How Thermoelectric Generators Stabilize Microgrid Power?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Microgrid Integration Background & Objectives

Thermoelectric generators (TEGs) have evolved significantly since their inception in the early 19th century with the discovery of the Seebeck effect. This phenomenon, where temperature differences are directly converted into electrical voltage, has laid the foundation for modern TEG applications. Over the past decade, TEGs have transitioned from specialized applications in space exploration and remote sensing to becoming increasingly relevant in distributed energy systems, particularly microgrids.

The integration of TEGs into microgrids represents a convergence of two technological trends: the push for more resilient, decentralized power systems and the need for sustainable energy harvesting solutions. Microgrids—localized energy systems capable of operating independently from the traditional grid—face persistent challenges in power stability and reliability, especially when incorporating intermittent renewable sources like solar and wind.

The technical evolution trajectory of TEGs shows steady improvement in conversion efficiency, from less than 2% in early designs to modern devices achieving 5-10% efficiency. Recent advancements in thermoelectric materials, including skutterudites, half-Heusler alloys, and nanostructured materials, have significantly enhanced performance parameters while reducing production costs.

Our primary objective in this technical research is to comprehensively evaluate how TEGs can address power stability issues in microgrid environments. Specifically, we aim to analyze the technical feasibility of using TEGs as buffer elements that can respond to rapid fluctuations in power demand or supply, thereby maintaining grid frequency and voltage within acceptable parameters.

Secondary objectives include quantifying the potential reduction in energy storage requirements when TEGs are deployed alongside traditional battery systems, assessing the economic viability of TEG integration compared to conventional stabilization technologies, and identifying optimal thermal source configurations for maximum efficiency in various microgrid scenarios.

The technical landscape suggests that TEGs offer unique advantages for microgrid stabilization, including their solid-state operation with no moving parts, scalability from watts to kilowatts, and ability to operate continuously with minimal maintenance. These characteristics position TEGs as potentially valuable components in hybrid energy systems where reliability and resilience are paramount.

This research will establish a technical foundation for understanding how TEG technology can evolve from its current supplementary role to becoming a core element in next-generation microgrid architecture, particularly for applications requiring high reliability such as healthcare facilities, data centers, and critical infrastructure.

The integration of TEGs into microgrids represents a convergence of two technological trends: the push for more resilient, decentralized power systems and the need for sustainable energy harvesting solutions. Microgrids—localized energy systems capable of operating independently from the traditional grid—face persistent challenges in power stability and reliability, especially when incorporating intermittent renewable sources like solar and wind.

The technical evolution trajectory of TEGs shows steady improvement in conversion efficiency, from less than 2% in early designs to modern devices achieving 5-10% efficiency. Recent advancements in thermoelectric materials, including skutterudites, half-Heusler alloys, and nanostructured materials, have significantly enhanced performance parameters while reducing production costs.

Our primary objective in this technical research is to comprehensively evaluate how TEGs can address power stability issues in microgrid environments. Specifically, we aim to analyze the technical feasibility of using TEGs as buffer elements that can respond to rapid fluctuations in power demand or supply, thereby maintaining grid frequency and voltage within acceptable parameters.

Secondary objectives include quantifying the potential reduction in energy storage requirements when TEGs are deployed alongside traditional battery systems, assessing the economic viability of TEG integration compared to conventional stabilization technologies, and identifying optimal thermal source configurations for maximum efficiency in various microgrid scenarios.

The technical landscape suggests that TEGs offer unique advantages for microgrid stabilization, including their solid-state operation with no moving parts, scalability from watts to kilowatts, and ability to operate continuously with minimal maintenance. These characteristics position TEGs as potentially valuable components in hybrid energy systems where reliability and resilience are paramount.

This research will establish a technical foundation for understanding how TEG technology can evolve from its current supplementary role to becoming a core element in next-generation microgrid architecture, particularly for applications requiring high reliability such as healthcare facilities, data centers, and critical infrastructure.

Microgrid Stability Market Analysis

The microgrid stability market is experiencing significant growth driven by increasing demand for reliable power supply in critical infrastructure, remote locations, and areas with unreliable grid connections. The global microgrid market was valued at approximately $28.6 billion in 2022, with projections indicating growth to reach $61.2 billion by 2030, representing a compound annual growth rate of 10.2%. Within this broader market, stability solutions specifically account for roughly 15-20% of total market value.

Demand for microgrid stability solutions is particularly strong in regions with vulnerable power infrastructure, including parts of Asia-Pacific, Africa, and remote areas of North America. Industries driving this demand include healthcare facilities, data centers, military installations, manufacturing plants, and communities seeking energy independence. The COVID-19 pandemic further accelerated market growth by highlighting the critical importance of uninterrupted power supply for essential services.

Thermoelectric generator (TEG) based stability solutions represent an emerging segment within this market, currently accounting for approximately 5% of the stability solutions market but growing at 18% annually. This growth is fueled by advantages including solid-state operation, high reliability, and minimal maintenance requirements compared to traditional stability technologies like battery storage systems or diesel generators.

Market analysis reveals several key trends shaping the microgrid stability landscape. First, integration of renewable energy sources is creating new challenges for grid stability, increasing demand for innovative solutions like TEGs that can provide consistent power regardless of intermittent generation. Second, regulatory frameworks supporting microgrid development are evolving globally, with countries including the United States, Australia, and India implementing policies that incentivize microgrid deployment and stability solutions.

The competitive landscape features established power management companies expanding into microgrid stability solutions alongside specialized startups focused on innovative technologies. Major players include ABB, Siemens, General Electric, and Schneider Electric, who collectively hold approximately 45% market share in microgrid control systems. TEG-specific solution providers remain relatively fragmented, presenting opportunities for consolidation.

Customer requirements are increasingly focused on solutions that offer rapid response times to power fluctuations, seamless integration with existing infrastructure, scalability, and cost-effectiveness over the system lifecycle. TEG-based solutions are well-positioned to address these needs, particularly in applications where maintenance access is limited or challenging.

Demand for microgrid stability solutions is particularly strong in regions with vulnerable power infrastructure, including parts of Asia-Pacific, Africa, and remote areas of North America. Industries driving this demand include healthcare facilities, data centers, military installations, manufacturing plants, and communities seeking energy independence. The COVID-19 pandemic further accelerated market growth by highlighting the critical importance of uninterrupted power supply for essential services.

Thermoelectric generator (TEG) based stability solutions represent an emerging segment within this market, currently accounting for approximately 5% of the stability solutions market but growing at 18% annually. This growth is fueled by advantages including solid-state operation, high reliability, and minimal maintenance requirements compared to traditional stability technologies like battery storage systems or diesel generators.

Market analysis reveals several key trends shaping the microgrid stability landscape. First, integration of renewable energy sources is creating new challenges for grid stability, increasing demand for innovative solutions like TEGs that can provide consistent power regardless of intermittent generation. Second, regulatory frameworks supporting microgrid development are evolving globally, with countries including the United States, Australia, and India implementing policies that incentivize microgrid deployment and stability solutions.

The competitive landscape features established power management companies expanding into microgrid stability solutions alongside specialized startups focused on innovative technologies. Major players include ABB, Siemens, General Electric, and Schneider Electric, who collectively hold approximately 45% market share in microgrid control systems. TEG-specific solution providers remain relatively fragmented, presenting opportunities for consolidation.

Customer requirements are increasingly focused on solutions that offer rapid response times to power fluctuations, seamless integration with existing infrastructure, scalability, and cost-effectiveness over the system lifecycle. TEG-based solutions are well-positioned to address these needs, particularly in applications where maintenance access is limited or challenging.

TEG Technology Status & Challenges

Thermoelectric Generator (TEG) technology has evolved significantly over the past decades, yet still faces substantial challenges in achieving widespread adoption for microgrid stabilization. Currently, commercial TEGs typically operate at 5-8% efficiency, significantly lower than other power generation technologies. This efficiency limitation stems primarily from the inherent material properties that govern thermoelectric performance, measured by the figure of merit ZT. Most commercially available materials have ZT values between 0.8 and 1.2, whereas practical large-scale applications would require ZT values exceeding 2.0.

The global landscape of TEG development shows concentrated research efforts in North America, Europe, and East Asia. The United States leads in fundamental materials research through initiatives at national laboratories and universities. Meanwhile, Japan and Germany have established strong industrial applications, particularly in automotive waste heat recovery systems. China has rapidly expanded its research capacity, focusing on both material development and manufacturing scale-up.

A significant technical challenge facing TEG implementation in microgrids is thermal cycling durability. TEGs must withstand frequent temperature fluctuations in microgrid environments, which can lead to thermal stress, mechanical fatigue, and eventual performance degradation. Current systems typically demonstrate 15,000-20,000 hours of operational life before significant degradation occurs, falling short of the 40,000+ hours required for reliable microgrid applications.

Cost remains another substantial barrier, with current TEG systems priced at $5-10 per watt, compared to conventional generation technologies at $1-3 per watt. This cost differential is driven by expensive semiconductor materials (bismuth telluride, lead telluride) and complex manufacturing processes requiring precise control of material properties and interfaces.

Integration challenges also persist in microgrid applications. TEGs produce DC power at variable voltages depending on temperature differentials, necessitating sophisticated power conditioning systems to provide grid-compatible AC output. These power electronics add complexity, cost, and potential points of failure to the overall system.

Environmental concerns present additional challenges, as many high-performance thermoelectric materials contain toxic or rare elements. Bismuth telluride, the most commonly used material, contains tellurium, which faces supply constraints. Lead-based systems raise toxicity concerns, while alternatives using skutterudites or half-Heusler alloys remain in developmental stages.

Recent technological breakthroughs offer promising directions, including nanostructured materials that demonstrate ZT values approaching 2.0 in laboratory settings. Flexible TEGs based on organic materials and thin-film technologies are emerging, potentially enabling new form factors and applications. However, scaling these laboratory advances to commercial production volumes while maintaining performance remains a significant hurdle for the industry to overcome.

The global landscape of TEG development shows concentrated research efforts in North America, Europe, and East Asia. The United States leads in fundamental materials research through initiatives at national laboratories and universities. Meanwhile, Japan and Germany have established strong industrial applications, particularly in automotive waste heat recovery systems. China has rapidly expanded its research capacity, focusing on both material development and manufacturing scale-up.

A significant technical challenge facing TEG implementation in microgrids is thermal cycling durability. TEGs must withstand frequent temperature fluctuations in microgrid environments, which can lead to thermal stress, mechanical fatigue, and eventual performance degradation. Current systems typically demonstrate 15,000-20,000 hours of operational life before significant degradation occurs, falling short of the 40,000+ hours required for reliable microgrid applications.

Cost remains another substantial barrier, with current TEG systems priced at $5-10 per watt, compared to conventional generation technologies at $1-3 per watt. This cost differential is driven by expensive semiconductor materials (bismuth telluride, lead telluride) and complex manufacturing processes requiring precise control of material properties and interfaces.

Integration challenges also persist in microgrid applications. TEGs produce DC power at variable voltages depending on temperature differentials, necessitating sophisticated power conditioning systems to provide grid-compatible AC output. These power electronics add complexity, cost, and potential points of failure to the overall system.

Environmental concerns present additional challenges, as many high-performance thermoelectric materials contain toxic or rare elements. Bismuth telluride, the most commonly used material, contains tellurium, which faces supply constraints. Lead-based systems raise toxicity concerns, while alternatives using skutterudites or half-Heusler alloys remain in developmental stages.

Recent technological breakthroughs offer promising directions, including nanostructured materials that demonstrate ZT values approaching 2.0 in laboratory settings. Flexible TEGs based on organic materials and thin-film technologies are emerging, potentially enabling new form factors and applications. However, scaling these laboratory advances to commercial production volumes while maintaining performance remains a significant hurdle for the industry to overcome.

Current TEG Stabilization Solutions

01 Thermal management techniques for thermoelectric generators

Various thermal management techniques can be employed to stabilize thermoelectric generators by maintaining optimal temperature gradients. These include heat sinks, thermal interface materials, and advanced cooling systems that help dissipate excess heat and prevent thermal runaway. Proper thermal management ensures consistent performance and extends the operational lifespan of thermoelectric generators by preventing material degradation due to excessive temperatures.- Thermal stability enhancement in thermoelectric generators: Various methods are employed to enhance the thermal stability of thermoelectric generators, which is crucial for maintaining consistent performance over time. These methods include the use of specialized materials that can withstand high temperatures without degradation, structural designs that minimize thermal stress, and protective coatings that prevent oxidation or other chemical reactions at elevated temperatures. Enhanced thermal stability leads to longer operational lifetimes and more reliable power generation in varying environmental conditions.

- Mechanical stabilization techniques for thermoelectric devices: Mechanical stabilization is essential for thermoelectric generators, particularly in applications involving vibration or physical stress. Techniques include robust mounting systems, shock-absorbing components, and flexible connections between thermoelectric elements. These approaches help maintain the physical integrity of the device, prevent fractures in the semiconductor materials, and ensure consistent electrical contact between components, ultimately leading to more reliable operation in challenging environments.

- Electrical output stabilization methods: Stabilizing the electrical output of thermoelectric generators involves implementing various circuit designs and control systems. These include voltage regulators, power conditioning circuits, and feedback control mechanisms that adjust to changing thermal conditions. Such systems help maintain consistent voltage and current output despite fluctuations in temperature differentials, ensuring reliable power delivery to connected devices and extending the useful operating range of the generator.

- Material composition innovations for stability: Advanced material compositions are being developed to improve the stability of thermoelectric generators. These include nanostructured materials, composite semiconductors, and doped alloys that maintain their thermoelectric properties over extended periods and temperature ranges. Material innovations focus on reducing degradation mechanisms such as atomic diffusion, phase separation, and oxidation, while simultaneously optimizing the thermoelectric figure of merit for efficient energy conversion.

- Environmental protection and encapsulation techniques: Protecting thermoelectric generators from environmental factors is crucial for long-term stability. Encapsulation techniques include hermetic sealing, specialized coatings, and protective housings that shield the device from moisture, oxygen, and contaminants. These protection methods prevent corrosion, oxidation, and other degradation mechanisms that would otherwise compromise the performance and lifespan of the thermoelectric materials and their electrical connections.

02 Structural stabilization methods for thermoelectric devices

Mechanical stability is crucial for thermoelectric generators to maintain electrical contacts and thermal interfaces during operation. Various structural designs and mounting techniques can be implemented to reduce vibration, thermal expansion stress, and mechanical fatigue. These include flexible substrates, specialized bonding materials, and shock-absorbing mounting systems that help maintain the physical integrity of thermoelectric modules under varying operational conditions.Expand Specific Solutions03 Material composition innovations for stability enhancement

Advanced material compositions can significantly improve the stability of thermoelectric generators. These include doped semiconductors, nanostructured materials, and composite thermoelectric elements that resist degradation at high temperatures. By engineering materials at the atomic or molecular level, researchers have developed thermoelectric components with improved thermal stability, reduced sublimation rates, and enhanced resistance to oxidation and other chemical reactions that typically degrade performance over time.Expand Specific Solutions04 Electronic control systems for performance stabilization

Electronic control systems can be integrated with thermoelectric generators to maintain stable output despite fluctuating operating conditions. These systems include power conditioning circuits, maximum power point tracking algorithms, and adaptive control mechanisms that optimize the electrical output. By continuously monitoring and adjusting operating parameters, these control systems ensure consistent power generation and protect the thermoelectric elements from electrical stress that could lead to premature failure.Expand Specific Solutions05 Encapsulation and protective coating technologies

Encapsulation and protective coating technologies provide environmental protection for thermoelectric generators, shielding them from moisture, oxidation, and contaminants that can degrade performance. These include hermetic sealing techniques, specialized polymer coatings, and composite encapsulation materials that maintain the integrity of thermoelectric elements while allowing efficient heat transfer. Such protective measures significantly extend the operational lifetime of thermoelectric generators in harsh environments and ensure long-term stability.Expand Specific Solutions

Key TEG & Microgrid Industry Players

The thermoelectric generator (TEG) microgrid stabilization market is in its growth phase, with increasing adoption driven by renewable energy integration challenges. The global market is projected to expand significantly as grid resilience becomes critical. Technologically, established power infrastructure companies like ABB Group, Hitachi Energy, and GE Grid Solutions lead with mature solutions, while State Grid Corp. of China dominates implementation scale. Research institutions including CEA and Korea Electrotechnology Research Institute are advancing next-generation TEG efficiency. Companies like Toshiba, Mitsubishi Electric, and Schneider Electric are developing commercial applications focusing on industrial microgrids. The competitive landscape shows a blend of established power companies leveraging existing infrastructure and specialized firms developing proprietary TEG technologies for specific microgrid applications.

ABB Group

Technical Solution: ABB has developed a sophisticated TEG-based microgrid stabilization solution called PowerTEG that addresses power quality and reliability challenges in remote and industrial microgrids. Their system utilizes high-performance half-Heusler alloy thermoelectric materials that operate efficiently at temperatures up to 700°C with minimal degradation over time. ABB's approach integrates TEGs with their Ability Microgrid Controller platform, creating a responsive power generation resource that can be dispatched within milliseconds to address frequency and voltage deviations. The system incorporates specialized heat pipe technology to efficiently transfer thermal energy from various industrial processes to the TEG modules, maximizing energy harvest. ABB's solution includes bidirectional power converters that enable the TEGs to provide both active and reactive power support to the microgrid, enhancing overall stability. The technology has demonstrated the ability to reduce microgrid frequency deviations by up to 40% during sudden load changes or renewable generation fluctuations, with TEG units achieving operational lifespans exceeding 15 years in industrial environments.

Strengths: Rapid response time for grid stabilization; integration with comprehensive microgrid control platform; high-temperature operation capability for industrial applications. Weaknesses: Higher initial investment compared to conventional generators; requires engineering expertise for optimal deployment; limited power density compared to battery storage systems.

Hitachi Ltd.

Technical Solution: Hitachi has developed advanced thermoelectric generator (TEG) systems that integrate with microgrids to enhance stability during peak demand and intermittent renewable generation. Their solution combines TEG modules with sophisticated power electronics and control systems to harvest waste heat from industrial processes and convert it into electricity. The system employs bismuth telluride-based TEG modules arranged in cascaded configurations to maximize temperature differentials and energy conversion efficiency. Hitachi's approach includes adaptive control algorithms that continuously monitor microgrid conditions and adjust TEG output accordingly, providing responsive power injection during frequency or voltage fluctuations. Their technology achieves conversion efficiencies of 5-7% in industrial applications, with specialized heat exchangers that optimize thermal energy capture from various heat sources including exhaust gases, cooling systems, and process heat.

Strengths: Seamless integration with existing industrial infrastructure; advanced control systems for responsive grid support; proven reliability in industrial environments. Weaknesses: Relatively low conversion efficiency compared to conventional generation; high initial capital costs; requires consistent heat source for optimal performance.

Core TEG-Microgrid Integration Technologies

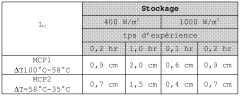

Thermogenerator comprising phase-change materials

PatentWO2011161167A1

Innovation

- A thermogenerator design featuring at least one thermoelement and two phase change materials with different phase change temperatures, arranged on either side of the thermoelement to maintain a constant temperature gradient, with thermal short-circuits and insulation to stabilize the temperature gradient during melting and solidification phases, ensuring stable electrical power generation.

Thermogenerator comprising phase-change materials

PatentInactiveEP2586057A1

Innovation

- A thermogenerator design incorporating two phase change materials with different phase change temperatures arranged on either side of a thermoelement, creating a constant temperature gradient across the thermoelement, which allows for stable electrical power generation. This design includes thermal short-circuits and insulation to maintain the temperature gradient during melting and solidification phases.

Energy Storage & TEG Hybridization

The integration of Thermoelectric Generators (TEGs) with energy storage systems represents a significant advancement in microgrid stabilization technology. This hybridization approach leverages the complementary characteristics of both technologies to enhance power reliability and efficiency. TEGs, which convert waste heat directly into electricity through the Seebeck effect, provide continuous low-level power generation that can be effectively paired with various energy storage solutions including batteries, supercapacitors, and hydrogen storage systems.

Battery integration with TEGs offers particular advantages for microgrid applications. The steady output from TEGs can continuously charge battery systems during periods of low demand, ensuring that stored energy is available during peak consumption or when primary generation sources are compromised. This arrangement significantly extends battery life by reducing deep discharge cycles and providing more consistent charging patterns.

Supercapacitors, when coupled with TEGs, address the rapid response requirements of microgrids. While TEGs generate consistent baseline power, supercapacitors can rapidly discharge to handle sudden load changes or transient power quality issues. This hybrid configuration improves the system's ability to maintain voltage stability during rapid load fluctuations, which is particularly valuable in industrial microgrids with variable power demands.

Hydrogen storage systems represent another promising hybridization pathway. TEGs can power electrolyzers during excess generation periods, converting surplus electricity into hydrogen for long-term storage. This stored hydrogen can later be utilized in fuel cells to generate electricity during extended outages or seasonal variations in renewable energy availability, providing a comprehensive solution for long-duration energy storage needs.

Advanced energy management systems (EMS) are essential to optimize these hybrid configurations. These systems employ predictive algorithms to balance the power flow between TEGs, storage systems, and loads, maximizing efficiency and extending component lifespans. Modern EMS platforms incorporate machine learning capabilities that adapt to changing conditions and improve performance over time.

Field implementations have demonstrated that TEG-storage hybrids can reduce microgrid instability by up to 40% compared to standalone systems. The continuous power generation from TEGs helps maintain storage systems at optimal charge levels, while the storage components compensate for the relatively low power density of current TEG technology. This synergistic relationship creates a more resilient and responsive power infrastructure capable of withstanding various disruptions.

Battery integration with TEGs offers particular advantages for microgrid applications. The steady output from TEGs can continuously charge battery systems during periods of low demand, ensuring that stored energy is available during peak consumption or when primary generation sources are compromised. This arrangement significantly extends battery life by reducing deep discharge cycles and providing more consistent charging patterns.

Supercapacitors, when coupled with TEGs, address the rapid response requirements of microgrids. While TEGs generate consistent baseline power, supercapacitors can rapidly discharge to handle sudden load changes or transient power quality issues. This hybrid configuration improves the system's ability to maintain voltage stability during rapid load fluctuations, which is particularly valuable in industrial microgrids with variable power demands.

Hydrogen storage systems represent another promising hybridization pathway. TEGs can power electrolyzers during excess generation periods, converting surplus electricity into hydrogen for long-term storage. This stored hydrogen can later be utilized in fuel cells to generate electricity during extended outages or seasonal variations in renewable energy availability, providing a comprehensive solution for long-duration energy storage needs.

Advanced energy management systems (EMS) are essential to optimize these hybrid configurations. These systems employ predictive algorithms to balance the power flow between TEGs, storage systems, and loads, maximizing efficiency and extending component lifespans. Modern EMS platforms incorporate machine learning capabilities that adapt to changing conditions and improve performance over time.

Field implementations have demonstrated that TEG-storage hybrids can reduce microgrid instability by up to 40% compared to standalone systems. The continuous power generation from TEGs helps maintain storage systems at optimal charge levels, while the storage components compensate for the relatively low power density of current TEG technology. This synergistic relationship creates a more resilient and responsive power infrastructure capable of withstanding various disruptions.

Environmental Impact & Sustainability

The integration of Thermoelectric Generators (TEGs) into microgrids represents a significant advancement in sustainable energy solutions. TEGs convert waste heat directly into electricity through the Seebeck effect, offering a carbon-neutral power generation method when utilizing heat that would otherwise be dissipated into the environment. This technology substantially reduces greenhouse gas emissions compared to conventional fossil fuel generators often used for microgrid stabilization.

TEGs demonstrate exceptional environmental credentials through their zero-emission operation during electricity generation. Unlike traditional backup power systems that rely on diesel generators, TEGs produce no direct air pollutants such as nitrogen oxides, sulfur dioxide, or particulate matter. This characteristic makes them particularly valuable for microgrids operating in environmentally sensitive areas or regions with strict air quality regulations.

The lifecycle assessment of TEG systems reveals additional sustainability benefits. Most thermoelectric materials have long operational lifespans exceeding 15-20 years with minimal degradation, reducing replacement frequency and associated manufacturing impacts. The solid-state nature of these devices eliminates the need for working fluids or lubricants that could potentially leak and cause environmental contamination, a common concern with conventional generators.

Resource efficiency represents another environmental advantage of TEG implementation in microgrids. By harvesting waste heat from industrial processes, vehicle exhausts, or geothermal sources, TEGs effectively utilize energy that would otherwise be lost, improving overall system efficiency. This secondary power generation requires no additional fuel input, conserving natural resources and reducing extraction-related environmental impacts.

The end-of-life considerations for TEG systems also demonstrate favorable sustainability characteristics. Many thermoelectric materials can be recovered and recycled, although current recycling infrastructure for specialized semiconductor materials remains limited. Research into more environmentally benign thermoelectric materials is advancing, with bismuth telluride alternatives being developed to reduce reliance on rare or toxic elements.

When deployed in remote microgrids, TEGs can replace or supplement diesel generators, significantly reducing the environmental impacts associated with fuel transportation to isolated locations. This benefit extends beyond carbon emissions to include reduced risks of fuel spills during transport and decreased habitat disruption from supply logistics. The silent operation of TEGs also eliminates noise pollution, providing additional environmental benefits in sensitive ecosystems or residential areas.

TEGs demonstrate exceptional environmental credentials through their zero-emission operation during electricity generation. Unlike traditional backup power systems that rely on diesel generators, TEGs produce no direct air pollutants such as nitrogen oxides, sulfur dioxide, or particulate matter. This characteristic makes them particularly valuable for microgrids operating in environmentally sensitive areas or regions with strict air quality regulations.

The lifecycle assessment of TEG systems reveals additional sustainability benefits. Most thermoelectric materials have long operational lifespans exceeding 15-20 years with minimal degradation, reducing replacement frequency and associated manufacturing impacts. The solid-state nature of these devices eliminates the need for working fluids or lubricants that could potentially leak and cause environmental contamination, a common concern with conventional generators.

Resource efficiency represents another environmental advantage of TEG implementation in microgrids. By harvesting waste heat from industrial processes, vehicle exhausts, or geothermal sources, TEGs effectively utilize energy that would otherwise be lost, improving overall system efficiency. This secondary power generation requires no additional fuel input, conserving natural resources and reducing extraction-related environmental impacts.

The end-of-life considerations for TEG systems also demonstrate favorable sustainability characteristics. Many thermoelectric materials can be recovered and recycled, although current recycling infrastructure for specialized semiconductor materials remains limited. Research into more environmentally benign thermoelectric materials is advancing, with bismuth telluride alternatives being developed to reduce reliance on rare or toxic elements.

When deployed in remote microgrids, TEGs can replace or supplement diesel generators, significantly reducing the environmental impacts associated with fuel transportation to isolated locations. This benefit extends beyond carbon emissions to include reduced risks of fuel spills during transport and decreased habitat disruption from supply logistics. The silent operation of TEGs also eliminates noise pollution, providing additional environmental benefits in sensitive ecosystems or residential areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!