How Thermoelectric Generators Enhance Industrial Automation?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Generation Background and Objectives

Thermoelectric generation technology has evolved significantly since its discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion of temperature differences to electric voltage. This discovery laid the foundation for what would later become known as thermoelectric generators (TEGs). The subsequent development of the field was marked by the contributions of Jean Charles Athanase Peltier and William Thomson (Lord Kelvin), who further expanded the theoretical understanding of thermoelectric effects.

The modern era of thermoelectric generation began in the mid-20th century with the development of semiconductor-based thermoelectric materials, which significantly improved conversion efficiency. These advancements enabled practical applications in various fields, including space exploration, where radioisotope thermoelectric generators (RTGs) have powered spacecraft and remote installations for decades.

In recent years, thermoelectric generation has gained renewed interest due to its potential in waste heat recovery and energy harvesting applications, particularly in industrial settings. The global push for energy efficiency and sustainable practices has accelerated research and development in this field, leading to the emergence of novel materials and innovative designs that promise higher conversion efficiencies and lower costs.

The integration of thermoelectric generators into industrial automation systems represents a convergence of energy harvesting technology with Industry 4.0 principles. This integration aims to enhance the autonomy and reliability of industrial sensors, control systems, and IoT devices by providing localized power generation from waste heat sources that are abundant in industrial environments.

The primary technical objectives in this field include improving the thermoelectric figure of merit (ZT) of materials, developing more efficient heat exchange mechanisms, optimizing system designs for specific industrial applications, and reducing manufacturing costs to enable widespread adoption. Current research focuses on nanostructured materials, flexible thermoelectric generators, and hybrid systems that combine thermoelectric generation with other energy harvesting technologies.

Another key objective is the seamless integration of TEGs with wireless sensor networks and industrial control systems, enabling self-powered monitoring and control capabilities in environments where conventional power sources are impractical or unreliable. This integration requires addressing challenges related to power management, thermal interface materials, and system durability under harsh industrial conditions.

The long-term vision for thermoelectric generation in industrial automation extends beyond simple power generation to include active thermal management, predictive maintenance through temperature monitoring, and contribution to overall energy efficiency improvements in industrial processes. As manufacturing techniques advance and new materials emerge, thermoelectric technology is poised to become an integral component of sustainable industrial automation systems.

The modern era of thermoelectric generation began in the mid-20th century with the development of semiconductor-based thermoelectric materials, which significantly improved conversion efficiency. These advancements enabled practical applications in various fields, including space exploration, where radioisotope thermoelectric generators (RTGs) have powered spacecraft and remote installations for decades.

In recent years, thermoelectric generation has gained renewed interest due to its potential in waste heat recovery and energy harvesting applications, particularly in industrial settings. The global push for energy efficiency and sustainable practices has accelerated research and development in this field, leading to the emergence of novel materials and innovative designs that promise higher conversion efficiencies and lower costs.

The integration of thermoelectric generators into industrial automation systems represents a convergence of energy harvesting technology with Industry 4.0 principles. This integration aims to enhance the autonomy and reliability of industrial sensors, control systems, and IoT devices by providing localized power generation from waste heat sources that are abundant in industrial environments.

The primary technical objectives in this field include improving the thermoelectric figure of merit (ZT) of materials, developing more efficient heat exchange mechanisms, optimizing system designs for specific industrial applications, and reducing manufacturing costs to enable widespread adoption. Current research focuses on nanostructured materials, flexible thermoelectric generators, and hybrid systems that combine thermoelectric generation with other energy harvesting technologies.

Another key objective is the seamless integration of TEGs with wireless sensor networks and industrial control systems, enabling self-powered monitoring and control capabilities in environments where conventional power sources are impractical or unreliable. This integration requires addressing challenges related to power management, thermal interface materials, and system durability under harsh industrial conditions.

The long-term vision for thermoelectric generation in industrial automation extends beyond simple power generation to include active thermal management, predictive maintenance through temperature monitoring, and contribution to overall energy efficiency improvements in industrial processes. As manufacturing techniques advance and new materials emerge, thermoelectric technology is poised to become an integral component of sustainable industrial automation systems.

Industrial Automation Market Demand Analysis

The industrial automation market has witnessed significant growth over the past decade, driven by the increasing need for operational efficiency, reduced labor costs, and enhanced productivity across manufacturing sectors. According to recent market research, the global industrial automation market was valued at approximately $175 billion in 2020 and is projected to reach $265 billion by 2025, growing at a CAGR of 8.7% during the forecast period.

Thermoelectric generators (TEGs) are emerging as a critical component within this expanding market, particularly as industries seek sustainable energy harvesting solutions to power the growing number of sensors and devices required for Industry 4.0 implementation. The demand for TEGs in industrial automation stems from several key market factors.

Energy efficiency has become a paramount concern for manufacturing facilities worldwide, with approximately 20-50% of industrial energy input being lost as waste heat. This represents a substantial opportunity for TEGs, which can convert this waste heat directly into electrical power. Market surveys indicate that over 65% of industrial facility managers consider energy recovery systems a high priority investment for the next five years.

The proliferation of Industrial Internet of Things (IIoT) devices is another significant market driver. With the number of connected industrial devices expected to exceed 50 billion by 2025, the demand for reliable, maintenance-free power sources for remote sensors has intensified. Traditional wiring solutions are often cost-prohibitive, with installation costs reaching up to $2,500 per meter in complex industrial environments.

Regulatory pressures are also influencing market demand. Environmental regulations in major industrial economies are increasingly stringent, with carbon emission reduction targets ranging from 20% to 55% by 2030 compared to 1990 levels. This regulatory landscape has accelerated the adoption of energy recovery technologies like TEGs.

Sector-specific analysis reveals varying degrees of TEG adoption potential. The oil and gas industry, with its abundance of waste heat sources and remote monitoring needs, represents the largest current market segment at 32% of TEG industrial applications. Chemical processing follows at 24%, while power generation facilities account for 18% of the market.

Geographically, North America leads TEG adoption in industrial automation with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 12.3% annually, driven by rapid industrialization in China and India.

Customer pain points driving TEG demand include the high cost of power infrastructure for remote sensors (cited by 78% of industrial automation managers), maintenance challenges for battery-powered devices (65%), and increasing pressure to improve sustainability metrics (59%).

Thermoelectric generators (TEGs) are emerging as a critical component within this expanding market, particularly as industries seek sustainable energy harvesting solutions to power the growing number of sensors and devices required for Industry 4.0 implementation. The demand for TEGs in industrial automation stems from several key market factors.

Energy efficiency has become a paramount concern for manufacturing facilities worldwide, with approximately 20-50% of industrial energy input being lost as waste heat. This represents a substantial opportunity for TEGs, which can convert this waste heat directly into electrical power. Market surveys indicate that over 65% of industrial facility managers consider energy recovery systems a high priority investment for the next five years.

The proliferation of Industrial Internet of Things (IIoT) devices is another significant market driver. With the number of connected industrial devices expected to exceed 50 billion by 2025, the demand for reliable, maintenance-free power sources for remote sensors has intensified. Traditional wiring solutions are often cost-prohibitive, with installation costs reaching up to $2,500 per meter in complex industrial environments.

Regulatory pressures are also influencing market demand. Environmental regulations in major industrial economies are increasingly stringent, with carbon emission reduction targets ranging from 20% to 55% by 2030 compared to 1990 levels. This regulatory landscape has accelerated the adoption of energy recovery technologies like TEGs.

Sector-specific analysis reveals varying degrees of TEG adoption potential. The oil and gas industry, with its abundance of waste heat sources and remote monitoring needs, represents the largest current market segment at 32% of TEG industrial applications. Chemical processing follows at 24%, while power generation facilities account for 18% of the market.

Geographically, North America leads TEG adoption in industrial automation with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 12.3% annually, driven by rapid industrialization in China and India.

Customer pain points driving TEG demand include the high cost of power infrastructure for remote sensors (cited by 78% of industrial automation managers), maintenance challenges for battery-powered devices (65%), and increasing pressure to improve sustainability metrics (59%).

TEG Technology Status and Implementation Challenges

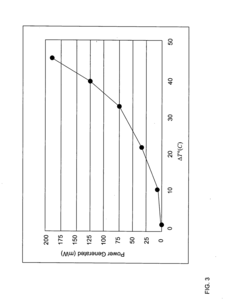

Thermoelectric generators (TEGs) have gained significant traction in industrial automation applications, yet their widespread implementation faces several technical and practical challenges. Currently, commercial TEG systems operate at efficiency levels between 5-8%, significantly lower than other power generation technologies. This efficiency limitation stems primarily from the inherent properties of thermoelectric materials, characterized by the dimensionless figure of merit ZT, which for most commercial materials remains below 2.0.

The global landscape of TEG technology shows concentrated development in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading research initiatives. Recent advancements have focused on nanostructured materials and quantum well structures to improve ZT values, with laboratory demonstrations achieving ZT values approaching 2.5 in controlled environments.

A major technical hurdle for industrial implementation is the thermal cycling durability of TEG modules. Industrial environments often subject these devices to extreme temperature fluctuations, causing thermal expansion mismatches between different materials in the TEG assembly. This leads to mechanical stress, delamination, and eventual performance degradation over time, limiting the operational lifespan of these systems.

Heat management represents another significant challenge. Effective TEG operation requires maintaining substantial temperature differentials across the device, necessitating sophisticated heat sink designs and thermal interface materials. In dusty or corrosive industrial environments, heat exchanger fouling can rapidly diminish performance, requiring regular maintenance interventions.

Manufacturing scalability also presents obstacles. Current production methods for high-performance thermoelectric materials often involve complex processes that are difficult to scale economically. The precision required for assembling multi-layer TEG modules with minimal contact resistance between components further complicates mass production efforts.

Material constraints add another dimension of difficulty. Many high-performance thermoelectric materials contain rare or toxic elements like tellurium, bismuth, or lead. This raises concerns about supply chain sustainability and environmental impact, particularly as deployment scales increase. Research into earth-abundant alternatives has shown promise but generally delivers lower performance metrics.

System integration challenges persist when incorporating TEGs into existing industrial infrastructure. The relatively low power density of current TEG technology necessitates significant surface area for meaningful power generation, creating space utilization conflicts in compact industrial settings. Additionally, the DC output of TEGs requires power conditioning electronics for integration with industrial control systems or the grid, adding complexity and cost.

The global landscape of TEG technology shows concentrated development in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading research initiatives. Recent advancements have focused on nanostructured materials and quantum well structures to improve ZT values, with laboratory demonstrations achieving ZT values approaching 2.5 in controlled environments.

A major technical hurdle for industrial implementation is the thermal cycling durability of TEG modules. Industrial environments often subject these devices to extreme temperature fluctuations, causing thermal expansion mismatches between different materials in the TEG assembly. This leads to mechanical stress, delamination, and eventual performance degradation over time, limiting the operational lifespan of these systems.

Heat management represents another significant challenge. Effective TEG operation requires maintaining substantial temperature differentials across the device, necessitating sophisticated heat sink designs and thermal interface materials. In dusty or corrosive industrial environments, heat exchanger fouling can rapidly diminish performance, requiring regular maintenance interventions.

Manufacturing scalability also presents obstacles. Current production methods for high-performance thermoelectric materials often involve complex processes that are difficult to scale economically. The precision required for assembling multi-layer TEG modules with minimal contact resistance between components further complicates mass production efforts.

Material constraints add another dimension of difficulty. Many high-performance thermoelectric materials contain rare or toxic elements like tellurium, bismuth, or lead. This raises concerns about supply chain sustainability and environmental impact, particularly as deployment scales increase. Research into earth-abundant alternatives has shown promise but generally delivers lower performance metrics.

System integration challenges persist when incorporating TEGs into existing industrial infrastructure. The relatively low power density of current TEG technology necessitates significant surface area for meaningful power generation, creating space utilization conflicts in compact industrial settings. Additionally, the DC output of TEGs requires power conditioning electronics for integration with industrial control systems or the grid, adding complexity and cost.

Current TEG Integration Solutions for Industrial Systems

01 Material optimization for thermoelectric efficiency

Advanced materials can significantly enhance the efficiency of thermoelectric generators by improving the Seebeck coefficient and reducing thermal conductivity. These materials include nanostructured semiconductors, skutterudites, and novel alloys that can operate effectively across various temperature ranges. The optimization of these materials focuses on increasing the figure of merit (ZT) through band engineering and carrier concentration control, resulting in higher power output and conversion efficiency.- Material composition optimization for thermoelectric generators: Enhancing thermoelectric generators through advanced material compositions involves developing novel semiconductor materials with improved Seebeck coefficients and reduced thermal conductivity. These optimized materials can significantly increase the conversion efficiency of thermal energy to electrical energy. Techniques include doping conventional thermoelectric materials, creating nanostructured composites, and developing new alloys that exhibit superior thermoelectric properties at various operating temperatures.

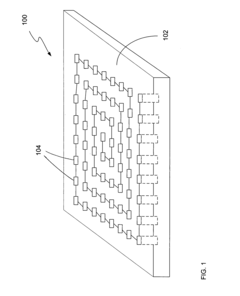

- Structural design improvements for thermoelectric devices: Innovative structural designs can enhance the performance of thermoelectric generators by optimizing heat flow paths and electrical connections. These designs include segmented or cascaded structures, modular configurations, and specialized geometries that maximize temperature gradients across the thermoelectric elements. Advanced manufacturing techniques allow for precise fabrication of complex structures that improve thermal management and overall system efficiency.

- Integration of waste heat recovery systems: Thermoelectric generators can be enhanced by effectively integrating them with waste heat recovery systems from industrial processes, vehicle exhaust, or other heat-generating applications. These integrated systems capture thermal energy that would otherwise be lost and convert it into useful electrical power. The design focuses on maximizing heat transfer to the thermoelectric elements while maintaining optimal temperature differentials for efficient energy conversion.

- Nanotechnology applications in thermoelectric generation: Nanotechnology offers significant opportunities for enhancing thermoelectric generators through quantum confinement effects and engineered thermal boundary resistance. Nanoscale structures such as quantum dots, nanowires, and superlattices can reduce thermal conductivity while maintaining good electrical conductivity, thereby increasing the figure of merit (ZT) of thermoelectric materials. These nanostructured materials can be fabricated using various deposition techniques and self-assembly processes to create highly efficient thermoelectric devices.

- Circuit and system-level optimization techniques: Enhancing thermoelectric generators through circuit and system-level optimizations involves developing advanced power conditioning electronics, implementing maximum power point tracking algorithms, and creating intelligent control systems. These techniques ensure that thermoelectric generators operate at their optimal efficiency points under varying temperature conditions. Additionally, hybrid systems that combine thermoelectric generation with other renewable energy sources can provide more reliable and efficient power generation solutions.

02 Structural design improvements for heat transfer

Innovative structural designs can enhance heat transfer and thermal management in thermoelectric generators. These designs include segmented leg structures, cascaded modules, and optimized heat exchanger configurations that maximize temperature gradients across the thermoelectric elements. By improving heat flow pathways and reducing thermal resistance, these structural enhancements lead to increased power generation efficiency and better utilization of available thermal energy.Expand Specific Solutions03 Integration of waste heat recovery systems

Thermoelectric generators can be enhanced by integrating them with waste heat recovery systems in industrial processes, automotive applications, and power plants. These integrated systems capture thermal energy that would otherwise be lost and convert it into useful electricity. The integration involves specialized heat exchangers, thermal interface materials, and control systems that optimize the temperature differential across the thermoelectric modules, thereby increasing overall system efficiency and energy recovery.Expand Specific Solutions04 Nanotechnology applications in thermoelectric devices

Nanotechnology offers significant opportunities for enhancing thermoelectric generators through quantum confinement effects, phonon scattering, and electron filtering. Nanoscale structures such as quantum dots, nanowires, and superlattices can be engineered to selectively scatter phonons while allowing electrons to flow, thereby reducing thermal conductivity without compromising electrical conductivity. These nanoscale modifications lead to higher ZT values and improved conversion efficiency in thermoelectric devices.Expand Specific Solutions05 Hybrid and flexible thermoelectric systems

Hybrid thermoelectric systems combine conventional thermoelectric materials with emerging technologies such as organic thermoelectrics, flexible substrates, and thin-film deposition techniques. These hybrid approaches enable the development of flexible, lightweight, and conformable thermoelectric generators that can be integrated into wearable devices, textiles, and curved surfaces. The flexibility and adaptability of these systems allow for more diverse applications and improved performance under varying operating conditions.Expand Specific Solutions

Leading TEG Manufacturers and Automation Integrators

The thermoelectric generator (TEG) market in industrial automation is currently in a growth phase, with increasing adoption across manufacturing sectors. The market size is projected to expand significantly as industries seek energy harvesting solutions to power IoT sensors and remote monitoring systems. Technologically, TEGs are advancing from basic applications toward more sophisticated implementations, with varying degrees of maturity across applications. Leading players include established industrial automation companies like Rosemount (Emerson) and Robert Bosch GmbH, alongside specialized TEG developers such as Gentherm and O-Flexx Technologies. Automotive manufacturers including BMW, Ford, and Hyundai-Kia are investing in TEG technology for waste heat recovery applications, while research institutions like ETRI and University of Michigan are advancing fundamental technologies to improve conversion efficiency and reduce costs.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered the integration of thermoelectric generators in industrial automation through their Energy Harvesting System (EHS) platform. Their solution captures waste heat from industrial processes and converts it into electrical energy to power autonomous wireless sensor networks across manufacturing facilities. Bosch's TEG modules are designed with specialized bismuth telluride semiconductor materials that deliver conversion efficiencies of 8-10% under optimal conditions. The company has developed a modular approach where TEG units can be scaled and configured to match specific industrial heat sources, from low-grade waste heat (80-150°C) to high-temperature applications (400-600°C). Their systems include proprietary power management circuits that optimize energy extraction across fluctuating temperature conditions, storing excess energy in supercapacitors or lithium-ion batteries to ensure continuous operation of critical sensors and control systems even when temperature differentials temporarily decrease.

Strengths: Comprehensive end-to-end solution from heat capture to power management; modular design allows customization for diverse industrial environments; extensive industrial automation expertise enables seamless integration with existing systems. Weaknesses: Higher implementation costs compared to traditional wired solutions; requires careful thermal engineering to maximize efficiency; performance dependent on consistent waste heat availability which may vary in some industrial processes.

Toshiba Corp.

Technical Solution: Toshiba has developed a sophisticated thermoelectric generation system specifically designed for industrial automation applications. Their approach utilizes advanced silicon-germanium alloys and skutterudite materials that demonstrate superior performance at high temperatures (300-600°C), making them ideal for heavy industrial environments. Toshiba's proprietary manufacturing process creates highly efficient p-n junctions that minimize electrical resistance while maximizing thermal conductivity differentials. Their industrial TEG modules achieve power densities of up to 1W/cm² under optimal conditions, significantly higher than conventional TEG solutions. Toshiba has implemented these systems in steel manufacturing facilities, power plants, and chemical processing plants, where they power distributed control systems, environmental monitoring equipment, and emergency backup systems. Their integrated solution includes specialized heat exchangers that maximize thermal transfer efficiency from industrial processes to the TEG modules, along with advanced power conditioning electronics that optimize output voltage for various industrial automation devices.

Strengths: Exceptional high-temperature performance suitable for harsh industrial environments; highly scalable design that can be implemented from small sensors to larger control systems; proven reliability with documented operational lifespans exceeding 10 years in continuous industrial use. Weaknesses: Higher initial cost compared to conventional power solutions; requires precise thermal engineering to achieve optimal performance; limited effectiveness in applications with small temperature differentials.

Key Patents and Innovations in Industrial TEG Applications

Industrial thermoelectric generator

PatentActiveUS20080078434A1

Innovation

- A thermoelectric generation assembly with thermally insulative materials surrounding thermoelectric elements, allowing them to be in contact with a process heat source while exposing the other side to the ambient environment, thereby generating electricity while maintaining thermal insulation, using a series connection of thermoelectric modules to enhance power generation.

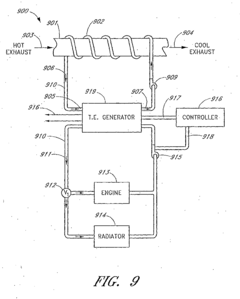

Thermoelectric power generator for variable thermal power source

PatentInactiveEP2282357A3

Innovation

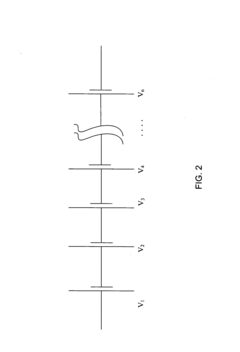

- A thermoelectric power generation system with multiple modules and a controller that dynamically adjusts thermal power delivery and waste heat management, allowing for optimal operation across changing conditions by directing thermal power to appropriate modules and locations, thereby maintaining efficient power production.

Energy Efficiency and Sustainability Impact Assessment

The implementation of Thermoelectric Generators (TEGs) in industrial automation systems presents significant opportunities for enhancing energy efficiency and sustainability across manufacturing sectors. TEGs capture waste heat from industrial processes and convert it directly into electrical energy, creating a circular energy flow within facilities that would otherwise be lost to the environment.

Assessment of energy recovery potential indicates that industrial processes typically waste 20-50% of input energy as heat. TEGs can recover between 5-15% of this waste heat, depending on temperature differentials and system design. This recovery translates to measurable reductions in primary energy consumption, with pilot implementations demonstrating energy savings of 8-12% in metal processing facilities and 5-10% in chemical manufacturing operations.

Carbon footprint analysis reveals that TEG integration can reduce industrial CO2 emissions by 3-7% through decreased reliance on grid electricity. For a medium-sized manufacturing facility, this represents approximately 500-1,500 metric tons of CO2 equivalent annually. The lifecycle assessment of TEG systems shows favorable sustainability metrics, with energy payback periods typically ranging from 1.5 to 3 years, depending on application specifics and operational parameters.

The environmental impact extends beyond carbon reduction. By capturing waste heat that would otherwise contribute to thermal pollution, TEGs help mitigate local environmental heating effects. Additionally, the solid-state nature of thermoelectric technology eliminates the need for working fluids or moving parts common in traditional heat recovery systems, reducing potential environmental contamination risks and maintenance-related waste.

Resource efficiency improvements manifest through reduced primary resource consumption for electricity generation. For industries with continuous high-temperature processes, TEG implementation can offset grid electricity requirements by 3-8%, representing significant resource conservation over facility operational lifespans. This reduction in external energy dependency also enhances operational resilience against energy price volatility and supply disruptions.

Long-term sustainability benefits include extended equipment life through better thermal management and reduced thermal stress on industrial components. The modular nature of TEG systems also supports circular economy principles, as units can be reconfigured, redeployed, or recycled as facility needs evolve. With proper material selection and design considerations, modern TEG systems achieve recyclability rates exceeding 85% by mass, further enhancing their sustainability credentials.

Assessment of energy recovery potential indicates that industrial processes typically waste 20-50% of input energy as heat. TEGs can recover between 5-15% of this waste heat, depending on temperature differentials and system design. This recovery translates to measurable reductions in primary energy consumption, with pilot implementations demonstrating energy savings of 8-12% in metal processing facilities and 5-10% in chemical manufacturing operations.

Carbon footprint analysis reveals that TEG integration can reduce industrial CO2 emissions by 3-7% through decreased reliance on grid electricity. For a medium-sized manufacturing facility, this represents approximately 500-1,500 metric tons of CO2 equivalent annually. The lifecycle assessment of TEG systems shows favorable sustainability metrics, with energy payback periods typically ranging from 1.5 to 3 years, depending on application specifics and operational parameters.

The environmental impact extends beyond carbon reduction. By capturing waste heat that would otherwise contribute to thermal pollution, TEGs help mitigate local environmental heating effects. Additionally, the solid-state nature of thermoelectric technology eliminates the need for working fluids or moving parts common in traditional heat recovery systems, reducing potential environmental contamination risks and maintenance-related waste.

Resource efficiency improvements manifest through reduced primary resource consumption for electricity generation. For industries with continuous high-temperature processes, TEG implementation can offset grid electricity requirements by 3-8%, representing significant resource conservation over facility operational lifespans. This reduction in external energy dependency also enhances operational resilience against energy price volatility and supply disruptions.

Long-term sustainability benefits include extended equipment life through better thermal management and reduced thermal stress on industrial components. The modular nature of TEG systems also supports circular economy principles, as units can be reconfigured, redeployed, or recycled as facility needs evolve. With proper material selection and design considerations, modern TEG systems achieve recyclability rates exceeding 85% by mass, further enhancing their sustainability credentials.

ROI Analysis and Implementation Cost Considerations

The implementation of thermoelectric generators (TEGs) in industrial automation requires careful financial analysis to justify investment. Initial capital expenditure for TEG systems typically ranges from $2,000 to $15,000 per kilowatt of generating capacity, depending on scale and application specifics. This includes costs for the TEG modules, heat exchangers, power conditioning equipment, and integration with existing systems. Installation expenses generally add 20-35% to hardware costs, with more complex retrofits commanding premium rates.

Operational expenses remain minimal compared to traditional power generation systems, as TEGs contain no moving parts and require limited maintenance. Annual maintenance costs typically range from 1-3% of initial capital investment, primarily for heat exchanger cleaning and occasional electrical system checks. The durability of modern TEG systems, with operational lifespans of 15-25 years, significantly enhances long-term ROI calculations.

Return on investment timelines vary considerably by application. In waste heat recovery applications where heat sources exceed 300°C, ROI periods of 2-4 years are achievable, particularly in continuous operation environments like steel mills or glass manufacturing. For lower temperature differentials (100-200°C), ROI extends to 4-7 years but remains viable for long-term industrial planning. Energy cost savings represent the primary financial benefit, with TEGs capable of generating electricity at $0.02-0.08 per kWh when utilizing waste heat that would otherwise be discarded.

Secondary financial benefits include reduced downtime for remote monitoring systems, decreased maintenance costs for wireless sensor networks, and potential regulatory compliance advantages. Carbon reduction credits in applicable jurisdictions can further improve financial performance, potentially reducing ROI periods by 10-15% in regions with robust carbon pricing mechanisms.

Implementation cost optimization strategies include phased deployment approaches, beginning with high-temperature applications that deliver faster returns before expanding to moderate temperature scenarios. Modular TEG systems allow for scalable implementation, reducing initial capital requirements while providing proof-of-concept validation. Government incentives for energy efficiency and renewable energy integration can significantly offset implementation costs, with programs in North America, Europe, and Asia offering grants or tax incentives covering 20-40% of qualifying expenses.

Risk mitigation considerations include thorough thermal profiling before implementation, pilot testing in non-critical applications, and performance guarantees from technology providers. These measures help ensure projected ROI figures materialize in real-world applications while minimizing disruption to existing industrial processes.

Operational expenses remain minimal compared to traditional power generation systems, as TEGs contain no moving parts and require limited maintenance. Annual maintenance costs typically range from 1-3% of initial capital investment, primarily for heat exchanger cleaning and occasional electrical system checks. The durability of modern TEG systems, with operational lifespans of 15-25 years, significantly enhances long-term ROI calculations.

Return on investment timelines vary considerably by application. In waste heat recovery applications where heat sources exceed 300°C, ROI periods of 2-4 years are achievable, particularly in continuous operation environments like steel mills or glass manufacturing. For lower temperature differentials (100-200°C), ROI extends to 4-7 years but remains viable for long-term industrial planning. Energy cost savings represent the primary financial benefit, with TEGs capable of generating electricity at $0.02-0.08 per kWh when utilizing waste heat that would otherwise be discarded.

Secondary financial benefits include reduced downtime for remote monitoring systems, decreased maintenance costs for wireless sensor networks, and potential regulatory compliance advantages. Carbon reduction credits in applicable jurisdictions can further improve financial performance, potentially reducing ROI periods by 10-15% in regions with robust carbon pricing mechanisms.

Implementation cost optimization strategies include phased deployment approaches, beginning with high-temperature applications that deliver faster returns before expanding to moderate temperature scenarios. Modular TEG systems allow for scalable implementation, reducing initial capital requirements while providing proof-of-concept validation. Government incentives for energy efficiency and renewable energy integration can significantly offset implementation costs, with programs in North America, Europe, and Asia offering grants or tax incentives covering 20-40% of qualifying expenses.

Risk mitigation considerations include thorough thermal profiling before implementation, pilot testing in non-critical applications, and performance guarantees from technology providers. These measures help ensure projected ROI figures materialize in real-world applications while minimizing disruption to existing industrial processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!