Thermoelectric Generators In Advanced Medical Diagnostics Equipment

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Medical Diagnostics Background & Objectives

Thermoelectric Generators (TEGs) have emerged as a transformative technology in the medical diagnostics sector, leveraging the Seebeck effect to convert temperature differentials into electrical energy. The evolution of this technology dates back to the early 19th century with Thomas Johann Seebeck's discovery, but its application in medical diagnostics represents a relatively recent advancement that has gained significant momentum over the past decade.

The medical diagnostics industry has traditionally faced challenges related to power supply reliability, device portability, and operational longevity in remote settings. TEGs address these challenges by offering a sustainable power generation solution that harnesses the natural temperature gradient between the human body and the ambient environment, typically ranging from 1-5°C, which can generate sufficient power for low-energy diagnostic equipment.

Recent technological breakthroughs in thermoelectric materials, particularly the development of nanostructured bismuth telluride and skutterudite compounds, have substantially improved conversion efficiency from below 5% to approaching 15% in laboratory settings. This efficiency enhancement has catalyzed the integration of TEGs into various medical diagnostic platforms, including continuous glucose monitors, wearable ECG devices, and portable ultrasound systems.

The primary objective of implementing TEGs in advanced medical diagnostics equipment is to develop self-powered devices that eliminate dependency on conventional batteries, thereby extending operational lifespan and reducing maintenance requirements. This aligns with the broader healthcare trend toward decentralized diagnostics and point-of-care testing, which necessitates reliable power solutions in diverse environmental conditions.

Additionally, TEG technology aims to enable the next generation of implantable diagnostic devices by providing a biocompatible power source that utilizes the body's natural thermal energy. This could revolutionize continuous health monitoring for chronic conditions such as diabetes, cardiovascular diseases, and neurological disorders by allowing for real-time data collection without the need for external power sources or frequent battery replacements.

The convergence of TEG technology with miniaturized sensors, wireless communication protocols, and advanced data analytics presents an opportunity to create intelligent diagnostic ecosystems that can operate autonomously in resource-limited settings. This technological synergy supports global health initiatives aimed at improving diagnostic accessibility in underserved regions where conventional power infrastructure may be unreliable or nonexistent.

The medical diagnostics industry has traditionally faced challenges related to power supply reliability, device portability, and operational longevity in remote settings. TEGs address these challenges by offering a sustainable power generation solution that harnesses the natural temperature gradient between the human body and the ambient environment, typically ranging from 1-5°C, which can generate sufficient power for low-energy diagnostic equipment.

Recent technological breakthroughs in thermoelectric materials, particularly the development of nanostructured bismuth telluride and skutterudite compounds, have substantially improved conversion efficiency from below 5% to approaching 15% in laboratory settings. This efficiency enhancement has catalyzed the integration of TEGs into various medical diagnostic platforms, including continuous glucose monitors, wearable ECG devices, and portable ultrasound systems.

The primary objective of implementing TEGs in advanced medical diagnostics equipment is to develop self-powered devices that eliminate dependency on conventional batteries, thereby extending operational lifespan and reducing maintenance requirements. This aligns with the broader healthcare trend toward decentralized diagnostics and point-of-care testing, which necessitates reliable power solutions in diverse environmental conditions.

Additionally, TEG technology aims to enable the next generation of implantable diagnostic devices by providing a biocompatible power source that utilizes the body's natural thermal energy. This could revolutionize continuous health monitoring for chronic conditions such as diabetes, cardiovascular diseases, and neurological disorders by allowing for real-time data collection without the need for external power sources or frequent battery replacements.

The convergence of TEG technology with miniaturized sensors, wireless communication protocols, and advanced data analytics presents an opportunity to create intelligent diagnostic ecosystems that can operate autonomously in resource-limited settings. This technological synergy supports global health initiatives aimed at improving diagnostic accessibility in underserved regions where conventional power infrastructure may be unreliable or nonexistent.

Market Analysis for TEG-Powered Medical Devices

The global market for TEG-powered medical devices is experiencing significant growth, driven by increasing demand for portable and self-powered diagnostic equipment. Current market valuations indicate the thermoelectric generator segment in medical diagnostics reached approximately $218 million in 2022, with projections suggesting a compound annual growth rate of 7.8% through 2030. This growth trajectory is particularly pronounced in regions with expanding healthcare infrastructure, notably Asia-Pacific and parts of Latin America.

Market penetration analysis reveals that TEG technology has achieved strongest adoption in wearable health monitoring devices, capturing nearly 23% of the self-powered wearable medical device market. Point-of-care diagnostic equipment represents the second largest application segment, with implantable medical devices showing the fastest growth rate at 9.2% annually.

Consumer demand patterns demonstrate increasing preference for medical devices offering extended operational periods without recharging or battery replacement. A recent healthcare technology survey indicated that 68% of medical professionals consider power autonomy a critical factor when selecting diagnostic equipment for remote or field deployment. This preference is particularly strong in emergency medicine and rural healthcare settings.

Competitive landscape assessment identifies three distinct market segments: high-precision laboratory equipment, portable clinical devices, and consumer-grade health monitoring tools. The laboratory segment commands premium pricing but represents a smaller volume market, while consumer applications offer lower margins but substantially larger unit sales potential.

Regional market analysis shows North America currently leading in TEG medical device adoption with 42% market share, followed by Europe at 31% and Asia-Pacific at 19%. However, growth rates in emerging markets significantly outpace established regions, with India and China recording annual market expansion exceeding 12%.

Pricing trends indicate gradual cost reduction as manufacturing scales increase, with average unit costs decreasing 5.3% annually over the past three years. This trend is accelerating adoption in price-sensitive markets and expanding the potential application range. Market forecasts suggest the integration of TEG technology will expand beyond current applications into surgical equipment, patient monitoring systems, and advanced imaging devices by 2025.

Customer segmentation analysis reveals hospitals and large clinical facilities represent 47% of current purchasing volume, with individual practitioners and smaller clinics accounting for 29%, and direct consumer sales comprising the remaining 24%. Each segment demonstrates distinct purchasing criteria and price sensitivity profiles.

Market penetration analysis reveals that TEG technology has achieved strongest adoption in wearable health monitoring devices, capturing nearly 23% of the self-powered wearable medical device market. Point-of-care diagnostic equipment represents the second largest application segment, with implantable medical devices showing the fastest growth rate at 9.2% annually.

Consumer demand patterns demonstrate increasing preference for medical devices offering extended operational periods without recharging or battery replacement. A recent healthcare technology survey indicated that 68% of medical professionals consider power autonomy a critical factor when selecting diagnostic equipment for remote or field deployment. This preference is particularly strong in emergency medicine and rural healthcare settings.

Competitive landscape assessment identifies three distinct market segments: high-precision laboratory equipment, portable clinical devices, and consumer-grade health monitoring tools. The laboratory segment commands premium pricing but represents a smaller volume market, while consumer applications offer lower margins but substantially larger unit sales potential.

Regional market analysis shows North America currently leading in TEG medical device adoption with 42% market share, followed by Europe at 31% and Asia-Pacific at 19%. However, growth rates in emerging markets significantly outpace established regions, with India and China recording annual market expansion exceeding 12%.

Pricing trends indicate gradual cost reduction as manufacturing scales increase, with average unit costs decreasing 5.3% annually over the past three years. This trend is accelerating adoption in price-sensitive markets and expanding the potential application range. Market forecasts suggest the integration of TEG technology will expand beyond current applications into surgical equipment, patient monitoring systems, and advanced imaging devices by 2025.

Customer segmentation analysis reveals hospitals and large clinical facilities represent 47% of current purchasing volume, with individual practitioners and smaller clinics accounting for 29%, and direct consumer sales comprising the remaining 24%. Each segment demonstrates distinct purchasing criteria and price sensitivity profiles.

Current TEG Technology Challenges in Healthcare

Despite significant advancements in thermoelectric generator (TEG) technology, several critical challenges persist in healthcare applications, particularly for advanced medical diagnostics equipment. The primary limitation remains the relatively low conversion efficiency of current TEG systems, typically ranging between 5-8% in medical settings. This efficiency constraint significantly impacts the power generation capacity needed for sophisticated diagnostic equipment that requires stable and continuous energy supply.

Material limitations present another substantial hurdle. Conventional TEG materials like bismuth telluride (Bi2Te3) contain toxic elements that raise biocompatibility concerns in medical environments. Additionally, these materials often demonstrate performance degradation when subjected to sterilization processes necessary for medical equipment, compromising their long-term reliability in clinical settings.

Thermal management represents a complex challenge unique to medical applications. The human body's natural temperature regulation mechanisms actively work against maintaining the temperature differential required for optimal TEG operation. This physiological reality significantly restricts the potential power output when TEGs are deployed in or on the body for diagnostic purposes.

Size and form factor constraints further complicate TEG integration into medical diagnostic devices. Modern medical equipment increasingly demands miniaturization while maintaining functionality, creating a difficult engineering balance between power generation capacity and device dimensions. Current TEG technologies struggle to deliver sufficient power density within the strict spatial limitations of advanced diagnostic tools.

Cost factors remain prohibitive for widespread adoption. The specialized materials and precision manufacturing processes required for medical-grade TEGs contribute to high production expenses that can range from $50-200 per watt of generating capacity, significantly exceeding alternative power solutions.

Regulatory hurdles present non-technical but equally important challenges. Medical TEG applications must navigate complex approval processes from organizations like the FDA, requiring extensive documentation of safety, reliability, and performance consistency. The lengthy certification timeline often conflicts with the rapid innovation cycles in medical technology development.

Integration complexity with existing medical systems poses additional difficulties. TEGs must interface seamlessly with sensitive diagnostic equipment without introducing electromagnetic interference or compromising measurement accuracy, requiring sophisticated power conditioning circuits that add complexity and potential points of failure.

Material limitations present another substantial hurdle. Conventional TEG materials like bismuth telluride (Bi2Te3) contain toxic elements that raise biocompatibility concerns in medical environments. Additionally, these materials often demonstrate performance degradation when subjected to sterilization processes necessary for medical equipment, compromising their long-term reliability in clinical settings.

Thermal management represents a complex challenge unique to medical applications. The human body's natural temperature regulation mechanisms actively work against maintaining the temperature differential required for optimal TEG operation. This physiological reality significantly restricts the potential power output when TEGs are deployed in or on the body for diagnostic purposes.

Size and form factor constraints further complicate TEG integration into medical diagnostic devices. Modern medical equipment increasingly demands miniaturization while maintaining functionality, creating a difficult engineering balance between power generation capacity and device dimensions. Current TEG technologies struggle to deliver sufficient power density within the strict spatial limitations of advanced diagnostic tools.

Cost factors remain prohibitive for widespread adoption. The specialized materials and precision manufacturing processes required for medical-grade TEGs contribute to high production expenses that can range from $50-200 per watt of generating capacity, significantly exceeding alternative power solutions.

Regulatory hurdles present non-technical but equally important challenges. Medical TEG applications must navigate complex approval processes from organizations like the FDA, requiring extensive documentation of safety, reliability, and performance consistency. The lengthy certification timeline often conflicts with the rapid innovation cycles in medical technology development.

Integration complexity with existing medical systems poses additional difficulties. TEGs must interface seamlessly with sensitive diagnostic equipment without introducing electromagnetic interference or compromising measurement accuracy, requiring sophisticated power conditioning circuits that add complexity and potential points of failure.

Current TEG Implementation in Diagnostic Equipment

01 Materials and structures for thermoelectric generators

Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and novel junction configurations that improve the Seebeck effect. Advanced material compositions and structural arrangements help optimize the temperature gradient across the device, resulting in more efficient conversion of heat into electrical energy.- Materials and structures for thermoelectric generators: Various materials and structural designs are used to enhance the efficiency of thermoelectric generators. These include specialized semiconductor materials, nanostructured elements, and composite materials that improve the Seebeck coefficient while reducing thermal conductivity. Advanced structural designs incorporate multiple layers or segmented elements to optimize performance across different temperature gradients, maximizing power output from temperature differentials.

- Waste heat recovery applications: Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Applications include exhaust systems in vehicles, industrial processes, and power plants where significant temperature differentials exist, contributing to improved overall energy efficiency and reduced environmental impact.

- Wearable and portable thermoelectric devices: Miniaturized thermoelectric generators are being developed for wearable and portable applications. These devices harvest body heat or environmental temperature differences to power small electronic devices such as sensors, medical implants, and wearable technology. The designs focus on flexibility, lightweight materials, and integration with textiles or other substrates to enable comfortable wearability while maintaining sufficient power generation.

- Optimization and modeling techniques: Advanced computational methods and modeling techniques are employed to optimize thermoelectric generator designs. These include finite element analysis, machine learning algorithms, and simulation tools that predict performance under various operating conditions. Such techniques help engineers identify optimal material combinations, geometric configurations, and operating parameters to maximize conversion efficiency and power output before physical prototyping.

- Novel junction and interface designs: Innovative junction and interface designs are being developed to enhance thermoelectric performance. These include specialized electrical contacts, thermal interface materials, and junction geometries that minimize contact resistance and maximize temperature differentials across the thermoelectric elements. Some designs incorporate segmented or cascaded junctions to optimize performance across broader temperature ranges, while others focus on reducing parasitic heat losses at interfaces.

02 Waste heat recovery applications

Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. The technology is particularly valuable in manufacturing processes, power plants, and vehicle exhaust systems where significant heat is generated as a byproduct of operation.Expand Specific Solutions03 Portable and wearable thermoelectric power generation

Miniaturized thermoelectric generators are being developed for portable and wearable applications. These compact devices harvest body heat or environmental temperature differences to power small electronics, medical devices, and sensors. The technology enables self-powered wearable systems that eliminate the need for battery replacement, making them particularly useful for health monitoring and Internet of Things applications.Expand Specific Solutions04 Efficiency enhancement techniques

Various techniques are employed to enhance the efficiency of thermoelectric generators. These include segmented leg designs, cascaded structures, and thermal concentration methods that maximize the temperature differential across the device. Advanced manufacturing processes and novel junction designs help reduce internal resistance and thermal losses, significantly improving conversion efficiency and power output.Expand Specific Solutions05 Integration with renewable energy systems

Thermoelectric generators are increasingly integrated with other renewable energy systems to create hybrid power generation solutions. These combined systems leverage multiple energy sources such as solar, geothermal, or biomass heat to enhance overall efficiency and reliability. The integration allows for more consistent power generation across varying environmental conditions and times of day.Expand Specific Solutions

Key Industry Players in Medical TEG Development

The thermoelectric generator (TEG) market in advanced medical diagnostics is currently in its growth phase, with increasing adoption driven by demands for portable and self-powered medical devices. The global market is projected to expand significantly as healthcare facilities seek energy-efficient solutions. Technologically, the field shows varying maturity levels across companies. Industry leaders like Gentherm and KELK Ltd. have established specialized TEG technologies, while diversified corporations such as Toyota, Sony, and Toshiba are leveraging their semiconductor expertise to develop medical-grade thermoelectric solutions. Research institutions including California Institute of Technology and Interuniversitair Micro-Electronica Centrum are advancing fundamental technologies, while medical-focused entities like Covidien and NovoCure are exploring specific diagnostic applications, indicating a competitive landscape with multiple entry points.

Stichting IMEC Nederland

Technical Solution: IMEC has developed ultra-thin flexible thermoelectric generator technology specifically designed for integration into advanced medical wearables and diagnostic equipment. Their proprietary manufacturing process creates TEG modules as thin as 100 micrometers using MEMS fabrication techniques compatible with standard semiconductor processing. These modules utilize advanced silicon-germanium alloys and nano-structured bismuth telluride with precisely controlled doping profiles to optimize performance at near-body temperatures. IMEC's flexible TEG technology incorporates specialized thermal interface materials and microchannel heat spreaders that maximize thermal gradient utilization in constrained medical device form factors. Their modules achieve power densities up to 30μW/cm² at temperature differentials as low as 5°C, sufficient for powering low-energy biosensors and wireless data transmission circuits in continuous health monitoring applications. The technology includes integrated power management circuitry that optimizes energy harvesting across varying thermal conditions, enabling extended operation of diagnostic equipment without battery replacement.

Strengths: Industry-leading thinness and flexibility ideal for wearable diagnostic applications; seamless integration with existing semiconductor manufacturing processes; excellent performance at low temperature differentials typical in medical environments; compatible with mass production techniques. Weaknesses: Lower absolute power output compared to rigid TEG alternatives; requires specialized packaging to maintain long-term reliability in biological environments; higher initial cost compared to conventional power solutions; performance sensitive to thermal interface quality.

KELK Ltd.

Technical Solution: KELK Ltd. has developed advanced Bismuth Telluride-based thermoelectric generators (TEGs) specifically optimized for medical diagnostic equipment. Their proprietary manufacturing process creates highly efficient modules with ZT values exceeding 1.0 at room temperature, allowing for precise temperature control in sensitive diagnostic instruments. KELK's medical-grade TEGs feature ultra-thin form factors (as thin as 1.5mm) with power densities up to 1W/cm² while maintaining biocompatibility standards required for medical applications. Their technology enables both cooling and power generation capabilities, allowing diagnostic equipment to maintain precise temperatures for reagents and samples while simultaneously harvesting waste heat to extend battery life of portable devices. KELK's modules incorporate specialized ceramic substrates that provide electrical isolation while maximizing thermal conductivity, essential for applications where patient safety is paramount.

Strengths: Industry-leading efficiency in room-temperature applications; medical-grade biocompatible materials; dual-function capability (cooling and power generation); ultra-thin form factors ideal for space-constrained medical devices. Weaknesses: Higher cost compared to conventional cooling solutions; limited high-temperature performance; requires specialized integration expertise; thermal cycling can affect long-term reliability.

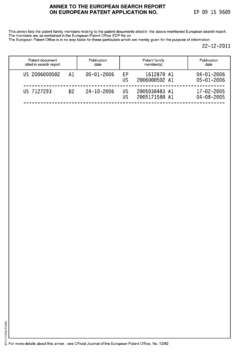

Critical Patents in Medical Thermoelectric Generation

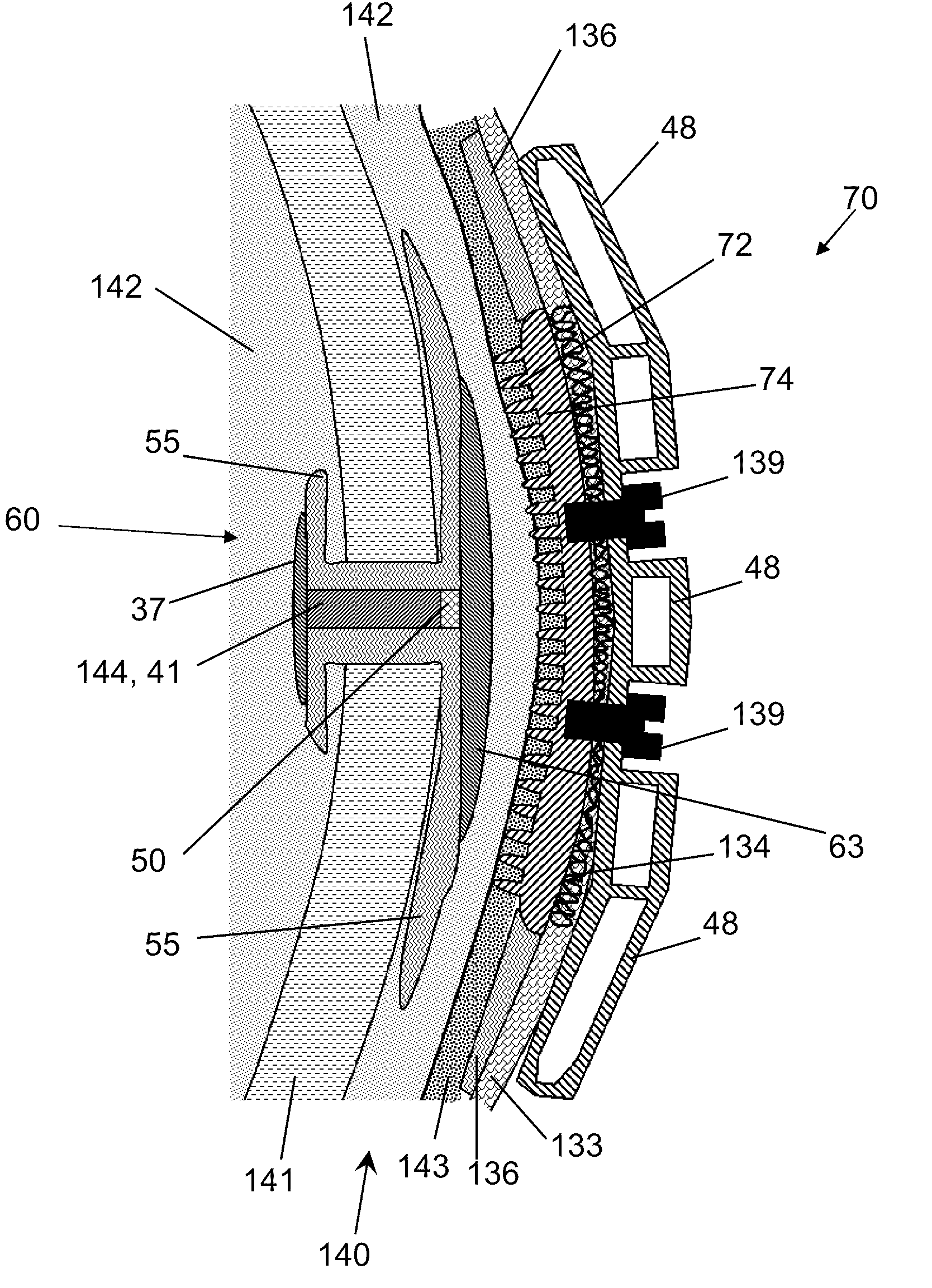

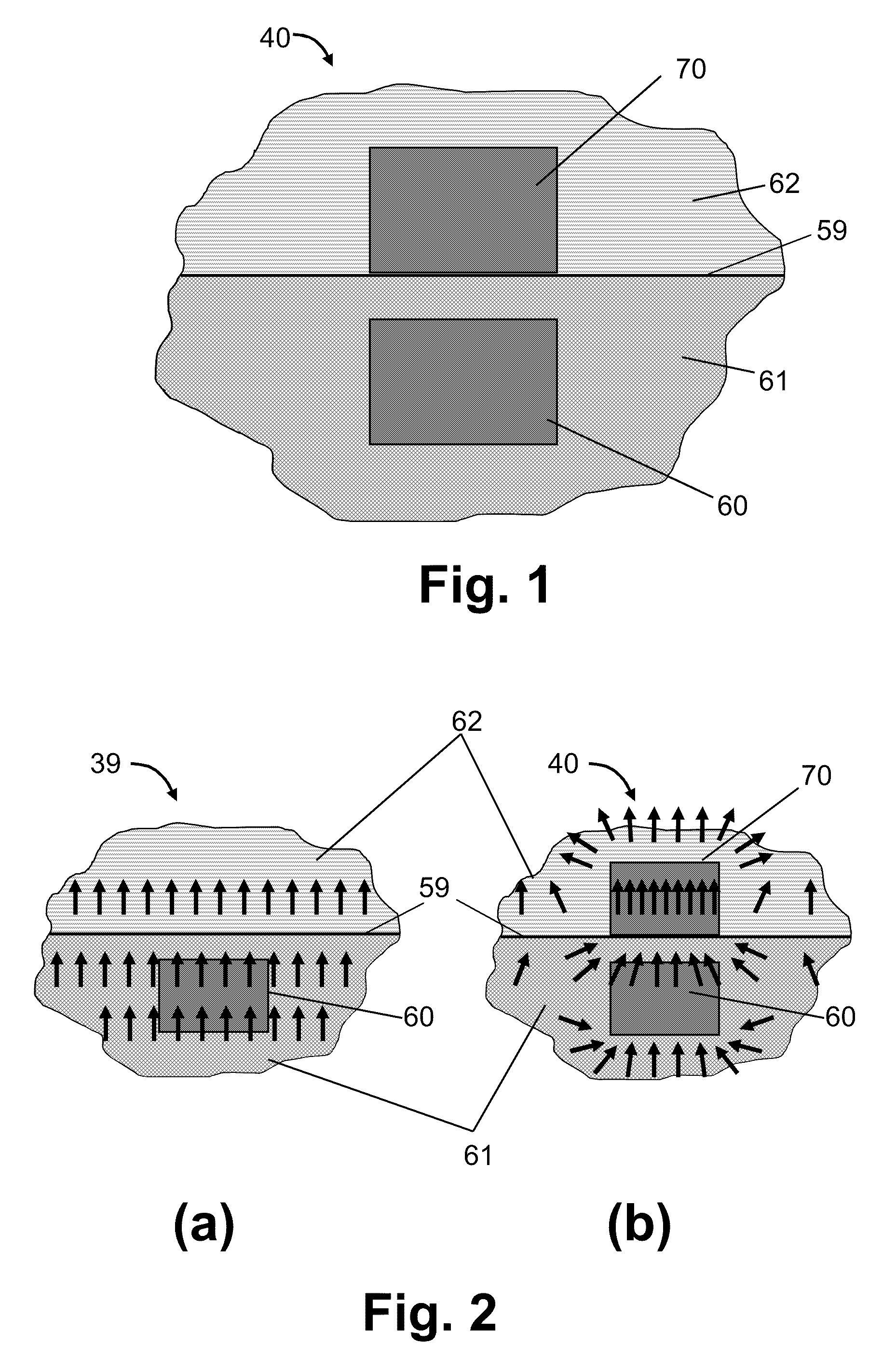

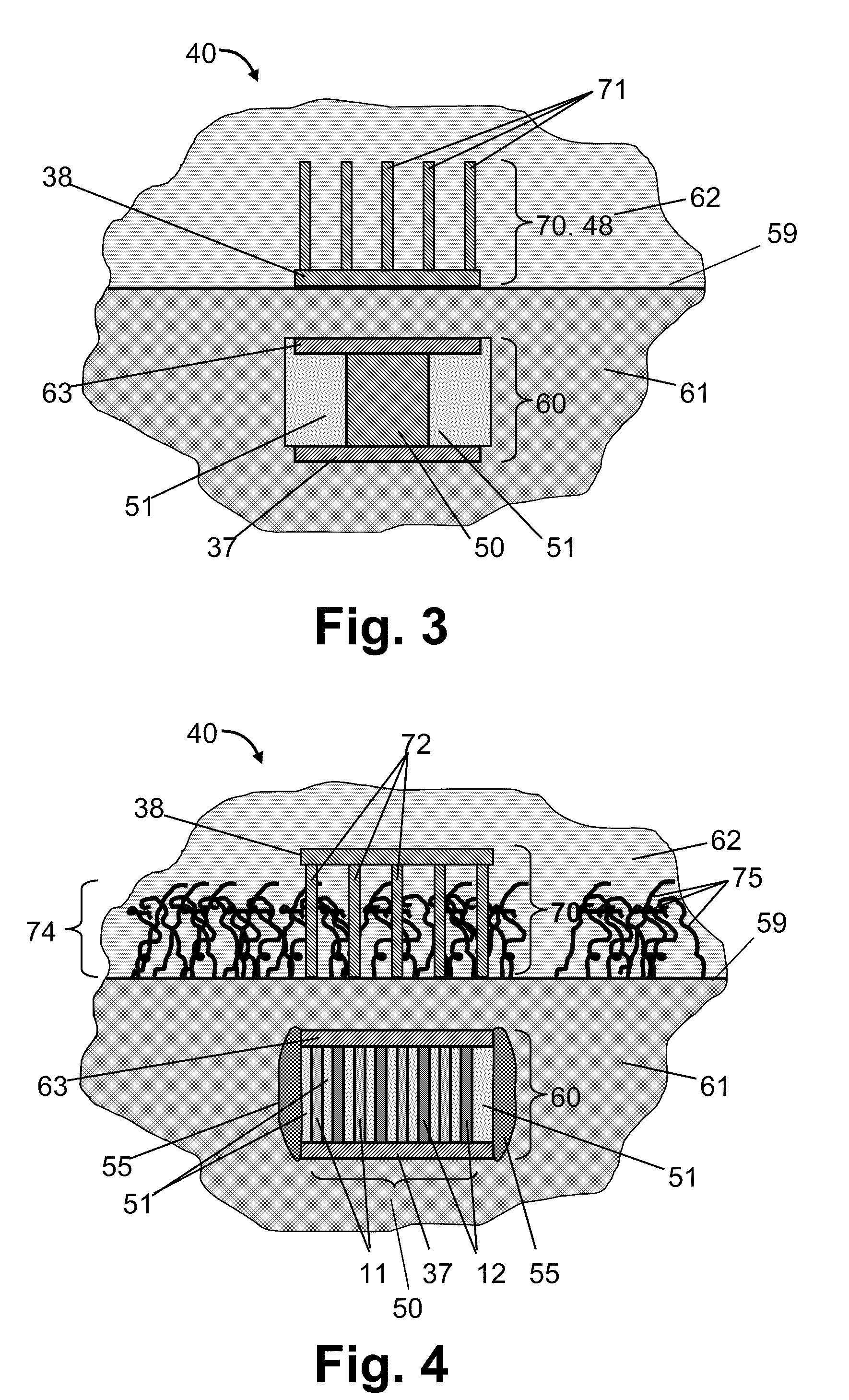

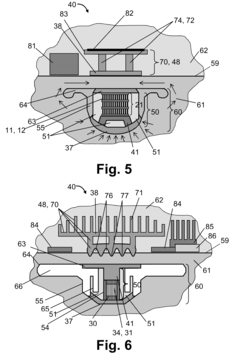

Thermoelectric Generator for Implants and Embedded Devices

PatentInactiveUS20090292335A1

Innovation

- A thermoelectric generator system comprising an implantable unit and a wearable or external unit, thermally connected to enhance heat flow efficiency, utilizing larger thermally conductive and insulating elements to redirect and increase heat flow through the thermopile unit, thereby increasing power generation.

Thermoelectric generator for implants and embedded devices

PatentInactiveEP2124267A3

Innovation

- A thermoelectric generator system comprising an implantable unit and a wearable or external unit, thermally connected to enhance heat flow and increase temperature differences, utilizing larger thermal matching plates, cold plates, and radiators to redirect and improve heat flow through the thermopile unit.

Regulatory Framework for TEG Medical Applications

The regulatory landscape for Thermoelectric Generators (TEGs) in medical applications presents a complex framework that manufacturers and developers must navigate carefully. In the United States, the Food and Drug Administration (FDA) classifies TEG-based medical diagnostic equipment primarily under Class II medical devices, requiring premarket notification (510(k)) submissions that demonstrate substantial equivalence to legally marketed devices. For novel TEG applications without predicates, a De Novo classification request or Premarket Approval (PMA) may be necessary, significantly extending the regulatory timeline.

The European Union's regulatory approach centers on the Medical Device Regulation (MDR 2017/745), which replaced the previous Medical Device Directive in 2021. TEG-based diagnostic equipment typically falls under Class IIa or IIb, depending on the intended use and invasiveness. Manufacturers must demonstrate compliance with General Safety and Performance Requirements (GSPRs) and implement a comprehensive Quality Management System (QMS) according to ISO 13485 standards.

International Electrotechnical Commission (IEC) standards play a crucial role in TEG medical applications, particularly IEC 60601-1 for electrical medical equipment safety and IEC 60601-1-2 for electromagnetic compatibility. Additionally, ISO 14971 for risk management and ISO 10993 series for biocompatibility assessment are mandatory for devices with patient contact.

Thermal safety regulations present unique challenges for TEG applications, as these devices inherently operate on temperature differentials. Standards limiting maximum surface temperatures (typically 41°C for long-term patient contact) must be addressed through careful thermal management design. Power generation aspects of TEGs also necessitate compliance with electrical safety standards, including leakage current limitations and electrical isolation requirements.

Environmental considerations have gained regulatory significance, with the EU's Restriction of Hazardous Substances (RoHS) Directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations affecting material selection for TEGs. Many traditional thermoelectric materials contain bismuth telluride and other substances that require careful environmental impact assessment.

Emerging regulatory trends indicate a shift toward more stringent post-market surveillance requirements, with both the FDA and EU MDR emphasizing continuous monitoring of device performance and safety. The unique power generation capabilities of TEGs also intersect with cybersecurity regulations when integrated with connected diagnostic equipment, requiring compliance with frameworks like the FDA's Cybersecurity in Medical Devices guidance and the EU's Network and Information Systems (NIS) Directive.

The European Union's regulatory approach centers on the Medical Device Regulation (MDR 2017/745), which replaced the previous Medical Device Directive in 2021. TEG-based diagnostic equipment typically falls under Class IIa or IIb, depending on the intended use and invasiveness. Manufacturers must demonstrate compliance with General Safety and Performance Requirements (GSPRs) and implement a comprehensive Quality Management System (QMS) according to ISO 13485 standards.

International Electrotechnical Commission (IEC) standards play a crucial role in TEG medical applications, particularly IEC 60601-1 for electrical medical equipment safety and IEC 60601-1-2 for electromagnetic compatibility. Additionally, ISO 14971 for risk management and ISO 10993 series for biocompatibility assessment are mandatory for devices with patient contact.

Thermal safety regulations present unique challenges for TEG applications, as these devices inherently operate on temperature differentials. Standards limiting maximum surface temperatures (typically 41°C for long-term patient contact) must be addressed through careful thermal management design. Power generation aspects of TEGs also necessitate compliance with electrical safety standards, including leakage current limitations and electrical isolation requirements.

Environmental considerations have gained regulatory significance, with the EU's Restriction of Hazardous Substances (RoHS) Directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations affecting material selection for TEGs. Many traditional thermoelectric materials contain bismuth telluride and other substances that require careful environmental impact assessment.

Emerging regulatory trends indicate a shift toward more stringent post-market surveillance requirements, with both the FDA and EU MDR emphasizing continuous monitoring of device performance and safety. The unique power generation capabilities of TEGs also intersect with cybersecurity regulations when integrated with connected diagnostic equipment, requiring compliance with frameworks like the FDA's Cybersecurity in Medical Devices guidance and the EU's Network and Information Systems (NIS) Directive.

Energy Efficiency & Sustainability Considerations

The integration of Thermoelectric Generators (TEGs) in advanced medical diagnostics equipment presents significant opportunities for enhancing energy efficiency and sustainability in healthcare settings. TEGs offer a unique advantage by converting waste heat from diagnostic equipment into usable electricity, creating a closed-loop energy system that reduces overall power consumption. This energy recovery mechanism can decrease the carbon footprint of medical facilities while extending the operational duration of portable diagnostic devices.

Current implementations demonstrate that TEGs can recover between 5-15% of waste heat energy from medical diagnostic equipment, depending on the temperature differential and generator efficiency. When deployed in imaging systems such as MRI machines, which generate substantial heat during operation, TEGs can recapture energy that would otherwise require additional cooling systems to dissipate, thus providing dual efficiency benefits.

The materials used in modern TEGs are increasingly being developed with sustainability in mind. Traditional thermoelectric materials containing lead, tellurium, and other rare or toxic elements are gradually being replaced by more abundant and environmentally friendly alternatives. Research into organic thermoelectric materials and silicon-based compounds shows promising results for creating more sustainable TEG solutions specifically tailored for medical applications.

Life cycle assessment studies indicate that the environmental impact of incorporating TEGs into medical diagnostic equipment is offset within 2-3 years of operation through energy savings. The extended lifespan of equipment batteries and reduced grid electricity consumption contribute significantly to this positive environmental balance. Furthermore, the modular nature of TEG systems allows for easier maintenance and component replacement, reducing electronic waste.

For portable diagnostic devices deployed in remote or resource-limited settings, TEGs offer critical sustainability advantages. By harvesting body heat or ambient temperature differentials, these generators can extend device operation without requiring frequent battery replacements or access to electrical infrastructure. This capability is particularly valuable in developing regions where healthcare sustainability intersects with accessibility concerns.

Looking forward, the integration of TEGs with other renewable energy technologies presents opportunities for creating nearly self-sufficient medical diagnostic systems. Combined approaches utilizing solar photovoltaics for daytime operation and TEGs for continuous energy harvesting could dramatically reduce the energy dependency of next-generation medical equipment, aligning with global healthcare sustainability goals and carbon reduction targets.

Current implementations demonstrate that TEGs can recover between 5-15% of waste heat energy from medical diagnostic equipment, depending on the temperature differential and generator efficiency. When deployed in imaging systems such as MRI machines, which generate substantial heat during operation, TEGs can recapture energy that would otherwise require additional cooling systems to dissipate, thus providing dual efficiency benefits.

The materials used in modern TEGs are increasingly being developed with sustainability in mind. Traditional thermoelectric materials containing lead, tellurium, and other rare or toxic elements are gradually being replaced by more abundant and environmentally friendly alternatives. Research into organic thermoelectric materials and silicon-based compounds shows promising results for creating more sustainable TEG solutions specifically tailored for medical applications.

Life cycle assessment studies indicate that the environmental impact of incorporating TEGs into medical diagnostic equipment is offset within 2-3 years of operation through energy savings. The extended lifespan of equipment batteries and reduced grid electricity consumption contribute significantly to this positive environmental balance. Furthermore, the modular nature of TEG systems allows for easier maintenance and component replacement, reducing electronic waste.

For portable diagnostic devices deployed in remote or resource-limited settings, TEGs offer critical sustainability advantages. By harvesting body heat or ambient temperature differentials, these generators can extend device operation without requiring frequent battery replacements or access to electrical infrastructure. This capability is particularly valuable in developing regions where healthcare sustainability intersects with accessibility concerns.

Looking forward, the integration of TEGs with other renewable energy technologies presents opportunities for creating nearly self-sufficient medical diagnostic systems. Combined approaches utilizing solar photovoltaics for daytime operation and TEGs for continuous energy harvesting could dramatically reduce the energy dependency of next-generation medical equipment, aligning with global healthcare sustainability goals and carbon reduction targets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!