Composite Foil Designs For Conformal Thermoelectric Generators

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal TEG Technology Background and Objectives

Thermoelectric generators (TEGs) have evolved significantly since their discovery in the early 19th century, with the Seebeck effect first observed in 1821. Traditional TEG designs have predominantly featured rigid, flat structures that limit their application in non-planar surfaces. The emergence of conformal TEG technology represents a paradigm shift, enabling these energy harvesting devices to adapt to curved, irregular, and dynamic surfaces while maintaining optimal performance characteristics.

Composite foil designs for conformal TEGs leverage advanced materials science and innovative manufacturing techniques to create flexible, thin-film thermoelectric materials that can be applied to various geometries. This approach addresses the fundamental limitation of conventional TEGs by enabling effective thermal energy harvesting from non-flat heat sources, which are prevalent in numerous real-world applications including wearable electronics, automotive components, industrial equipment, and aerospace systems.

The technological evolution trajectory indicates a clear movement from bulk thermoelectric materials toward thin-film and now composite foil structures. This progression has been driven by the increasing demand for energy harvesting solutions that can operate effectively in space-constrained environments and on irregular surfaces. The miniaturization trend in electronics and the growing interest in self-powered systems have further accelerated research in this domain.

Current objectives for composite foil conformal TEG technology focus on several key areas: enhancing conversion efficiency beyond the current 5-10% range, improving mechanical flexibility while maintaining thermoelectric performance, developing cost-effective manufacturing processes for large-scale production, and extending operational lifespan under repeated mechanical stress and thermal cycling conditions.

A critical technical goal involves optimizing the interface between different materials in the composite structure to minimize thermal resistance while maximizing electrical conductivity. Additionally, researchers aim to develop composite foils that can withstand significant mechanical deformation (>10% strain) without performance degradation, enabling applications on highly curved or dynamic surfaces.

The field is also pursuing advancements in material combinations that can operate efficiently across wider temperature differentials, particularly in the low-temperature range (ΔT < 100°C) where many potential applications exist. This includes exploring novel semiconductor composites, organic thermoelectric materials, and hybrid organic-inorganic structures that offer superior flexibility compared to traditional inorganic thermoelectric compounds.

Long-term objectives include the development of self-healing composite foils that can maintain performance integrity over extended periods, as well as environmentally sustainable materials that reduce reliance on rare or toxic elements commonly used in high-performance thermoelectric compounds.

Composite foil designs for conformal TEGs leverage advanced materials science and innovative manufacturing techniques to create flexible, thin-film thermoelectric materials that can be applied to various geometries. This approach addresses the fundamental limitation of conventional TEGs by enabling effective thermal energy harvesting from non-flat heat sources, which are prevalent in numerous real-world applications including wearable electronics, automotive components, industrial equipment, and aerospace systems.

The technological evolution trajectory indicates a clear movement from bulk thermoelectric materials toward thin-film and now composite foil structures. This progression has been driven by the increasing demand for energy harvesting solutions that can operate effectively in space-constrained environments and on irregular surfaces. The miniaturization trend in electronics and the growing interest in self-powered systems have further accelerated research in this domain.

Current objectives for composite foil conformal TEG technology focus on several key areas: enhancing conversion efficiency beyond the current 5-10% range, improving mechanical flexibility while maintaining thermoelectric performance, developing cost-effective manufacturing processes for large-scale production, and extending operational lifespan under repeated mechanical stress and thermal cycling conditions.

A critical technical goal involves optimizing the interface between different materials in the composite structure to minimize thermal resistance while maximizing electrical conductivity. Additionally, researchers aim to develop composite foils that can withstand significant mechanical deformation (>10% strain) without performance degradation, enabling applications on highly curved or dynamic surfaces.

The field is also pursuing advancements in material combinations that can operate efficiently across wider temperature differentials, particularly in the low-temperature range (ΔT < 100°C) where many potential applications exist. This includes exploring novel semiconductor composites, organic thermoelectric materials, and hybrid organic-inorganic structures that offer superior flexibility compared to traditional inorganic thermoelectric compounds.

Long-term objectives include the development of self-healing composite foils that can maintain performance integrity over extended periods, as well as environmentally sustainable materials that reduce reliance on rare or toxic elements commonly used in high-performance thermoelectric compounds.

Market Analysis for Flexible Thermoelectric Applications

The flexible thermoelectric generator (TEG) market is experiencing significant growth driven by the increasing demand for wearable electronics, IoT devices, and energy harvesting solutions. The global market for flexible thermoelectric materials and devices is projected to reach $745 million by 2027, growing at a CAGR of 18.3% from 2022. This growth is primarily fueled by the expanding wearable technology sector, which itself is expected to surpass $100 billion by 2028.

Conformal thermoelectric generators based on composite foil designs address a critical market need for power sources that can adapt to irregular surfaces while harvesting waste heat. The healthcare sector represents the largest application segment, with medical wearables requiring reliable, body-conforming power sources for continuous health monitoring. This segment accounts for approximately 32% of the flexible TEG market.

Consumer electronics follows closely, representing 28% of market demand, where flexible TEGs are increasingly integrated into smartphones, smartwatches, and fitness trackers to extend battery life. The industrial IoT sector constitutes about 21% of the market, utilizing conformal TEGs for powering remote sensors in environments with temperature gradients.

Regional analysis reveals North America currently leads the market with 38% share, driven by strong R&D investments and early technology adoption. Asia-Pacific is the fastest-growing region with a 22.4% CAGR, supported by manufacturing capabilities and increasing electronic device production in countries like China, South Korea, and Japan.

Customer demand patterns indicate a strong preference for TEGs with power densities exceeding 1 mW/cm² at temperature differences of less than 10°C, particularly for body-heat harvesting applications. Flexibility requirements typically specify operational stability through at least 10,000 bending cycles with a minimum bending radius of 5 mm.

Market barriers include relatively high production costs, with current flexible TEG solutions priced at $10-15 per watt, significantly higher than rigid alternatives. Technical challenges in maintaining consistent electrical connections in flexible substrates also limit widespread adoption.

Emerging market opportunities exist in smart textiles, where the integration of composite foil TEGs could enable self-powered garments with a projected market value of $4.72 billion by 2030. The automotive sector also presents growth potential, with conformal TEGs potentially recovering waste heat from irregularly shaped components, addressing a market estimated at $2.1 billion by 2028.

Conformal thermoelectric generators based on composite foil designs address a critical market need for power sources that can adapt to irregular surfaces while harvesting waste heat. The healthcare sector represents the largest application segment, with medical wearables requiring reliable, body-conforming power sources for continuous health monitoring. This segment accounts for approximately 32% of the flexible TEG market.

Consumer electronics follows closely, representing 28% of market demand, where flexible TEGs are increasingly integrated into smartphones, smartwatches, and fitness trackers to extend battery life. The industrial IoT sector constitutes about 21% of the market, utilizing conformal TEGs for powering remote sensors in environments with temperature gradients.

Regional analysis reveals North America currently leads the market with 38% share, driven by strong R&D investments and early technology adoption. Asia-Pacific is the fastest-growing region with a 22.4% CAGR, supported by manufacturing capabilities and increasing electronic device production in countries like China, South Korea, and Japan.

Customer demand patterns indicate a strong preference for TEGs with power densities exceeding 1 mW/cm² at temperature differences of less than 10°C, particularly for body-heat harvesting applications. Flexibility requirements typically specify operational stability through at least 10,000 bending cycles with a minimum bending radius of 5 mm.

Market barriers include relatively high production costs, with current flexible TEG solutions priced at $10-15 per watt, significantly higher than rigid alternatives. Technical challenges in maintaining consistent electrical connections in flexible substrates also limit widespread adoption.

Emerging market opportunities exist in smart textiles, where the integration of composite foil TEGs could enable self-powered garments with a projected market value of $4.72 billion by 2030. The automotive sector also presents growth potential, with conformal TEGs potentially recovering waste heat from irregularly shaped components, addressing a market estimated at $2.1 billion by 2028.

Current Challenges in Composite Foil TEG Development

Despite significant advancements in composite foil thermoelectric generators (TEGs), several critical challenges continue to impede their widespread adoption and optimal performance. Material compatibility remains a fundamental issue, as the integration of different thermoelectric materials with varying thermal expansion coefficients often leads to mechanical stress and potential delamination during thermal cycling. This incompatibility significantly reduces the operational lifespan of composite foil TEGs and limits their reliability in real-world applications.

Manufacturing scalability presents another substantial hurdle. Current production techniques for composite foil TEGs are predominantly laboratory-focused, utilizing processes that are difficult to scale for mass production without compromising performance characteristics. The precision required for thin-film deposition and the complexity of creating effective electrical connections between different thermoelectric materials contribute to high production costs and inconsistent quality control.

Thermal management within composite foil designs continues to challenge engineers. The ultra-thin profile of these generators, while advantageous for flexibility and conformability, creates difficulties in efficiently directing heat flow and maintaining optimal temperature gradients. Heat spreading and parasitic thermal losses significantly reduce conversion efficiency, particularly in low-temperature differential applications where these generators would be most valuable.

Electrical contact resistance at material interfaces represents a persistent technical obstacle. As composite designs necessarily incorporate multiple material junctions, each interface introduces additional resistance that degrades overall performance. Current solutions involving specialized interface materials or processing techniques add complexity and cost without fully resolving the issue.

Mechanical durability under repeated flexing and conforming to irregular surfaces remains problematic. While flexibility is a key advantage of foil-based TEGs, this same characteristic introduces mechanical fatigue concerns. Microcracks develop in thermoelectric materials and interconnects during repeated flexing, progressively degrading performance over time and limiting application in dynamic environments.

Environmental stability poses significant challenges, particularly for organic or hybrid thermoelectric materials often used in flexible composite designs. Exposure to oxygen, moisture, and UV radiation can cause material degradation, while temperature extremes beyond design parameters accelerate performance decline. Effective encapsulation solutions that maintain flexibility while providing environmental protection remain elusive.

Power density limitations continue to restrict application potential. Current composite foil TEGs typically generate power in the microwatt to milliwatt range per square centimeter, insufficient for many potential applications. Increasing power output without compromising the thin, flexible form factor represents a significant engineering challenge requiring innovative material and design approaches.

Manufacturing scalability presents another substantial hurdle. Current production techniques for composite foil TEGs are predominantly laboratory-focused, utilizing processes that are difficult to scale for mass production without compromising performance characteristics. The precision required for thin-film deposition and the complexity of creating effective electrical connections between different thermoelectric materials contribute to high production costs and inconsistent quality control.

Thermal management within composite foil designs continues to challenge engineers. The ultra-thin profile of these generators, while advantageous for flexibility and conformability, creates difficulties in efficiently directing heat flow and maintaining optimal temperature gradients. Heat spreading and parasitic thermal losses significantly reduce conversion efficiency, particularly in low-temperature differential applications where these generators would be most valuable.

Electrical contact resistance at material interfaces represents a persistent technical obstacle. As composite designs necessarily incorporate multiple material junctions, each interface introduces additional resistance that degrades overall performance. Current solutions involving specialized interface materials or processing techniques add complexity and cost without fully resolving the issue.

Mechanical durability under repeated flexing and conforming to irregular surfaces remains problematic. While flexibility is a key advantage of foil-based TEGs, this same characteristic introduces mechanical fatigue concerns. Microcracks develop in thermoelectric materials and interconnects during repeated flexing, progressively degrading performance over time and limiting application in dynamic environments.

Environmental stability poses significant challenges, particularly for organic or hybrid thermoelectric materials often used in flexible composite designs. Exposure to oxygen, moisture, and UV radiation can cause material degradation, while temperature extremes beyond design parameters accelerate performance decline. Effective encapsulation solutions that maintain flexibility while providing environmental protection remain elusive.

Power density limitations continue to restrict application potential. Current composite foil TEGs typically generate power in the microwatt to milliwatt range per square centimeter, insufficient for many potential applications. Increasing power output without compromising the thin, flexible form factor represents a significant engineering challenge requiring innovative material and design approaches.

State-of-the-Art Composite Foil TEG Solutions

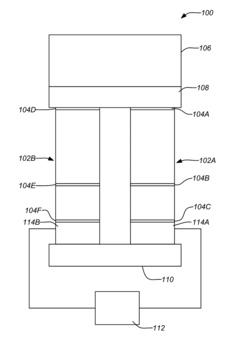

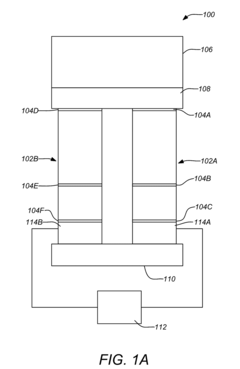

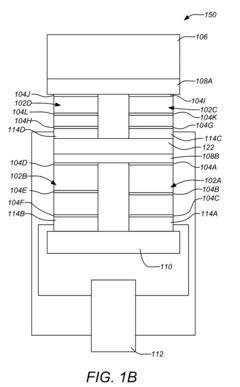

01 Flexible composite foil structures for conformal thermoelectric generators

Flexible composite foil structures are designed to enable thermoelectric generators to conform to irregular surfaces. These structures typically incorporate thin-film thermoelectric materials deposited on flexible substrates, allowing the generator to bend and adapt to curved surfaces while maintaining electrical connectivity. The flexibility of these composite foils ensures maximum thermal contact with heat sources of varying geometries, improving energy harvesting efficiency in wearable and portable applications.- Flexible composite foil structures for conformal thermoelectric generators: Flexible composite foil structures are designed to enable thermoelectric generators to conform to irregular surfaces. These structures typically incorporate thin-film thermoelectric materials deposited on flexible substrates, allowing the generator to bend and adapt to curved surfaces while maintaining electrical connectivity. The flexibility of these composite foils ensures maximum thermal contact with heat sources of varying geometries, improving energy harvesting efficiency in wearable and portable applications.

- Multi-layer foil designs for thermal and electrical optimization: Multi-layer composite foil designs incorporate specialized layers for optimizing both thermal and electrical properties of conformal thermoelectric generators. These designs typically include thermal interface layers, electrical insulation layers, and conductive pathways arranged in a strategic configuration. By carefully engineering the layer structure, these composite foils can maximize temperature gradients across thermoelectric elements while ensuring efficient electrical connectivity, resulting in improved power output from the thermoelectric generator system.

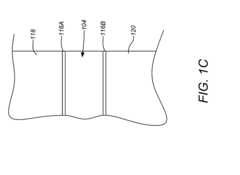

- Manufacturing techniques for conformal thermoelectric foils: Advanced manufacturing techniques are employed to create composite foils for conformal thermoelectric generators. These methods include roll-to-roll processing, thin-film deposition, laser patterning, and lamination processes that enable mass production of flexible thermoelectric materials. The manufacturing approaches focus on creating uniform thermoelectric elements with consistent electrical properties while maintaining mechanical flexibility. These techniques allow for cost-effective production of large-area conformal thermoelectric generators that can be applied to various surface geometries.

- Novel materials for high-performance conformal thermoelectric foils: Innovative material compositions are developed for enhancing the performance of conformal thermoelectric generators. These materials include advanced semiconductor alloys, nanostructured composites, and organic thermoelectric compounds that can be formed into flexible foils. The materials are engineered to exhibit high Seebeck coefficients, low thermal conductivity, and good electrical conductivity while maintaining mechanical flexibility. By incorporating these novel materials into composite foil structures, the power generation capability and efficiency of conformal thermoelectric generators can be significantly improved.

- Integration systems for conformal thermoelectric foil generators: Integration systems are designed to effectively incorporate conformal thermoelectric foil generators into various applications. These systems include specialized mounting methods, electrical connection techniques, and thermal management solutions that optimize the performance of the thermoelectric foils when applied to irregular surfaces. The integration approaches focus on maximizing thermal contact with heat sources while providing reliable electrical connections to power management circuits. These systems enable the practical implementation of conformal thermoelectric generators in applications such as wearable electronics, automotive components, and industrial equipment.

02 Multi-layer composite designs for thermal and electrical optimization

Multi-layer composite designs incorporate various materials strategically layered to optimize both thermal and electrical properties of conformal thermoelectric generators. These designs typically include conductive layers for electrical connectivity, insulating layers to direct heat flow, and specialized interface materials to reduce thermal resistance between layers. The multi-layer approach allows for independent optimization of thermal conductivity and electrical resistance pathways, resulting in higher conversion efficiency while maintaining the flexibility needed for conformal applications.Expand Specific Solutions03 Novel material combinations for enhanced thermoelectric performance

Advanced material combinations are employed in composite foil designs to enhance the thermoelectric performance of conformal generators. These combinations may include organic-inorganic hybrid materials, nanostructured composites, or polymer-based thermoelectric materials that offer improved flexibility while maintaining good thermoelectric properties. By carefully selecting and engineering material interfaces, these composite foils can achieve higher Seebeck coefficients and lower thermal conductivity, leading to improved figure of merit (ZT) values while preserving mechanical flexibility for conformal applications.Expand Specific Solutions04 Manufacturing techniques for conformal thermoelectric foils

Specialized manufacturing techniques are developed for producing conformal thermoelectric composite foils. These techniques include roll-to-roll processing, screen printing, physical vapor deposition on flexible substrates, and laser patterning methods. Advanced manufacturing approaches enable precise control of layer thickness, interface quality, and thermoelectric leg geometry while maintaining the mechanical flexibility required for conformal applications. These fabrication methods are critical for scaling production while ensuring consistent performance of the thermoelectric generators across irregular surfaces.Expand Specific Solutions05 Integration systems for conformal thermoelectric generators

Integration systems are designed to effectively incorporate conformal thermoelectric composite foils into practical applications. These systems address challenges such as electrical interconnection, thermal interface management, and mechanical protection of the flexible thermoelectric elements. Specialized mounting techniques, connector designs, and encapsulation methods ensure that the conformal generators maintain optimal contact with heat sources while being protected from environmental factors. These integration approaches enable the deployment of conformal thermoelectric generators in applications ranging from wearable electronics to industrial waste heat recovery systems.Expand Specific Solutions

Leading Companies in Flexible Thermoelectric Industry

The thermoelectric generator (TEG) composite foil design market is in its growth phase, with increasing interest in waste heat recovery applications. The competitive landscape features established electronics giants like Philips, LG Chem, and Murata Manufacturing alongside specialized players such as O-Flexx Technologies. Research institutions including CEA, KAIST, and Karlsruhe Institute of Technology are driving innovation through fundamental research. The market is characterized by a blend of commercial and research activities, with companies like Hyundai and Continental Emitec exploring automotive applications. Technical challenges in material design and manufacturing processes remain, though recent advancements in composite foil technology by companies like Kobe Steel and Guangzhou Fangbang Electronics are improving efficiency and conformability for irregular surfaces.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai Motor has pioneered composite foil thermoelectric generators specifically designed for automotive applications. Their technology integrates thin-film thermoelectric materials with flexible metal substrates to create conformal TEGs that can be wrapped around exhaust pipes and catalytic converters. The company's approach uses a multi-layer structure with bismuth-telluride and skutterudite-based materials optimized for different temperature zones along the exhaust system. Their proprietary manufacturing process involves precision deposition of thermoelectric materials onto pre-shaped metal foils, followed by laser patterning to create the electrical connections. This results in TEGs that can withstand the harsh automotive environment while generating up to 500W of electrical power from waste heat in mid-size vehicles. Hyundai has successfully integrated these systems with vehicle electrical networks to reduce alternator load and improve fuel efficiency by approximately 3-5% in real-world driving conditions.

Strengths: Specifically engineered for automotive applications with high durability in harsh environments; seamless integration with existing vehicle electrical systems; proven fuel efficiency improvements in production vehicles. Weaknesses: Higher initial cost compared to conventional alternator systems; performance varies significantly with driving conditions and ambient temperature; requires sophisticated thermal management to prevent overheating.

The Regents of the University of California

Technical Solution: The University of California has developed a groundbreaking approach to conformal thermoelectric generators through their research at multiple campuses. Their composite foil design incorporates novel nanostructured materials with flexible polymer substrates to create highly adaptable TEGs. The technology utilizes a proprietary combination of solution-processed thermoelectric materials, including lead telluride quantum dots and PEDOT:PSS conductive polymers, arranged in precisely controlled heterostructures. Their manufacturing process involves inkjet printing and spin-coating techniques that enable precise deposition of thermoelectric materials in complex patterns. This results in lightweight, flexible TEGs with thickness under 500 μm that can conform to virtually any surface geometry. The UC system has demonstrated these TEGs in various applications, including wearable electronics and building energy harvesting, achieving power densities of up to 2.5 mW/cm² at temperature differentials of just 50°C. Their recent advancements include self-healing interfaces that maintain electrical connectivity even under mechanical stress and deformation.

Strengths: Exceptional flexibility and conformability to complex surfaces; environmentally friendly manufacturing processes; compatibility with low-grade waste heat sources (50-150°C). Weaknesses: Lower power output compared to inorganic rigid TEGs; durability concerns with polymer-based substrates over extended periods; current manufacturing techniques challenging to scale for mass production.

Critical Patents in Conformal Thermoelectric Technology

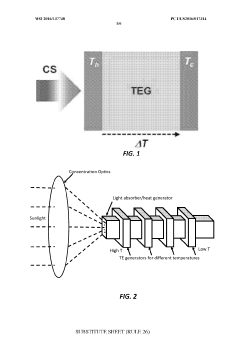

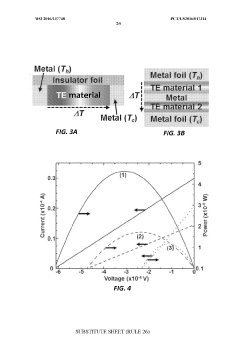

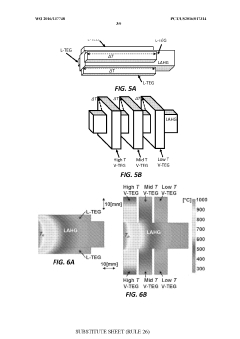

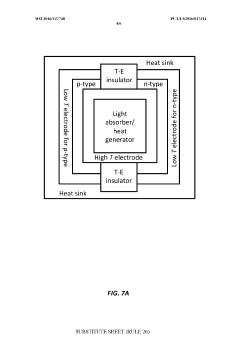

Multi-stage thermoelectric generator monolithically integrated on a light absorber

PatentWO2016137748A1

Innovation

- A solar-powered thermoelectric generator with a light absorbing and heat generating element that creates a thermal gradient, monolithically integrating multiple thermoelectric generators using various materials and configurations, such as microcrystal TE films on insulator or conductor foils, to maximize energy conversion from concentrated sunlight without the need for complex cooling systems.

Applying compliant compliant interfacial layers in thermoelectric devices

PatentInactiveUS20170077379A1

Innovation

- Incorporating mechanically compliant and thermally/electrically conductive nickel foam or nickel graphite composite layers between thermoelectric segments or between segments and interconnects to alleviate thermal stresses, using reduced density structures and bonding techniques like brazing to maintain conductivity.

Manufacturing Processes for Composite Thermoelectric Foils

The manufacturing of composite thermoelectric foils requires specialized processes that balance precision, scalability, and cost-effectiveness. Current manufacturing approaches can be categorized into several distinct methodologies, each with specific advantages for conformal thermoelectric generator applications.

Physical vapor deposition (PVD) techniques, including sputtering and thermal evaporation, have emerged as leading methods for creating thin-film thermoelectric materials on flexible substrates. These processes enable precise control over film thickness down to nanometer scale, which is crucial for optimizing the thermoelectric figure of merit (ZT). Multi-target sputtering systems allow for gradient composition control, facilitating the creation of functionally graded thermoelectric materials that maximize performance across temperature differentials.

Solution-based manufacturing processes offer complementary advantages for composite foil production. Screen printing, inkjet printing, and aerosol jet printing enable direct patterning of thermoelectric materials onto flexible substrates. These techniques utilize thermoelectric inks formulated from nanoparticle suspensions or precursor solutions, which can be tailored for viscosity and surface tension to ensure proper adhesion and electrical connectivity. Post-deposition annealing processes are typically required to achieve optimal crystallinity and electrical properties.

Roll-to-roll (R2R) processing represents a significant advancement for high-volume production of thermoelectric foils. This continuous manufacturing approach integrates multiple process steps including substrate preparation, material deposition, patterning, and encapsulation. Recent innovations in R2R systems have demonstrated throughput rates exceeding 10 m²/hour while maintaining thickness uniformity within ±5%.

Lamination techniques play a critical role in creating multi-layer composite structures. Advanced thermal lamination processes using pressure-sensitive adhesives compatible with thermoelectric materials enable the creation of mechanically robust, flexible modules. Laser-assisted bonding has shown promise for creating reliable electrical interconnections between thermoelectric elements without introducing excessive thermal stress to temperature-sensitive components.

Surface modification treatments represent an essential step in manufacturing workflows. Plasma treatment and chemical functionalization methods improve adhesion between dissimilar materials in the composite structure. These treatments also enhance long-term stability by mitigating delamination risks under thermal cycling conditions typical in conformal thermoelectric generator applications.

Quality control systems incorporating in-line electrical characterization and optical inspection have become standard in advanced manufacturing lines. These systems enable real-time monitoring of critical parameters including Seebeck coefficient uniformity, electrical conductivity, and mechanical integrity, ensuring consistent performance across production batches.

Physical vapor deposition (PVD) techniques, including sputtering and thermal evaporation, have emerged as leading methods for creating thin-film thermoelectric materials on flexible substrates. These processes enable precise control over film thickness down to nanometer scale, which is crucial for optimizing the thermoelectric figure of merit (ZT). Multi-target sputtering systems allow for gradient composition control, facilitating the creation of functionally graded thermoelectric materials that maximize performance across temperature differentials.

Solution-based manufacturing processes offer complementary advantages for composite foil production. Screen printing, inkjet printing, and aerosol jet printing enable direct patterning of thermoelectric materials onto flexible substrates. These techniques utilize thermoelectric inks formulated from nanoparticle suspensions or precursor solutions, which can be tailored for viscosity and surface tension to ensure proper adhesion and electrical connectivity. Post-deposition annealing processes are typically required to achieve optimal crystallinity and electrical properties.

Roll-to-roll (R2R) processing represents a significant advancement for high-volume production of thermoelectric foils. This continuous manufacturing approach integrates multiple process steps including substrate preparation, material deposition, patterning, and encapsulation. Recent innovations in R2R systems have demonstrated throughput rates exceeding 10 m²/hour while maintaining thickness uniformity within ±5%.

Lamination techniques play a critical role in creating multi-layer composite structures. Advanced thermal lamination processes using pressure-sensitive adhesives compatible with thermoelectric materials enable the creation of mechanically robust, flexible modules. Laser-assisted bonding has shown promise for creating reliable electrical interconnections between thermoelectric elements without introducing excessive thermal stress to temperature-sensitive components.

Surface modification treatments represent an essential step in manufacturing workflows. Plasma treatment and chemical functionalization methods improve adhesion between dissimilar materials in the composite structure. These treatments also enhance long-term stability by mitigating delamination risks under thermal cycling conditions typical in conformal thermoelectric generator applications.

Quality control systems incorporating in-line electrical characterization and optical inspection have become standard in advanced manufacturing lines. These systems enable real-time monitoring of critical parameters including Seebeck coefficient uniformity, electrical conductivity, and mechanical integrity, ensuring consistent performance across production batches.

Energy Harvesting Applications and Integration Strategies

Conformal thermoelectric generators (CTEGs) based on composite foil designs represent a significant advancement in energy harvesting technologies, offering versatile applications across multiple sectors. These flexible generators can be integrated into various systems where temperature differentials exist, converting otherwise wasted heat into usable electrical energy.

In industrial environments, CTEGs can be wrapped around hot pipes, exhaust systems, or machinery components to capture thermal energy that would typically dissipate into the environment. The conformal nature of these generators allows for maximized surface contact with irregular-shaped heat sources, significantly improving energy conversion efficiency compared to rigid thermoelectric systems.

The automotive sector presents particularly promising applications, with CTEGs potentially integrated into exhaust systems to recover waste heat and improve overall vehicle efficiency. This recovered energy can supplement the electrical system, reducing alternator load and consequently improving fuel economy. For electric vehicles, these systems can extend battery range by harvesting thermal energy from various components.

Wearable technology represents another frontier for CTEG integration. The flexible composite foil design enables incorporation into clothing or accessories, harvesting body heat to power low-energy devices such as health monitors, GPS trackers, or communication devices. This application is especially valuable in remote locations where conventional power sources are unavailable.

Building infrastructure also offers significant integration opportunities. CTEGs can be incorporated into HVAC systems, window frames, or building envelopes to capture temperature differentials between indoor and outdoor environments. This harvested energy can power sensors for smart building management systems or contribute to overall energy efficiency.

The integration strategy for CTEGs requires careful consideration of thermal interface materials to maximize heat transfer efficiency. Thermal interface materials must maintain good contact between the heat source and the generator while accommodating the mechanical flexibility of the composite foil. Additionally, electrical integration systems must be designed to handle the variable power output characteristic of thermoelectric generators.

Manufacturing processes present another critical integration consideration. The composite nature of these foils necessitates production techniques that can reliably combine different materials while maintaining thermoelectric properties and mechanical flexibility. Roll-to-roll processing shows promise for large-scale, cost-effective production of these composite foil generators.

Future integration strategies may focus on hybrid energy harvesting systems, where CTEGs work in conjunction with other technologies such as photovoltaics or piezoelectrics to create more robust and versatile energy harvesting solutions for next-generation autonomous devices and systems.

In industrial environments, CTEGs can be wrapped around hot pipes, exhaust systems, or machinery components to capture thermal energy that would typically dissipate into the environment. The conformal nature of these generators allows for maximized surface contact with irregular-shaped heat sources, significantly improving energy conversion efficiency compared to rigid thermoelectric systems.

The automotive sector presents particularly promising applications, with CTEGs potentially integrated into exhaust systems to recover waste heat and improve overall vehicle efficiency. This recovered energy can supplement the electrical system, reducing alternator load and consequently improving fuel economy. For electric vehicles, these systems can extend battery range by harvesting thermal energy from various components.

Wearable technology represents another frontier for CTEG integration. The flexible composite foil design enables incorporation into clothing or accessories, harvesting body heat to power low-energy devices such as health monitors, GPS trackers, or communication devices. This application is especially valuable in remote locations where conventional power sources are unavailable.

Building infrastructure also offers significant integration opportunities. CTEGs can be incorporated into HVAC systems, window frames, or building envelopes to capture temperature differentials between indoor and outdoor environments. This harvested energy can power sensors for smart building management systems or contribute to overall energy efficiency.

The integration strategy for CTEGs requires careful consideration of thermal interface materials to maximize heat transfer efficiency. Thermal interface materials must maintain good contact between the heat source and the generator while accommodating the mechanical flexibility of the composite foil. Additionally, electrical integration systems must be designed to handle the variable power output characteristic of thermoelectric generators.

Manufacturing processes present another critical integration consideration. The composite nature of these foils necessitates production techniques that can reliably combine different materials while maintaining thermoelectric properties and mechanical flexibility. Roll-to-roll processing shows promise for large-scale, cost-effective production of these composite foil generators.

Future integration strategies may focus on hybrid energy harvesting systems, where CTEGs work in conjunction with other technologies such as photovoltaics or piezoelectrics to create more robust and versatile energy harvesting solutions for next-generation autonomous devices and systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!