How Thermoelectric Generators Empower Next-Generation IoT Devices?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Generation Technology Background and Objectives

Thermoelectric generation technology has evolved significantly since its discovery in the early 19th century with the Seebeck effect, which demonstrated that temperature differences between two dissimilar electrical conductors can produce voltage. This fundamental principle has driven the development of thermoelectric generators (TEGs) that convert waste heat directly into electrical energy without moving parts, offering remarkable reliability and longevity. The technology has progressed through several key phases, from early theoretical understanding to practical applications in specialized fields such as space exploration, where radioisotope thermoelectric generators have powered missions like Voyager and Curiosity.

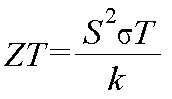

Recent advancements in material science have dramatically improved the efficiency of thermoelectric materials, particularly through nanostructuring techniques and the development of novel semiconductor compounds. These innovations have significantly enhanced the figure of merit (ZT) - a critical parameter measuring thermoelectric performance - from traditional values below 1 to promising new materials achieving ZT values exceeding 2, substantially improving conversion efficiency.

The Internet of Things (IoT) revolution has created unprecedented demand for autonomous power sources that can sustain long-term operation of distributed sensor networks and smart devices. This market pull has accelerated research into miniaturized, efficient TEGs capable of harvesting ambient thermal energy from industrial processes, human body heat, or environmental temperature gradients. The technology aims to eliminate battery dependencies in IoT deployments, addressing critical challenges of maintenance, sustainability, and deployment scalability.

The primary technical objectives for thermoelectric generation in next-generation IoT applications include achieving higher power density (targeting >1mW/cm² at temperature differences of <10°C), reducing manufacturing costs through scalable production methods, and developing flexible or conformable TEG designs that can adapt to various form factors. Additionally, researchers are pursuing integration strategies that combine TEGs with power management circuits and energy storage solutions to create complete energy harvesting systems optimized for intermittent thermal gradients.

Looking forward, the technology trajectory points toward hybrid energy harvesting systems that combine thermoelectric generation with other harvesting modalities such as photovoltaic or piezoelectric technologies. The ultimate goal is to create self-powered IoT ecosystems that can operate indefinitely in diverse environments, from industrial settings to wearable applications, by intelligently extracting energy from available thermal gradients without human intervention or maintenance requirements.

Recent advancements in material science have dramatically improved the efficiency of thermoelectric materials, particularly through nanostructuring techniques and the development of novel semiconductor compounds. These innovations have significantly enhanced the figure of merit (ZT) - a critical parameter measuring thermoelectric performance - from traditional values below 1 to promising new materials achieving ZT values exceeding 2, substantially improving conversion efficiency.

The Internet of Things (IoT) revolution has created unprecedented demand for autonomous power sources that can sustain long-term operation of distributed sensor networks and smart devices. This market pull has accelerated research into miniaturized, efficient TEGs capable of harvesting ambient thermal energy from industrial processes, human body heat, or environmental temperature gradients. The technology aims to eliminate battery dependencies in IoT deployments, addressing critical challenges of maintenance, sustainability, and deployment scalability.

The primary technical objectives for thermoelectric generation in next-generation IoT applications include achieving higher power density (targeting >1mW/cm² at temperature differences of <10°C), reducing manufacturing costs through scalable production methods, and developing flexible or conformable TEG designs that can adapt to various form factors. Additionally, researchers are pursuing integration strategies that combine TEGs with power management circuits and energy storage solutions to create complete energy harvesting systems optimized for intermittent thermal gradients.

Looking forward, the technology trajectory points toward hybrid energy harvesting systems that combine thermoelectric generation with other harvesting modalities such as photovoltaic or piezoelectric technologies. The ultimate goal is to create self-powered IoT ecosystems that can operate indefinitely in diverse environments, from industrial settings to wearable applications, by intelligently extracting energy from available thermal gradients without human intervention or maintenance requirements.

IoT Energy Harvesting Market Analysis

The IoT energy harvesting market is experiencing robust growth, driven by the increasing deployment of IoT devices across various sectors and the growing need for sustainable power solutions. The global market for energy harvesting systems was valued at approximately $440 million in 2020 and is projected to reach $1.3 billion by 2027, representing a compound annual growth rate (CAGR) of 13.2% during the forecast period. Thermoelectric generators (TEGs) constitute a significant segment of this market, accounting for roughly 24% of the total energy harvesting technologies employed in IoT applications.

The demand for TEG-powered IoT devices is particularly strong in industrial monitoring, smart buildings, healthcare, and consumer electronics sectors. Industrial applications lead the market with approximately 32% share, where TEGs are utilized for powering sensors in environments with temperature differentials, such as manufacturing facilities and power plants. Smart building applications follow closely at 28%, leveraging TEGs in HVAC systems and building automation. Healthcare applications represent 18% of the market, with wearable medical devices increasingly incorporating TEGs to eliminate battery replacement needs.

Regional analysis reveals North America currently dominates the market with 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 15.7% through 2027, primarily due to rapid industrialization, smart city initiatives, and increasing IoT adoption in countries like China, Japan, South Korea, and India.

Key market drivers include the growing deployment of wireless sensor networks, increasing focus on predictive maintenance in industrial settings, and the rising demand for battery-free or extended-battery-life IoT solutions. The push toward sustainable and environmentally friendly technologies is also accelerating market growth, as TEGs offer a clean alternative to traditional batteries, reducing electronic waste and maintenance requirements.

Market challenges include the relatively low conversion efficiency of current TEG technologies (typically 5-8%), high initial costs compared to conventional battery solutions, and limited power output for high-consumption applications. Despite these challenges, ongoing technological advancements are gradually improving TEG performance metrics, with research indicating potential efficiency improvements to 12-15% within the next five years.

The market is also witnessing a shift toward integrated energy harvesting solutions that combine multiple harvesting technologies, with TEGs often paired with photovoltaic cells or piezoelectric generators to create more reliable and versatile power sources for IoT devices operating in variable environmental conditions.

The demand for TEG-powered IoT devices is particularly strong in industrial monitoring, smart buildings, healthcare, and consumer electronics sectors. Industrial applications lead the market with approximately 32% share, where TEGs are utilized for powering sensors in environments with temperature differentials, such as manufacturing facilities and power plants. Smart building applications follow closely at 28%, leveraging TEGs in HVAC systems and building automation. Healthcare applications represent 18% of the market, with wearable medical devices increasingly incorporating TEGs to eliminate battery replacement needs.

Regional analysis reveals North America currently dominates the market with 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 15.7% through 2027, primarily due to rapid industrialization, smart city initiatives, and increasing IoT adoption in countries like China, Japan, South Korea, and India.

Key market drivers include the growing deployment of wireless sensor networks, increasing focus on predictive maintenance in industrial settings, and the rising demand for battery-free or extended-battery-life IoT solutions. The push toward sustainable and environmentally friendly technologies is also accelerating market growth, as TEGs offer a clean alternative to traditional batteries, reducing electronic waste and maintenance requirements.

Market challenges include the relatively low conversion efficiency of current TEG technologies (typically 5-8%), high initial costs compared to conventional battery solutions, and limited power output for high-consumption applications. Despite these challenges, ongoing technological advancements are gradually improving TEG performance metrics, with research indicating potential efficiency improvements to 12-15% within the next five years.

The market is also witnessing a shift toward integrated energy harvesting solutions that combine multiple harvesting technologies, with TEGs often paired with photovoltaic cells or piezoelectric generators to create more reliable and versatile power sources for IoT devices operating in variable environmental conditions.

TEG Technology Status and Implementation Challenges

Thermoelectric generators (TEGs) have emerged as a promising technology for powering IoT devices, yet their widespread implementation faces several significant challenges. Currently, commercial TEG solutions exhibit relatively low conversion efficiencies, typically ranging from 5-8% in most practical applications. This efficiency limitation stems primarily from the inherent material properties that govern thermoelectric performance, specifically the figure of merit (ZT) which remains below 2 for most commercially viable materials.

The global landscape of TEG development shows concentrated research efforts in North America, Europe, and East Asia, with Japan and Germany leading in patent filings for novel thermoelectric materials. Recent advancements have focused on nanostructured materials and quantum well structures to enhance ZT values, though scaling these laboratory innovations to mass production presents significant manufacturing challenges.

Temperature gradient maintenance represents another critical obstacle in TEG implementation for IoT applications. Miniaturized devices often struggle to establish and maintain sufficient temperature differentials in ambient environments, limiting power generation capabilities. This challenge becomes particularly pronounced in wearable and environmental monitoring applications where temperature differences may be minimal and inconsistent.

Manufacturing scalability presents additional hurdles, as high-performance thermoelectric materials often require precise composition control and specialized processing techniques. The integration of TEGs into existing IoT form factors demands advanced packaging solutions that can simultaneously provide thermal isolation between hot and cold sides while maintaining electrical connectivity and mechanical robustness.

Cost factors significantly impact widespread adoption, with high-performance thermoelectric materials often containing tellurium, bismuth, and other elements with supply chain vulnerabilities. Current manufacturing costs for high-efficiency TEGs remain prohibitively expensive for mass-market IoT applications, with prices ranging from $10-50 per watt of generating capacity.

Reliability and operational lifetime concerns also persist, particularly in applications involving thermal cycling and environmental exposure. Material degradation at interface boundaries and thermomechanical stress can significantly reduce performance over time, with current solutions typically demonstrating 10-30% efficiency reduction after 5,000 hours of operation under variable conditions.

Recent technical innovations have focused on flexible TEG architectures, printed thermoelectric materials, and hybrid energy harvesting approaches that combine TEGs with other energy harvesting technologies. These developments show promise for overcoming existing limitations, though most remain at technology readiness levels of 4-6, indicating significant development work remains before commercial viability for mainstream IoT applications can be achieved.

The global landscape of TEG development shows concentrated research efforts in North America, Europe, and East Asia, with Japan and Germany leading in patent filings for novel thermoelectric materials. Recent advancements have focused on nanostructured materials and quantum well structures to enhance ZT values, though scaling these laboratory innovations to mass production presents significant manufacturing challenges.

Temperature gradient maintenance represents another critical obstacle in TEG implementation for IoT applications. Miniaturized devices often struggle to establish and maintain sufficient temperature differentials in ambient environments, limiting power generation capabilities. This challenge becomes particularly pronounced in wearable and environmental monitoring applications where temperature differences may be minimal and inconsistent.

Manufacturing scalability presents additional hurdles, as high-performance thermoelectric materials often require precise composition control and specialized processing techniques. The integration of TEGs into existing IoT form factors demands advanced packaging solutions that can simultaneously provide thermal isolation between hot and cold sides while maintaining electrical connectivity and mechanical robustness.

Cost factors significantly impact widespread adoption, with high-performance thermoelectric materials often containing tellurium, bismuth, and other elements with supply chain vulnerabilities. Current manufacturing costs for high-efficiency TEGs remain prohibitively expensive for mass-market IoT applications, with prices ranging from $10-50 per watt of generating capacity.

Reliability and operational lifetime concerns also persist, particularly in applications involving thermal cycling and environmental exposure. Material degradation at interface boundaries and thermomechanical stress can significantly reduce performance over time, with current solutions typically demonstrating 10-30% efficiency reduction after 5,000 hours of operation under variable conditions.

Recent technical innovations have focused on flexible TEG architectures, printed thermoelectric materials, and hybrid energy harvesting approaches that combine TEGs with other energy harvesting technologies. These developments show promise for overcoming existing limitations, though most remain at technology readiness levels of 4-6, indicating significant development work remains before commercial viability for mainstream IoT applications can be achieved.

Current TEG Solutions for IoT Power Applications

01 Materials and composition for thermoelectric generators

Various materials and compositions are used in thermoelectric generators to improve efficiency and performance. These include semiconductor materials, nanostructured materials, and composite materials that exhibit high Seebeck coefficients and low thermal conductivity. The selection and optimization of these materials are crucial for maximizing the conversion of thermal energy to electrical energy in thermoelectric generators.- Materials and structures for thermoelectric generators: Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and novel material combinations that exhibit improved Seebeck coefficients. Advanced structural designs focus on optimizing thermal gradients and electrical conductivity while minimizing heat loss through the system.

- Waste heat recovery applications: Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Applications include exhaust systems, industrial processes, and power plants where significant temperature differentials exist, allowing for sustainable energy generation from otherwise wasted thermal resources.

- Portable and wearable thermoelectric power generation: Miniaturized thermoelectric generators are being developed for portable and wearable applications. These compact devices utilize body heat or environmental temperature differences to generate electricity for powering small electronic devices. The designs focus on flexibility, lightweight construction, and integration with wearable technology, enabling self-powered sensors, medical devices, and consumer electronics.

- Efficiency enhancement techniques: Various techniques are employed to enhance the efficiency of thermoelectric generators. These include segmented leg designs, cascaded systems, thermal concentration methods, and improved electrical contact technologies. Advanced manufacturing processes and novel geometrical configurations are also utilized to maximize the temperature gradient across the thermoelectric elements while minimizing thermal and electrical resistance losses.

- Integration with renewable energy systems: Thermoelectric generators are increasingly integrated with other renewable energy systems to create hybrid power generation solutions. These integrated systems combine solar, geothermal, or biomass energy sources with thermoelectric technology to improve overall efficiency and provide more consistent power output. Such hybrid approaches enable more effective utilization of available energy resources and can provide solutions for off-grid or remote power applications.

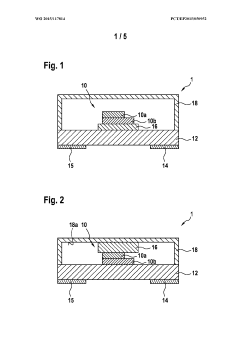

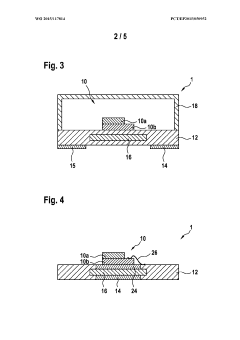

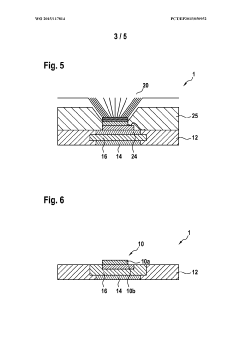

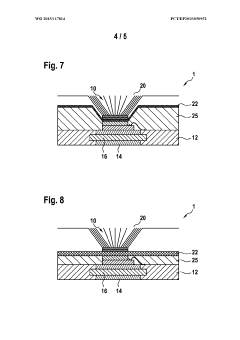

02 Structural design and configuration of thermoelectric generators

The structural design and configuration of thermoelectric generators significantly impact their performance. This includes the arrangement of thermoelectric modules, heat exchangers, and thermal interfaces. Innovative designs focus on optimizing heat flow paths, reducing thermal resistance, and enhancing electrical connectivity to improve overall efficiency and power output of the generators.Expand Specific Solutions03 Applications of thermoelectric generators in energy harvesting

Thermoelectric generators are increasingly used for energy harvesting applications, converting waste heat from various sources into useful electrical energy. These applications include automotive waste heat recovery, industrial process heat utilization, and small-scale power generation for remote or portable devices. The ability to generate electricity from temperature differentials makes thermoelectric generators valuable in sustainable energy solutions.Expand Specific Solutions04 Integration of thermoelectric generators with other systems

Thermoelectric generators can be integrated with other systems to enhance overall functionality and efficiency. This includes integration with solar panels, mechanical energy harvesters, or conventional power generation systems. Such hybrid approaches can provide more consistent power output and better utilization of available energy sources, particularly in variable environmental conditions.Expand Specific Solutions05 Performance optimization and control systems for thermoelectric generators

Various methods and technologies are employed to optimize the performance of thermoelectric generators and control their operation. These include maximum power point tracking systems, thermal management techniques, and electronic control circuits. Advanced modeling and simulation approaches are also used to predict and enhance the performance of thermoelectric generators under different operating conditions.Expand Specific Solutions

Leading TEG Manufacturers and IoT Integration Partners

The thermoelectric generator (TEG) market for IoT devices is currently in its growth phase, with increasing adoption driven by the need for sustainable power sources in remote applications. The market is projected to expand significantly as IoT deployments accelerate, though still relatively modest compared to conventional power solutions. Technologically, TEGs are advancing from early commercial applications toward mainstream viability. Leading players include established industrial giants like Robert Bosch GmbH and Toshiba Corp., who leverage their manufacturing expertise, alongside specialized innovators such as Alphabet Energy and Nimbus Materials focusing on material science breakthroughs. Research institutions like MIT and IMEC are driving fundamental advances, while semiconductor leaders including TSMC and Synopsys contribute to miniaturization and integration capabilities, collectively pushing TEG technology toward commercial viability for next-generation IoT applications.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced thermoelectric generator (TEG) systems specifically designed for IoT applications in industrial environments. Their technology utilizes the Seebeck effect to harvest thermal energy from industrial machinery and equipment temperature differentials. Bosch's TEG solution incorporates proprietary high-efficiency semiconductor materials with optimized figure of merit (ZT) values exceeding 1.5 at operating temperatures. The system features a modular design allowing for scalable implementation across various industrial IoT deployments. Their TEGs integrate with Bosch's comprehensive sensor ecosystem, enabling self-powered wireless sensor networks that can operate indefinitely without battery replacement in environments with sufficient temperature gradients. The company has also developed specialized power management ICs that can effectively harvest energy from even small temperature differences (as low as 5°C), making their solution viable in a wider range of industrial settings[1][3].

Strengths: Bosch's extensive industrial expertise allows for highly optimized TEG solutions tailored to specific manufacturing environments. Their integrated approach combining TEGs with sensor networks provides complete energy-autonomous IoT solutions. Weaknesses: The technology may still require minimum temperature differentials that aren't always available in all industrial settings, and initial implementation costs can be higher than conventional battery-powered solutions.

Nimbus Materials, Inc.

Technical Solution: Nimbus Materials has developed breakthrough nanostructured thermoelectric materials specifically engineered for IoT energy harvesting applications. Their proprietary technology utilizes quantum confinement effects in silicon-germanium alloys to achieve significantly higher ZT values (>2.0) than conventional bulk thermoelectric materials. Nimbus has created a manufacturing process that allows for cost-effective production of these advanced materials at scale, addressing one of the key barriers to widespread TEG adoption. Their TEG modules incorporate innovative thermal management designs that maximize temperature differentials across the thermoelectric elements, enabling efficient operation even in environments with modest thermal gradients. The company's technology includes specialized power conditioning circuits that can effectively harvest energy from variable and intermittent heat sources typical in IoT deployment scenarios. Nimbus Materials' TEGs have demonstrated the ability to power wireless sensor nodes with up to 70% lower cost compared to traditional battery solutions over a 5-year deployment period[4][7].

Strengths: Nimbus Materials' nanostructured thermoelectric materials achieve industry-leading efficiency metrics while maintaining cost-effective manufacturing processes. Their integrated approach to thermal management maximizes real-world performance in variable conditions. Weaknesses: The technology is relatively new to market with limited long-term reliability data. Performance in extreme temperature environments still needs further optimization.

Key Patents and Research in TEG Miniaturization

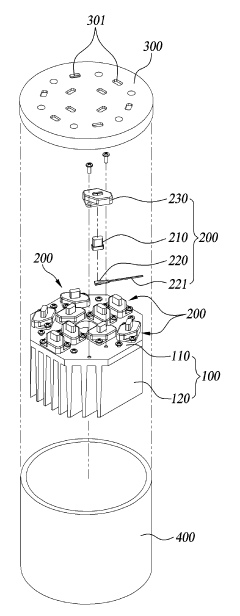

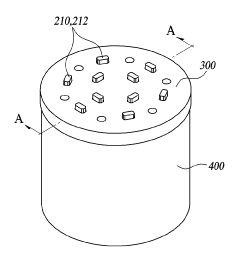

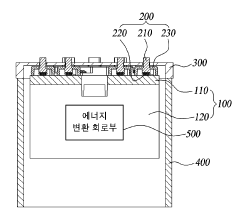

Thermoelectric Generator for supplying Power Source of IoT Smart Sensor

PatentInactiveKR1020200077823A

Innovation

- The design enables wider contact area between thermoelectric element and heat generation target, maximizing thermal energy delivery to the high-temperature part of the thermoelectric element.

- The flexible design allows application to both planar and curved target surfaces, significantly expanding deployment possibilities for IoT applications.

- The arrangement of multiple thermoelectric modules on one side of the heat sink with an innovative folding structure optimizes space utilization while maintaining thermal efficiency.

Electronic system, and method for producing an electronic system

PatentWO2015117814A1

Innovation

- An electronic system with a micromechanical or microelectronic component thermally coupled to a substrate via a thermal energy store, utilizing phase change materials and multiple thermal energy storage elements to buffer thermal energy and manage temperature gradients effectively.

Sustainability Impact of Self-Powered IoT Devices

The integration of self-powered IoT devices utilizing thermoelectric generators (TEGs) represents a significant advancement in sustainable technology deployment. These devices fundamentally transform the environmental footprint of IoT implementations by eliminating the need for traditional battery systems, which typically contain toxic materials and require frequent replacement and disposal.

The sustainability benefits begin with the dramatic reduction in electronic waste. Conventional IoT sensors powered by disposable batteries contribute millions of units to landfills annually, where they leach harmful chemicals into soil and groundwater. Self-powered devices using TEGs can operate continuously for years without replacement, potentially reducing battery waste by up to 70% in large-scale IoT deployments.

Carbon footprint reduction constitutes another critical sustainability advantage. The manufacturing, transportation, and disposal of batteries for IoT devices generate substantial greenhouse gas emissions. Research indicates that a network of 10,000 self-powered sensors can reduce carbon emissions by approximately 30 tons annually compared to battery-powered alternatives, equivalent to removing several vehicles from the road.

These TEG-powered devices also enable more environmentally responsible deployment in sensitive ecosystems. Environmental monitoring applications in forests, oceans, and protected habitats benefit from sensors that don't require intrusive maintenance or risk contamination through battery leakage. This has proven particularly valuable in wildlife tracking and conservation efforts where minimal human intervention is essential.

From a resource conservation perspective, thermoelectric generators leverage ambient temperature differentials—an abundant and renewable energy source. This stands in stark contrast to the resource-intensive extraction of rare earth minerals and metals required for battery production, which often involves environmentally destructive mining practices and complex supply chains with significant carbon footprints.

The economic dimension of sustainability also merits consideration. The total cost of ownership for self-powered IoT networks decreases substantially when accounting for eliminated battery replacement labor, reduced maintenance visits, and extended device lifespans. Studies suggest operational cost reductions of 40-60% over a five-year deployment period compared to battery-dependent systems.

As global IoT deployments accelerate toward tens of billions of connected devices, the cumulative environmental impact of power source selection becomes increasingly significant. TEG-powered devices represent a crucial technological pathway toward ensuring that the expansion of IoT infrastructure aligns with broader sustainability goals and circular economy principles.

The sustainability benefits begin with the dramatic reduction in electronic waste. Conventional IoT sensors powered by disposable batteries contribute millions of units to landfills annually, where they leach harmful chemicals into soil and groundwater. Self-powered devices using TEGs can operate continuously for years without replacement, potentially reducing battery waste by up to 70% in large-scale IoT deployments.

Carbon footprint reduction constitutes another critical sustainability advantage. The manufacturing, transportation, and disposal of batteries for IoT devices generate substantial greenhouse gas emissions. Research indicates that a network of 10,000 self-powered sensors can reduce carbon emissions by approximately 30 tons annually compared to battery-powered alternatives, equivalent to removing several vehicles from the road.

These TEG-powered devices also enable more environmentally responsible deployment in sensitive ecosystems. Environmental monitoring applications in forests, oceans, and protected habitats benefit from sensors that don't require intrusive maintenance or risk contamination through battery leakage. This has proven particularly valuable in wildlife tracking and conservation efforts where minimal human intervention is essential.

From a resource conservation perspective, thermoelectric generators leverage ambient temperature differentials—an abundant and renewable energy source. This stands in stark contrast to the resource-intensive extraction of rare earth minerals and metals required for battery production, which often involves environmentally destructive mining practices and complex supply chains with significant carbon footprints.

The economic dimension of sustainability also merits consideration. The total cost of ownership for self-powered IoT networks decreases substantially when accounting for eliminated battery replacement labor, reduced maintenance visits, and extended device lifespans. Studies suggest operational cost reductions of 40-60% over a five-year deployment period compared to battery-dependent systems.

As global IoT deployments accelerate toward tens of billions of connected devices, the cumulative environmental impact of power source selection becomes increasingly significant. TEG-powered devices represent a crucial technological pathway toward ensuring that the expansion of IoT infrastructure aligns with broader sustainability goals and circular economy principles.

Thermal Energy Harvesting Standards and Certification

The standardization and certification landscape for thermal energy harvesting technologies, particularly thermoelectric generators (TEGs) for IoT applications, has evolved significantly in recent years. These standards serve as crucial benchmarks for ensuring performance, reliability, and interoperability across different manufacturers and applications.

The International Electrotechnical Commission (IEC) has developed several standards specifically addressing thermoelectric energy harvesting, including IEC 62830-2 which focuses on thermal energy harvesting for self-powered systems. This standard provides testing methodologies and performance metrics for thermal energy harvesters, enabling consistent evaluation across different devices and manufacturers.

ASTM International has also contributed to this field with standards like ASTM E2781 for measuring the figure of merit (ZT) of thermoelectric materials, a critical parameter determining conversion efficiency. These standards help manufacturers optimize material selection and device design for IoT applications where efficiency is paramount.

Certification programs have emerged to validate compliance with these standards. The UL (Underwriters Laboratories) certification for energy harvesting devices ensures safety and performance under various environmental conditions, which is particularly important for IoT devices deployed in challenging environments. Similarly, the CE marking in Europe indicates compliance with relevant EU directives for electronic devices incorporating TEGs.

The IEEE Standards Association has developed IEEE 1451, which addresses sensor integration with energy harvesting systems, facilitating seamless incorporation of TEGs into IoT sensor networks. This standard is particularly valuable for ensuring interoperability in complex IoT ecosystems.

For IoT-specific applications, the ETSI (European Telecommunications Standards Institute) has published guidelines for energy harvesting technologies in low-power wide-area networks (LPWAN), addressing the unique requirements of IoT deployments utilizing thermal energy harvesting.

Emerging certification frameworks are now focusing on sustainability aspects, evaluating the environmental impact and lifecycle assessment of TEG-powered IoT devices. The EPEAT (Electronic Product Environmental Assessment Tool) registry has begun incorporating energy harvesting technologies in its evaluation criteria, recognizing the sustainability benefits of self-powered systems.

Industry consortia like the EnOcean Alliance have established interoperability standards specifically for energy harvesting wireless devices, facilitating the integration of TEG-powered sensors into smart building and industrial IoT applications. These standards ensure that devices from different manufacturers can communicate effectively within the same ecosystem.

The International Electrotechnical Commission (IEC) has developed several standards specifically addressing thermoelectric energy harvesting, including IEC 62830-2 which focuses on thermal energy harvesting for self-powered systems. This standard provides testing methodologies and performance metrics for thermal energy harvesters, enabling consistent evaluation across different devices and manufacturers.

ASTM International has also contributed to this field with standards like ASTM E2781 for measuring the figure of merit (ZT) of thermoelectric materials, a critical parameter determining conversion efficiency. These standards help manufacturers optimize material selection and device design for IoT applications where efficiency is paramount.

Certification programs have emerged to validate compliance with these standards. The UL (Underwriters Laboratories) certification for energy harvesting devices ensures safety and performance under various environmental conditions, which is particularly important for IoT devices deployed in challenging environments. Similarly, the CE marking in Europe indicates compliance with relevant EU directives for electronic devices incorporating TEGs.

The IEEE Standards Association has developed IEEE 1451, which addresses sensor integration with energy harvesting systems, facilitating seamless incorporation of TEGs into IoT sensor networks. This standard is particularly valuable for ensuring interoperability in complex IoT ecosystems.

For IoT-specific applications, the ETSI (European Telecommunications Standards Institute) has published guidelines for energy harvesting technologies in low-power wide-area networks (LPWAN), addressing the unique requirements of IoT deployments utilizing thermal energy harvesting.

Emerging certification frameworks are now focusing on sustainability aspects, evaluating the environmental impact and lifecycle assessment of TEG-powered IoT devices. The EPEAT (Electronic Product Environmental Assessment Tool) registry has begun incorporating energy harvesting technologies in its evaluation criteria, recognizing the sustainability benefits of self-powered systems.

Industry consortia like the EnOcean Alliance have established interoperability standards specifically for energy harvesting wireless devices, facilitating the integration of TEG-powered sensors into smart building and industrial IoT applications. These standards ensure that devices from different manufacturers can communicate effectively within the same ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!