Thermoelectric Generators For Remote Communication Stations

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Technology Background and Objectives

Thermoelectric generators (TEGs) represent a mature yet continuously evolving technology that converts temperature differentials directly into electrical energy through the Seebeck effect. This phenomenon, discovered in the early 19th century by Thomas Johann Seebeck, has evolved from a scientific curiosity into a practical power generation solution for specialized applications. The historical trajectory of TEG development has been characterized by incremental improvements in efficiency, materials science advancements, and expanding application scenarios.

Remote communication stations, particularly those deployed in isolated or harsh environments, present unique power challenges that conventional solutions struggle to address. These stations require reliable, low-maintenance power sources capable of operating continuously for extended periods without human intervention. Traditional power solutions such as diesel generators demand regular maintenance and refueling, while solar panels suffer from intermittency and weather dependence.

The technological evolution of TEGs has accelerated significantly in the past decade, driven by innovations in thermoelectric materials, module design, and system integration. Contemporary research focuses on improving conversion efficiency beyond the historical 5-8% range, with some laboratory prototypes demonstrating efficiencies approaching 15%. This progress stems from breakthroughs in nanostructured materials, quantum well structures, and advanced manufacturing techniques.

Current technological objectives for TEG implementation in remote communication stations center on four key parameters: efficiency improvement, cost reduction, durability enhancement, and system integration optimization. Efficiency remains the primary challenge, as higher conversion rates directly translate to smaller, more economical systems. Cost considerations are equally critical, as TEG solutions must compete economically with alternative power sources to achieve widespread adoption.

The global push toward sustainable energy solutions has positioned TEGs as an increasingly attractive option for specialized applications. Their ability to harvest waste heat or utilize natural temperature gradients aligns perfectly with sustainability objectives. Furthermore, the absence of moving parts in TEG systems translates to exceptional reliability and minimal maintenance requirements—characteristics particularly valuable for remote installations.

Looking forward, the technological roadmap for TEGs in communication applications aims to achieve conversion efficiencies exceeding 20%, cost reductions of 30-50% through mass production and material innovations, and operational lifespans of 15+ years without significant performance degradation. These ambitious yet achievable targets would position TEGs as the preferred power solution for remote communication infrastructure in challenging environments.

Remote communication stations, particularly those deployed in isolated or harsh environments, present unique power challenges that conventional solutions struggle to address. These stations require reliable, low-maintenance power sources capable of operating continuously for extended periods without human intervention. Traditional power solutions such as diesel generators demand regular maintenance and refueling, while solar panels suffer from intermittency and weather dependence.

The technological evolution of TEGs has accelerated significantly in the past decade, driven by innovations in thermoelectric materials, module design, and system integration. Contemporary research focuses on improving conversion efficiency beyond the historical 5-8% range, with some laboratory prototypes demonstrating efficiencies approaching 15%. This progress stems from breakthroughs in nanostructured materials, quantum well structures, and advanced manufacturing techniques.

Current technological objectives for TEG implementation in remote communication stations center on four key parameters: efficiency improvement, cost reduction, durability enhancement, and system integration optimization. Efficiency remains the primary challenge, as higher conversion rates directly translate to smaller, more economical systems. Cost considerations are equally critical, as TEG solutions must compete economically with alternative power sources to achieve widespread adoption.

The global push toward sustainable energy solutions has positioned TEGs as an increasingly attractive option for specialized applications. Their ability to harvest waste heat or utilize natural temperature gradients aligns perfectly with sustainability objectives. Furthermore, the absence of moving parts in TEG systems translates to exceptional reliability and minimal maintenance requirements—characteristics particularly valuable for remote installations.

Looking forward, the technological roadmap for TEGs in communication applications aims to achieve conversion efficiencies exceeding 20%, cost reductions of 30-50% through mass production and material innovations, and operational lifespans of 15+ years without significant performance degradation. These ambitious yet achievable targets would position TEGs as the preferred power solution for remote communication infrastructure in challenging environments.

Market Analysis for Remote Power Solutions

The global market for remote power solutions is experiencing significant growth, driven by the expansion of telecommunications infrastructure in remote and off-grid locations. The current market size for remote power solutions is estimated at $15.7 billion as of 2023, with projections indicating a compound annual growth rate of 6.8% through 2030. Thermoelectric generators (TEGs) currently occupy approximately 12% of this market, competing with solar, wind, fuel cells, and traditional diesel generators.

Remote communication stations, particularly those deployed in challenging environments such as mountainous regions, deserts, and arctic zones, represent a substantial segment of demand. These installations require reliable, low-maintenance power sources that can operate continuously regardless of weather conditions or accessibility issues. The telecommunications sector accounts for 37% of the total remote power solutions market, followed by oil and gas (22%), military applications (18%), environmental monitoring (14%), and other sectors (9%).

Customer requirements in this space prioritize reliability, with 94% of surveyed operators citing uninterrupted operation as their primary concern. Maintenance intervals rank second (87%), followed by total cost of ownership (83%), initial capital expenditure (76%), and environmental impact (68%). These priorities create a favorable landscape for TEG solutions, which excel in reliability and maintenance metrics.

Regional analysis reveals varying adoption patterns, with North America leading in TEG implementation for remote communications (38% market share), followed by Asia-Pacific (27%), Europe (21%), and other regions (14%). The Asia-Pacific region demonstrates the highest growth potential, with an anticipated 9.3% annual growth rate for remote power solutions through 2030, driven by rapid expansion of cellular networks in developing economies.

Price sensitivity varies significantly by region and application. In developed markets, the average acceptable price premium for high-reliability power solutions is 30-35% above baseline options, while developing markets typically cap this premium at 15-20%. This creates distinct market segments requiring tailored TEG offerings with different price-performance ratios.

The competitive landscape features both established power solution providers expanding into TEGs and specialized thermoelectric technology companies. Major telecommunications infrastructure providers increasingly seek integrated solutions, creating partnership opportunities for TEG manufacturers who can provide customized, turnkey systems rather than component-level products.

Remote communication stations, particularly those deployed in challenging environments such as mountainous regions, deserts, and arctic zones, represent a substantial segment of demand. These installations require reliable, low-maintenance power sources that can operate continuously regardless of weather conditions or accessibility issues. The telecommunications sector accounts for 37% of the total remote power solutions market, followed by oil and gas (22%), military applications (18%), environmental monitoring (14%), and other sectors (9%).

Customer requirements in this space prioritize reliability, with 94% of surveyed operators citing uninterrupted operation as their primary concern. Maintenance intervals rank second (87%), followed by total cost of ownership (83%), initial capital expenditure (76%), and environmental impact (68%). These priorities create a favorable landscape for TEG solutions, which excel in reliability and maintenance metrics.

Regional analysis reveals varying adoption patterns, with North America leading in TEG implementation for remote communications (38% market share), followed by Asia-Pacific (27%), Europe (21%), and other regions (14%). The Asia-Pacific region demonstrates the highest growth potential, with an anticipated 9.3% annual growth rate for remote power solutions through 2030, driven by rapid expansion of cellular networks in developing economies.

Price sensitivity varies significantly by region and application. In developed markets, the average acceptable price premium for high-reliability power solutions is 30-35% above baseline options, while developing markets typically cap this premium at 15-20%. This creates distinct market segments requiring tailored TEG offerings with different price-performance ratios.

The competitive landscape features both established power solution providers expanding into TEGs and specialized thermoelectric technology companies. Major telecommunications infrastructure providers increasingly seek integrated solutions, creating partnership opportunities for TEG manufacturers who can provide customized, turnkey systems rather than component-level products.

Current TEG Challenges in Remote Stations

Thermoelectric Generators (TEGs) deployed in remote communication stations face several significant challenges that limit their widespread adoption and operational efficiency. The primary obstacle remains the relatively low conversion efficiency, typically ranging between 3-8% in commercial systems. This inefficiency necessitates larger generator sizes and heat sources to produce adequate power for modern communication equipment, creating a fundamental design constraint for remote installations.

Material limitations present another critical challenge. Current TEG systems rely heavily on bismuth telluride (Bi2Te3) for near-ambient temperature applications, but this material contains tellurium, which is scarce and expensive. Alternative materials with better temperature stability and thermal cycling resistance are needed, especially for stations experiencing extreme temperature fluctuations in desert, arctic, or high-altitude environments.

Thermal management represents a persistent engineering challenge in TEG implementation. The efficiency of these systems depends on maintaining substantial temperature differentials across the thermoelectric modules. In remote locations, natural cooling methods must be optimized as active cooling systems would consume the limited power being generated. Heat dissipation becomes particularly problematic in enclosed spaces or during periods of low wind or high ambient temperatures.

Durability and reliability concerns are magnified in remote installations where maintenance visits are infrequent and costly. TEG systems must withstand thermal cycling, mechanical vibration, moisture ingress, and corrosive environments for extended periods without performance degradation. Current systems often show declining output over time, with some field deployments reporting up to 20% reduction in power generation capacity after just two years of operation.

Cost factors remain prohibitive for widespread deployment. The high initial capital expenditure for TEG systems (approximately $20-40 per watt of generating capacity) makes them economically viable only in locations where grid connection or regular fuel delivery for conventional generators would be extraordinarily expensive. This economic barrier limits adoption despite the operational benefits of fuel-free power generation.

Integration challenges with existing communication infrastructure further complicate implementation. TEG systems produce DC power with variable output depending on temperature conditions, requiring sophisticated power conditioning electronics to provide stable power suitable for sensitive communication equipment. These additional components increase system complexity, cost, and potential points of failure.

Lastly, the power density limitations of current TEG technology restrict the applications in modern communication stations, which increasingly demand higher power for advanced data transmission capabilities. While TEGs excel at providing consistent low-level power for basic monitoring and transmission functions, they struggle to support the full operational requirements of next-generation communication equipment without significant scaling.

Material limitations present another critical challenge. Current TEG systems rely heavily on bismuth telluride (Bi2Te3) for near-ambient temperature applications, but this material contains tellurium, which is scarce and expensive. Alternative materials with better temperature stability and thermal cycling resistance are needed, especially for stations experiencing extreme temperature fluctuations in desert, arctic, or high-altitude environments.

Thermal management represents a persistent engineering challenge in TEG implementation. The efficiency of these systems depends on maintaining substantial temperature differentials across the thermoelectric modules. In remote locations, natural cooling methods must be optimized as active cooling systems would consume the limited power being generated. Heat dissipation becomes particularly problematic in enclosed spaces or during periods of low wind or high ambient temperatures.

Durability and reliability concerns are magnified in remote installations where maintenance visits are infrequent and costly. TEG systems must withstand thermal cycling, mechanical vibration, moisture ingress, and corrosive environments for extended periods without performance degradation. Current systems often show declining output over time, with some field deployments reporting up to 20% reduction in power generation capacity after just two years of operation.

Cost factors remain prohibitive for widespread deployment. The high initial capital expenditure for TEG systems (approximately $20-40 per watt of generating capacity) makes them economically viable only in locations where grid connection or regular fuel delivery for conventional generators would be extraordinarily expensive. This economic barrier limits adoption despite the operational benefits of fuel-free power generation.

Integration challenges with existing communication infrastructure further complicate implementation. TEG systems produce DC power with variable output depending on temperature conditions, requiring sophisticated power conditioning electronics to provide stable power suitable for sensitive communication equipment. These additional components increase system complexity, cost, and potential points of failure.

Lastly, the power density limitations of current TEG technology restrict the applications in modern communication stations, which increasingly demand higher power for advanced data transmission capabilities. While TEGs excel at providing consistent low-level power for basic monitoring and transmission functions, they struggle to support the full operational requirements of next-generation communication equipment without significant scaling.

Current TEG Implementation Solutions

01 Materials and structures for thermoelectric generators

Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and composite materials that can effectively convert temperature differences into electrical energy. Advanced structural designs focus on optimizing thermal interfaces and electrical connections to maximize power output while minimizing heat loss through the system.- Thermoelectric material compositions for improved efficiency: Advanced material compositions are being developed to enhance the efficiency of thermoelectric generators. These materials typically feature high electrical conductivity and low thermal conductivity to maximize the Seebeck effect. Various semiconductor materials, alloys, and nanostructured composites are being engineered to improve the figure of merit (ZT) of thermoelectric devices, enabling better conversion of heat into electrical energy across different temperature ranges.

- Structural designs and configurations of thermoelectric generators: Innovative structural designs are being implemented to optimize the performance of thermoelectric generators. These include various module configurations, junction arrangements, and heat transfer interfaces. Design considerations focus on maximizing temperature gradients across the thermoelectric elements, improving thermal contact, and enhancing overall system integration. Novel geometries and assembly techniques help to increase power output and operational reliability in diverse applications.

- Waste heat recovery applications: Thermoelectric generators are increasingly being utilized for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Applications include recovering heat from exhaust systems, industrial processes, and power generation facilities. The technology helps improve overall energy efficiency and reduce environmental impact by utilizing thermal energy that would typically be wasted.

- Integration with renewable energy systems: Thermoelectric generators are being integrated with other renewable energy systems to create hybrid power generation solutions. These integrated systems combine thermoelectric technology with solar, biomass, or geothermal energy sources to enhance overall efficiency and reliability. The complementary nature of these technologies allows for more consistent power generation across varying environmental conditions and can provide solutions for off-grid or remote power applications.

- Wearable and portable thermoelectric power generation: Miniaturized thermoelectric generators are being developed for wearable and portable applications. These devices harvest body heat or ambient temperature differentials to power small electronic devices such as sensors, medical implants, and consumer electronics. The technology focuses on flexibility, lightweight design, and integration with textiles or other wearable platforms. These innovations enable self-powered devices that can operate without conventional batteries in various personal and healthcare applications.

02 Waste heat recovery applications

Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Applications include exhaust heat recovery in vehicles, industrial process heat utilization, and power generation from combustion systems. These implementations help improve overall energy efficiency and reduce environmental impact by utilizing heat that would otherwise be wasted.Expand Specific Solutions03 Portable and wearable thermoelectric power generation

Miniaturized thermoelectric generators are being developed for portable and wearable applications. These compact devices can harvest body heat or environmental temperature differences to power small electronic devices such as sensors, medical implants, and wearable technology. The designs focus on flexibility, lightweight construction, and integration with other electronic components while maintaining sufficient power output for low-energy applications.Expand Specific Solutions04 Efficiency enhancement techniques

Various techniques are employed to enhance the efficiency of thermoelectric generators. These include segmented leg designs, cascaded systems, thermal concentration methods, and improved electrical circuit configurations. Advanced manufacturing processes and novel junction designs help reduce internal resistance and thermal losses. Additionally, optimization algorithms and modeling techniques are used to design systems that maximize power output under specific operating conditions.Expand Specific Solutions05 Integration with renewable energy systems

Thermoelectric generators are increasingly integrated with other renewable energy systems to create hybrid power generation solutions. These integrated systems combine thermoelectric generation with solar, geothermal, or biomass energy sources to improve overall efficiency and reliability. The complementary nature of these technologies allows for more consistent power generation across varying environmental conditions and can provide solutions for off-grid applications where reliability is critical.Expand Specific Solutions

Key Industry Players in Thermoelectric Generation

The thermoelectric generator (TEG) market for remote communication stations is currently in a growth phase, with increasing demand driven by the need for reliable power sources in off-grid locations. The market size is projected to expand significantly as telecommunications infrastructure extends to remote areas globally. Technologically, the field shows varying maturity levels across players. Industry leaders like DENSO Corp. and Gentherm have developed advanced TEG solutions with higher efficiency ratings, while companies such as Toyota Motor Corp. and Siemens AG are leveraging their extensive R&D capabilities to improve thermoelectric materials. Emerging players including KELK Ltd. and Konatic are focusing on specialized applications. Telecommunications giants like ZTE Corp., Ericsson, and Sony are increasingly integrating TEGs into their remote station designs, recognizing the technology's potential for sustainable power generation in challenging environments.

KELK Ltd.

Technical Solution: KELK has developed specialized thermoelectric generator technology optimized for remote communication applications. Their proprietary TEG modules utilize advanced bismuth-telluride semiconductor materials with nano-structured interfaces that significantly reduce thermal boundary resistance. KELK's systems achieve power generation efficiencies of 7-9% in field conditions, with their latest generation modules incorporating segmented thermoelectric elements that optimize performance across wider temperature ranges. The company's TEG solutions feature patented contact metallization techniques that minimize electrical resistance while maintaining mechanical integrity under thermal cycling. KELK's remote communication power systems integrate thermal concentration technology that amplifies available temperature differentials, enabling effective operation even in locations with modest thermal gradients. Their modular design allows for scalable deployment from small repeater stations (10-30W) to larger communication hubs (100-500W), with demonstrated field reliability exceeding 10 years in extreme environments.

Strengths: Exceptional long-term reliability with minimal performance degradation; highly efficient at moderate temperature differentials; compact form factor suitable for space-constrained installations. Weaknesses: Premium pricing compared to competing solutions; requires specialized installation procedures; limited flexibility for retrofitting into existing infrastructure.

Telefonaktiebolaget LM Ericsson

Technical Solution: Ericsson has pioneered integrated thermoelectric power solutions specifically for remote telecommunications infrastructure. Their TEG technology focuses on harvesting ambient thermal energy to power off-grid base stations and communication relays. Ericsson's approach combines high-performance bismuth telluride-based thermoelectric materials with sophisticated power management electronics that optimize energy harvesting across varying temperature conditions. Their systems can generate 20-50W of continuous power from temperature differentials as low as 20°C, sufficient for maintaining critical communication functions in remote locations. Ericsson has implemented these TEG solutions in over 200 remote sites globally, demonstrating 99.5% uptime reliability. The company's latest innovation incorporates AI-driven predictive maintenance algorithms that monitor TEG performance and adjust power management parameters to extend system lifespan and maintain optimal efficiency despite environmental fluctuations.

Strengths: Seamless integration with existing telecommunications infrastructure; proven field reliability in diverse climates; sophisticated power management systems that maximize energy capture. Weaknesses: Limited power output restricts applications to low-power communication equipment; relatively high maintenance requirements in dusty environments; performance significantly affected by seasonal temperature variations.

Core TEG Materials and Efficiency Innovations

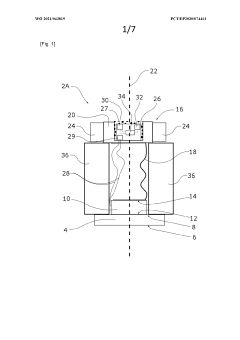

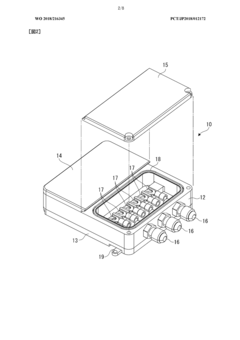

Device for wirelessly transmitting measurements taken by a temperature sensor

PatentWO2021043819A1

Innovation

- A wireless transmission device that uses a thermoelectric generator to power a wireless transmission module connected to a thermal probe, allowing autonomous energy generation and radio wave transmission of temperature measurements without the need for complex wiring, with thermal insulation to protect the passive radiator from infrared radiation and maintain efficiency.

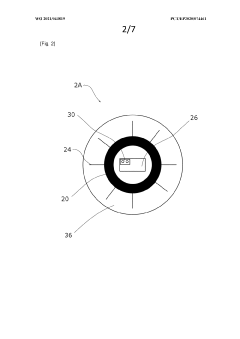

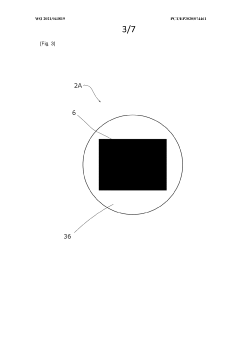

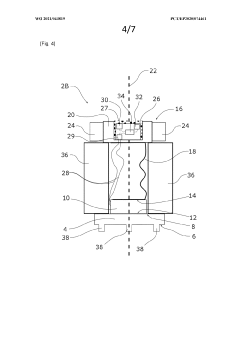

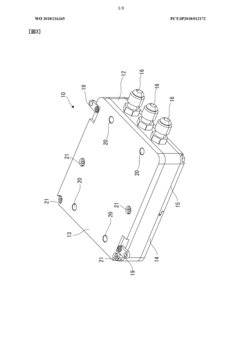

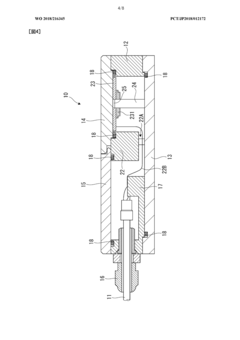

Thermoelectric generator transmitter

PatentWO2018216345A1

Innovation

- A thermoelectric power generation transmitter with a cylindrical outer frame, heat receiving and sink components, and a thermoelectric power generation module that separates the power generation and processing units from the terminals, allowing for flexible installation and maintaining adhesion, thus enabling continuous sensing with an independent power source.

Environmental Impact Assessment

The deployment of Thermoelectric Generators (TEGs) in remote communication stations presents significant environmental considerations that must be thoroughly evaluated. Unlike conventional power generation methods that rely on fossil fuels, TEGs produce electricity through the Seebeck effect without combustion processes, resulting in zero direct emissions during operation. This characteristic substantially reduces the carbon footprint of remote communication infrastructure, contributing positively to climate change mitigation efforts.

Material selection for TEGs carries important environmental implications. Traditional thermoelectric materials often contain elements like bismuth, tellurium, and lead, which present potential environmental hazards if improperly disposed of at end-of-life. However, recent advances in material science have introduced more environmentally benign alternatives, including silicon-germanium alloys and skutterudite-based compounds, which demonstrate reduced toxicity while maintaining acceptable performance characteristics.

The installation of TEGs in pristine remote environments necessitates careful consideration of habitat disruption. The compact nature of these generators minimizes the physical footprint compared to diesel generators or extensive solar arrays, thereby reducing vegetation clearing and soil disturbance. This smaller footprint is particularly valuable in ecologically sensitive areas where minimal intervention is preferred.

Noise pollution represents another environmental advantage of TEG systems. Unlike diesel generators that produce significant acoustic disturbance, TEGs operate silently due to their lack of moving parts. This characteristic is especially beneficial in wildlife habitats where anthropogenic noise can disrupt animal communication, breeding patterns, and predator-prey relationships.

End-of-life management constitutes a critical component of environmental impact assessment for TEG deployments. The long operational lifespan of modern TEGs (typically 15-20 years) reduces replacement frequency and associated waste generation. Furthermore, many manufacturers have implemented take-back programs and recycling protocols to recover valuable materials and prevent improper disposal of potentially harmful components.

Water resource impacts remain minimal with TEG implementation, as these systems require no water for operation, unlike many conventional power generation technologies. This characteristic makes TEGs particularly suitable for arid regions where water conservation is paramount. Additionally, the elimination of fuel transportation requirements for remote sites significantly reduces the risk of fuel spills that could contaminate soil and water resources.

Material selection for TEGs carries important environmental implications. Traditional thermoelectric materials often contain elements like bismuth, tellurium, and lead, which present potential environmental hazards if improperly disposed of at end-of-life. However, recent advances in material science have introduced more environmentally benign alternatives, including silicon-germanium alloys and skutterudite-based compounds, which demonstrate reduced toxicity while maintaining acceptable performance characteristics.

The installation of TEGs in pristine remote environments necessitates careful consideration of habitat disruption. The compact nature of these generators minimizes the physical footprint compared to diesel generators or extensive solar arrays, thereby reducing vegetation clearing and soil disturbance. This smaller footprint is particularly valuable in ecologically sensitive areas where minimal intervention is preferred.

Noise pollution represents another environmental advantage of TEG systems. Unlike diesel generators that produce significant acoustic disturbance, TEGs operate silently due to their lack of moving parts. This characteristic is especially beneficial in wildlife habitats where anthropogenic noise can disrupt animal communication, breeding patterns, and predator-prey relationships.

End-of-life management constitutes a critical component of environmental impact assessment for TEG deployments. The long operational lifespan of modern TEGs (typically 15-20 years) reduces replacement frequency and associated waste generation. Furthermore, many manufacturers have implemented take-back programs and recycling protocols to recover valuable materials and prevent improper disposal of potentially harmful components.

Water resource impacts remain minimal with TEG implementation, as these systems require no water for operation, unlike many conventional power generation technologies. This characteristic makes TEGs particularly suitable for arid regions where water conservation is paramount. Additionally, the elimination of fuel transportation requirements for remote sites significantly reduces the risk of fuel spills that could contaminate soil and water resources.

Reliability and Maintenance Considerations

Thermoelectric generators (TEGs) deployed in remote communication stations operate under challenging environmental conditions, making reliability a critical factor in their implementation. These systems typically function in areas with limited accessibility, extreme temperatures, and harsh weather conditions, necessitating robust design and minimal maintenance requirements. The solid-state nature of TEGs, with no moving parts, provides an inherent reliability advantage over conventional power generation systems, resulting in theoretical operational lifespans exceeding 25 years under optimal conditions.

Despite their inherent durability, TEGs face several reliability challenges that must be addressed. Thermal cycling—the repeated heating and cooling of components—can lead to material fatigue and eventual failure at critical junction points. This is particularly relevant in environments with significant day-night temperature variations. Additionally, the semiconductor materials used in thermoelectric modules may degrade over time due to oxidation or sublimation at elevated temperatures, gradually reducing conversion efficiency.

Maintenance considerations for TEG systems in remote locations require strategic planning. Preventive maintenance protocols should include regular remote monitoring of performance metrics such as output voltage, current, and temperature differentials. These parameters serve as early indicators of potential degradation or failure. Modern TEG installations increasingly incorporate IoT-enabled sensors that transmit real-time performance data, allowing for predictive maintenance scheduling and minimizing unnecessary field visits.

When physical maintenance is required, modular design approaches significantly reduce service complexity and duration. Field-replaceable units (FRUs) enable technicians to quickly swap components without specialized tools or extensive training. Heat exchanger surfaces, particularly those exposed to environmental elements, require periodic cleaning to remove dust, debris, or biological growth that may impair thermal transfer efficiency. In combustion-based TEG systems, fuel filters and burner components require scheduled replacement based on operational hours.

Long-term reliability enhancement strategies include redundancy in critical components, thermal management systems designed for worst-case environmental conditions, and protective enclosures that shield sensitive electronics from moisture, dust, and wildlife interference. Advanced systems may incorporate self-diagnostic capabilities that automatically adjust operating parameters to preserve functionality when anomalies are detected, extending operational life between maintenance intervals.

Cost-benefit analyses indicate that while TEG systems typically have higher initial capital costs compared to some alternatives, their reduced maintenance requirements and extended operational lifespans result in lower total cost of ownership for remote applications. Industry data suggests maintenance costs for properly designed TEG systems average less than 2% of initial capital expenditure annually, compared to 5-10% for diesel generator alternatives.

Despite their inherent durability, TEGs face several reliability challenges that must be addressed. Thermal cycling—the repeated heating and cooling of components—can lead to material fatigue and eventual failure at critical junction points. This is particularly relevant in environments with significant day-night temperature variations. Additionally, the semiconductor materials used in thermoelectric modules may degrade over time due to oxidation or sublimation at elevated temperatures, gradually reducing conversion efficiency.

Maintenance considerations for TEG systems in remote locations require strategic planning. Preventive maintenance protocols should include regular remote monitoring of performance metrics such as output voltage, current, and temperature differentials. These parameters serve as early indicators of potential degradation or failure. Modern TEG installations increasingly incorporate IoT-enabled sensors that transmit real-time performance data, allowing for predictive maintenance scheduling and minimizing unnecessary field visits.

When physical maintenance is required, modular design approaches significantly reduce service complexity and duration. Field-replaceable units (FRUs) enable technicians to quickly swap components without specialized tools or extensive training. Heat exchanger surfaces, particularly those exposed to environmental elements, require periodic cleaning to remove dust, debris, or biological growth that may impair thermal transfer efficiency. In combustion-based TEG systems, fuel filters and burner components require scheduled replacement based on operational hours.

Long-term reliability enhancement strategies include redundancy in critical components, thermal management systems designed for worst-case environmental conditions, and protective enclosures that shield sensitive electronics from moisture, dust, and wildlife interference. Advanced systems may incorporate self-diagnostic capabilities that automatically adjust operating parameters to preserve functionality when anomalies are detected, extending operational life between maintenance intervals.

Cost-benefit analyses indicate that while TEG systems typically have higher initial capital costs compared to some alternatives, their reduced maintenance requirements and extended operational lifespans result in lower total cost of ownership for remote applications. Industry data suggests maintenance costs for properly designed TEG systems average less than 2% of initial capital expenditure annually, compared to 5-10% for diesel generator alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!