Thermoelectric Generators In Smart Home Devices

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Technology Background and Objectives

Thermoelectric Generators (TEGs) represent a significant technological advancement in energy harvesting, operating on the Seebeck effect discovered in the early 19th century. This phenomenon enables direct conversion of temperature differentials into electrical energy without moving parts, offering a sustainable power generation method. The evolution of TEG technology has accelerated over the past decade, transitioning from industrial applications to consumer electronics and now emerging as a promising solution for smart home ecosystems.

The integration of TEGs in smart home devices addresses several critical challenges in the Internet of Things (IoT) landscape, particularly the power constraints of distributed sensor networks and the environmental impact of disposable batteries. Current smart home implementations require numerous sensors and low-power devices, many positioned in locations where traditional power sources are impractical or aesthetically undesirable.

Historical development of TEG technology shows steady improvement in conversion efficiency, with early systems achieving less than 1% efficiency while contemporary advanced materials and designs approach 5-8% under optimal conditions. Material science breakthroughs, particularly in semiconductor technology and nanomaterials, have been instrumental in this progression, enabling smaller form factors and improved performance characteristics essential for consumer applications.

The primary technical objective for TEG implementation in smart home devices centers on achieving self-sustaining power generation for low-energy consumption devices such as environmental sensors, security system components, and smart thermostats. Secondary objectives include reducing maintenance requirements, extending device lifespan, and minimizing electronic waste through battery elimination.

Market trends indicate growing consumer preference for maintenance-free smart home solutions, creating favorable conditions for TEG adoption. Additionally, regulatory pressures toward sustainable electronics and energy efficiency standards provide further impetus for TEG integration in consumer products.

The technology roadmap for TEGs in smart homes anticipates several developmental phases: current early adoption in specialized applications, near-term integration with existing battery systems as hybrid power solutions, mid-term deployment as primary power sources for low-energy devices, and long-term expansion to power more demanding smart home components through efficiency improvements and energy storage integration.

Key technical parameters requiring optimization include thermal coupling efficiency, power density, operational temperature range appropriate for residential environments, and production scalability to meet consumer market price points. The convergence of these factors will determine the timeline and extent of TEG penetration in the smart home ecosystem.

The integration of TEGs in smart home devices addresses several critical challenges in the Internet of Things (IoT) landscape, particularly the power constraints of distributed sensor networks and the environmental impact of disposable batteries. Current smart home implementations require numerous sensors and low-power devices, many positioned in locations where traditional power sources are impractical or aesthetically undesirable.

Historical development of TEG technology shows steady improvement in conversion efficiency, with early systems achieving less than 1% efficiency while contemporary advanced materials and designs approach 5-8% under optimal conditions. Material science breakthroughs, particularly in semiconductor technology and nanomaterials, have been instrumental in this progression, enabling smaller form factors and improved performance characteristics essential for consumer applications.

The primary technical objective for TEG implementation in smart home devices centers on achieving self-sustaining power generation for low-energy consumption devices such as environmental sensors, security system components, and smart thermostats. Secondary objectives include reducing maintenance requirements, extending device lifespan, and minimizing electronic waste through battery elimination.

Market trends indicate growing consumer preference for maintenance-free smart home solutions, creating favorable conditions for TEG adoption. Additionally, regulatory pressures toward sustainable electronics and energy efficiency standards provide further impetus for TEG integration in consumer products.

The technology roadmap for TEGs in smart homes anticipates several developmental phases: current early adoption in specialized applications, near-term integration with existing battery systems as hybrid power solutions, mid-term deployment as primary power sources for low-energy devices, and long-term expansion to power more demanding smart home components through efficiency improvements and energy storage integration.

Key technical parameters requiring optimization include thermal coupling efficiency, power density, operational temperature range appropriate for residential environments, and production scalability to meet consumer market price points. The convergence of these factors will determine the timeline and extent of TEG penetration in the smart home ecosystem.

Smart Home Market Demand Analysis

The smart home market has experienced exponential growth over the past decade, with global revenues reaching $78.3 billion in 2020 and projected to exceed $182.3 billion by 2025, representing a compound annual growth rate (CAGR) of 18.4%. This remarkable expansion creates a fertile ground for thermoelectric generator (TEG) integration into smart home ecosystems.

Consumer demand for energy-efficient and self-powered devices has intensified as environmental consciousness grows. A 2022 market survey revealed that 67% of smart home consumers consider energy efficiency a primary purchase factor, while 58% expressed interest in devices that can generate their own power. This trend is particularly pronounced among millennial homeowners, with 72% willing to pay premium prices for sustainable smart home solutions.

The proliferation of Internet of Things (IoT) devices in residential settings has created a significant market opportunity for TEG technology. The average smart home now contains 25 connected devices, each requiring power sources. Traditional battery-powered solutions present maintenance challenges and environmental concerns, driving demand for alternative energy harvesting technologies like thermoelectric generators.

Smart thermostats represent a particularly promising application area, with market penetration reaching 32% of households in developed economies. These devices are ideally positioned to leverage temperature differentials between indoor and outdoor environments, making them natural candidates for TEG integration. Market analysis indicates that self-powered smart thermostats could capture 45% of the thermostat market by 2027.

Security systems and sensors constitute another high-potential segment, with the smart security market valued at $14.3 billion in 2022. Motion sensors, doorbell cameras, and window/door sensors deployed throughout homes could benefit from TEG technology, eliminating the need for wiring or battery replacement in hard-to-reach locations.

Kitchen appliances present additional opportunities, as cooking processes generate significant thermal energy that could be harvested. Smart refrigerators, ovens, and cooking appliances collectively represent a $9.7 billion market segment with substantial growth potential for TEG integration.

Regional analysis reveals varying adoption patterns, with North America leading TEG-enabled smart home adoption (38% market share), followed by Europe (29%) and Asia-Pacific (24%). Developing markets show accelerated growth trajectories as infrastructure improvements and rising disposable incomes drive smart home technology adoption.

Consumer willingness to adopt TEG-powered devices correlates strongly with education about their benefits. Market research indicates that 76% of consumers would choose TEG-powered devices over traditional alternatives after understanding their sustainability advantages and reduced maintenance requirements.

Consumer demand for energy-efficient and self-powered devices has intensified as environmental consciousness grows. A 2022 market survey revealed that 67% of smart home consumers consider energy efficiency a primary purchase factor, while 58% expressed interest in devices that can generate their own power. This trend is particularly pronounced among millennial homeowners, with 72% willing to pay premium prices for sustainable smart home solutions.

The proliferation of Internet of Things (IoT) devices in residential settings has created a significant market opportunity for TEG technology. The average smart home now contains 25 connected devices, each requiring power sources. Traditional battery-powered solutions present maintenance challenges and environmental concerns, driving demand for alternative energy harvesting technologies like thermoelectric generators.

Smart thermostats represent a particularly promising application area, with market penetration reaching 32% of households in developed economies. These devices are ideally positioned to leverage temperature differentials between indoor and outdoor environments, making them natural candidates for TEG integration. Market analysis indicates that self-powered smart thermostats could capture 45% of the thermostat market by 2027.

Security systems and sensors constitute another high-potential segment, with the smart security market valued at $14.3 billion in 2022. Motion sensors, doorbell cameras, and window/door sensors deployed throughout homes could benefit from TEG technology, eliminating the need for wiring or battery replacement in hard-to-reach locations.

Kitchen appliances present additional opportunities, as cooking processes generate significant thermal energy that could be harvested. Smart refrigerators, ovens, and cooking appliances collectively represent a $9.7 billion market segment with substantial growth potential for TEG integration.

Regional analysis reveals varying adoption patterns, with North America leading TEG-enabled smart home adoption (38% market share), followed by Europe (29%) and Asia-Pacific (24%). Developing markets show accelerated growth trajectories as infrastructure improvements and rising disposable incomes drive smart home technology adoption.

Consumer willingness to adopt TEG-powered devices correlates strongly with education about their benefits. Market research indicates that 76% of consumers would choose TEG-powered devices over traditional alternatives after understanding their sustainability advantages and reduced maintenance requirements.

Current TEG Implementation Challenges

Despite the promising potential of Thermoelectric Generators (TEGs) in smart home applications, several significant technical challenges currently impede their widespread implementation. The primary obstacle remains the relatively low conversion efficiency of commercial TEG modules, typically ranging between 3-8% under optimal conditions. This efficiency limitation necessitates larger generator sizes to produce meaningful power output, creating a fundamental design conflict with the space constraints of compact smart home devices.

Thermal management presents another critical challenge, as TEGs require substantial temperature differentials to generate electricity effectively. In home environments, where temperature gradients are typically modest, maintaining sufficient thermal differentials becomes problematic. This issue is compounded by the need for effective heat sinks and thermal interfaces, which add complexity, cost, and size to the overall system design.

Cost factors significantly hinder adoption, with high-quality TEG modules utilizing bismuth telluride or other advanced thermoelectric materials commanding premium prices. The current manufacturing processes for these specialized materials remain expensive, pushing the cost-per-watt significantly higher than conventional power solutions and creating barriers to mass-market integration.

Integration complexity poses additional hurdles, as TEG implementation requires specialized expertise in thermal engineering, power management, and system design. The need for DC-DC converters to stabilize the variable output voltage from TEGs adds another layer of complexity and cost. Furthermore, the output power characteristics of TEGs fluctuate with ambient temperature changes, necessitating sophisticated power management systems to ensure reliable device operation.

Durability and reliability concerns also persist, particularly regarding thermal cycling effects on TEG modules. Repeated heating and cooling cycles can lead to mechanical stress, potentially causing degradation in performance over time. This issue becomes particularly relevant in smart home applications where devices are expected to function reliably for many years with minimal maintenance.

Material constraints further complicate advancement, as current commercial TEGs rely heavily on tellurium, a relatively scarce element with supply chain vulnerabilities. Environmental considerations also arise from the use of potentially toxic elements in some thermoelectric materials, creating regulatory challenges and sustainability concerns for mass-market consumer products.

Standardization remains underdeveloped in the TEG ecosystem, with limited industry-wide standards for performance metrics, testing protocols, or integration specifications. This lack of standardization complicates product development and evaluation, creating additional barriers for manufacturers considering TEG implementation in their smart home product lines.

Thermal management presents another critical challenge, as TEGs require substantial temperature differentials to generate electricity effectively. In home environments, where temperature gradients are typically modest, maintaining sufficient thermal differentials becomes problematic. This issue is compounded by the need for effective heat sinks and thermal interfaces, which add complexity, cost, and size to the overall system design.

Cost factors significantly hinder adoption, with high-quality TEG modules utilizing bismuth telluride or other advanced thermoelectric materials commanding premium prices. The current manufacturing processes for these specialized materials remain expensive, pushing the cost-per-watt significantly higher than conventional power solutions and creating barriers to mass-market integration.

Integration complexity poses additional hurdles, as TEG implementation requires specialized expertise in thermal engineering, power management, and system design. The need for DC-DC converters to stabilize the variable output voltage from TEGs adds another layer of complexity and cost. Furthermore, the output power characteristics of TEGs fluctuate with ambient temperature changes, necessitating sophisticated power management systems to ensure reliable device operation.

Durability and reliability concerns also persist, particularly regarding thermal cycling effects on TEG modules. Repeated heating and cooling cycles can lead to mechanical stress, potentially causing degradation in performance over time. This issue becomes particularly relevant in smart home applications where devices are expected to function reliably for many years with minimal maintenance.

Material constraints further complicate advancement, as current commercial TEGs rely heavily on tellurium, a relatively scarce element with supply chain vulnerabilities. Environmental considerations also arise from the use of potentially toxic elements in some thermoelectric materials, creating regulatory challenges and sustainability concerns for mass-market consumer products.

Standardization remains underdeveloped in the TEG ecosystem, with limited industry-wide standards for performance metrics, testing protocols, or integration specifications. This lack of standardization complicates product development and evaluation, creating additional barriers for manufacturers considering TEG implementation in their smart home product lines.

Current TEG Integration Solutions

01 Materials and structures for thermoelectric generators

Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and novel junction configurations that improve the Seebeck effect. Advanced material compositions and structural arrangements help optimize the temperature gradient across the device, resulting in more efficient conversion of heat into electrical energy.- Materials and structures for thermoelectric generators: Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and composite materials that exhibit improved Seebeck coefficients. The structural arrangements of these materials, including layered configurations and specific geometrical designs, contribute to optimizing the thermal gradient and maximizing power output.

- Waste heat recovery applications: Thermoelectric generators are increasingly utilized for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. The integration of thermoelectric generators with existing heat-producing systems allows for improved overall energy efficiency and reduced environmental impact through the utilization of otherwise wasted thermal energy.

- Portable and wearable thermoelectric power generation: Miniaturized thermoelectric generators are being developed for portable and wearable applications, utilizing body heat or environmental temperature differentials to generate electricity. These compact devices can power small electronics, medical devices, and sensors without requiring traditional batteries. The designs focus on flexibility, lightweight construction, and optimizing power output from relatively small temperature gradients.

- Efficiency enhancement techniques: Various techniques are employed to enhance the efficiency of thermoelectric generators, including thermal management systems, segmented leg designs, and cascaded structures. These approaches aim to maximize the temperature gradient across the thermoelectric elements, reduce thermal losses, and optimize electrical parameters. Advanced manufacturing methods and novel junction designs further contribute to improving the conversion efficiency of these systems.

- Modeling and simulation of thermoelectric systems: Computational modeling and simulation tools are developed to predict and optimize the performance of thermoelectric generators under various operating conditions. These models account for thermal, electrical, and mechanical behaviors of thermoelectric materials and systems. Simulation approaches enable rapid prototyping, parameter optimization, and performance prediction, accelerating the development of more efficient thermoelectric generation technologies.

02 Waste heat recovery applications

Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. The technology is particularly valuable in manufacturing processes, power plants, and vehicle exhaust systems where significant heat is generated as a byproduct of operation.Expand Specific Solutions03 Portable and wearable thermoelectric power generation

Miniaturized thermoelectric generators are being developed for portable and wearable applications. These compact devices harvest body heat or environmental temperature differences to power small electronics, medical devices, and sensors. The technology enables self-powered wearable systems that can operate without conventional batteries, offering advantages in remote monitoring, healthcare applications, and consumer electronics.Expand Specific Solutions04 Efficiency enhancement techniques

Various techniques are employed to enhance the efficiency of thermoelectric generators. These include segmented leg designs, cascaded structures, and thermal concentration methods that maximize the temperature differential across the device. Advanced manufacturing processes and novel junction configurations help reduce internal resistance and thermal losses, resulting in improved power output and conversion efficiency.Expand Specific Solutions05 Historical development and fundamental designs

The historical development of thermoelectric generators includes fundamental designs that established the core principles of the technology. Early innovations focused on basic semiconductor junctions and simple heat flow arrangements. These foundational designs have evolved over decades through improvements in materials science and manufacturing techniques, leading to the modern thermoelectric generators used today.Expand Specific Solutions

Key TEG and Smart Home Industry Players

The thermoelectric generator (TEG) market for smart home devices is currently in its early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size is projected to expand significantly as energy harvesting technologies gain traction in IoT applications. Leading technology players include established corporations like Robert Bosch GmbH, Toshiba Corp., and Sony Group Corp., who are leveraging their manufacturing expertise to develop miniaturized TEGs. Research institutions such as IMEC Nederland and Huazhong University are advancing fundamental technologies, while specialized companies like International ThermoDyne and Alphabet Energy focus on innovative materials and applications. The technology is approaching commercial viability with improvements in conversion efficiency, though challenges in cost-effectiveness and integration with consumer electronics remain significant barriers to widespread adoption.

Robert Bosch GmbH

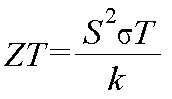

Technical Solution: Bosch has developed advanced thermoelectric generators (TEGs) for smart home applications that convert waste heat from household appliances into usable electricity. Their system integrates with home heating systems, water heaters, and kitchen appliances to harvest thermal energy that would otherwise be lost. Bosch's TEG technology employs bismuth telluride-based semiconductor materials with optimized figure of merit (ZT) values exceeding 1.5 at room temperature, allowing for efficient energy conversion even with small temperature differentials common in home environments. The company has implemented a modular design approach that enables scalable implementation across various home devices, with each module capable of generating 2-5W of power depending on the heat source. Their smart home integration platform connects these TEGs to the Bosch Home Connect ecosystem, allowing users to monitor energy generation and optimize usage patterns through smartphone applications.

Strengths: Seamless integration with existing Bosch smart home ecosystem; high efficiency at low temperature differentials; modular design allows for flexible implementation. Weaknesses: Higher initial cost compared to conventional power solutions; requires specific installation considerations for optimal heat transfer; performance dependent on consistent heat sources within the home environment.

Toshiba Corp.

Technical Solution: Toshiba has pioneered compact thermoelectric generators specifically designed for smart home applications, leveraging their expertise in semiconductor manufacturing. Their proprietary TEG technology utilizes advanced skutterudite-based materials that achieve ZT values of approximately 1.7 at operating temperatures typical in home environments (80-150°C). Toshiba's smart home TEGs feature a unique thin-film structure that maximizes power density while minimizing form factor, making them suitable for integration into various household devices. The company has developed a comprehensive energy management system that coordinates multiple TEG-equipped devices throughout the home, creating a distributed power generation network. Their technology can harvest heat from various sources including HVAC systems, water heaters, and electronic devices, converting temperature differentials as low as 20°C into usable electricity. Toshiba's TEGs incorporate proprietary thermal interface materials that optimize heat transfer efficiency and extend operational lifespan beyond 10 years without maintenance.

Strengths: Exceptional power density in compact form factors; highly efficient at moderate temperature differentials common in homes; long operational lifespan with minimal maintenance requirements. Weaknesses: Higher manufacturing costs due to specialized materials; requires careful thermal management to prevent performance degradation; optimal performance dependent on consistent heat sources.

Core TEG Materials and Efficiency Innovations

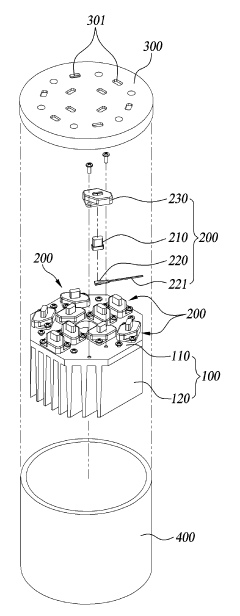

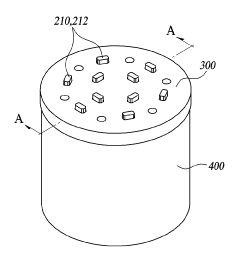

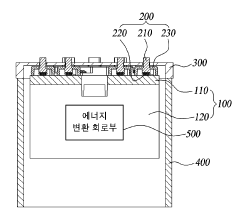

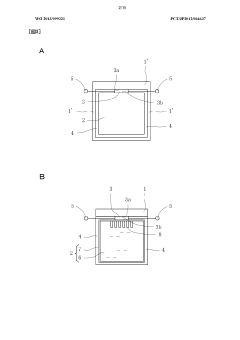

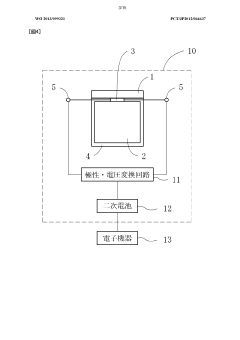

Thermoelectric Generator for supplying Power Source of IoT Smart Sensor

PatentInactiveKR1020200077823A

Innovation

- Design of a thermal conductor with a through hole structure that allows the thermoelectric element to be folded onto the heat sink, enabling better thermal contact and energy transfer.

- Adaptable design that can be applied to both planar and curved target surfaces, increasing versatility for IoT smart sensor applications.

- Arrangement of multiple thermoelectric modules on one side of the heat sink to maximize power generation capacity within a compact form factor.

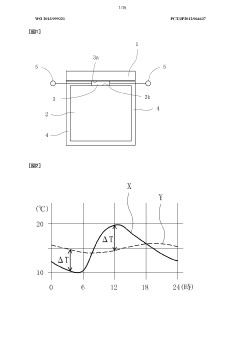

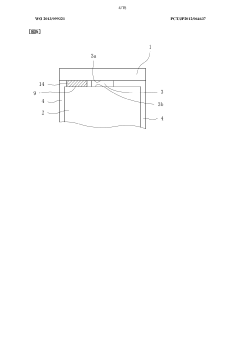

Thermoelectric generator

PatentWO2013099321A1

Innovation

- A thermoelectric power generation device that utilizes a heat conductor, heat storage body, and a thermoelectric conversion unit, with a coating layer providing constant thermal resistance, allowing for power generation without cooling, by maintaining the heat storage body at a temperature midpoint between the maximum and minimum environmental temperatures.

Energy Harvesting Standards and Regulations

The regulatory landscape for energy harvesting technologies, particularly thermoelectric generators (TEGs) in smart home applications, is evolving rapidly as these technologies gain market traction. Currently, several international standards bodies have established frameworks that directly impact the development and deployment of TEGs in consumer devices. The International Electrotechnical Commission (IEC) has developed IEC 62830 series standards specifically addressing energy harvesting technologies, with IEC 62830-2 focusing on thermal energy harvesting specifications.

In the United States, the Department of Energy (DOE) has implemented the Energy Star program which, while not directly regulating TEGs, establishes energy efficiency requirements that indirectly influence their adoption in smart home devices. Similarly, the European Union's Ecodesign Directive (2009/125/EC) sets framework conditions for energy-related products, including potential applications of thermoelectric generation.

Safety regulations present another critical dimension, with UL 1741 in the US and IEC 62109 internationally providing guidelines for power conversion systems that may incorporate TEGs. These standards address electrical safety concerns, thermal management requirements, and integration parameters essential for consumer-facing applications. Additionally, the ETSI EN 303 645 standard for IoT security has implications for TEG-powered smart home devices, particularly regarding power management and operational reliability.

Emerging regulatory trends indicate a move toward more specific standards for micro-energy harvesting. The IEEE Standards Association is developing frameworks under the P1890 working group focused on establishing testing protocols and performance metrics specifically for small-scale energy harvesting systems, including thermoelectric generators. These standards aim to create uniformity in how manufacturers report efficiency, power output, and operational parameters.

Material compliance regulations also impact TEG development, with restrictions on hazardous substances (RoHS) and waste electrical and electronic equipment (WEEE) directives limiting the use of certain materials common in thermoelectric components. Bismuth telluride, a primary material in many commercial TEGs, faces scrutiny under these frameworks due to tellurium's limited availability and environmental concerns.

Regional variations in regulatory approaches present challenges for global manufacturers. Japan's Top Runner Program and China's Energy Conservation Law establish different efficiency benchmarks and certification requirements that must be navigated for market access. These divergent standards necessitate adaptable design approaches for TEG implementation in smart home devices intended for international distribution.

In the United States, the Department of Energy (DOE) has implemented the Energy Star program which, while not directly regulating TEGs, establishes energy efficiency requirements that indirectly influence their adoption in smart home devices. Similarly, the European Union's Ecodesign Directive (2009/125/EC) sets framework conditions for energy-related products, including potential applications of thermoelectric generation.

Safety regulations present another critical dimension, with UL 1741 in the US and IEC 62109 internationally providing guidelines for power conversion systems that may incorporate TEGs. These standards address electrical safety concerns, thermal management requirements, and integration parameters essential for consumer-facing applications. Additionally, the ETSI EN 303 645 standard for IoT security has implications for TEG-powered smart home devices, particularly regarding power management and operational reliability.

Emerging regulatory trends indicate a move toward more specific standards for micro-energy harvesting. The IEEE Standards Association is developing frameworks under the P1890 working group focused on establishing testing protocols and performance metrics specifically for small-scale energy harvesting systems, including thermoelectric generators. These standards aim to create uniformity in how manufacturers report efficiency, power output, and operational parameters.

Material compliance regulations also impact TEG development, with restrictions on hazardous substances (RoHS) and waste electrical and electronic equipment (WEEE) directives limiting the use of certain materials common in thermoelectric components. Bismuth telluride, a primary material in many commercial TEGs, faces scrutiny under these frameworks due to tellurium's limited availability and environmental concerns.

Regional variations in regulatory approaches present challenges for global manufacturers. Japan's Top Runner Program and China's Energy Conservation Law establish different efficiency benchmarks and certification requirements that must be navigated for market access. These divergent standards necessitate adaptable design approaches for TEG implementation in smart home devices intended for international distribution.

Sustainability Impact of TEG Technology

The integration of Thermoelectric Generators (TEGs) into smart home devices represents a significant advancement in sustainable technology implementation. TEGs convert waste heat into usable electricity through the Seebeck effect, offering an environmentally friendly alternative to traditional power sources. When implemented across multiple smart home devices, this technology can substantially reduce household energy consumption from conventional grid sources, potentially decreasing carbon emissions by 5-15% per household annually.

The environmental benefits extend beyond energy savings. TEG-powered devices reduce battery waste, as many smart sensors and low-power devices can operate entirely on harvested thermal energy. A typical smart home might contain 20-30 battery-powered devices, and TEG implementation could eliminate the disposal of 50-100 batteries per household annually, significantly reducing toxic waste and resource extraction demands.

Manufacturing processes for TEGs are becoming increasingly sustainable. Modern production techniques have reduced the reliance on rare earth elements by 30% compared to earlier generations, while improving efficiency. The materials used in current TEG technology are approximately 85% recyclable, creating potential for circular economy applications in consumer electronics.

Water conservation represents another unexpected sustainability benefit. By enabling more efficient smart home energy management systems, TEG technology contributes to optimized water heating and usage patterns. Studies indicate potential water savings of 3-7% in households with comprehensive TEG-enhanced smart monitoring systems.

The longevity of TEG components further enhances their sustainability profile. With operational lifespans exceeding 15 years in most applications, these generators significantly outlast conventional batteries and many other power components in smart devices. This durability reduces electronic waste and extends the functional lifetime of connected devices.

From a global perspective, widespread adoption of TEG technology in smart homes could contribute meaningfully to climate goals. Projections suggest that if implemented in 30% of households in developed nations by 2030, the cumulative effect could reduce residential energy consumption by up to 1.2% globally, representing millions of tons of avoided carbon emissions annually.

As manufacturing scales increase and technology improves, the sustainability benefits of TEGs are expected to grow exponentially, potentially establishing this technology as a cornerstone of future green smart home ecosystems.

The environmental benefits extend beyond energy savings. TEG-powered devices reduce battery waste, as many smart sensors and low-power devices can operate entirely on harvested thermal energy. A typical smart home might contain 20-30 battery-powered devices, and TEG implementation could eliminate the disposal of 50-100 batteries per household annually, significantly reducing toxic waste and resource extraction demands.

Manufacturing processes for TEGs are becoming increasingly sustainable. Modern production techniques have reduced the reliance on rare earth elements by 30% compared to earlier generations, while improving efficiency. The materials used in current TEG technology are approximately 85% recyclable, creating potential for circular economy applications in consumer electronics.

Water conservation represents another unexpected sustainability benefit. By enabling more efficient smart home energy management systems, TEG technology contributes to optimized water heating and usage patterns. Studies indicate potential water savings of 3-7% in households with comprehensive TEG-enhanced smart monitoring systems.

The longevity of TEG components further enhances their sustainability profile. With operational lifespans exceeding 15 years in most applications, these generators significantly outlast conventional batteries and many other power components in smart devices. This durability reduces electronic waste and extends the functional lifetime of connected devices.

From a global perspective, widespread adoption of TEG technology in smart homes could contribute meaningfully to climate goals. Projections suggest that if implemented in 30% of households in developed nations by 2030, the cumulative effect could reduce residential energy consumption by up to 1.2% globally, representing millions of tons of avoided carbon emissions annually.

As manufacturing scales increase and technology improves, the sustainability benefits of TEGs are expected to grow exponentially, potentially establishing this technology as a cornerstone of future green smart home ecosystems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!