Thermoelectric Generators For Oil And Gas Industry Applications

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Technology Background and Objectives

Thermoelectric Generators (TEGs) have evolved significantly since their discovery in the early 19th century when Thomas Johann Seebeck first observed the thermoelectric effect in 1821. This phenomenon, where temperature differences are directly converted into electrical voltage, forms the fundamental principle behind TEG technology. Over the past two centuries, thermoelectric materials and device designs have progressed from simple metallic junctions to sophisticated semiconductor-based systems with increasingly higher efficiency.

In the oil and gas industry context, TEGs represent a promising solution for power generation in remote locations where traditional power infrastructure is impractical or prohibitively expensive. These generators harness waste heat from various processes—including flare systems, exhaust gases, and hot production fluids—converting otherwise wasted thermal energy into valuable electrical power without requiring moving parts or additional fuel sources.

The technological evolution of TEGs has been marked by significant improvements in conversion efficiency, from less than 1% in early designs to modern systems achieving 5-8% efficiency. Recent advancements in material science, particularly in nanostructured thermoelectric materials and quantum well structures, suggest potential for reaching 10-15% efficiency in the near future, which would dramatically expand viable application scenarios in the oil and gas sector.

Current industry applications primarily focus on powering remote monitoring systems, cathodic protection systems, and small-scale instrumentation. However, the technology trajectory indicates potential for scaling to support larger power requirements for wellhead operations, pipeline monitoring stations, and offshore platforms, reducing dependence on diesel generators and decreasing operational carbon footprints.

The primary technical objectives for TEG development in oil and gas applications include: increasing conversion efficiency to make the technology economically viable for broader deployment; enhancing durability to withstand harsh operating environments including high temperatures, corrosive conditions, and mechanical stresses; reducing manufacturing costs through improved materials and production techniques; and developing integrated systems that combine TEGs with existing infrastructure to maximize value extraction from waste heat sources.

Additionally, as the industry faces increasing pressure to reduce emissions and improve sustainability metrics, TEGs offer a pathway to capture energy that would otherwise be wasted, aligning with broader decarbonization goals. The technology aims to provide reliable power generation with minimal maintenance requirements, addressing the operational challenges of remote and offshore installations where regular maintenance activities are logistically difficult and expensive.

In the oil and gas industry context, TEGs represent a promising solution for power generation in remote locations where traditional power infrastructure is impractical or prohibitively expensive. These generators harness waste heat from various processes—including flare systems, exhaust gases, and hot production fluids—converting otherwise wasted thermal energy into valuable electrical power without requiring moving parts or additional fuel sources.

The technological evolution of TEGs has been marked by significant improvements in conversion efficiency, from less than 1% in early designs to modern systems achieving 5-8% efficiency. Recent advancements in material science, particularly in nanostructured thermoelectric materials and quantum well structures, suggest potential for reaching 10-15% efficiency in the near future, which would dramatically expand viable application scenarios in the oil and gas sector.

Current industry applications primarily focus on powering remote monitoring systems, cathodic protection systems, and small-scale instrumentation. However, the technology trajectory indicates potential for scaling to support larger power requirements for wellhead operations, pipeline monitoring stations, and offshore platforms, reducing dependence on diesel generators and decreasing operational carbon footprints.

The primary technical objectives for TEG development in oil and gas applications include: increasing conversion efficiency to make the technology economically viable for broader deployment; enhancing durability to withstand harsh operating environments including high temperatures, corrosive conditions, and mechanical stresses; reducing manufacturing costs through improved materials and production techniques; and developing integrated systems that combine TEGs with existing infrastructure to maximize value extraction from waste heat sources.

Additionally, as the industry faces increasing pressure to reduce emissions and improve sustainability metrics, TEGs offer a pathway to capture energy that would otherwise be wasted, aligning with broader decarbonization goals. The technology aims to provide reliable power generation with minimal maintenance requirements, addressing the operational challenges of remote and offshore installations where regular maintenance activities are logistically difficult and expensive.

Oil & Gas Industry TEG Market Analysis

The global market for Thermoelectric Generators (TEGs) in the oil and gas industry is experiencing significant growth, driven by increasing demand for reliable power sources in remote locations and the industry's push toward more sustainable operations. Currently valued at approximately $45 million in 2023, the oil and gas TEG market is projected to reach $78 million by 2028, representing a compound annual growth rate of 11.6% during the forecast period.

North America dominates the market with roughly 38% share, followed by Europe (27%) and Asia-Pacific (21%). This regional distribution aligns with the concentration of major oil and gas operations and the adoption rate of advanced technologies in these regions. The Middle East, despite being a hub for oil production, currently accounts for only 9% of the TEG market but is showing the fastest growth rate at 14.2% annually.

The market segmentation reveals distinct application areas within the industry. Offshore platforms represent the largest application segment (42%), where TEGs provide critical power for monitoring systems, telecommunications, and emergency equipment. Pipeline monitoring systems account for 28% of applications, followed by remote well sites (18%) and processing facilities (12%).

Key market drivers include the increasing need for reliable power in remote locations where grid connectivity is unavailable or unreliable. The industry's focus on reducing carbon emissions has also accelerated TEG adoption, as these generators can convert waste heat from various processes into usable electricity, improving overall energy efficiency. Additionally, the declining maintenance costs of modern TEG systems compared to traditional generators has improved their economic viability.

Market restraints include the relatively high initial investment costs, with industrial-grade TEGs for oil and gas applications typically costing between $5,000 and $25,000 per unit depending on power output capacity. The limited power generation efficiency of current TEG technology (typically 5-8%) also remains a challenge, though this is gradually improving with technological advancements.

Customer demand patterns indicate growing interest in integrated TEG solutions that combine with other renewable energy sources such as solar panels to create hybrid power systems. There is also increasing demand for TEGs with remote monitoring capabilities and predictive maintenance features, reflecting the industry's broader move toward digitalization and IoT integration.

The competitive landscape features established players like Gentherm, Laird Thermal Systems, and II-VI Marlow dominating with a combined market share of 47%, alongside emerging specialized providers focusing exclusively on energy harvesting solutions for oil and gas applications.

North America dominates the market with roughly 38% share, followed by Europe (27%) and Asia-Pacific (21%). This regional distribution aligns with the concentration of major oil and gas operations and the adoption rate of advanced technologies in these regions. The Middle East, despite being a hub for oil production, currently accounts for only 9% of the TEG market but is showing the fastest growth rate at 14.2% annually.

The market segmentation reveals distinct application areas within the industry. Offshore platforms represent the largest application segment (42%), where TEGs provide critical power for monitoring systems, telecommunications, and emergency equipment. Pipeline monitoring systems account for 28% of applications, followed by remote well sites (18%) and processing facilities (12%).

Key market drivers include the increasing need for reliable power in remote locations where grid connectivity is unavailable or unreliable. The industry's focus on reducing carbon emissions has also accelerated TEG adoption, as these generators can convert waste heat from various processes into usable electricity, improving overall energy efficiency. Additionally, the declining maintenance costs of modern TEG systems compared to traditional generators has improved their economic viability.

Market restraints include the relatively high initial investment costs, with industrial-grade TEGs for oil and gas applications typically costing between $5,000 and $25,000 per unit depending on power output capacity. The limited power generation efficiency of current TEG technology (typically 5-8%) also remains a challenge, though this is gradually improving with technological advancements.

Customer demand patterns indicate growing interest in integrated TEG solutions that combine with other renewable energy sources such as solar panels to create hybrid power systems. There is also increasing demand for TEGs with remote monitoring capabilities and predictive maintenance features, reflecting the industry's broader move toward digitalization and IoT integration.

The competitive landscape features established players like Gentherm, Laird Thermal Systems, and II-VI Marlow dominating with a combined market share of 47%, alongside emerging specialized providers focusing exclusively on energy harvesting solutions for oil and gas applications.

Current TEG Implementation Challenges

Despite the promising potential of Thermoelectric Generators (TEGs) in oil and gas applications, several significant implementation challenges currently limit their widespread adoption. The harsh operating environments of oil and gas facilities present extreme temperature fluctuations, corrosive substances, and high-pressure conditions that can compromise TEG durability and performance. Standard TEG materials and construction often deteriorate rapidly under these conditions, necessitating specialized designs that substantially increase costs.

Efficiency limitations represent another major hurdle, with most commercial TEGs operating at only 5-8% conversion efficiency. This low efficiency requires larger TEG arrays to generate meaningful power outputs, creating spatial constraints in already crowded industrial installations. The efficiency challenge becomes particularly pronounced in remote locations where space optimization is critical for operational feasibility.

Cost-effectiveness remains problematic across the implementation spectrum. The specialized materials required for high-temperature differentials—typically rare earth elements and advanced semiconductors—carry significant material costs. When combined with custom engineering requirements for specific deployment scenarios, the total implementation expense often exceeds the perceived value of the energy harvested, particularly when compared to traditional power solutions.

System integration complexities further complicate TEG deployment. Existing oil and gas infrastructure was rarely designed with waste heat recovery in mind, requiring substantial retrofitting to accommodate TEG systems. The integration must address thermal interface management, electrical output conditioning, and physical mounting considerations without disrupting primary operations or compromising safety protocols.

Maintenance requirements present ongoing operational challenges. While TEGs theoretically offer solid-state reliability with no moving parts, the reality in oil and gas environments involves regular inspection and maintenance to address thermal cycling fatigue, connection degradation, and performance optimization. Remote locations exacerbate these challenges, as maintenance visits carry significant logistical costs.

Regulatory compliance and certification processes add another layer of complexity. TEG systems must meet stringent industry safety standards, particularly regarding electrical systems in potentially explosive atmospheres. The certification process for new technologies in these environments is typically lengthy and expensive, creating market entry barriers for innovative TEG solutions.

Scalability limitations also restrict widespread implementation. Current manufacturing processes for high-quality thermoelectric materials remain largely batch-oriented rather than continuous, creating production bottlenecks and limiting economies of scale that could otherwise drive down costs.

Efficiency limitations represent another major hurdle, with most commercial TEGs operating at only 5-8% conversion efficiency. This low efficiency requires larger TEG arrays to generate meaningful power outputs, creating spatial constraints in already crowded industrial installations. The efficiency challenge becomes particularly pronounced in remote locations where space optimization is critical for operational feasibility.

Cost-effectiveness remains problematic across the implementation spectrum. The specialized materials required for high-temperature differentials—typically rare earth elements and advanced semiconductors—carry significant material costs. When combined with custom engineering requirements for specific deployment scenarios, the total implementation expense often exceeds the perceived value of the energy harvested, particularly when compared to traditional power solutions.

System integration complexities further complicate TEG deployment. Existing oil and gas infrastructure was rarely designed with waste heat recovery in mind, requiring substantial retrofitting to accommodate TEG systems. The integration must address thermal interface management, electrical output conditioning, and physical mounting considerations without disrupting primary operations or compromising safety protocols.

Maintenance requirements present ongoing operational challenges. While TEGs theoretically offer solid-state reliability with no moving parts, the reality in oil and gas environments involves regular inspection and maintenance to address thermal cycling fatigue, connection degradation, and performance optimization. Remote locations exacerbate these challenges, as maintenance visits carry significant logistical costs.

Regulatory compliance and certification processes add another layer of complexity. TEG systems must meet stringent industry safety standards, particularly regarding electrical systems in potentially explosive atmospheres. The certification process for new technologies in these environments is typically lengthy and expensive, creating market entry barriers for innovative TEG solutions.

Scalability limitations also restrict widespread implementation. Current manufacturing processes for high-quality thermoelectric materials remain largely batch-oriented rather than continuous, creating production bottlenecks and limiting economies of scale that could otherwise drive down costs.

Existing TEG Solutions for Oil & Gas Applications

01 Materials and structures for thermoelectric generators

Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and composite materials that exhibit improved Seebeck coefficients. The structural arrangements of these materials, such as layered configurations or specific geometric patterns, can significantly impact the performance of thermoelectric generators by optimizing heat flow and electrical conductivity.- Materials and structures for thermoelectric generators: Various materials and structural designs are employed in thermoelectric generators to enhance energy conversion efficiency. These include specialized semiconductor materials, nanostructured elements, and novel junction configurations that improve the Seebeck effect. Advanced material compositions and structural arrangements help maximize the temperature gradient across the device, leading to more efficient conversion of heat into electrical energy.

- Waste heat recovery applications: Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Implementation strategies include integration with exhaust systems, industrial processes, and power generation facilities, providing supplementary power while reducing overall energy consumption and environmental impact.

- Portable and wearable thermoelectric power generation: Miniaturized thermoelectric generators are being developed for portable and wearable applications, utilizing body heat or ambient temperature differences to generate electricity. These compact devices can power small electronics, medical devices, and IoT sensors without requiring battery replacement. Design considerations focus on flexibility, comfort, and maximizing power output from relatively small temperature differentials.

- Efficiency enhancement techniques: Various techniques are employed to enhance the efficiency of thermoelectric generators, including thermal concentration, segmented designs, and cascaded systems. These approaches optimize heat flow management, reduce thermal resistance, and maximize the temperature gradient across the thermoelectric elements. Advanced manufacturing methods and novel geometrical configurations also contribute to improved performance and higher power output.

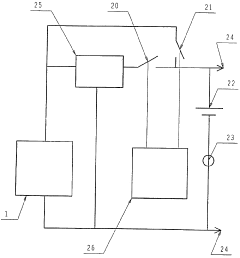

- Modeling and simulation of thermoelectric systems: Computational modeling and simulation tools are essential for designing and optimizing thermoelectric generators. These methods enable prediction of performance under various operating conditions, material selection, and structural optimization before physical prototyping. Advanced algorithms account for complex thermal and electrical interactions, helping engineers develop more efficient and reliable thermoelectric power generation systems.

02 Waste heat recovery applications

Thermoelectric generators are increasingly used for waste heat recovery in various industrial and automotive applications. These systems capture thermal energy that would otherwise be lost and convert it into usable electricity. Applications include recovering heat from exhaust systems, industrial processes, and power generation facilities. The integration of these generators into existing systems requires specialized designs to maximize heat capture while maintaining system efficiency.Expand Specific Solutions03 Portable and wearable thermoelectric power generation

Miniaturized thermoelectric generators are being developed for portable and wearable applications. These compact devices can harvest body heat or environmental temperature differentials to power small electronic devices or sensors. The designs focus on flexibility, lightweight construction, and integration with other components. Advancements in this area include flexible substrates, biocompatible materials, and low-temperature operation capabilities.Expand Specific Solutions04 Efficiency enhancement techniques

Various techniques are employed to enhance the efficiency of thermoelectric generators. These include segmented leg designs, cascaded systems, thermal concentration methods, and electrical circuit optimizations. Advanced manufacturing processes such as additive manufacturing and precision deposition techniques allow for more complex and efficient thermoelectric structures. Additionally, hybrid systems that combine thermoelectric generation with other energy harvesting technologies can improve overall system performance.Expand Specific Solutions05 Modeling and simulation of thermoelectric systems

Computational modeling and simulation tools are essential for designing and optimizing thermoelectric generators. These include finite element analysis, multiphysics simulations, and machine learning approaches to predict performance under various operating conditions. Simulation techniques help in understanding heat flow patterns, electrical characteristics, and material behavior at different temperatures. These tools enable rapid prototyping and testing of new designs without the need for extensive physical experimentation.Expand Specific Solutions

Key TEG Manufacturers and Energy Companies

The thermoelectric generator (TEG) market for oil and gas applications is currently in a growth phase, with increasing adoption driven by remote power generation needs and energy efficiency initiatives. The global market size is expanding steadily, projected to reach significant value as energy harvesting technologies gain traction. From a technological maturity perspective, the landscape shows varied development stages with established industrial players like Siemens AG, Robert Bosch GmbH, and Toyota Motor Corp leading commercial applications, while research institutions such as California Institute of Technology and Northwestern University drive fundamental innovations. Companies like Gentherm and Rosemount are developing specialized TEG solutions for harsh environments, while automotive manufacturers including Hyundai, Kia, and BMW are transferring their expertise to industrial applications, creating a competitive ecosystem balancing mature implementations with emerging breakthrough technologies.

Siemens AG

Technical Solution: Siemens has pioneered integrated thermoelectric generator systems for oil and gas infrastructure that capture waste heat from flare stacks, compressor stations, and processing facilities. Their TEG technology employs bismuth telluride and lead telluride semiconductor materials optimized for different temperature ranges encountered in oil and gas operations. Siemens' solution features a comprehensive energy management system that integrates with existing SCADA infrastructure, allowing for remote monitoring and control of power generation. The company's TEG units are designed with redundant arrays to ensure reliability and incorporate advanced heat exchangers that maximize thermal transfer efficiency. Siemens has implemented these systems at offshore platforms and remote pipeline stations, where they provide 5-50kW of continuous power for critical instrumentation, monitoring equipment, and emergency systems. Their TEGs achieve payback periods of 2-4 years in remote locations where traditional power infrastructure is costly to install and maintain.

Strengths: Seamless integration with existing industrial control systems; comprehensive solution including power conditioning and storage; global service network for maintenance and support. Weaknesses: Systems require significant engineering customization for each installation site; relatively large footprint compared to some competing technologies; performance highly dependent on consistent heat source availability.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has developed specialized thermoelectric generator technology tailored for oil and gas applications, particularly focusing on offshore platforms and remote production sites. Their TEG systems utilize advanced half-Heusler alloys and silicide-based materials that offer enhanced performance in the temperature ranges typical of oil and gas operations. IFP's technology features innovative thermal interface materials that maximize heat transfer efficiency while accommodating thermal expansion and contraction cycles. Their systems are designed with modular architecture allowing for easy scaling from small 1kW units for instrumentation power to larger 50kW systems for more substantial power needs. IFP has implemented proprietary surface treatments and coatings that provide exceptional corrosion resistance in marine and high-sulfur environments. Their TEGs incorporate advanced power conditioning electronics that deliver stable output despite fluctuating heat sources, making them particularly valuable for powering sensitive monitoring and control equipment in remote locations where grid power is unavailable or unreliable.

Strengths: Exceptional corrosion resistance for marine and high-sulfur environments; highly scalable modular design; specialized expertise in offshore applications with proven installations. Weaknesses: Higher cost per watt compared to some competitors; more limited global service network; technology optimized for specific temperature ranges rather than broad applicability.

Critical TEG Materials and Efficiency Innovations

Thermoelectric generator

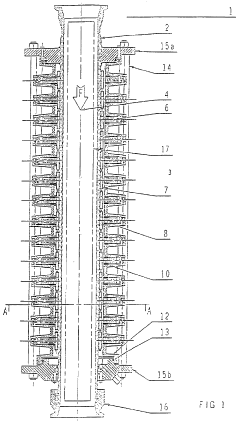

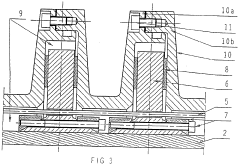

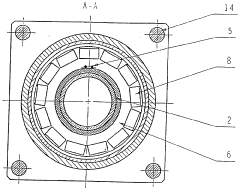

PatentWO1997038451A1

Innovation

- The thermoelectric generator positions modules with heat exchange surfaces perpendicular to fluid flow and uses flanges and annular stirrups to ensure electrical insulation and pressure resistance, allowing for increased module density and deeper operation.

Thermoelectric generator

PatentInactiveEP0836751A1

Innovation

- The thermoelectric generator positions modules with heat exchange surfaces perpendicular to the fluid flow, secured between flanges and enclosed by annular stirrups, ensuring optimal heat transfer and pressure resistance, allowing for increased power generation and operation at depths up to 2000 meters.

Environmental Impact and Sustainability Benefits

The implementation of Thermoelectric Generators (TEGs) in oil and gas operations represents a significant advancement toward reducing the industry's environmental footprint. TEGs convert waste heat directly into electricity without moving parts, combustion processes, or harmful emissions, offering a clean alternative to conventional power generation methods commonly used in remote oil and gas facilities.

By harnessing waste heat that would otherwise be vented to the atmosphere, TEGs contribute to greenhouse gas reduction efforts. Quantitative assessments indicate that TEG implementation can reduce carbon emissions by 25-40% at typical wellhead operations compared to diesel generators. This reduction becomes particularly significant when multiplied across thousands of remote facilities worldwide.

Water conservation represents another critical environmental benefit. Unlike traditional power generation systems that may require water for cooling, TEGs operate without water consumption. In water-stressed regions where many oil and gas operations are located, this characteristic provides a substantial sustainability advantage, potentially saving millions of gallons annually across industry operations.

The lifecycle analysis of TEGs reveals favorable sustainability metrics compared to alternatives. With operational lifespans exceeding 15 years and minimal maintenance requirements, TEGs reduce the environmental impacts associated with frequent equipment replacement and maintenance activities. The materials used in TEG construction, while including some rare elements, are increasingly being designed for recyclability, with manufacturers developing closed-loop recovery systems.

TEGs also contribute to noise pollution reduction, operating silently compared to conventional generators. This benefit is particularly valuable in environmentally sensitive areas or operations near communities, helping companies meet increasingly stringent environmental compliance requirements while improving relationships with local stakeholders.

From a regulatory perspective, TEGs help oil and gas companies adapt to evolving environmental regulations. As carbon pricing mechanisms and emissions restrictions become more prevalent globally, TEG implementation represents a proactive approach to compliance while potentially generating carbon credits in applicable jurisdictions.

The sustainability benefits extend to operational resilience. By enabling distributed power generation at the point of use, TEGs reduce transmission losses and infrastructure vulnerability, contributing to more efficient resource utilization across the energy production chain. This alignment with circular economy principles positions TEGs as an important technology in the industry's broader sustainability transformation.

By harnessing waste heat that would otherwise be vented to the atmosphere, TEGs contribute to greenhouse gas reduction efforts. Quantitative assessments indicate that TEG implementation can reduce carbon emissions by 25-40% at typical wellhead operations compared to diesel generators. This reduction becomes particularly significant when multiplied across thousands of remote facilities worldwide.

Water conservation represents another critical environmental benefit. Unlike traditional power generation systems that may require water for cooling, TEGs operate without water consumption. In water-stressed regions where many oil and gas operations are located, this characteristic provides a substantial sustainability advantage, potentially saving millions of gallons annually across industry operations.

The lifecycle analysis of TEGs reveals favorable sustainability metrics compared to alternatives. With operational lifespans exceeding 15 years and minimal maintenance requirements, TEGs reduce the environmental impacts associated with frequent equipment replacement and maintenance activities. The materials used in TEG construction, while including some rare elements, are increasingly being designed for recyclability, with manufacturers developing closed-loop recovery systems.

TEGs also contribute to noise pollution reduction, operating silently compared to conventional generators. This benefit is particularly valuable in environmentally sensitive areas or operations near communities, helping companies meet increasingly stringent environmental compliance requirements while improving relationships with local stakeholders.

From a regulatory perspective, TEGs help oil and gas companies adapt to evolving environmental regulations. As carbon pricing mechanisms and emissions restrictions become more prevalent globally, TEG implementation represents a proactive approach to compliance while potentially generating carbon credits in applicable jurisdictions.

The sustainability benefits extend to operational resilience. By enabling distributed power generation at the point of use, TEGs reduce transmission losses and infrastructure vulnerability, contributing to more efficient resource utilization across the energy production chain. This alignment with circular economy principles positions TEGs as an important technology in the industry's broader sustainability transformation.

Regulatory Framework for Energy Harvesting in Oil & Gas

The regulatory landscape governing energy harvesting technologies in the oil and gas industry is complex and multifaceted, with significant implications for the deployment of thermoelectric generators (TEGs). These regulations span multiple jurisdictions and address various aspects including safety standards, environmental protection, and energy efficiency requirements.

At the international level, organizations such as the International Electrotechnical Commission (IEC) have established standards like IEC 62830 for energy harvesting devices, which provide guidelines for performance measurement and safety requirements. The International Organization for Standardization (ISO) has also developed relevant standards for equipment operating in hazardous environments typical of oil and gas facilities.

In the United States, regulatory oversight is primarily managed by agencies including the Department of Energy (DOE), which promotes energy efficiency technologies, and the Bureau of Safety and Environmental Enforcement (BSEE) for offshore applications. The National Electric Code (NEC) and standards from the American Petroleum Institute (API) provide specific requirements for electrical equipment in hazardous locations, directly impacting TEG installations.

European regulations are generally more stringent, with the ATEX Directive governing equipment used in explosive atmospheres and the Energy Efficiency Directive encouraging the adoption of energy recovery technologies. These frameworks significantly influence TEG design and implementation requirements for European oil and gas operations.

Environmental regulations present both challenges and opportunities for TEG deployment. While carbon pricing mechanisms and emissions trading schemes in various regions can incentivize the adoption of energy harvesting technologies that reduce greenhouse gas emissions, compliance with environmental impact assessment requirements may add complexity to implementation projects.

Certification processes represent a critical regulatory hurdle for TEG technologies. Equipment must typically undergo rigorous testing and certification by recognized bodies such as UL (Underwriters Laboratories), CSA (Canadian Standards Association), or DEKRA in Europe before deployment in hazardous oil and gas environments. These certifications verify compliance with explosion protection, electrical safety, and performance standards.

Recent regulatory trends indicate a shift toward more supportive frameworks for energy harvesting technologies. Several jurisdictions have introduced incentive programs, tax benefits, and streamlined approval processes for technologies that improve energy efficiency and reduce environmental impact in industrial operations, potentially accelerating TEG adoption in the oil and gas sector.

At the international level, organizations such as the International Electrotechnical Commission (IEC) have established standards like IEC 62830 for energy harvesting devices, which provide guidelines for performance measurement and safety requirements. The International Organization for Standardization (ISO) has also developed relevant standards for equipment operating in hazardous environments typical of oil and gas facilities.

In the United States, regulatory oversight is primarily managed by agencies including the Department of Energy (DOE), which promotes energy efficiency technologies, and the Bureau of Safety and Environmental Enforcement (BSEE) for offshore applications. The National Electric Code (NEC) and standards from the American Petroleum Institute (API) provide specific requirements for electrical equipment in hazardous locations, directly impacting TEG installations.

European regulations are generally more stringent, with the ATEX Directive governing equipment used in explosive atmospheres and the Energy Efficiency Directive encouraging the adoption of energy recovery technologies. These frameworks significantly influence TEG design and implementation requirements for European oil and gas operations.

Environmental regulations present both challenges and opportunities for TEG deployment. While carbon pricing mechanisms and emissions trading schemes in various regions can incentivize the adoption of energy harvesting technologies that reduce greenhouse gas emissions, compliance with environmental impact assessment requirements may add complexity to implementation projects.

Certification processes represent a critical regulatory hurdle for TEG technologies. Equipment must typically undergo rigorous testing and certification by recognized bodies such as UL (Underwriters Laboratories), CSA (Canadian Standards Association), or DEKRA in Europe before deployment in hazardous oil and gas environments. These certifications verify compliance with explosion protection, electrical safety, and performance standards.

Recent regulatory trends indicate a shift toward more supportive frameworks for energy harvesting technologies. Several jurisdictions have introduced incentive programs, tax benefits, and streamlined approval processes for technologies that improve energy efficiency and reduce environmental impact in industrial operations, potentially accelerating TEG adoption in the oil and gas sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!