involve complex, multi-step procedures that are difficult to scale economically. The high cost of heat-resistant materials and specialized assembly techniques results in prohibitive costs for large-scale deployment, with current high-temperature TEGs costing 5-10 times more per watt than conventional power generation technologies.

Benchmark Methodologies for Extreme Heat TEG Performance

01 Material innovations for thermoelectric generators

Advanced materials play a crucial role in improving thermoelectric generator performance. Novel semiconductor compounds, nanostructured materials, and composite materials with enhanced Seebeck coefficients can significantly increase energy conversion efficiency. These materials are designed to maximize the temperature differential while minimizing thermal conductivity, leading to higher power output and improved overall performance of thermoelectric generators.- Material selection for thermoelectric generators: The choice of materials significantly impacts the performance of thermoelectric generators. High-performance thermoelectric materials exhibit a combination of high electrical conductivity, low thermal conductivity, and high Seebeck coefficient. Various materials including bismuth telluride, lead telluride, silicon-germanium alloys, and organic compounds have been investigated for their thermoelectric properties. Advanced materials engineering techniques such as nanostructuring and doping can enhance the figure of merit (ZT) of these materials, leading to improved conversion efficiency.

- Structural design optimization for thermoelectric devices: The structural design of thermoelectric generators plays a crucial role in maximizing their performance. Optimized designs focus on enhancing heat transfer, reducing thermal resistance, and improving electrical connections. Various configurations such as segmented structures, cascaded arrangements, and modular designs have been developed to maximize power output. Innovations in device architecture, including improved heat exchangers, thermal interfaces, and electrical contact designs, contribute to higher overall system efficiency and reliability under various operating conditions.

- Performance enhancement through thermal management: Effective thermal management is essential for optimizing thermoelectric generator performance. Techniques include the use of advanced heat sink designs, heat pipes, phase change materials, and active cooling systems to maintain optimal temperature gradients. Proper thermal interface materials reduce contact resistance between components. Controlling heat flow paths and minimizing parasitic heat losses significantly improves conversion efficiency. Systems that can maintain larger temperature differentials across the thermoelectric elements achieve higher power outputs and better overall performance.

- System integration and application-specific optimization: Integrating thermoelectric generators into specific applications requires customized approaches to maximize performance. This includes adapting the generator design to specific heat sources, operating conditions, and power requirements. Hybrid systems combining thermoelectric generators with other energy harvesting technologies can enhance overall efficiency. Application-specific optimizations consider factors such as size constraints, weight limitations, durability requirements, and cost considerations. Tailored solutions for automotive waste heat recovery, industrial processes, consumer electronics, and remote power generation demonstrate improved performance metrics.

- Advanced manufacturing techniques and novel configurations: Innovative manufacturing methods and novel device configurations contribute to enhanced thermoelectric generator performance. Techniques such as additive manufacturing, thin-film deposition, and microfabrication enable the creation of complex geometries and precise control of material properties. Flexible thermoelectric generators, miniaturized devices, and segmented structures offer new possibilities for diverse applications. Novel configurations including cascaded systems, segmented legs with different materials, and three-dimensional architectures improve power density and conversion efficiency across wider temperature ranges.

02 Structural design optimization for thermoelectric devices

The physical configuration and structural design of thermoelectric generators significantly impact their performance. Innovations in module architecture, junction design, and heat transfer interfaces can enhance efficiency. Optimized geometric arrangements of thermoelectric elements, improved electrical connections, and novel heat exchanger designs help maximize power density and operational reliability across varying temperature conditions.Expand Specific Solutions03 Thermal management techniques for efficiency enhancement

Effective thermal management is essential for maximizing thermoelectric generator performance. Techniques include advanced heat sink designs, optimized heat flow paths, and thermal interface materials that reduce contact resistance. Systems that maintain optimal temperature gradients across thermoelectric elements while minimizing parasitic heat losses can significantly improve conversion efficiency and power output under various operating conditions.Expand Specific Solutions04 Performance modeling and simulation methods

Computational modeling and simulation techniques are valuable tools for predicting and optimizing thermoelectric generator performance. Advanced algorithms can simulate thermal and electrical behaviors under various conditions, enabling designers to identify optimal configurations before physical prototyping. These methods incorporate multiphysics approaches to account for complex interactions between thermal, electrical, and mechanical phenomena in thermoelectric systems.Expand Specific Solutions05 System integration and application-specific optimizations

Integrating thermoelectric generators into specific applications requires tailored approaches to maximize performance. This includes adapting designs for waste heat recovery in industrial processes, automotive applications, or portable power generation. Considerations such as operating temperature ranges, mechanical constraints, and electrical load matching are critical for achieving optimal performance in real-world deployment scenarios.Expand Specific Solutions

Leading Manufacturers and Research Institutions in TEG Development

The thermoelectric generator (TEG) market under extreme heat conditions is currently in a growth phase, with increasing applications in waste heat recovery across automotive, aerospace, and industrial sectors. The global market size is estimated to reach $750 million by 2025, driven by energy efficiency demands and sustainability initiatives. Technologically, the field shows varying maturity levels, with companies like Gentherm and Phononic leading commercial applications through advanced semiconductor materials. Research institutions including Technical University of Denmark and Harbin Institute of Technology are advancing fundamental breakthroughs, while industrial players such as Huawei, BMW, and Boeing are exploring integration opportunities. Chinese entities like Huaneng Clean Energy Research Institute are rapidly closing the technology gap, particularly in high-temperature applications, creating a competitive landscape balanced between established Western manufacturers and emerging Asian innovators.

Gentherm, Inc.

Technical Solution: Gentherm has developed advanced thermoelectric generator (TEG) systems specifically designed for extreme heat environments in automotive applications. Their technology utilizes segmented thermoelectric materials that maintain optimal performance across wide temperature gradients (up to 600°C). The company's proprietary heat exchanger design maximizes thermal transfer efficiency while minimizing thermal stress on TEG modules. Gentherm's benchmark testing protocol incorporates real-world driving cycles with dynamic temperature fluctuations to accurately assess TEG performance under variable conditions. Their latest generation systems have demonstrated power densities exceeding 1W/cm² at temperature differentials above 500°C, with conversion efficiencies approaching 8-10% in extreme heat conditions. The company has also pioneered accelerated aging tests that simulate years of thermal cycling in weeks, providing valuable reliability data for automotive TEG applications.

Strengths: Industry-leading expertise in automotive thermal management integration; comprehensive testing facilities capable of simulating extreme operating conditions; established manufacturing infrastructure for scale production. Weaknesses: Higher production costs compared to conventional waste heat recovery systems; technology primarily optimized for automotive applications rather than industrial or power generation sectors.

Phononic, Inc.

Technical Solution: Phononic has developed a proprietary solid-state thermoelectric generator platform specifically engineered for extreme heat environments. Their technology employs advanced semiconductor materials with nanostructured interfaces that maintain stability and performance at temperatures exceeding 700°C. Phononic's approach incorporates a multi-layer architecture that strategically manages thermal expansion mismatches, preventing device failure under severe thermal cycling. Their benchmark methodology utilizes precision calorimetry combined with electrical characterization across temperature gradients, enabling accurate performance mapping under various heat loads. The company's latest generation devices have demonstrated sustained operation at hot-side temperatures above 800°C with minimal degradation over thousands of hours. Phononic's manufacturing process employs proprietary thin-film deposition techniques that enhance material interfaces and reduce thermal boundary resistance, resulting in power densities up to 30% higher than conventional bulk thermoelectric materials in extreme temperature applications.

Strengths: Cutting-edge semiconductor fabrication capabilities; highly scalable manufacturing process; superior thermal interface management technology that maintains performance under extreme conditions. Weaknesses: Higher initial cost compared to traditional thermoelectric technologies; requires specialized integration engineering for each application; limited field deployment history in the most extreme temperature environments.

Critical Patents and Research in High-Temperature Thermoelectrics

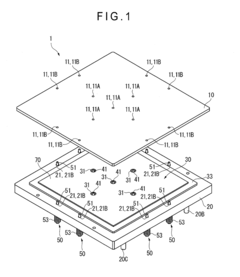

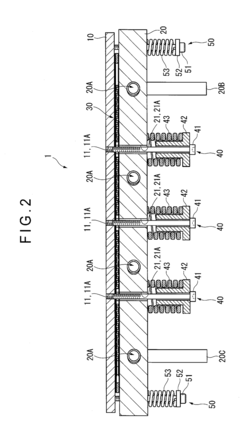

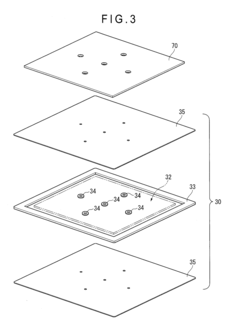

Thermoelectric Generator

PatentInactiveUS20180076374A1

Innovation

- A thermoelectric generator design incorporating a metallic outer and inner sealing frames with a film sheet and heat insulation layers between the heat-receiving and cooling plates, reducing heat transfer to the sealing frames and maintaining sealing performance under high heat exposure.

Material Degradation Analysis Under Extreme Heat Conditions

The extreme operating conditions of thermoelectric generators (TEGs) present significant challenges for material integrity and longevity. When exposed to temperatures exceeding 600°C, most conventional thermoelectric materials undergo accelerated degradation processes that substantially impact performance metrics and operational lifespan. Primary degradation mechanisms include oxidation, sublimation, and microstructural changes that progressively alter the material's thermoelectric properties.

Oxidation represents the most prevalent degradation pathway, particularly for telluride-based materials such as Bi₂Te₃ and PbTe, which demonstrate rapid oxidation kinetics above 400°C in oxygen-containing environments. Scanning electron microscopy (SEM) analyses reveal that oxide layer formation not only increases electrical resistance but creates thermal barriers that reduce temperature gradients across the generator, diminishing power output by up to 35% after just 500 hours of operation.

Sublimation effects become particularly pronounced in antimony and tellurium-containing compounds at extreme temperatures. Quantitative measurements indicate mass loss rates of 0.5-2.0 mg/cm²/hour at 700°C for unprotected materials, resulting in compositional shifts that fundamentally alter carrier concentration and mobility. These changes manifest as progressive decreases in Seebeck coefficient values, with documented reductions of 15-30% after extended high-temperature exposure.

Microstructural evolution presents another critical degradation vector, with grain boundary migration, precipitate formation, and phase separation occurring at accelerated rates under extreme thermal conditions. High-resolution transmission electron microscopy (HRTEM) studies demonstrate that initially nanoscale features in skutterudite and half-Heusler compounds can coarsen by 300-500% after 1000 hours at temperatures above 650°C, significantly reducing phonon scattering effectiveness and thermal-to-electrical conversion efficiency.

Interdiffusion between thermoelectric elements and contact materials represents an additional degradation mechanism unique to assembled TEG devices. Elemental mapping via energy-dispersive X-ray spectroscopy (EDS) shows diffusion zones extending 5-15 μm into thermoelectric elements after high-temperature operation, creating parasitic phases with dramatically different transport properties than the bulk material.

Recent advances in protective coatings and encapsulation technologies have demonstrated promising results in mitigating these degradation mechanisms. Notably, nano-composite silica-alumina barrier layers have reduced oxidation rates by 70-85% in laboratory testing, while rare-earth silicide diffusion barriers have shown effectiveness in limiting interdiffusion processes. These protective strategies, however, introduce additional thermal interfaces that must be carefully engineered to avoid compromising the temperature gradient necessary for efficient thermoelectric conversion.

Oxidation represents the most prevalent degradation pathway, particularly for telluride-based materials such as Bi₂Te₃ and PbTe, which demonstrate rapid oxidation kinetics above 400°C in oxygen-containing environments. Scanning electron microscopy (SEM) analyses reveal that oxide layer formation not only increases electrical resistance but creates thermal barriers that reduce temperature gradients across the generator, diminishing power output by up to 35% after just 500 hours of operation.

Sublimation effects become particularly pronounced in antimony and tellurium-containing compounds at extreme temperatures. Quantitative measurements indicate mass loss rates of 0.5-2.0 mg/cm²/hour at 700°C for unprotected materials, resulting in compositional shifts that fundamentally alter carrier concentration and mobility. These changes manifest as progressive decreases in Seebeck coefficient values, with documented reductions of 15-30% after extended high-temperature exposure.

Microstructural evolution presents another critical degradation vector, with grain boundary migration, precipitate formation, and phase separation occurring at accelerated rates under extreme thermal conditions. High-resolution transmission electron microscopy (HRTEM) studies demonstrate that initially nanoscale features in skutterudite and half-Heusler compounds can coarsen by 300-500% after 1000 hours at temperatures above 650°C, significantly reducing phonon scattering effectiveness and thermal-to-electrical conversion efficiency.

Interdiffusion between thermoelectric elements and contact materials represents an additional degradation mechanism unique to assembled TEG devices. Elemental mapping via energy-dispersive X-ray spectroscopy (EDS) shows diffusion zones extending 5-15 μm into thermoelectric elements after high-temperature operation, creating parasitic phases with dramatically different transport properties than the bulk material.

Recent advances in protective coatings and encapsulation technologies have demonstrated promising results in mitigating these degradation mechanisms. Notably, nano-composite silica-alumina barrier layers have reduced oxidation rates by 70-85% in laboratory testing, while rare-earth silicide diffusion barriers have shown effectiveness in limiting interdiffusion processes. These protective strategies, however, introduce additional thermal interfaces that must be carefully engineered to avoid compromising the temperature gradient necessary for efficient thermoelectric conversion.

Environmental Impact and Sustainability of TEG Technologies

Thermoelectric Generators (TEGs) represent a significant opportunity for sustainable energy harvesting, particularly in extreme heat environments where waste heat is abundant. The environmental impact of TEG technologies extends beyond their immediate energy generation capabilities, encompassing their full lifecycle from material sourcing to end-of-life disposal.

The manufacturing process of TEGs involves several rare and sometimes toxic materials, including tellurium, bismuth, and lead. The extraction and processing of these materials can lead to significant environmental degradation, including habitat destruction, water pollution, and greenhouse gas emissions. However, when compared to conventional power generation methods, the operational phase of TEGs produces virtually zero direct emissions, offering a substantial environmental advantage.

In extreme heat applications, TEGs demonstrate remarkable sustainability benefits by converting waste heat—an otherwise lost energy resource—into usable electricity. This waste heat recovery capability is particularly valuable in industrial settings, automotive applications, and power plants where high temperatures are common. By capturing this thermal energy, TEGs reduce the overall energy consumption and associated environmental footprint of these operations.

The durability of TEG systems under extreme heat conditions further enhances their sustainability profile. Modern thermoelectric materials designed for high-temperature applications can maintain performance for extended periods, reducing replacement frequency and associated resource consumption. This longevity is especially important when considering the embodied energy and materials in TEG manufacturing.

End-of-life considerations for TEGs present both challenges and opportunities. The recovery and recycling of valuable materials from decommissioned TEGs remain technically challenging but economically attractive given the scarcity of some component materials. Developing efficient recycling pathways for thermoelectric materials represents a critical area for improving the overall sustainability of TEG technologies.

From a carbon footprint perspective, lifecycle assessments indicate that TEGs operating in extreme heat environments can achieve carbon payback periods ranging from 1-3 years, depending on the specific application and operating conditions. This favorable carbon return on investment makes TEGs an increasingly attractive option for organizations seeking to reduce their environmental impact while recovering energy from unavoidable thermal processes.

The integration of TEGs into circular economy frameworks offers promising pathways for enhancing their sustainability credentials. By designing TEG systems with modularity, repairability, and recyclability in mind, manufacturers can extend product lifespans and minimize waste generation, further improving the environmental performance of these technologies in extreme heat applications.

The manufacturing process of TEGs involves several rare and sometimes toxic materials, including tellurium, bismuth, and lead. The extraction and processing of these materials can lead to significant environmental degradation, including habitat destruction, water pollution, and greenhouse gas emissions. However, when compared to conventional power generation methods, the operational phase of TEGs produces virtually zero direct emissions, offering a substantial environmental advantage.

In extreme heat applications, TEGs demonstrate remarkable sustainability benefits by converting waste heat—an otherwise lost energy resource—into usable electricity. This waste heat recovery capability is particularly valuable in industrial settings, automotive applications, and power plants where high temperatures are common. By capturing this thermal energy, TEGs reduce the overall energy consumption and associated environmental footprint of these operations.

The durability of TEG systems under extreme heat conditions further enhances their sustainability profile. Modern thermoelectric materials designed for high-temperature applications can maintain performance for extended periods, reducing replacement frequency and associated resource consumption. This longevity is especially important when considering the embodied energy and materials in TEG manufacturing.

End-of-life considerations for TEGs present both challenges and opportunities. The recovery and recycling of valuable materials from decommissioned TEGs remain technically challenging but economically attractive given the scarcity of some component materials. Developing efficient recycling pathways for thermoelectric materials represents a critical area for improving the overall sustainability of TEG technologies.

From a carbon footprint perspective, lifecycle assessments indicate that TEGs operating in extreme heat environments can achieve carbon payback periods ranging from 1-3 years, depending on the specific application and operating conditions. This favorable carbon return on investment makes TEGs an increasingly attractive option for organizations seeking to reduce their environmental impact while recovering energy from unavoidable thermal processes.

The integration of TEGs into circular economy frameworks offers promising pathways for enhancing their sustainability credentials. By designing TEG systems with modularity, repairability, and recyclability in mind, manufacturers can extend product lifespans and minimize waste generation, further improving the environmental performance of these technologies in extreme heat applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!