Thermoelectric Generators In Aerospace Satellite Systems

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace TEG Technology Evolution and Objectives

Thermoelectric Generators (TEGs) have evolved significantly since their inception in aerospace applications during the early space race. Initially developed as power sources for remote satellites in the 1960s, these solid-state devices convert thermal energy directly into electrical energy through the Seebeck effect, offering unique advantages for space missions where reliability and longevity are paramount.

The evolution of TEG technology in aerospace applications has been marked by several key milestones. Early radioisotope thermoelectric generators (RTGs) used in NASA's Pioneer and Voyager missions demonstrated remarkable longevity, continuing to function decades after launch. These early systems utilized silicon-germanium thermoelectric materials with conversion efficiencies of approximately 6-7%.

By the 1990s, advancements in material science led to the development of improved thermoelectric materials with higher figure of merit (ZT) values, pushing conversion efficiencies toward 8-10%. The Mars Curiosity rover, launched in 2011, represented a significant advancement with its Multi-Mission Radioisotope Thermoelectric Generator (MMRTG) providing approximately 110 watts of electrical power at the beginning of the mission.

Current technological objectives focus on enhancing the efficiency and specific power of TEGs for aerospace applications. Research efforts are directed toward developing advanced thermoelectric materials with higher ZT values, including skutterudites, half-Heusler alloys, and quantum-engineered materials that can potentially achieve conversion efficiencies exceeding 15%.

Another critical objective is the miniaturization of TEG systems for small satellite applications, where power generation capabilities must be balanced against strict mass and volume constraints. This has led to exploration of thin-film thermoelectric materials and advanced manufacturing techniques such as 3D printing of thermoelectric components.

The integration of TEGs with other power systems represents another important development trajectory. Hybrid systems combining TEGs with photovoltaic arrays aim to provide more reliable power generation across varying orbital conditions and eclipse periods, addressing the intermittent nature of solar power in certain orbital configurations.

Looking forward, the aerospace industry is pursuing TEGs capable of operating in extreme environments, including high-radiation zones around Jupiter and near-Sun missions where temperature differentials can be maximized. Additionally, there is growing interest in developing TEGs that can harvest waste heat from satellite subsystems, potentially improving overall system efficiency while reducing thermal management challenges.

The evolution of TEG technology in aerospace applications has been marked by several key milestones. Early radioisotope thermoelectric generators (RTGs) used in NASA's Pioneer and Voyager missions demonstrated remarkable longevity, continuing to function decades after launch. These early systems utilized silicon-germanium thermoelectric materials with conversion efficiencies of approximately 6-7%.

By the 1990s, advancements in material science led to the development of improved thermoelectric materials with higher figure of merit (ZT) values, pushing conversion efficiencies toward 8-10%. The Mars Curiosity rover, launched in 2011, represented a significant advancement with its Multi-Mission Radioisotope Thermoelectric Generator (MMRTG) providing approximately 110 watts of electrical power at the beginning of the mission.

Current technological objectives focus on enhancing the efficiency and specific power of TEGs for aerospace applications. Research efforts are directed toward developing advanced thermoelectric materials with higher ZT values, including skutterudites, half-Heusler alloys, and quantum-engineered materials that can potentially achieve conversion efficiencies exceeding 15%.

Another critical objective is the miniaturization of TEG systems for small satellite applications, where power generation capabilities must be balanced against strict mass and volume constraints. This has led to exploration of thin-film thermoelectric materials and advanced manufacturing techniques such as 3D printing of thermoelectric components.

The integration of TEGs with other power systems represents another important development trajectory. Hybrid systems combining TEGs with photovoltaic arrays aim to provide more reliable power generation across varying orbital conditions and eclipse periods, addressing the intermittent nature of solar power in certain orbital configurations.

Looking forward, the aerospace industry is pursuing TEGs capable of operating in extreme environments, including high-radiation zones around Jupiter and near-Sun missions where temperature differentials can be maximized. Additionally, there is growing interest in developing TEGs that can harvest waste heat from satellite subsystems, potentially improving overall system efficiency while reducing thermal management challenges.

Market Analysis for Space-Based Power Generation

The space-based power generation market is experiencing significant growth, driven by increasing satellite deployments and the expanding space economy. Current market valuations indicate the global space power systems sector reached approximately $2.8 billion in 2022, with projections suggesting growth to $5.7 billion by 2030, representing a compound annual growth rate of 9.3%. Thermoelectric generators (TEGs) constitute a critical segment within this market, valued at roughly $320 million specifically for aerospace applications.

Demand analysis reveals three primary market segments: commercial satellite operators (58% market share), government space agencies (32%), and military/defense applications (10%). Commercial operators are increasingly deploying mega-constellations of small satellites, creating substantial demand for reliable power generation solutions that can function throughout extended missions without maintenance.

The market landscape is characterized by high barriers to entry due to stringent qualification requirements and extensive testing protocols necessary for space-rated components. This has resulted in a concentrated supplier ecosystem dominated by established aerospace contractors and specialized power system manufacturers. However, emerging players from adjacent industries are beginning to enter the market with innovative thermoelectric materials and designs.

Regional market distribution shows North America leading with 45% market share, primarily due to NASA and commercial space activities. Europe follows at 28%, with significant contributions from ESA programs. Asia-Pacific represents the fastest-growing region at 18% market share with a 12.4% growth rate, driven by ambitious space programs in China, Japan, and India.

Customer requirements analysis indicates increasing demand for power systems with higher specific power (W/kg), improved conversion efficiency, and enhanced radiation resistance. Mission lifetimes are extending from typical 5-7 year operations to 10-15 years, necessitating more durable power generation solutions. This trend directly benefits thermoelectric generators, which offer exceptional reliability due to their lack of moving parts.

Market forecasts suggest radioisotope thermoelectric generators (RTGs) will maintain premium market positioning for deep space missions, while solar-thermoelectric hybrid systems are gaining traction for Earth-orbiting satellites. The miniaturization trend in satellite design is creating new opportunities for compact, efficient TEG solutions that can be integrated into smaller form factors.

Price sensitivity varies significantly by application segment, with commercial operators prioritizing cost-effectiveness, while government and defense customers emphasize performance and reliability over price considerations. This market dynamic creates distinct entry points for different TEG technologies based on their performance-to-cost ratios.

Demand analysis reveals three primary market segments: commercial satellite operators (58% market share), government space agencies (32%), and military/defense applications (10%). Commercial operators are increasingly deploying mega-constellations of small satellites, creating substantial demand for reliable power generation solutions that can function throughout extended missions without maintenance.

The market landscape is characterized by high barriers to entry due to stringent qualification requirements and extensive testing protocols necessary for space-rated components. This has resulted in a concentrated supplier ecosystem dominated by established aerospace contractors and specialized power system manufacturers. However, emerging players from adjacent industries are beginning to enter the market with innovative thermoelectric materials and designs.

Regional market distribution shows North America leading with 45% market share, primarily due to NASA and commercial space activities. Europe follows at 28%, with significant contributions from ESA programs. Asia-Pacific represents the fastest-growing region at 18% market share with a 12.4% growth rate, driven by ambitious space programs in China, Japan, and India.

Customer requirements analysis indicates increasing demand for power systems with higher specific power (W/kg), improved conversion efficiency, and enhanced radiation resistance. Mission lifetimes are extending from typical 5-7 year operations to 10-15 years, necessitating more durable power generation solutions. This trend directly benefits thermoelectric generators, which offer exceptional reliability due to their lack of moving parts.

Market forecasts suggest radioisotope thermoelectric generators (RTGs) will maintain premium market positioning for deep space missions, while solar-thermoelectric hybrid systems are gaining traction for Earth-orbiting satellites. The miniaturization trend in satellite design is creating new opportunities for compact, efficient TEG solutions that can be integrated into smaller form factors.

Price sensitivity varies significantly by application segment, with commercial operators prioritizing cost-effectiveness, while government and defense customers emphasize performance and reliability over price considerations. This market dynamic creates distinct entry points for different TEG technologies based on their performance-to-cost ratios.

Current TEG Implementation Challenges in Satellites

Despite the promising potential of Thermoelectric Generators (TEGs) in satellite systems, several significant implementation challenges currently limit their widespread adoption and optimal performance in space applications. The harsh space environment presents extreme temperature fluctuations that can stress TEG materials beyond their design parameters, potentially leading to accelerated degradation and reduced operational lifespan.

Material limitations constitute a primary obstacle, as current thermoelectric materials exhibit relatively low conversion efficiencies, typically ranging from 5-8% in space applications. This inefficiency necessitates larger generator sizes to produce meaningful power outputs, creating a problematic trade-off against the premium placed on mass and volume in spacecraft design. Additionally, the thermal cycling experienced during orbit transitions between sunlight and shadow can induce mechanical stress in TEG components, potentially causing microfractures and performance deterioration over time.

Integration challenges with satellite thermal management systems present another significant hurdle. TEGs require substantial temperature differentials to generate electricity efficiently, yet satellites are designed with sophisticated thermal control systems that actively work to minimize such temperature gradients. This fundamental conflict creates design complexities that engineers must carefully balance to optimize both thermal management and power generation capabilities.

Reliability concerns also persist in the space environment, where radiation exposure can alter semiconductor properties of thermoelectric materials, potentially degrading performance over extended missions. The vacuum conditions of space eliminate convective heat transfer, limiting thermal management options and potentially creating hotspots that accelerate material degradation in TEG modules.

Cost factors remain prohibitive for many mission profiles, as high-performance thermoelectric materials often incorporate rare or expensive elements like tellurium, bismuth, and various rare earth metals. The specialized manufacturing processes required for space-grade TEGs further inflate costs, making them economically viable primarily for specific long-duration missions where alternative power sources are impractical.

Scalability presents additional complications, as power requirements for modern satellites continue to increase while available surface area for TEG deployment remains constrained. Current TEG technologies struggle to achieve the power density necessary to serve as primary power sources for anything beyond small satellites or specific subsystems.

Testing and qualification procedures for space-grade TEGs are exceptionally rigorous, requiring extensive validation under simulated space conditions. The long-term performance data for newer, more efficient thermoelectric materials remains limited, creating uncertainty for mission planners considering TEG implementation for extended satellite operations.

Material limitations constitute a primary obstacle, as current thermoelectric materials exhibit relatively low conversion efficiencies, typically ranging from 5-8% in space applications. This inefficiency necessitates larger generator sizes to produce meaningful power outputs, creating a problematic trade-off against the premium placed on mass and volume in spacecraft design. Additionally, the thermal cycling experienced during orbit transitions between sunlight and shadow can induce mechanical stress in TEG components, potentially causing microfractures and performance deterioration over time.

Integration challenges with satellite thermal management systems present another significant hurdle. TEGs require substantial temperature differentials to generate electricity efficiently, yet satellites are designed with sophisticated thermal control systems that actively work to minimize such temperature gradients. This fundamental conflict creates design complexities that engineers must carefully balance to optimize both thermal management and power generation capabilities.

Reliability concerns also persist in the space environment, where radiation exposure can alter semiconductor properties of thermoelectric materials, potentially degrading performance over extended missions. The vacuum conditions of space eliminate convective heat transfer, limiting thermal management options and potentially creating hotspots that accelerate material degradation in TEG modules.

Cost factors remain prohibitive for many mission profiles, as high-performance thermoelectric materials often incorporate rare or expensive elements like tellurium, bismuth, and various rare earth metals. The specialized manufacturing processes required for space-grade TEGs further inflate costs, making them economically viable primarily for specific long-duration missions where alternative power sources are impractical.

Scalability presents additional complications, as power requirements for modern satellites continue to increase while available surface area for TEG deployment remains constrained. Current TEG technologies struggle to achieve the power density necessary to serve as primary power sources for anything beyond small satellites or specific subsystems.

Testing and qualification procedures for space-grade TEGs are exceptionally rigorous, requiring extensive validation under simulated space conditions. The long-term performance data for newer, more efficient thermoelectric materials remains limited, creating uncertainty for mission planners considering TEG implementation for extended satellite operations.

State-of-the-Art Satellite TEG Solutions

01 Thermoelectric material compositions for improved efficiency

Advanced material compositions are being developed to enhance the efficiency of thermoelectric generators. These materials typically feature high electrical conductivity and low thermal conductivity to maximize the Seebeck effect. Innovations include nanostructured materials, semiconductor alloys, and composite structures that can operate effectively across various temperature ranges, significantly improving the conversion of heat to electricity compared to conventional materials.- Materials and structures for thermoelectric generators: Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and novel junction configurations that improve the Seebeck effect. Advanced material compositions and structural arrangements help maximize the temperature differential across the device, leading to more efficient conversion of heat into electrical energy.

- Waste heat recovery applications: Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Implementation strategies include integration with exhaust systems, industrial processes, and power generation facilities, providing supplementary power while reducing overall energy consumption and environmental impact.

- Portable and wearable thermoelectric power generation: Miniaturized thermoelectric generators are being developed for portable and wearable applications, utilizing body heat or ambient temperature differentials. These compact devices can power small electronics, medical devices, and IoT sensors without requiring battery replacement. Design considerations include flexibility, comfort, durability, and maximizing power output from relatively small temperature gradients available in wearable contexts.

- Hybrid energy systems with thermoelectric components: Thermoelectric generators are increasingly integrated into hybrid energy systems that combine multiple generation technologies. These systems may pair thermoelectric elements with solar panels, fuel cells, or conventional generators to create more reliable and efficient power solutions. The complementary nature of these technologies allows for continuous power generation under varying environmental conditions and energy demands.

- Modeling and optimization techniques: Advanced computational methods and simulation techniques are employed to model and optimize thermoelectric generator performance. These approaches include thermal modeling, electrical characterization, and system-level optimization to maximize power output and efficiency. Simulation tools help predict performance under various operating conditions, enabling designers to refine device parameters before physical prototyping and implementation.

02 Structural designs for thermoelectric generators

Novel structural designs are being implemented to optimize the performance of thermoelectric generators. These designs focus on improving heat transfer, reducing thermal resistance, and enhancing overall system efficiency. Approaches include modular configurations, flexible architectures, and integrated cooling systems that allow for better adaptation to different heat sources and operating conditions.Expand Specific Solutions03 Waste heat recovery applications

Thermoelectric generators are increasingly being utilized for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into useful electrical power. Implementation areas include exhaust systems, industrial processes, and power plants, contributing to improved energy efficiency and reduced environmental impact.Expand Specific Solutions04 Miniaturized and wearable thermoelectric generators

Compact and flexible thermoelectric generators are being developed for portable and wearable applications. These devices can harvest body heat or ambient thermal energy to power small electronic devices or sensors. Innovations in this area include thin-film technologies, flexible substrates, and integration with textiles or other wearable platforms, enabling self-powered systems for healthcare monitoring, IoT devices, and consumer electronics.Expand Specific Solutions05 System integration and power management

Advanced integration techniques and power management systems are being developed to optimize the performance of thermoelectric generators in real-world applications. These approaches include DC-DC converters, maximum power point tracking algorithms, and hybrid energy systems that combine thermoelectric generation with other power sources. Such integrations enhance overall system efficiency, reliability, and adaptability to varying thermal conditions and load requirements.Expand Specific Solutions

Leading Aerospace TEG Manufacturers and Competitors

The thermoelectric generator market in aerospace satellite systems is currently in a growth phase, with increasing adoption driven by reliability requirements for long-duration space missions. Market size is expanding as satellite deployments accelerate globally, particularly for communications and Earth observation applications. Technologically, established aerospace entities like Boeing, China Academy of Space Technology, and The Aerospace Corporation lead development with mature solutions, while research institutions including California Institute of Technology and Harbin Institute of Technology advance fundamental innovations. Companies like Gentherm and Atomos Nuclear & Space are commercializing specialized thermoelectric technologies, creating a competitive landscape balanced between traditional aerospace giants and emerging technology providers focused on improving efficiency, reducing weight, and extending operational lifespans of satellite power systems.

The Boeing Co.

Technical Solution: Boeing has pioneered integrated thermoelectric power systems for satellite applications that combine radioisotope heat sources with advanced thermoelectric materials. Their proprietary design utilizes segmented thermoelectric legs with carefully engineered thermal interfaces to minimize parasitic heat losses. Boeing's TEG systems feature redundant thermal paths and power conditioning electronics specifically designed to handle the unique radiation environment of space. The company has developed specialized manufacturing techniques for thermoelectric modules that can withstand launch vibrations and thermal cycling in orbit. Their systems incorporate passive thermal control mechanisms and have demonstrated operational lifespans exceeding 15 years in space environments, with power degradation rates below 0.8% per year. Boeing's latest generation TEGs employ advanced skutterudite and telluride compounds with precisely controlled doping profiles to optimize the Seebeck coefficient across varying operational temperatures.

Strengths: Exceptional system integration capabilities leveraging decades of spacecraft design experience; proven long-term reliability in actual space missions; advanced thermal management expertise. Weaknesses: Higher system complexity increases potential failure points; greater mass compared to newer specialized TEG designs; relatively conservative technology adoption approach limiting efficiency improvements.

China Academy of Space Technology

Technical Solution: China Academy of Space Technology (CAST) has developed advanced multi-stage thermoelectric generators for deep space missions, utilizing radioisotope heat sources with high-efficiency semiconductor materials. Their system employs a cascaded design with different semiconductor materials optimized for specific temperature ranges, achieving conversion efficiencies up to 8-10% in space environments. CAST's TEG systems incorporate radiation-hardened components and specialized thermal management solutions including heat pipes and multi-layer insulation to maintain optimal temperature gradients in the extreme thermal cycling conditions of space. Their latest generation incorporates skutterudite and telluride-based materials with nano-structuring techniques to enhance the ZT figure of merit, crucial for power generation efficiency in long-duration satellite missions.

Strengths: Exceptional radiation resistance and reliability for long-duration missions; advanced thermal cycling durability; high power-to-weight ratio optimized for launch constraints. Weaknesses: Higher initial development costs compared to conventional power systems; limited power scaling capabilities for higher-demand applications; dependence on specialized semiconductor material supply chains.

Critical Patents in Space-Grade Thermoelectric Materials

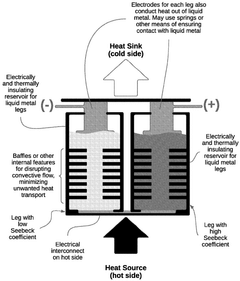

System and methods for high temperature liquid-metal thermoelectric power conversion

PatentWO2025095999A1

Innovation

- A thermoelectric generator system using liquid metal TEG junctions with legs made from metals, alloys, or composites that can operate at high temperatures, allowing for partial or full melting during operation, thereby achieving higher conversion efficiencies and tolerance to ionizing radiation.

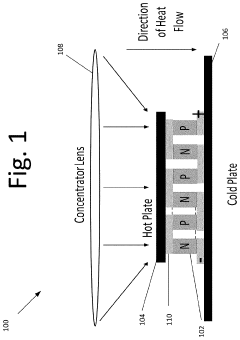

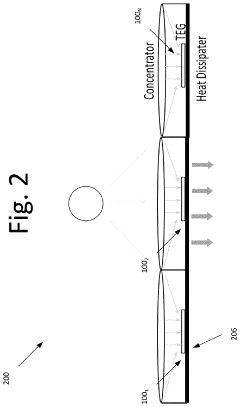

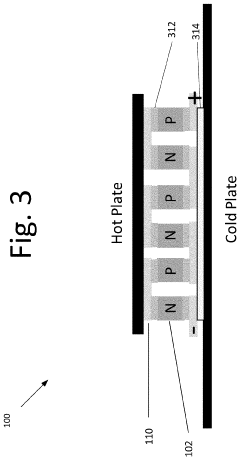

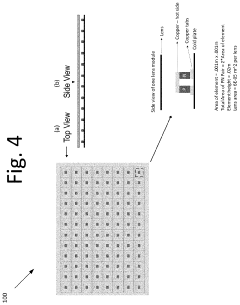

Thermoelectric array

PatentPendingUS20210336116A1

Innovation

- A thermoelectric array composed of semiconductor thermoelectric couples connected in series and parallel, utilizing a concentrator lens to focus solar heat onto a hot plate, with a cold plate for efficient heat dissipation, and materials like tin selenide for efficient thermal-to-electrical energy conversion, reducing costs and improving temperature tolerance.

Radiation Hardening for Space TEG Applications

Radiation hardening represents a critical consideration for Thermoelectric Generators (TEGs) deployed in aerospace satellite systems. The harsh radiation environment of space, characterized by high-energy particles and electromagnetic radiation, poses significant challenges to the operational integrity and longevity of TEG components. Satellite systems encounter various radiation sources including galactic cosmic rays, solar particle events, and trapped radiation in Earth's magnetosphere, all of which can induce both immediate and cumulative damage to semiconductor materials used in TEGs.

The primary radiation effects on TEG materials include displacement damage, where atomic lattice structures are disrupted, and ionization effects, which can alter electrical properties and create unwanted charge carriers. These phenomena directly impact the Seebeck coefficient, electrical conductivity, and thermal conductivity of thermoelectric materials, ultimately degrading conversion efficiency and power output over time.

Current radiation hardening approaches for space TEGs follow multiple strategic pathways. Material-level hardening involves developing radiation-resistant semiconductor compounds, with bismuth telluride alloys doped with specific elements showing promising radiation tolerance. Structural hardening incorporates specialized packaging techniques using radiation-absorbing materials like tungsten or tantalum to shield sensitive components from high-energy particles.

Circuit-level mitigation strategies implement redundant thermoelectric elements and fault-tolerant architectures that can maintain functionality even when individual components degrade. Advanced system designs incorporate radiation monitoring sensors that provide real-time data on radiation exposure, enabling adaptive operational adjustments to extend TEG lifespan.

Testing protocols for radiation-hardened TEGs have evolved significantly, with accelerated radiation testing using particle accelerators and cobalt-60 gamma sources becoming standard practice. These tests simulate years of space radiation exposure in compressed timeframes, allowing engineers to validate hardening techniques before deployment.

Recent innovations in radiation hardening include self-healing thermoelectric materials that can partially recover from radiation damage through thermal annealing processes. Additionally, nanoscale engineering of thermoelectric materials has demonstrated enhanced radiation resistance by incorporating engineered defect structures that trap and neutralize radiation-induced defects before they can propagate.

The radiation hardening qualification standards for space TEGs continue to evolve, with agencies like NASA, ESA, and JAXA establishing increasingly stringent requirements based on mission profiles and expected radiation environments. These standards typically specify minimum performance retention after exposure to defined radiation doses, ensuring TEGs can reliably power critical satellite systems throughout their operational lifetime.

The primary radiation effects on TEG materials include displacement damage, where atomic lattice structures are disrupted, and ionization effects, which can alter electrical properties and create unwanted charge carriers. These phenomena directly impact the Seebeck coefficient, electrical conductivity, and thermal conductivity of thermoelectric materials, ultimately degrading conversion efficiency and power output over time.

Current radiation hardening approaches for space TEGs follow multiple strategic pathways. Material-level hardening involves developing radiation-resistant semiconductor compounds, with bismuth telluride alloys doped with specific elements showing promising radiation tolerance. Structural hardening incorporates specialized packaging techniques using radiation-absorbing materials like tungsten or tantalum to shield sensitive components from high-energy particles.

Circuit-level mitigation strategies implement redundant thermoelectric elements and fault-tolerant architectures that can maintain functionality even when individual components degrade. Advanced system designs incorporate radiation monitoring sensors that provide real-time data on radiation exposure, enabling adaptive operational adjustments to extend TEG lifespan.

Testing protocols for radiation-hardened TEGs have evolved significantly, with accelerated radiation testing using particle accelerators and cobalt-60 gamma sources becoming standard practice. These tests simulate years of space radiation exposure in compressed timeframes, allowing engineers to validate hardening techniques before deployment.

Recent innovations in radiation hardening include self-healing thermoelectric materials that can partially recover from radiation damage through thermal annealing processes. Additionally, nanoscale engineering of thermoelectric materials has demonstrated enhanced radiation resistance by incorporating engineered defect structures that trap and neutralize radiation-induced defects before they can propagate.

The radiation hardening qualification standards for space TEGs continue to evolve, with agencies like NASA, ESA, and JAXA establishing increasingly stringent requirements based on mission profiles and expected radiation environments. These standards typically specify minimum performance retention after exposure to defined radiation doses, ensuring TEGs can reliably power critical satellite systems throughout their operational lifetime.

Reliability and Lifespan Assessment Methodologies

Reliability assessment of Thermoelectric Generators (TEGs) in aerospace satellite systems requires specialized methodologies due to the extreme operating conditions and mission-critical nature of these components. Traditional reliability testing frameworks have been adapted to address the unique challenges posed by the space environment, including radiation exposure, thermal cycling, and vacuum conditions.

The primary assessment methodologies currently employed include accelerated life testing (ALT), which subjects TEGs to stress conditions exceeding normal operational parameters to induce failures more rapidly. This approach allows engineers to extrapolate long-term performance characteristics within reasonable timeframes. Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) have been particularly valuable for identifying design weaknesses and manufacturing defects before deployment.

Physics of Failure (PoF) modeling has emerged as a critical methodology for TEG reliability assessment. This approach analyzes the fundamental physical mechanisms that lead to degradation and failure, such as thermal fatigue, diffusion, and mechanical stress. By understanding these mechanisms at a molecular level, engineers can develop more accurate lifetime predictions and design more robust systems.

Statistical reliability models, including Weibull analysis and Monte Carlo simulations, provide quantitative frameworks for predicting TEG lifespan. These models incorporate data from ground testing, previous missions, and theoretical calculations to generate probability distributions of failure rates over time. The aerospace industry typically requires reliability levels exceeding 0.999 for critical power systems, necessitating sophisticated statistical approaches.

Non-destructive evaluation techniques have been developed specifically for TEG assessment, including infrared thermography, acoustic microscopy, and electrical impedance spectroscopy. These methods allow for continuous monitoring of TEG health without compromising system integrity, enabling early detection of degradation patterns.

Digital twin technology represents the cutting edge of TEG reliability assessment. By creating virtual replicas of physical TEG systems that incorporate real-time operational data, engineers can simulate aging processes and predict maintenance needs with unprecedented accuracy. NASA and ESA have pioneered this approach for their long-duration deep space missions where traditional maintenance is impossible.

Standardization efforts by organizations such as ASTM International and the European Cooperation for Space Standardization (ECSS) have established unified testing protocols specifically for space-grade thermoelectric materials. These standards ensure consistency in reliability assessments across different manufacturers and mission profiles, facilitating more accurate comparisons and risk evaluations for mission planners.

The primary assessment methodologies currently employed include accelerated life testing (ALT), which subjects TEGs to stress conditions exceeding normal operational parameters to induce failures more rapidly. This approach allows engineers to extrapolate long-term performance characteristics within reasonable timeframes. Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) have been particularly valuable for identifying design weaknesses and manufacturing defects before deployment.

Physics of Failure (PoF) modeling has emerged as a critical methodology for TEG reliability assessment. This approach analyzes the fundamental physical mechanisms that lead to degradation and failure, such as thermal fatigue, diffusion, and mechanical stress. By understanding these mechanisms at a molecular level, engineers can develop more accurate lifetime predictions and design more robust systems.

Statistical reliability models, including Weibull analysis and Monte Carlo simulations, provide quantitative frameworks for predicting TEG lifespan. These models incorporate data from ground testing, previous missions, and theoretical calculations to generate probability distributions of failure rates over time. The aerospace industry typically requires reliability levels exceeding 0.999 for critical power systems, necessitating sophisticated statistical approaches.

Non-destructive evaluation techniques have been developed specifically for TEG assessment, including infrared thermography, acoustic microscopy, and electrical impedance spectroscopy. These methods allow for continuous monitoring of TEG health without compromising system integrity, enabling early detection of degradation patterns.

Digital twin technology represents the cutting edge of TEG reliability assessment. By creating virtual replicas of physical TEG systems that incorporate real-time operational data, engineers can simulate aging processes and predict maintenance needs with unprecedented accuracy. NASA and ESA have pioneered this approach for their long-duration deep space missions where traditional maintenance is impossible.

Standardization efforts by organizations such as ASTM International and the European Cooperation for Space Standardization (ECSS) have established unified testing protocols specifically for space-grade thermoelectric materials. These standards ensure consistency in reliability assessments across different manufacturers and mission profiles, facilitating more accurate comparisons and risk evaluations for mission planners.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!