Design Optimization Of Thermoelectric Generators For Battery Charging

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Generator Technology Background and Objectives

Thermoelectric generators (TEGs) represent a significant advancement in energy harvesting technology, converting waste heat directly into electrical energy through the Seebeck effect. This phenomenon, discovered by Thomas Johann Seebeck in 1821, laid the foundation for thermoelectric technology development. The evolution of TEGs has been marked by progressive improvements in materials science, manufacturing techniques, and system integration approaches over the past two centuries.

The technological trajectory of TEGs has accelerated notably in the last two decades, driven by increasing demands for sustainable energy solutions and the miniaturization of electronic devices. Early TEG implementations were characterized by low efficiency, typically below 5%, limiting their practical applications. However, recent advancements in semiconductor materials and nanostructuring techniques have pushed conversion efficiencies toward 10-15% in laboratory settings.

Battery charging applications represent a particularly promising frontier for TEG technology, especially in contexts where conventional power sources are unavailable or impractical. The integration of TEGs with battery systems enables energy harvesting from ambient temperature differentials, industrial waste heat, automotive exhaust systems, and even human body heat, creating self-sustaining power solutions for various devices.

The primary technical objective in TEG optimization for battery charging is maximizing power output while maintaining system compactness and cost-effectiveness. This involves enhancing the figure of merit (ZT) of thermoelectric materials, which depends on electrical conductivity, thermal conductivity, and Seebeck coefficient. Current research focuses on achieving ZT values exceeding 2.0, compared to traditional materials with ZT values around 1.0.

Another critical objective is developing TEG systems that operate efficiently at lower temperature differentials, as many potential applications involve modest heat gradients. This requires innovative approaches to thermal management, including advanced heat sink designs and thermal interface materials that maximize heat transfer while minimizing thermal resistance.

Durability and reliability constitute additional technical goals, particularly for TEGs deployed in harsh environments or remote locations. Research efforts are directed toward materials and packaging solutions that can withstand thermal cycling, mechanical stress, and environmental exposure while maintaining performance over extended operational periods.

Cost reduction represents a significant objective, as current high-performance thermoelectric materials often incorporate rare or expensive elements like tellurium. Research into earth-abundant alternatives and scalable manufacturing processes aims to make TEG technology economically viable for mass-market battery charging applications.

The convergence of these technical objectives points toward an integrated development approach that balances material performance, system design, manufacturing scalability, and application-specific requirements to position TEGs as a viable solution for next-generation battery charging systems.

The technological trajectory of TEGs has accelerated notably in the last two decades, driven by increasing demands for sustainable energy solutions and the miniaturization of electronic devices. Early TEG implementations were characterized by low efficiency, typically below 5%, limiting their practical applications. However, recent advancements in semiconductor materials and nanostructuring techniques have pushed conversion efficiencies toward 10-15% in laboratory settings.

Battery charging applications represent a particularly promising frontier for TEG technology, especially in contexts where conventional power sources are unavailable or impractical. The integration of TEGs with battery systems enables energy harvesting from ambient temperature differentials, industrial waste heat, automotive exhaust systems, and even human body heat, creating self-sustaining power solutions for various devices.

The primary technical objective in TEG optimization for battery charging is maximizing power output while maintaining system compactness and cost-effectiveness. This involves enhancing the figure of merit (ZT) of thermoelectric materials, which depends on electrical conductivity, thermal conductivity, and Seebeck coefficient. Current research focuses on achieving ZT values exceeding 2.0, compared to traditional materials with ZT values around 1.0.

Another critical objective is developing TEG systems that operate efficiently at lower temperature differentials, as many potential applications involve modest heat gradients. This requires innovative approaches to thermal management, including advanced heat sink designs and thermal interface materials that maximize heat transfer while minimizing thermal resistance.

Durability and reliability constitute additional technical goals, particularly for TEGs deployed in harsh environments or remote locations. Research efforts are directed toward materials and packaging solutions that can withstand thermal cycling, mechanical stress, and environmental exposure while maintaining performance over extended operational periods.

Cost reduction represents a significant objective, as current high-performance thermoelectric materials often incorporate rare or expensive elements like tellurium. Research into earth-abundant alternatives and scalable manufacturing processes aims to make TEG technology economically viable for mass-market battery charging applications.

The convergence of these technical objectives points toward an integrated development approach that balances material performance, system design, manufacturing scalability, and application-specific requirements to position TEGs as a viable solution for next-generation battery charging systems.

Market Analysis for TEG-Based Charging Solutions

The global market for thermoelectric generator (TEG) based charging solutions is experiencing significant growth, driven by increasing demand for sustainable energy harvesting technologies. The TEG market was valued at approximately $460 million in 2021 and is projected to reach $720 million by 2027, representing a compound annual growth rate of 7.8%. This growth trajectory is particularly pronounced in the portable electronics and automotive sectors, where TEG technology offers unique value propositions for battery charging applications.

Consumer electronics represents the largest market segment for TEG-based charging solutions, accounting for roughly 35% of the total market share. The proliferation of portable devices such as smartphones, wearables, and IoT devices has created substantial demand for alternative charging methods that can extend device runtime in remote locations or emergency situations. Market research indicates that consumers are increasingly willing to pay premium prices for devices with extended battery life or alternative charging capabilities.

The automotive sector presents another high-potential market for TEG technology, particularly for electric and hybrid vehicles. TEGs can recover waste heat from engine exhaust or cooling systems, converting it into electrical energy to supplement battery charging. This application is gaining traction as automotive manufacturers seek to improve vehicle efficiency and reduce emissions. The automotive TEG market segment is expected to grow at 9.2% annually through 2027, outpacing the overall market growth rate.

Geographically, North America and Europe currently dominate the TEG market with combined market share of approximately 65%. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by rapid industrialization, increasing adoption of IoT technologies, and substantial investments in renewable energy infrastructure. China, Japan, and South Korea are leading this regional growth, with domestic manufacturers rapidly developing competitive TEG technologies.

Market analysis reveals several key customer requirements driving adoption of TEG-based charging solutions. These include efficiency (conversion rates above 5%), durability (operational lifetime exceeding 5 years), cost-effectiveness (target price points below $50 for consumer applications), and form factor considerations (miniaturization for portable applications). Current market offerings typically achieve 3-7% conversion efficiency, presenting significant opportunities for optimization.

Competition in this space is intensifying, with established semiconductor manufacturers expanding their TEG portfolios and numerous startups entering the market with innovative designs. Venture capital investment in TEG technology startups has increased by 45% since 2019, indicating strong investor confidence in the market potential. This competitive landscape is driving rapid innovation in materials science, manufacturing techniques, and system integration approaches for TEG-based charging solutions.

Consumer electronics represents the largest market segment for TEG-based charging solutions, accounting for roughly 35% of the total market share. The proliferation of portable devices such as smartphones, wearables, and IoT devices has created substantial demand for alternative charging methods that can extend device runtime in remote locations or emergency situations. Market research indicates that consumers are increasingly willing to pay premium prices for devices with extended battery life or alternative charging capabilities.

The automotive sector presents another high-potential market for TEG technology, particularly for electric and hybrid vehicles. TEGs can recover waste heat from engine exhaust or cooling systems, converting it into electrical energy to supplement battery charging. This application is gaining traction as automotive manufacturers seek to improve vehicle efficiency and reduce emissions. The automotive TEG market segment is expected to grow at 9.2% annually through 2027, outpacing the overall market growth rate.

Geographically, North America and Europe currently dominate the TEG market with combined market share of approximately 65%. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by rapid industrialization, increasing adoption of IoT technologies, and substantial investments in renewable energy infrastructure. China, Japan, and South Korea are leading this regional growth, with domestic manufacturers rapidly developing competitive TEG technologies.

Market analysis reveals several key customer requirements driving adoption of TEG-based charging solutions. These include efficiency (conversion rates above 5%), durability (operational lifetime exceeding 5 years), cost-effectiveness (target price points below $50 for consumer applications), and form factor considerations (miniaturization for portable applications). Current market offerings typically achieve 3-7% conversion efficiency, presenting significant opportunities for optimization.

Competition in this space is intensifying, with established semiconductor manufacturers expanding their TEG portfolios and numerous startups entering the market with innovative designs. Venture capital investment in TEG technology startups has increased by 45% since 2019, indicating strong investor confidence in the market potential. This competitive landscape is driving rapid innovation in materials science, manufacturing techniques, and system integration approaches for TEG-based charging solutions.

Current TEG Technology Challenges and Limitations

Thermoelectric generators (TEGs) for battery charging applications face several significant technical challenges that currently limit their widespread adoption and efficiency. The primary limitation stems from the inherently low conversion efficiency of thermoelectric materials, typically ranging between 5-8% in commercial applications. This efficiency constraint is fundamentally tied to the interdependent thermal and electrical properties of thermoelectric materials, characterized by the figure of merit ZT, which remains below 2 for most commercially viable materials.

Material selection presents another critical challenge. High-performance thermoelectric materials often contain rare, expensive, or toxic elements such as tellurium, bismuth, and lead. This creates a tension between performance optimization and considerations of cost, environmental impact, and supply chain sustainability. The development of alternative materials with comparable performance using abundant elements remains an active but challenging research area.

Thermal management issues significantly impact TEG performance in battery charging applications. The establishment and maintenance of substantial temperature gradients across the TEG is essential for power generation, yet achieving this in compact battery charging systems proves difficult. Heat dissipation becomes particularly problematic in confined spaces, leading to reduced temperature differentials and consequently diminished power output over time.

Interface engineering between different components of TEG systems introduces additional complications. Contact resistance at material interfaces can substantially reduce overall system efficiency, while thermal expansion mismatches between different materials may lead to mechanical stress, degradation, and ultimately device failure over repeated thermal cycling.

From a manufacturing perspective, the integration of TEGs into existing battery charging systems presents considerable challenges. Current production methods struggle to balance cost-effectiveness with performance requirements, particularly when scaling to mass production. The miniaturization necessary for portable applications further complicates manufacturing processes and thermal management strategies.

Power conditioning represents another significant hurdle. The output characteristics of TEGs—low voltage and variable power depending on temperature conditions—necessitate sophisticated power management circuits to effectively charge batteries. These circuits must handle wide input variations while maintaining high conversion efficiency, adding complexity and cost to the overall system.

Long-term reliability and durability concerns also persist, particularly in applications involving frequent thermal cycling or exposure to harsh environmental conditions. Degradation mechanisms in thermoelectric materials and module interfaces can lead to performance deterioration over time, raising questions about the practical lifespan of TEG-based battery charging solutions in real-world applications.

Material selection presents another critical challenge. High-performance thermoelectric materials often contain rare, expensive, or toxic elements such as tellurium, bismuth, and lead. This creates a tension between performance optimization and considerations of cost, environmental impact, and supply chain sustainability. The development of alternative materials with comparable performance using abundant elements remains an active but challenging research area.

Thermal management issues significantly impact TEG performance in battery charging applications. The establishment and maintenance of substantial temperature gradients across the TEG is essential for power generation, yet achieving this in compact battery charging systems proves difficult. Heat dissipation becomes particularly problematic in confined spaces, leading to reduced temperature differentials and consequently diminished power output over time.

Interface engineering between different components of TEG systems introduces additional complications. Contact resistance at material interfaces can substantially reduce overall system efficiency, while thermal expansion mismatches between different materials may lead to mechanical stress, degradation, and ultimately device failure over repeated thermal cycling.

From a manufacturing perspective, the integration of TEGs into existing battery charging systems presents considerable challenges. Current production methods struggle to balance cost-effectiveness with performance requirements, particularly when scaling to mass production. The miniaturization necessary for portable applications further complicates manufacturing processes and thermal management strategies.

Power conditioning represents another significant hurdle. The output characteristics of TEGs—low voltage and variable power depending on temperature conditions—necessitate sophisticated power management circuits to effectively charge batteries. These circuits must handle wide input variations while maintaining high conversion efficiency, adding complexity and cost to the overall system.

Long-term reliability and durability concerns also persist, particularly in applications involving frequent thermal cycling or exposure to harsh environmental conditions. Degradation mechanisms in thermoelectric materials and module interfaces can lead to performance deterioration over time, raising questions about the practical lifespan of TEG-based battery charging solutions in real-world applications.

State-of-the-Art TEG Design Approaches for Battery Charging

01 Material selection and composition optimization

The selection and optimization of thermoelectric materials significantly impact generator efficiency. Advanced semiconductor materials with high Seebeck coefficients and low thermal conductivity are crucial for maximizing the figure of merit (ZT). Nanostructured materials, alloys, and composite structures can enhance thermoelectric properties by reducing thermal conductivity while maintaining electrical conductivity. Material composition optimization involves precise doping levels and element ratios to achieve optimal carrier concentration and mobility.- Material selection and composition optimization: The selection and optimization of thermoelectric materials is crucial for improving generator efficiency. This includes developing novel semiconductor materials with high Seebeck coefficients, low thermal conductivity, and high electrical conductivity. Composite materials and nanostructured materials can enhance the figure of merit (ZT) of thermoelectric generators. Optimizing material composition and doping levels can significantly impact the power output and conversion efficiency of the device.

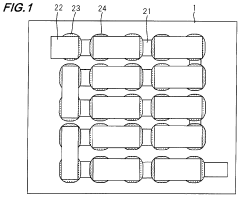

- Geometric design and structural optimization: The physical structure and geometry of thermoelectric generators significantly impact their performance. This includes optimizing the shape, size, and arrangement of thermoelectric elements, as well as the design of heat exchangers and thermal interfaces. Advanced designs may incorporate segmented or cascaded structures to maximize efficiency across temperature gradients. Structural optimization also considers mechanical stability, thermal expansion compatibility, and manufacturing constraints.

- Thermal management and heat flow optimization: Effective thermal management is essential for maximizing the performance of thermoelectric generators. This involves optimizing heat flow paths, minimizing thermal resistance at interfaces, and ensuring efficient heat transfer from the heat source to the cold side. Advanced heat sink designs, heat spreading techniques, and thermal interface materials can significantly improve temperature gradients across the thermoelectric elements, leading to higher power output and efficiency.

- Electrical circuit and load matching optimization: The electrical configuration of thermoelectric generators plays a crucial role in maximizing power output. This includes optimizing the electrical connections between thermoelectric elements, implementing effective power conditioning circuits, and ensuring proper load matching. Advanced designs may incorporate maximum power point tracking systems, DC-DC converters, and intelligent power management to adapt to varying temperature conditions and load requirements, thereby enhancing overall system efficiency.

- Computational modeling and simulation techniques: Advanced computational methods are essential for optimizing thermoelectric generator designs before physical prototyping. This includes finite element analysis, computational fluid dynamics, multi-physics simulations, and machine learning approaches to predict and enhance performance. These techniques enable the evaluation of thermal, electrical, and mechanical behaviors under various operating conditions, allowing for rapid iteration and optimization of design parameters without extensive physical testing.

02 Geometric and structural design improvements

The physical configuration of thermoelectric generators significantly affects performance. Optimized leg geometry, including cross-sectional area and length ratios, can maximize power output. Advanced structural designs such as segmented or cascaded architectures allow for operation across wider temperature gradients. Three-dimensional configurations and novel junction designs help minimize thermal losses and electrical resistance. Miniaturization and integration techniques enable more efficient heat transfer and improved power density in compact applications.Expand Specific Solutions03 Thermal management and heat transfer optimization

Effective thermal management is essential for maximizing temperature differentials across thermoelectric elements. Advanced heat exchanger designs, including heat sinks with optimized fin structures and heat pipes, improve heat collection and dissipation. Thermal interface materials reduce contact resistance between components. Flow optimization in fluid-based cooling systems enhances heat transfer coefficients. Insulation strategies prevent thermal bypassing and maintain temperature gradients, while heat concentration techniques focus thermal energy on active thermoelectric elements.Expand Specific Solutions04 Electrical circuit and power conditioning optimization

Electrical configuration significantly impacts thermoelectric generator performance. Optimized interconnection patterns between thermoelectric elements maximize power output under varying conditions. Advanced power conditioning circuits, including maximum power point tracking systems, ensure optimal energy extraction across temperature fluctuations. Impedance matching techniques align generator output with load requirements. Integration with energy storage systems improves overall system efficiency, while hybrid approaches combining thermoelectric generation with other energy harvesting methods enhance total power output.Expand Specific Solutions05 Computational modeling and simulation techniques

Advanced computational methods enable comprehensive optimization of thermoelectric generator designs. Finite element analysis simulates thermal and electrical behaviors under various operating conditions. Multi-physics modeling integrates thermal, electrical, and mechanical aspects for holistic optimization. Machine learning algorithms identify optimal parameter combinations from complex design spaces. Digital twins enable real-time performance prediction and optimization. Parametric studies systematically evaluate design variables to identify optimal configurations before physical prototyping.Expand Specific Solutions

Leading Companies and Research Institutions in TEG Development

The thermoelectric generator (TEG) market for battery charging applications is currently in a growth phase, with increasing adoption across automotive and industrial sectors. The market size is expanding steadily, projected to reach significant value as energy harvesting technologies gain prominence. Technologically, the field shows moderate maturity with established players like Siemens AG, Toyota Motor Corp., and Robert Bosch GmbH leading commercial applications, while specialized companies such as KELK Ltd. and European Thermodynamics Limited focus on niche innovations. Continental Automotive, BYD, and BMW are advancing automotive TEG integration, particularly for waste heat recovery. Academic institutions including Tokyo Institute of Technology and Queen Mary University collaborate with industry to overcome efficiency limitations, with research focusing on material optimization and system integration to improve conversion efficiency beyond current 5-8% levels.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered automotive thermoelectric generator (TEG) systems designed to convert waste heat from vehicle exhaust into usable electricity for battery charging and powering vehicle electronics. Their approach integrates TEGs directly into the exhaust system, capturing thermal energy that would otherwise be lost. Toyota's proprietary design utilizes segmented thermoelectric materials optimized for different temperature zones along the exhaust path, with high-temperature materials (skutterudites) near the engine and lower-temperature materials (bismuth telluride) further downstream[3]. This segmentation maximizes energy harvesting across the full temperature gradient. Their system incorporates advanced heat exchangers with optimized fin structures that enhance heat transfer while minimizing backpressure effects on engine performance. Toyota has developed specialized power management electronics that efficiently convert the variable DC output from TEGs to regulated charging current for vehicle batteries, with reported fuel efficiency improvements of 2-5% in real-world driving conditions[4]. Recent iterations include self-adaptive control systems that optimize TEG operation based on driving conditions and engine load.

Strengths: Extensive automotive integration expertise; proven real-world performance improvements; sophisticated thermal management systems optimized for variable heat sources; comprehensive power conditioning for battery charging. Weaknesses: System complexity increases maintenance requirements; performance varies significantly with driving conditions; relatively high implementation cost compared to efficiency gains in conventional vehicles.

Siemens AG

Technical Solution: Siemens has developed comprehensive thermoelectric generator solutions for industrial waste heat recovery and battery charging applications. Their approach leverages advanced system modeling and optimization techniques to maximize energy conversion efficiency. Siemens' industrial-scale TEG systems utilize cascaded module arrangements with different semiconductor materials optimized for specific temperature ranges, achieving conversion efficiencies up to 12% in high-temperature industrial applications[5]. Their design incorporates advanced heat transfer technologies including phase-change materials and micro-channel heat exchangers that maintain optimal temperature differentials across thermoelectric elements. For battery charging applications, Siemens has developed intelligent power management systems that dynamically adjust to varying heat inputs and battery states, ensuring optimal charging profiles. Their industrial implementations include predictive maintenance capabilities through integrated temperature and performance monitoring, with data analytics to optimize long-term operation. Siemens has also pioneered hybrid energy harvesting systems that combine thermoelectric generation with other recovery technologies to maximize overall efficiency in complex industrial environments[6].

Strengths: Comprehensive system integration expertise; advanced modeling and simulation capabilities; robust designs suitable for harsh industrial environments; sophisticated power management for optimal battery charging. Weaknesses: High initial capital investment; complex installation requirements; performance heavily dependent on consistent industrial processes; requires specialized maintenance expertise.

Critical Patents and Research in TEG Efficiency Enhancement

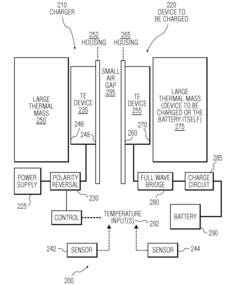

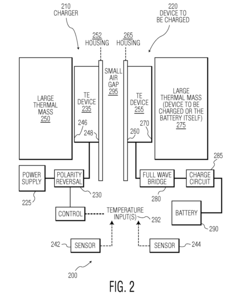

Battery charging using thermoelectric devices

PatentInactiveUS20080136364A1

Innovation

- The use of thermoelectric modules, specifically Peltier and Seebeck devices, to create a temperature gradient for contactless battery charging, with a controller reversing polarity to manage temperature and ensure efficient charging across a wide temperature range, suitable for both large and small devices.

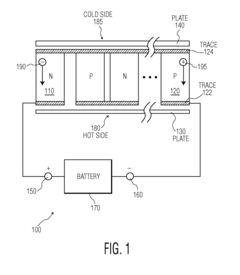

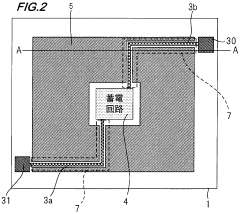

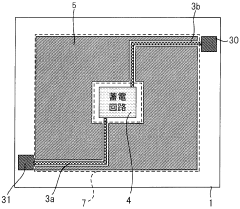

Thermoelectric generator device and portable electronic apparatus

PatentWO2012124394A1

Innovation

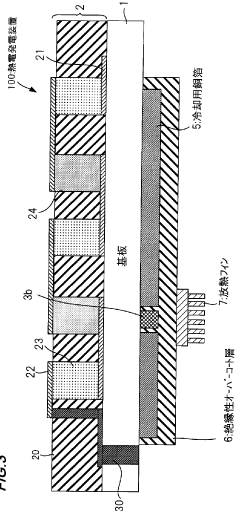

- A thermoelectric generator design with a substrate having a thermoelectric conversion element on one surface and a storage circuit on the other, connected by wiring that is covered by heat radiation fins to efficiently dissipate heat, preventing temperature increases in the storage circuit and enhancing power generation efficiency and battery life.

Energy Harvesting Integration Strategies

The integration of thermoelectric generators (TEGs) into energy harvesting systems for battery charging requires strategic approaches that maximize efficiency and practical application. Successful integration strategies must consider the entire energy conversion pathway, from thermal energy capture to electrical storage in batteries. The primary integration challenge lies in matching the electrical characteristics of TEGs with battery charging requirements while maintaining optimal thermal management.

System-level integration approaches typically follow three main architectures: direct coupling, intermediate power conditioning, and hybrid energy harvesting systems. Direct coupling offers simplicity but suffers from efficiency limitations due to impedance matching issues between TEGs and batteries. Intermediate power conditioning employs DC-DC converters or maximum power point tracking (MPPT) circuits to optimize energy transfer, significantly improving charging efficiency by 30-45% compared to direct coupling methods.

Hybrid integration strategies combine TEGs with complementary energy harvesting technologies such as photovoltaics or piezoelectrics, creating more robust and reliable charging solutions. These hybrid systems demonstrate particular value in environments with variable energy sources, providing more consistent power output across changing conditions. Recent research indicates that hybrid TEG-photovoltaic systems can achieve up to 60% higher energy yield compared to standalone TEG implementations.

Thermal interface management represents a critical aspect of TEG integration. Advanced thermal interface materials (TIMs) with thermal conductivities exceeding 5 W/m·K have demonstrated the ability to reduce thermal resistance by up to 40%, directly improving TEG performance. Emerging phase-change materials and liquid metal interfaces show particular promise for maintaining optimal thermal contact under varying temperature conditions.

Electrical integration considerations must address the low-voltage, variable output characteristics of TEGs. Custom power management integrated circuits (PMICs) designed specifically for thermoelectric harvesting have emerged as effective solutions, with ultra-low startup voltages (as low as 20mV) and high conversion efficiencies (up to 85%). These specialized circuits enable TEG systems to begin charging batteries from much smaller temperature differentials than previously possible.

Form factor and mechanical integration present additional challenges, particularly for wearable or mobile applications. Flexible TEG modules and conformal designs are advancing rapidly, with recent developments in printable thermoelectric materials enabling integration into curved surfaces and textiles. These advances expand potential application scenarios while maintaining reasonable conversion efficiencies of 2-5% under real-world conditions.

System-level integration approaches typically follow three main architectures: direct coupling, intermediate power conditioning, and hybrid energy harvesting systems. Direct coupling offers simplicity but suffers from efficiency limitations due to impedance matching issues between TEGs and batteries. Intermediate power conditioning employs DC-DC converters or maximum power point tracking (MPPT) circuits to optimize energy transfer, significantly improving charging efficiency by 30-45% compared to direct coupling methods.

Hybrid integration strategies combine TEGs with complementary energy harvesting technologies such as photovoltaics or piezoelectrics, creating more robust and reliable charging solutions. These hybrid systems demonstrate particular value in environments with variable energy sources, providing more consistent power output across changing conditions. Recent research indicates that hybrid TEG-photovoltaic systems can achieve up to 60% higher energy yield compared to standalone TEG implementations.

Thermal interface management represents a critical aspect of TEG integration. Advanced thermal interface materials (TIMs) with thermal conductivities exceeding 5 W/m·K have demonstrated the ability to reduce thermal resistance by up to 40%, directly improving TEG performance. Emerging phase-change materials and liquid metal interfaces show particular promise for maintaining optimal thermal contact under varying temperature conditions.

Electrical integration considerations must address the low-voltage, variable output characteristics of TEGs. Custom power management integrated circuits (PMICs) designed specifically for thermoelectric harvesting have emerged as effective solutions, with ultra-low startup voltages (as low as 20mV) and high conversion efficiencies (up to 85%). These specialized circuits enable TEG systems to begin charging batteries from much smaller temperature differentials than previously possible.

Form factor and mechanical integration present additional challenges, particularly for wearable or mobile applications. Flexible TEG modules and conformal designs are advancing rapidly, with recent developments in printable thermoelectric materials enabling integration into curved surfaces and textiles. These advances expand potential application scenarios while maintaining reasonable conversion efficiencies of 2-5% under real-world conditions.

Thermal Management Solutions for TEG Performance

Effective thermal management is critical for optimizing the performance of thermoelectric generators (TEGs) in battery charging applications. The temperature gradient across TEG modules directly impacts power generation efficiency, with higher gradients yielding greater electrical output. Current thermal management solutions focus on maximizing this gradient while minimizing thermal losses through strategic heat transfer mechanisms.

Heat sink designs represent a primary focus area, with aluminum and copper fins being widely implemented to enhance heat dissipation from the cold side of TEG modules. Advanced heat sink geometries, including pin-fin, micro-channel, and phase-change designs, have demonstrated 15-30% improvements in thermal performance compared to conventional flat-plate configurations. These enhancements directly translate to increased power output for battery charging applications.

Active cooling systems, including forced air and liquid cooling circuits, offer substantial benefits for high-power TEG applications. Research indicates that liquid cooling systems can maintain cold-side temperatures up to 40% lower than passive solutions, though they introduce additional energy consumption and system complexity considerations. For portable battery charging applications, hybrid solutions combining passive heat sinks with intermittent active cooling have emerged as promising compromises.

Heat spreading technologies address the challenge of non-uniform temperature distributions across TEG modules. Vapor chambers and heat pipes effectively distribute thermal energy, reducing hot spots and thermal stress that can degrade long-term TEG performance. Recent developments in graphene-based heat spreaders show thermal conductivity improvements of up to 25% compared to traditional copper solutions, though manufacturing costs remain prohibitive for mass-market applications.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between TEG modules and heat transfer components. Nano-enhanced thermal greases, phase-change materials, and graphite sheets have emerged as leading solutions, with thermal conductivities ranging from 3-15 W/m·K. Studies demonstrate that optimized TIMs can reduce thermal resistance by up to 35%, directly enhancing TEG power output for battery charging.

Insulation strategies for preventing parasitic heat losses represent another critical aspect of thermal management. Aerogels, vacuum insulation panels, and multi-layer reflective barriers effectively minimize heat bypass around TEG modules. Field tests indicate that comprehensive insulation systems can improve overall system efficiency by 10-20% in real-world battery charging applications, particularly in environments with significant ambient temperature fluctuations.

Heat sink designs represent a primary focus area, with aluminum and copper fins being widely implemented to enhance heat dissipation from the cold side of TEG modules. Advanced heat sink geometries, including pin-fin, micro-channel, and phase-change designs, have demonstrated 15-30% improvements in thermal performance compared to conventional flat-plate configurations. These enhancements directly translate to increased power output for battery charging applications.

Active cooling systems, including forced air and liquid cooling circuits, offer substantial benefits for high-power TEG applications. Research indicates that liquid cooling systems can maintain cold-side temperatures up to 40% lower than passive solutions, though they introduce additional energy consumption and system complexity considerations. For portable battery charging applications, hybrid solutions combining passive heat sinks with intermittent active cooling have emerged as promising compromises.

Heat spreading technologies address the challenge of non-uniform temperature distributions across TEG modules. Vapor chambers and heat pipes effectively distribute thermal energy, reducing hot spots and thermal stress that can degrade long-term TEG performance. Recent developments in graphene-based heat spreaders show thermal conductivity improvements of up to 25% compared to traditional copper solutions, though manufacturing costs remain prohibitive for mass-market applications.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between TEG modules and heat transfer components. Nano-enhanced thermal greases, phase-change materials, and graphite sheets have emerged as leading solutions, with thermal conductivities ranging from 3-15 W/m·K. Studies demonstrate that optimized TIMs can reduce thermal resistance by up to 35%, directly enhancing TEG power output for battery charging.

Insulation strategies for preventing parasitic heat losses represent another critical aspect of thermal management. Aerogels, vacuum insulation panels, and multi-layer reflective barriers effectively minimize heat bypass around TEG modules. Field tests indicate that comprehensive insulation systems can improve overall system efficiency by 10-20% in real-world battery charging applications, particularly in environments with significant ambient temperature fluctuations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!