Thermoelectric Generators For Next-Generation Consumer Electronics

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Technology Background and Objectives

Thermoelectric generators (TEGs) represent a promising technology that converts waste heat directly into electrical energy through the Seebeck effect. The concept dates back to Thomas Johann Seebeck's discovery in 1821, but only in recent decades has it gained significant attention for consumer electronics applications. TEG technology has evolved from bulky, inefficient systems to increasingly miniaturized and performance-optimized solutions suitable for integration into everyday devices.

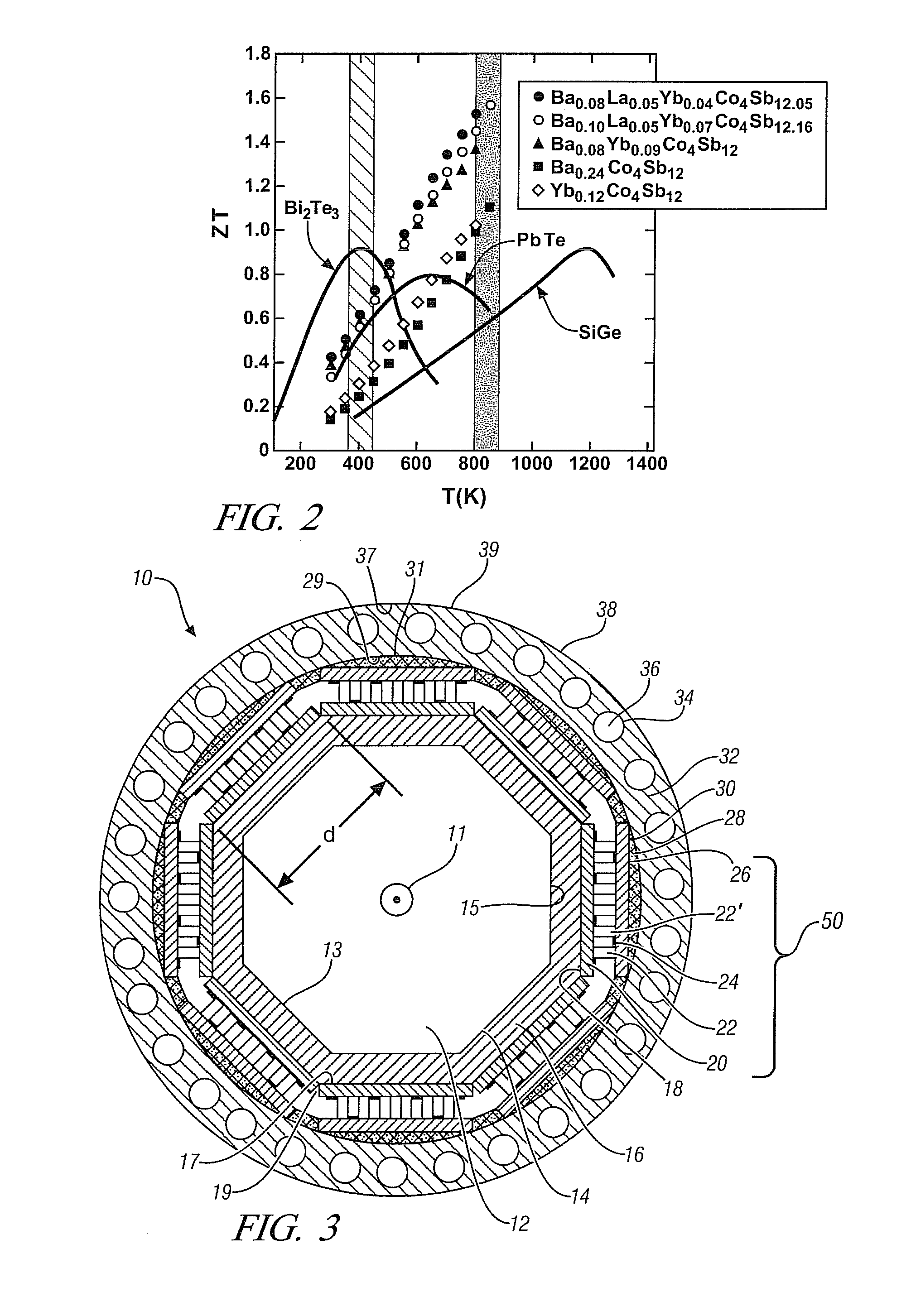

The evolution of TEG technology has been driven by advancements in material science, particularly the development of semiconductor materials with improved figure of merit (ZT). Traditional bismuth telluride (Bi2Te3) based TEGs have been supplemented by research into skutterudites, half-Heusler alloys, and more recently, nano-structured materials that significantly reduce thermal conductivity while maintaining electrical conductivity.

Current technological trends point toward flexible TEGs, ultra-thin designs, and improved power density to meet the demands of next-generation consumer electronics. The miniaturization trend aligns with the broader evolution of consumer electronics toward wearable technology, Internet of Things (IoT) devices, and self-powered sensors, creating new opportunities for energy harvesting solutions.

The primary objective of TEG technology development for consumer electronics is to achieve sufficient power generation efficiency (currently typically below 10%) to make these generators viable alternatives or supplements to traditional batteries. Secondary objectives include cost reduction, as current high-performance thermoelectric materials often contain rare or expensive elements, and improving mechanical flexibility to accommodate diverse form factors in modern devices.

Another critical goal is to optimize TEG performance at low temperature differentials (typically <10°C), which represents the realistic operating conditions in most consumer electronic environments. This contrasts with industrial applications where higher temperature gradients are available, making this a unique engineering challenge for consumer applications.

Long-term technological objectives include developing TEGs capable of powering smartphones and tablets for extended periods using only body heat or ambient temperature differences, creating truly "battery-free" wearable devices, and establishing standardized integration protocols for TEG modules in consumer electronics manufacturing.

The environmental sustainability aspect also forms a key objective, as TEG technology offers the potential to reduce electronic waste by extending device operation time between charges and potentially eliminating certain battery requirements altogether, aligning with global initiatives for greener technology solutions.

The evolution of TEG technology has been driven by advancements in material science, particularly the development of semiconductor materials with improved figure of merit (ZT). Traditional bismuth telluride (Bi2Te3) based TEGs have been supplemented by research into skutterudites, half-Heusler alloys, and more recently, nano-structured materials that significantly reduce thermal conductivity while maintaining electrical conductivity.

Current technological trends point toward flexible TEGs, ultra-thin designs, and improved power density to meet the demands of next-generation consumer electronics. The miniaturization trend aligns with the broader evolution of consumer electronics toward wearable technology, Internet of Things (IoT) devices, and self-powered sensors, creating new opportunities for energy harvesting solutions.

The primary objective of TEG technology development for consumer electronics is to achieve sufficient power generation efficiency (currently typically below 10%) to make these generators viable alternatives or supplements to traditional batteries. Secondary objectives include cost reduction, as current high-performance thermoelectric materials often contain rare or expensive elements, and improving mechanical flexibility to accommodate diverse form factors in modern devices.

Another critical goal is to optimize TEG performance at low temperature differentials (typically <10°C), which represents the realistic operating conditions in most consumer electronic environments. This contrasts with industrial applications where higher temperature gradients are available, making this a unique engineering challenge for consumer applications.

Long-term technological objectives include developing TEGs capable of powering smartphones and tablets for extended periods using only body heat or ambient temperature differences, creating truly "battery-free" wearable devices, and establishing standardized integration protocols for TEG modules in consumer electronics manufacturing.

The environmental sustainability aspect also forms a key objective, as TEG technology offers the potential to reduce electronic waste by extending device operation time between charges and potentially eliminating certain battery requirements altogether, aligning with global initiatives for greener technology solutions.

Market Demand Analysis for TEG in Consumer Electronics

The global market for Thermoelectric Generators (TEGs) in consumer electronics is experiencing significant growth, driven by increasing demand for portable, efficient, and sustainable power solutions. Current market research indicates that the TEG market for consumer electronics is projected to grow at a compound annual growth rate of 8.3% between 2023 and 2030, reaching approximately 750 million USD by the end of the forecast period.

Consumer electronics manufacturers are increasingly seeking alternative power sources due to several converging factors. The proliferation of Internet of Things (IoT) devices has created demand for self-powered sensors and systems that can operate without frequent battery replacement. Wearable technology represents another substantial market segment, with fitness trackers, smartwatches, and medical monitoring devices requiring reliable power sources that can harvest energy from body heat.

Market surveys reveal that consumers are increasingly concerned about environmental sustainability, with 67% of respondents expressing preference for electronics with green energy capabilities. This shift in consumer preference is pushing manufacturers to incorporate energy harvesting technologies like TEGs into their product designs. The reduction of e-waste through extended battery life or battery-free operation represents a significant market driver.

Regional analysis shows that North America and Asia-Pacific currently dominate the TEG consumer electronics market. Japan and South Korea lead in TEG technology integration, while China is rapidly expanding manufacturing capacity. European markets show strong growth potential due to stringent environmental regulations and consumer awareness.

Industry segmentation indicates that wearable devices constitute the largest application segment for TEGs, followed by smartphones and portable charging solutions. The medical wearables sub-segment is experiencing the fastest growth rate at 12.1% annually, as remote patient monitoring becomes increasingly important in healthcare delivery systems.

Key market challenges include cost barriers, with TEGs currently adding a premium of 15-30% to device manufacturing costs. Size and efficiency constraints also limit widespread adoption, as current commercial TEGs typically achieve only 5-8% conversion efficiency in consumer electronics applications.

Despite these challenges, market forecasts remain optimistic due to ongoing technological advancements. The miniaturization of TEG components and improvements in thermal interface materials are expected to expand market opportunities. Industry analysts predict that by 2025, TEGs will be standard components in premium wearables and will begin penetrating mid-range consumer electronics, creating a substantial market expansion opportunity.

Consumer electronics manufacturers are increasingly seeking alternative power sources due to several converging factors. The proliferation of Internet of Things (IoT) devices has created demand for self-powered sensors and systems that can operate without frequent battery replacement. Wearable technology represents another substantial market segment, with fitness trackers, smartwatches, and medical monitoring devices requiring reliable power sources that can harvest energy from body heat.

Market surveys reveal that consumers are increasingly concerned about environmental sustainability, with 67% of respondents expressing preference for electronics with green energy capabilities. This shift in consumer preference is pushing manufacturers to incorporate energy harvesting technologies like TEGs into their product designs. The reduction of e-waste through extended battery life or battery-free operation represents a significant market driver.

Regional analysis shows that North America and Asia-Pacific currently dominate the TEG consumer electronics market. Japan and South Korea lead in TEG technology integration, while China is rapidly expanding manufacturing capacity. European markets show strong growth potential due to stringent environmental regulations and consumer awareness.

Industry segmentation indicates that wearable devices constitute the largest application segment for TEGs, followed by smartphones and portable charging solutions. The medical wearables sub-segment is experiencing the fastest growth rate at 12.1% annually, as remote patient monitoring becomes increasingly important in healthcare delivery systems.

Key market challenges include cost barriers, with TEGs currently adding a premium of 15-30% to device manufacturing costs. Size and efficiency constraints also limit widespread adoption, as current commercial TEGs typically achieve only 5-8% conversion efficiency in consumer electronics applications.

Despite these challenges, market forecasts remain optimistic due to ongoing technological advancements. The miniaturization of TEG components and improvements in thermal interface materials are expected to expand market opportunities. Industry analysts predict that by 2025, TEGs will be standard components in premium wearables and will begin penetrating mid-range consumer electronics, creating a substantial market expansion opportunity.

Current TEG Development Status and Technical Challenges

Thermoelectric generators (TEGs) have reached a critical development stage in the consumer electronics sector. Current commercial TEGs typically achieve conversion efficiencies between 5-8%, significantly lower than other energy harvesting technologies. This efficiency limitation stems primarily from the inherent material constraints, specifically the interdependent relationship between electrical conductivity, thermal conductivity, and Seebeck coefficient—collectively measured as the figure of merit ZT.

Leading materials in commercial applications include bismuth telluride (Bi2Te3) compounds, which dominate the market with ZT values around 1 at room temperature. Recent laboratory breakthroughs have demonstrated enhanced ZT values approaching 2.0 through nanostructuring and advanced material engineering, though these have yet to be widely commercialized due to manufacturing scalability issues.

Miniaturization represents another significant challenge for consumer electronics integration. Current TEG modules are typically bulky compared to the increasingly compact form factors of modern devices. The industry is struggling to develop manufacturing techniques that can reliably produce microscale TEGs with consistent performance while maintaining cost-effectiveness.

Thermal management presents a persistent obstacle, as TEGs require substantial temperature differentials to generate meaningful power. In wearable and portable electronics, where temperature gradients are often minimal (typically less than 10°C), this fundamentally limits power generation capacity. Most current TEGs in consumer applications deliver power densities of only 10-50 μW/cm², insufficient for powering energy-intensive functions.

Cost remains prohibitive for mass-market adoption, with current TEG solutions ranging from $10-100 per watt of generating capacity. This pricing structure restricts their implementation primarily to premium devices or specialized applications where conventional power sources are impractical.

Geographic distribution of TEG technology development shows concentration in East Asia (particularly Japan and South Korea), North America, and Western Europe. Japanese companies hold approximately 40% of TEG-related patents, followed by the United States (25%) and South Korea (15%). China is rapidly expanding its research capacity in this field, with annual patent filings increasing at approximately 30% year-over-year.

Manufacturing scalability continues to impede widespread adoption. Current production methods involve complex multi-step processes that are difficult to integrate into existing consumer electronics manufacturing lines. Yield rates for high-performance TEGs remain below 70%, significantly higher than the sub-5% defect rates typical in mature electronics manufacturing.

Regulatory and environmental concerns also present challenges, as many high-performance thermoelectric materials contain toxic or rare elements like tellurium, antimony, and lead. This has prompted increased research into alternative materials that can deliver comparable performance while meeting increasingly stringent environmental regulations in major markets.

Leading materials in commercial applications include bismuth telluride (Bi2Te3) compounds, which dominate the market with ZT values around 1 at room temperature. Recent laboratory breakthroughs have demonstrated enhanced ZT values approaching 2.0 through nanostructuring and advanced material engineering, though these have yet to be widely commercialized due to manufacturing scalability issues.

Miniaturization represents another significant challenge for consumer electronics integration. Current TEG modules are typically bulky compared to the increasingly compact form factors of modern devices. The industry is struggling to develop manufacturing techniques that can reliably produce microscale TEGs with consistent performance while maintaining cost-effectiveness.

Thermal management presents a persistent obstacle, as TEGs require substantial temperature differentials to generate meaningful power. In wearable and portable electronics, where temperature gradients are often minimal (typically less than 10°C), this fundamentally limits power generation capacity. Most current TEGs in consumer applications deliver power densities of only 10-50 μW/cm², insufficient for powering energy-intensive functions.

Cost remains prohibitive for mass-market adoption, with current TEG solutions ranging from $10-100 per watt of generating capacity. This pricing structure restricts their implementation primarily to premium devices or specialized applications where conventional power sources are impractical.

Geographic distribution of TEG technology development shows concentration in East Asia (particularly Japan and South Korea), North America, and Western Europe. Japanese companies hold approximately 40% of TEG-related patents, followed by the United States (25%) and South Korea (15%). China is rapidly expanding its research capacity in this field, with annual patent filings increasing at approximately 30% year-over-year.

Manufacturing scalability continues to impede widespread adoption. Current production methods involve complex multi-step processes that are difficult to integrate into existing consumer electronics manufacturing lines. Yield rates for high-performance TEGs remain below 70%, significantly higher than the sub-5% defect rates typical in mature electronics manufacturing.

Regulatory and environmental concerns also present challenges, as many high-performance thermoelectric materials contain toxic or rare elements like tellurium, antimony, and lead. This has prompted increased research into alternative materials that can deliver comparable performance while meeting increasingly stringent environmental regulations in major markets.

Current TEG Implementation Solutions

01 Materials and structures for thermoelectric generators

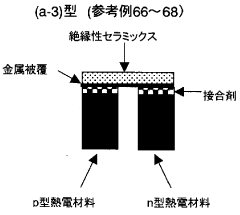

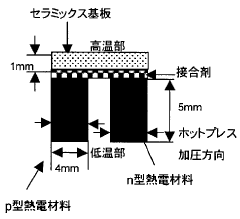

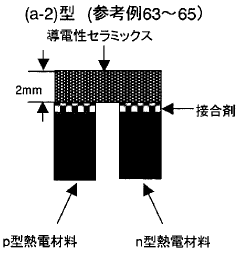

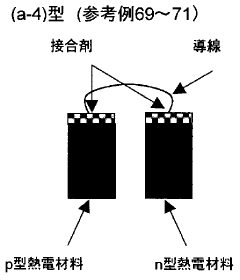

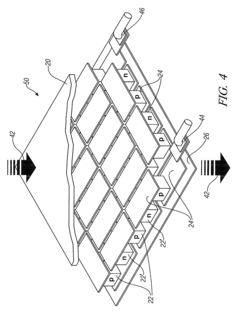

Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and novel junction configurations that improve the Seebeck effect. Advanced material compositions and structural arrangements help maximize the temperature gradient across the device, leading to more efficient conversion of heat into electrical energy.- Materials and composition for thermoelectric generators: Various materials and compositions are used in thermoelectric generators to improve efficiency and performance. These include specialized semiconductor materials, nanostructured materials, and composite structures that enhance the Seebeck effect while reducing thermal conductivity. The selection of materials with high thermoelectric figure of merit (ZT) is crucial for efficient energy conversion. Advanced manufacturing techniques allow for precise control of material properties at the nanoscale, resulting in improved thermoelectric performance.

- Design and structure of thermoelectric devices: The physical design and structure of thermoelectric generators significantly impact their efficiency and application versatility. Innovations include multi-stage designs, modular configurations, and specialized geometries that optimize heat flow and electrical output. Structural improvements focus on maximizing the temperature gradient across the device while minimizing thermal losses. Advanced designs incorporate features for durability in harsh environments and integration with existing systems.

- Integration with renewable energy systems: Thermoelectric generators can be integrated with other renewable energy systems to create hybrid solutions that improve overall efficiency. These integrations include solar-thermoelectric systems, waste heat recovery from industrial processes, and combination with geothermal sources. The complementary nature of these systems allows for more consistent energy production and better utilization of available thermal resources. Such hybrid approaches can significantly enhance the economic viability of renewable energy installations.

- Efficiency enhancement techniques: Various techniques are employed to enhance the efficiency of thermoelectric generators beyond material improvements. These include thermal concentration methods, electrical circuit optimizations, and advanced heat management systems. Segmented thermoelectric elements that operate efficiently across wider temperature ranges represent another approach. Computational modeling and simulation tools help predict and optimize performance under various operating conditions, leading to designs with significantly improved conversion efficiency.

- Applications in wearable and portable devices: Thermoelectric generators are increasingly being adapted for use in wearable and portable devices, harvesting body heat or environmental temperature differences to power electronics. These applications require miniaturization, flexibility, and biocompatibility considerations not present in industrial applications. Low-temperature differential thermoelectric generators enable self-powered sensors, medical devices, and consumer electronics. The development of flexible thermoelectric materials and thin-film technologies has expanded the potential application areas for body-heat powered devices.

02 Waste heat recovery applications

Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Implementation strategies include integration with exhaust systems, industrial processes, and power generation facilities, providing supplementary power while reducing overall energy consumption and environmental impact.Expand Specific Solutions03 Portable and wearable thermoelectric power generation

Miniaturized thermoelectric generators are being developed for portable and wearable applications, utilizing body heat or environmental temperature differences. These compact devices can power personal electronics, medical devices, and IoT sensors without requiring battery replacement. Design considerations focus on flexibility, comfort, and maximizing power output from small temperature differentials typically available in wearable contexts.Expand Specific Solutions04 Modeling and simulation techniques

Advanced computational methods are employed to model and simulate thermoelectric generator performance under various operating conditions. These techniques help optimize design parameters, predict energy output, and evaluate efficiency before physical prototyping. Simulation approaches include finite element analysis, multiphysics modeling, and machine learning algorithms that account for material properties, thermal interfaces, and electrical characteristics.Expand Specific Solutions05 Historical development and fundamental designs

The evolution of thermoelectric generator technology spans several decades, with fundamental designs establishing core principles still relevant today. Early innovations focused on basic semiconductor junctions, thermal coupling mechanisms, and electrical circuit configurations. These foundational approaches have informed modern advancements while demonstrating the enduring principles of direct thermal-to-electrical energy conversion through the Seebeck effect.Expand Specific Solutions

Key Industry Players in Thermoelectric Generation

Thermoelectric Generators (TEGs) for consumer electronics are currently in an early growth phase, with the market expected to expand significantly as energy harvesting technologies gain traction. The global TEG market, valued at approximately $460 million, is projected to grow at a CAGR of 8-10% through 2028. Leading players include established electronics manufacturers like Toshiba, Yamaha, and 3M Innovative Properties, alongside specialized research institutions such as MIT and AIST. Companies like STMicroelectronics and Robert Bosch are advancing miniaturization and efficiency improvements, while Toshiba Materials focuses on material innovations. The technology is approaching commercial viability for consumer applications, with efficiency improvements and cost reductions representing key development priorities as the industry transitions from research-dominated to product commercialization.

Toshiba Corp.

Technical Solution: Toshiba has developed a comprehensive thermoelectric generator technology specifically targeting next-generation consumer electronics. Their approach centers on proprietary n-type and p-type semiconductor materials with enhanced Seebeck coefficients while maintaining low electrical resistivity. Toshiba's TEG modules utilize a unique multi-layer structure that optimizes thermal gradients across the device, achieving conversion efficiencies approaching 9% at temperature differentials typical in consumer electronics (10-30°C). Their manufacturing process incorporates precision thin-film deposition techniques combined with advanced microfabrication methods, enabling the production of TEG arrays with thousands of thermocouples in compact form factors suitable for smartphones and wearables. Toshiba has developed specialized thermal interface materials that maximize heat transfer from device components to the TEG while minimizing parasitic thermal paths. Their technology includes integrated power management circuits designed to operate efficiently at the low voltages produced by TEGs, incorporating maximum power point tracking algorithms that dynamically adjust to changing thermal conditions. Toshiba's TEGs can generate 2-8mW/cm² depending on the application environment, sufficient for powering various sensors and low-power displays in consumer devices.

Strengths: Exceptional thermal engineering optimizing performance in real-world consumer device environments; highly integrated solution including power management; established manufacturing capabilities for mass production. Weaknesses: Higher cost compared to conventional power solutions; performance sensitivity to ambient temperature variations; challenges in achieving uniform thermal contact in complex device geometries.

3M Innovative Properties Co.

Technical Solution: 3M has developed a comprehensive thermoelectric generator technology platform specifically targeting consumer electronics applications. Their approach leverages proprietary thin-film deposition techniques to create flexible, lightweight TEGs that can be integrated into various form factors. 3M's solution utilizes advanced polymer-based substrates coated with specialized thermoelectric materials, achieving thickness profiles under 1mm while maintaining thermal stability. Their manufacturing process employs roll-to-roll production methods, enabling cost-effective mass production with high uniformity. The company has developed composite thermoelectric materials that balance performance and cost, achieving ZT values of approximately 1.2 while using reduced quantities of expensive elements like tellurium. 3M's TEGs incorporate proprietary thermal interface materials that maximize heat transfer efficiency between the generator and heat sources/sinks, addressing a critical challenge in consumer device integration. Their systems can generate 1-5mW/cm² at temperature differentials of 10-20°C, sufficient for powering low-energy sensors and displays in consumer products.

Strengths: Exceptional manufacturing scalability through established roll-to-roll processes; strong materials science expertise enabling optimized thermal interfaces; flexible form factors ideal for wearable integration. Weaknesses: Moderate conversion efficiency compared to laboratory-scale solutions; performance degradation at higher operating temperatures; challenges in achieving uniform electrical connections in flexible configurations.

Core TEG Patents and Technical Innovations

Thermoelectric generator

PatentWO2005064698A1

Innovation

- A thermoelectric generator module utilizing composite oxides as p-type and n-type thermoelectric conversion materials, combined with a catalytic combustion heat source, where the thermoelectric conversion elements are electrically connected in series and the heat source is integrated with a fuel container and preheater for efficient energy conversion.

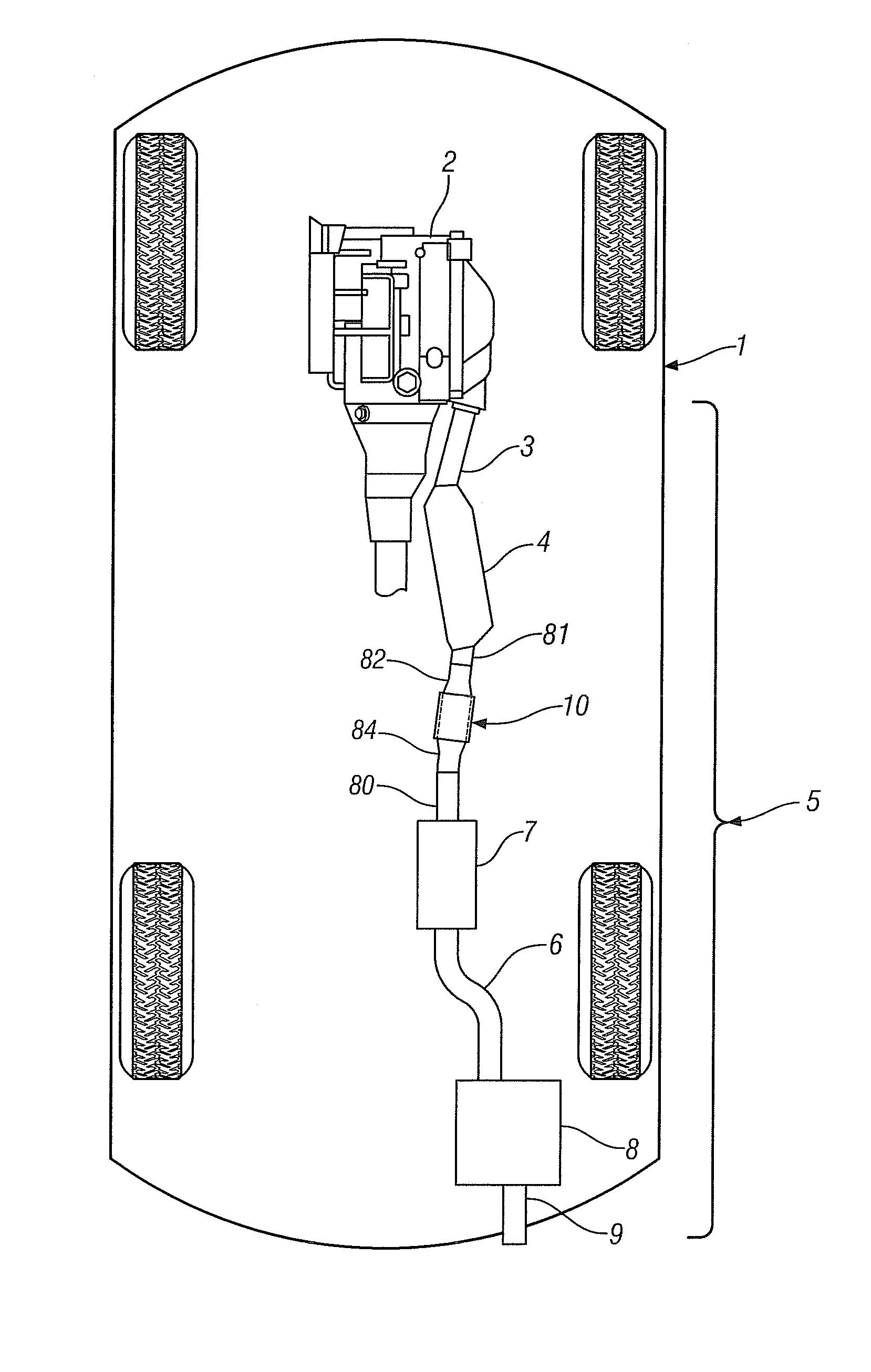

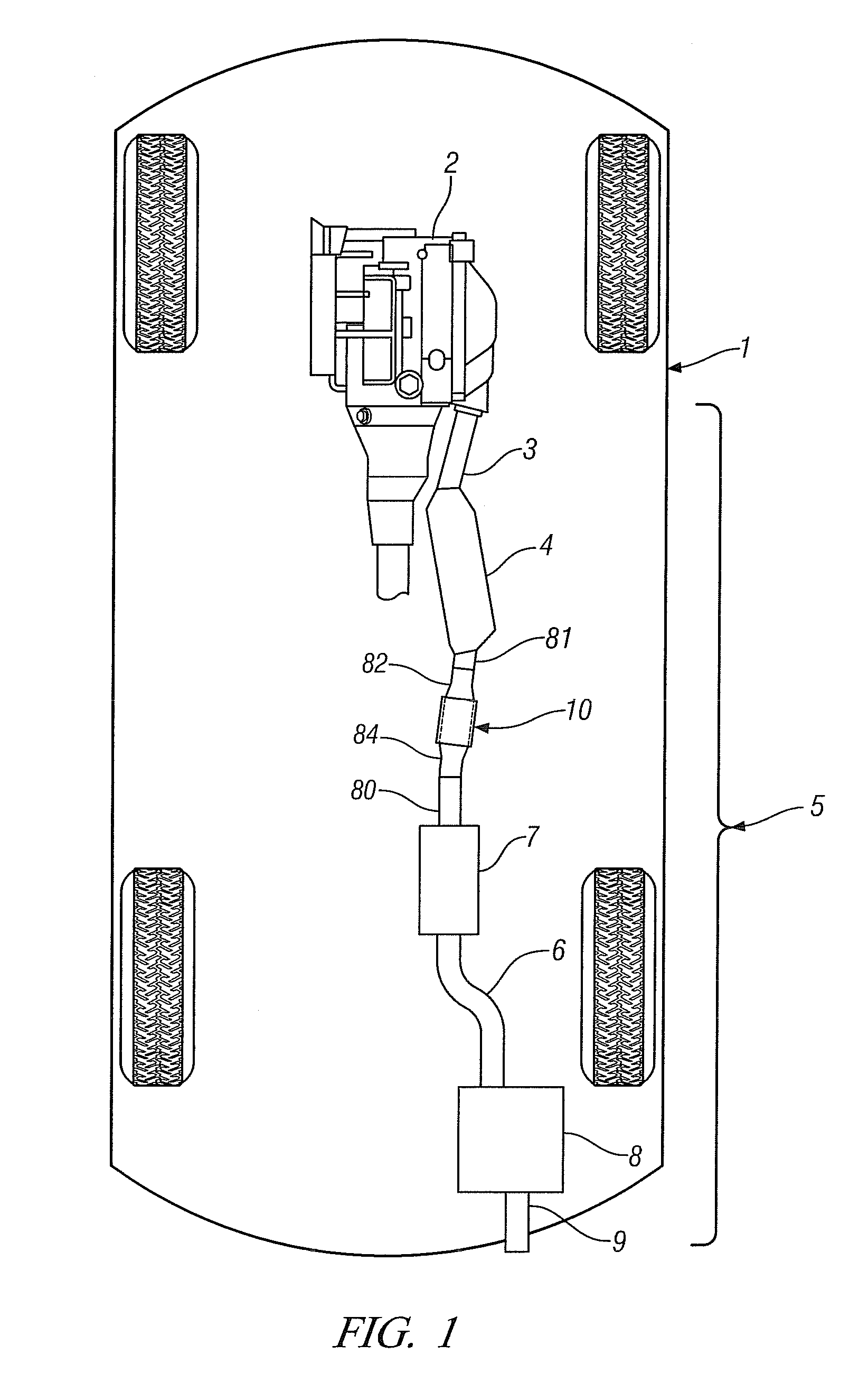

Thermoelectric generators incorporating phase-change materials for waste heat recovery from engine exhaust

PatentActiveUS20120073276A1

Innovation

- Integration of thermoelectric modules with phase-change materials in the exhaust conduit system to convert thermal energy from exhaust gases into electrical energy, using bypass pipes and air admittance to manage temperature and prevent overheating of thermoelectric modules.

Energy Harvesting Integration Strategies

The integration of thermoelectric generators (TEGs) into consumer electronics requires strategic approaches that maximize energy harvesting efficiency while maintaining device functionality and user experience. Current integration strategies focus on three primary methodologies: surface mounting, embedded integration, and modular attachment systems.

Surface mounting represents the most straightforward implementation, where TEG modules are attached to external device surfaces that experience temperature differentials. This approach is particularly effective for wearable technologies like smartwatches and fitness trackers, where body heat provides a consistent thermal gradient. Companies like Matrix Industries have pioneered this approach with their PowerWatch series, demonstrating viable commercial applications without compromising device aesthetics or comfort.

Embedded integration offers greater efficiency by incorporating TEGs directly into device architecture during manufacturing. This strategy enables optimal placement near heat-generating components such as processors or batteries, maximizing the temperature differential. Samsung and LG have filed patents exploring embedded TEG systems in smartphone designs that capture waste heat from processing units. The challenge lies in managing the additional design complexity and potential thermal management conflicts with existing cooling systems.

Modular attachment systems represent an emerging approach that allows for aftermarket TEG integration. These systems typically connect to devices via standardized interfaces such as USB-C ports or proprietary connectors. This strategy offers flexibility for consumers but faces efficiency limitations due to suboptimal thermal coupling.

Cross-platform integration frameworks are developing to standardize how harvested energy interfaces with device power management systems. The Adaptive Power Management Protocol (APMP) proposed by the Consumer Electronics Association provides guidelines for integrating variable energy sources like TEGs into conventional battery systems. This protocol enables devices to seamlessly transition between harvested energy and traditional power sources without disruption.

Material selection plays a crucial role in integration success. Flexible thermoelectric materials based on organic polymers or thin-film technologies enable conformable TEG solutions that can adapt to curved device surfaces. Northwestern University researchers have demonstrated printable thermoelectric inks that can be directly applied to device casings, potentially revolutionizing integration approaches.

Thermal interface materials (TIMs) represent another critical component in the integration strategy. Advanced TIMs with high thermal conductivity ensure efficient heat transfer between the device and TEG module. Innovations in graphene-enhanced thermal compounds have shown up to 35% improvement in thermal coupling efficiency compared to traditional materials.

As miniaturization continues to drive consumer electronics development, integration strategies must evolve toward nanoscale implementations that maintain efficiency while reducing spatial requirements. Recent advances in MEMS-based thermoelectric systems point toward future integration pathways that could enable TEG functionality even in the smallest wearable and IoT devices.

Surface mounting represents the most straightforward implementation, where TEG modules are attached to external device surfaces that experience temperature differentials. This approach is particularly effective for wearable technologies like smartwatches and fitness trackers, where body heat provides a consistent thermal gradient. Companies like Matrix Industries have pioneered this approach with their PowerWatch series, demonstrating viable commercial applications without compromising device aesthetics or comfort.

Embedded integration offers greater efficiency by incorporating TEGs directly into device architecture during manufacturing. This strategy enables optimal placement near heat-generating components such as processors or batteries, maximizing the temperature differential. Samsung and LG have filed patents exploring embedded TEG systems in smartphone designs that capture waste heat from processing units. The challenge lies in managing the additional design complexity and potential thermal management conflicts with existing cooling systems.

Modular attachment systems represent an emerging approach that allows for aftermarket TEG integration. These systems typically connect to devices via standardized interfaces such as USB-C ports or proprietary connectors. This strategy offers flexibility for consumers but faces efficiency limitations due to suboptimal thermal coupling.

Cross-platform integration frameworks are developing to standardize how harvested energy interfaces with device power management systems. The Adaptive Power Management Protocol (APMP) proposed by the Consumer Electronics Association provides guidelines for integrating variable energy sources like TEGs into conventional battery systems. This protocol enables devices to seamlessly transition between harvested energy and traditional power sources without disruption.

Material selection plays a crucial role in integration success. Flexible thermoelectric materials based on organic polymers or thin-film technologies enable conformable TEG solutions that can adapt to curved device surfaces. Northwestern University researchers have demonstrated printable thermoelectric inks that can be directly applied to device casings, potentially revolutionizing integration approaches.

Thermal interface materials (TIMs) represent another critical component in the integration strategy. Advanced TIMs with high thermal conductivity ensure efficient heat transfer between the device and TEG module. Innovations in graphene-enhanced thermal compounds have shown up to 35% improvement in thermal coupling efficiency compared to traditional materials.

As miniaturization continues to drive consumer electronics development, integration strategies must evolve toward nanoscale implementations that maintain efficiency while reducing spatial requirements. Recent advances in MEMS-based thermoelectric systems point toward future integration pathways that could enable TEG functionality even in the smallest wearable and IoT devices.

Sustainability Impact of TEG Technology

The integration of Thermoelectric Generator (TEG) technology into consumer electronics represents a significant advancement in sustainable energy practices. TEGs offer a unique opportunity to reduce the environmental footprint of electronic devices by harvesting waste heat and converting it into usable electricity, thereby extending battery life and potentially reducing the need for frequent charging or battery replacements.

From a lifecycle perspective, TEG implementation contributes to sustainability through multiple pathways. The reduction in battery consumption directly translates to fewer batteries entering the waste stream, addressing a significant environmental concern given the toxic materials present in conventional batteries and their poor recycling rates. Additionally, the extended operational life of devices equipped with TEGs means fewer replacements and consequently less electronic waste generation.

The manufacturing process of TEGs does involve some environmental considerations, particularly regarding the materials used. Traditional thermoelectric materials like bismuth telluride contain rare elements that may present resource scarcity and extraction-related environmental impacts. However, research into organic and abundant-element thermoelectric materials shows promise for mitigating these concerns, potentially enabling more environmentally benign production processes.

Energy efficiency improvements resulting from TEG integration can significantly reduce the carbon footprint of consumer electronics. By capturing and utilizing waste heat that would otherwise be dissipated into the environment, TEGs improve the overall energy efficiency of devices. This efficiency gain becomes particularly impactful when considering the cumulative effect across billions of consumer electronic devices worldwide.

In developing regions with limited access to reliable power grids, TEG technology offers substantial sustainability benefits. Self-powered or partially self-powered devices can reduce dependence on fossil fuel-based charging methods, such as diesel generators, which are common in off-grid areas. This transition supports cleaner air quality and reduced greenhouse gas emissions at local and global scales.

The circular economy potential of TEG technology is also noteworthy. As the technology matures, opportunities for recovering and reusing thermoelectric materials from discarded devices could emerge, further enhancing the sustainability profile of this technology. Additionally, the design principles behind TEGs align with broader sustainable product development goals, emphasizing resource efficiency and waste minimization.

Quantitatively, preliminary studies suggest that widespread adoption of TEG technology in consumer electronics could reduce global electronic waste by several percentage points and contribute to measurable reductions in energy consumption across the consumer electronics sector, supporting international climate change mitigation efforts.

From a lifecycle perspective, TEG implementation contributes to sustainability through multiple pathways. The reduction in battery consumption directly translates to fewer batteries entering the waste stream, addressing a significant environmental concern given the toxic materials present in conventional batteries and their poor recycling rates. Additionally, the extended operational life of devices equipped with TEGs means fewer replacements and consequently less electronic waste generation.

The manufacturing process of TEGs does involve some environmental considerations, particularly regarding the materials used. Traditional thermoelectric materials like bismuth telluride contain rare elements that may present resource scarcity and extraction-related environmental impacts. However, research into organic and abundant-element thermoelectric materials shows promise for mitigating these concerns, potentially enabling more environmentally benign production processes.

Energy efficiency improvements resulting from TEG integration can significantly reduce the carbon footprint of consumer electronics. By capturing and utilizing waste heat that would otherwise be dissipated into the environment, TEGs improve the overall energy efficiency of devices. This efficiency gain becomes particularly impactful when considering the cumulative effect across billions of consumer electronic devices worldwide.

In developing regions with limited access to reliable power grids, TEG technology offers substantial sustainability benefits. Self-powered or partially self-powered devices can reduce dependence on fossil fuel-based charging methods, such as diesel generators, which are common in off-grid areas. This transition supports cleaner air quality and reduced greenhouse gas emissions at local and global scales.

The circular economy potential of TEG technology is also noteworthy. As the technology matures, opportunities for recovering and reusing thermoelectric materials from discarded devices could emerge, further enhancing the sustainability profile of this technology. Additionally, the design principles behind TEGs align with broader sustainable product development goals, emphasizing resource efficiency and waste minimization.

Quantitatively, preliminary studies suggest that widespread adoption of TEG technology in consumer electronics could reduce global electronic waste by several percentage points and contribute to measurable reductions in energy consumption across the consumer electronics sector, supporting international climate change mitigation efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!