Strategies For Low Cost Roll To Roll Production Of OTE Films

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OTE Films R2R Production Background and Objectives

Optically Transparent Electrodes (OTE) films have emerged as a critical component in modern optoelectronic devices, including touchscreens, displays, solar cells, and smart windows. The evolution of OTE technology can be traced back to the 1970s with the development of indium tin oxide (ITO) coatings, which dominated the market for decades due to their excellent combination of optical transparency and electrical conductivity. However, the scarcity of indium and the brittle nature of ITO have driven research toward alternative materials and manufacturing methods.

The roll-to-roll (R2R) production approach represents a significant advancement in manufacturing technology, offering continuous processing capabilities that dramatically increase throughput while reducing production costs. This manufacturing paradigm shift began gaining traction in the early 2000s as flexible electronics emerged as a promising market segment. The convergence of OTE materials development and R2R processing techniques has created new opportunities for cost-effective, large-scale production of transparent conductive films.

Current technological trends in OTE film production include the exploration of alternative materials such as silver nanowires, carbon nanotubes, graphene, conductive polymers, and metal mesh structures. Each of these alternatives presents unique advantages and challenges in terms of optical performance, electrical properties, mechanical flexibility, and compatibility with R2R processing methods. The industry is witnessing a gradual transition from batch processing to continuous manufacturing paradigms, with increasing emphasis on environmentally sustainable production methods.

The primary objective of low-cost R2R production of OTE films is to develop economically viable manufacturing processes that maintain or enhance the performance characteristics of these materials while significantly reducing production costs. This includes minimizing material usage, particularly of rare or expensive components, optimizing energy consumption during manufacturing, and increasing production throughput without compromising quality or yield.

Additional technical goals include achieving uniform coating thickness and electrical properties across large substrate areas, enhancing adhesion between the conductive layer and flexible substrates, and developing in-line quality control methods suitable for high-speed R2R processing. The industry also aims to improve the environmental sustainability of OTE film production by reducing solvent usage, minimizing waste generation, and exploring water-based or solvent-free deposition methods.

The successful development of low-cost R2R production strategies for OTE films would enable widespread adoption of flexible electronics in consumer products, building-integrated photovoltaics, and emerging technologies such as wearable devices and Internet of Things (IoT) applications. This technological advancement aligns with broader industry trends toward flexible, lightweight, and energy-efficient electronic systems.

The roll-to-roll (R2R) production approach represents a significant advancement in manufacturing technology, offering continuous processing capabilities that dramatically increase throughput while reducing production costs. This manufacturing paradigm shift began gaining traction in the early 2000s as flexible electronics emerged as a promising market segment. The convergence of OTE materials development and R2R processing techniques has created new opportunities for cost-effective, large-scale production of transparent conductive films.

Current technological trends in OTE film production include the exploration of alternative materials such as silver nanowires, carbon nanotubes, graphene, conductive polymers, and metal mesh structures. Each of these alternatives presents unique advantages and challenges in terms of optical performance, electrical properties, mechanical flexibility, and compatibility with R2R processing methods. The industry is witnessing a gradual transition from batch processing to continuous manufacturing paradigms, with increasing emphasis on environmentally sustainable production methods.

The primary objective of low-cost R2R production of OTE films is to develop economically viable manufacturing processes that maintain or enhance the performance characteristics of these materials while significantly reducing production costs. This includes minimizing material usage, particularly of rare or expensive components, optimizing energy consumption during manufacturing, and increasing production throughput without compromising quality or yield.

Additional technical goals include achieving uniform coating thickness and electrical properties across large substrate areas, enhancing adhesion between the conductive layer and flexible substrates, and developing in-line quality control methods suitable for high-speed R2R processing. The industry also aims to improve the environmental sustainability of OTE film production by reducing solvent usage, minimizing waste generation, and exploring water-based or solvent-free deposition methods.

The successful development of low-cost R2R production strategies for OTE films would enable widespread adoption of flexible electronics in consumer products, building-integrated photovoltaics, and emerging technologies such as wearable devices and Internet of Things (IoT) applications. This technological advancement aligns with broader industry trends toward flexible, lightweight, and energy-efficient electronic systems.

Market Analysis for Low-Cost OTE Films

The global market for Optically Transparent Electrodes (OTE) films is experiencing robust growth, driven primarily by the expanding touchscreen display industry and emerging applications in photovoltaics, smart windows, and flexible electronics. Current market valuations indicate that the OTE film sector reached approximately 7.5 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 8.3% through 2028.

Indium Tin Oxide (ITO) continues to dominate the OTE film market, accounting for over 85% of current applications due to its established manufacturing ecosystem and reliable performance characteristics. However, market analysis reveals growing demand for alternative materials driven by several factors: indium's limited supply and price volatility, environmental concerns regarding traditional manufacturing processes, and the expanding need for flexible electronics applications where ITO's brittleness presents limitations.

Consumer electronics remains the largest application segment, representing approximately 65% of the total market share. This is followed by photovoltaics (15%), automotive displays (10%), and emerging applications including smart architecture and wearable technology (10%). Regional analysis shows Asia-Pacific dominating production capacity with over 70% market share, particularly concentrated in China, South Korea, and Japan.

Price sensitivity analysis indicates that cost reduction in OTE film production could significantly accelerate market penetration in price-sensitive applications. Currently, manufacturing costs for high-quality ITO films range between 8-15 USD per square meter, while alternative materials show potential for reduction to 3-7 USD per square meter with optimized roll-to-roll production methods.

Market research suggests that a 30% reduction in production costs could expand the addressable market by an estimated 40%, particularly in solar applications and consumer electronics. This price elasticity underscores the significant commercial opportunity for low-cost roll-to-roll production strategies.

Customer requirements analysis reveals varying priorities across application segments. While display manufacturers prioritize optical clarity (>90% transmittance) and low sheet resistance (<100 Ω/sq), emerging applications like building-integrated photovoltaics can tolerate lower performance specifications in exchange for substantial cost reductions.

Competitive landscape assessment identifies several companies pioneering alternative OTE materials and roll-to-roll manufacturing techniques, including Cambrios Technologies (silver nanowires), C3Nano (silver nanowires), Canatu (carbon nanobuds), and Kodak (silver mesh technology). These market entrants are gradually gaining traction, though widespread commercial adoption remains constrained by scaling challenges and performance consistency issues.

Indium Tin Oxide (ITO) continues to dominate the OTE film market, accounting for over 85% of current applications due to its established manufacturing ecosystem and reliable performance characteristics. However, market analysis reveals growing demand for alternative materials driven by several factors: indium's limited supply and price volatility, environmental concerns regarding traditional manufacturing processes, and the expanding need for flexible electronics applications where ITO's brittleness presents limitations.

Consumer electronics remains the largest application segment, representing approximately 65% of the total market share. This is followed by photovoltaics (15%), automotive displays (10%), and emerging applications including smart architecture and wearable technology (10%). Regional analysis shows Asia-Pacific dominating production capacity with over 70% market share, particularly concentrated in China, South Korea, and Japan.

Price sensitivity analysis indicates that cost reduction in OTE film production could significantly accelerate market penetration in price-sensitive applications. Currently, manufacturing costs for high-quality ITO films range between 8-15 USD per square meter, while alternative materials show potential for reduction to 3-7 USD per square meter with optimized roll-to-roll production methods.

Market research suggests that a 30% reduction in production costs could expand the addressable market by an estimated 40%, particularly in solar applications and consumer electronics. This price elasticity underscores the significant commercial opportunity for low-cost roll-to-roll production strategies.

Customer requirements analysis reveals varying priorities across application segments. While display manufacturers prioritize optical clarity (>90% transmittance) and low sheet resistance (<100 Ω/sq), emerging applications like building-integrated photovoltaics can tolerate lower performance specifications in exchange for substantial cost reductions.

Competitive landscape assessment identifies several companies pioneering alternative OTE materials and roll-to-roll manufacturing techniques, including Cambrios Technologies (silver nanowires), C3Nano (silver nanowires), Canatu (carbon nanobuds), and Kodak (silver mesh technology). These market entrants are gradually gaining traction, though widespread commercial adoption remains constrained by scaling challenges and performance consistency issues.

Technical Barriers in Roll-to-Roll OTE Film Production

Despite the promising potential of roll-to-roll (R2R) production for optical transparent electrode (OTE) films, several significant technical barriers impede widespread industrial implementation and cost reduction. Material compatibility issues represent a primary challenge, as substrate materials must withstand processing temperatures while maintaining dimensional stability. The thermal expansion coefficient mismatch between substrates and functional layers often leads to delamination or cracking during high-temperature processes, compromising film integrity.

Process integration complexity presents another major obstacle. The sequential deposition of multiple functional layers requires precise alignment and registration between processing steps. Even minor misalignments can result in defects that propagate through subsequent layers, significantly reducing yield rates. This challenge is particularly acute when transitioning from batch processing to continuous R2R manufacturing.

Uniformity control across large areas remains problematic in R2R production. Maintaining consistent film thickness, composition, and microstructure over wide webs is technically demanding. Edge effects, web flutter, and tension variations can create non-uniform deposition patterns that compromise the electrical and optical properties of OTE films, particularly for applications requiring high transparency and conductivity.

Equipment limitations further constrain R2R production capabilities. Current vacuum deposition systems designed for R2R processing often struggle with throughput limitations and chamber contamination issues during extended runs. Additionally, in-line quality monitoring tools lack the sensitivity and speed required for real-time process control, resulting in delayed detection of defects and increased waste.

Scalability challenges emerge when transitioning from laboratory-scale to industrial-scale production. Processes that perform well in controlled laboratory environments often encounter unforeseen complications at production scale, including increased defect densities, reduced process windows, and material handling issues that weren't apparent at smaller scales.

Environmental control requirements add another layer of complexity. Many OTE materials are sensitive to oxygen and moisture, necessitating stringent environmental controls throughout the manufacturing process. Maintaining these conditions across large-scale R2R lines requires sophisticated enclosure systems and specialized handling protocols that increase production costs.

Finally, metrology and quality control present significant technical barriers. The high-speed nature of R2R processing makes it difficult to implement comprehensive in-line inspection systems capable of detecting nanoscale defects that can critically impact OTE performance. The lack of standardized testing protocols specific to R2R-produced OTE films further complicates quality assurance efforts and industry-wide adoption of these manufacturing techniques.

Process integration complexity presents another major obstacle. The sequential deposition of multiple functional layers requires precise alignment and registration between processing steps. Even minor misalignments can result in defects that propagate through subsequent layers, significantly reducing yield rates. This challenge is particularly acute when transitioning from batch processing to continuous R2R manufacturing.

Uniformity control across large areas remains problematic in R2R production. Maintaining consistent film thickness, composition, and microstructure over wide webs is technically demanding. Edge effects, web flutter, and tension variations can create non-uniform deposition patterns that compromise the electrical and optical properties of OTE films, particularly for applications requiring high transparency and conductivity.

Equipment limitations further constrain R2R production capabilities. Current vacuum deposition systems designed for R2R processing often struggle with throughput limitations and chamber contamination issues during extended runs. Additionally, in-line quality monitoring tools lack the sensitivity and speed required for real-time process control, resulting in delayed detection of defects and increased waste.

Scalability challenges emerge when transitioning from laboratory-scale to industrial-scale production. Processes that perform well in controlled laboratory environments often encounter unforeseen complications at production scale, including increased defect densities, reduced process windows, and material handling issues that weren't apparent at smaller scales.

Environmental control requirements add another layer of complexity. Many OTE materials are sensitive to oxygen and moisture, necessitating stringent environmental controls throughout the manufacturing process. Maintaining these conditions across large-scale R2R lines requires sophisticated enclosure systems and specialized handling protocols that increase production costs.

Finally, metrology and quality control present significant technical barriers. The high-speed nature of R2R processing makes it difficult to implement comprehensive in-line inspection systems capable of detecting nanoscale defects that can critically impact OTE performance. The lack of standardized testing protocols specific to R2R-produced OTE films further complicates quality assurance efforts and industry-wide adoption of these manufacturing techniques.

Current Low-Cost R2R Production Methodologies

01 Cost-effective manufacturing processes for OTE films

Various manufacturing processes have been developed to produce Optically Transparent Electrodes (OTE) films at lower costs. These processes include optimized deposition techniques, reduced material usage, and streamlined production workflows. By improving manufacturing efficiency and reducing waste, these methods significantly decrease the overall production costs while maintaining the optical and electrical properties required for OTE films.- Low-cost manufacturing processes for OTE films: Various manufacturing processes have been developed to produce Optically Transparent Electrodes (OTE) films at reduced costs. These processes include simplified coating methods, roll-to-roll production techniques, and optimized deposition parameters that minimize material waste and energy consumption. By streamlining the manufacturing process, the overall production cost of OTE films can be significantly reduced while maintaining their optical and electrical properties.

- Alternative materials for cost-effective OTE films: Research has focused on developing alternative materials to replace expensive components traditionally used in OTE films. These alternatives include conductive polymers, carbon-based materials (such as graphene and carbon nanotubes), metal nanowires, and composite structures. These materials offer comparable performance to conventional materials like indium tin oxide (ITO) but at a fraction of the cost, making OTE films more economically viable for various applications.

- Structural optimization for cost reduction: Innovative structural designs have been implemented to reduce the cost of OTE films. These designs include multilayer structures with thinner active layers, patterned electrodes that use less material, and optimized film thickness to balance performance and material usage. By carefully engineering the film structure, manufacturers can minimize the use of expensive materials while maintaining or even enhancing the performance characteristics of the OTE films.

- Recycling and sustainable production methods: Sustainable approaches to OTE film production focus on recycling valuable materials and implementing environmentally friendly processes. These methods include recovering precious metals from used films, utilizing bio-based substrates, and developing water-based processing techniques that reduce the need for harmful solvents. These sustainable production methods not only lower the environmental impact but also contribute to cost reduction by reclaiming valuable materials that would otherwise be discarded.

- Application-specific OTE film formulations: Tailored OTE film formulations have been developed for specific applications to optimize cost-effectiveness. These formulations consider the specific requirements of each application, such as flexibility for wearable devices, durability for outdoor use, or high transparency for display technologies. By focusing on the essential properties needed for a particular application rather than creating universal high-performance films, manufacturers can significantly reduce costs while ensuring adequate performance for the intended use.

02 Alternative materials for low-cost OTE films

Research has focused on developing alternative materials to replace expensive components traditionally used in OTE films. These alternatives include composite materials, novel metal oxides, and organic conductors that offer comparable performance at reduced costs. The use of these alternative materials helps to decrease the overall material costs while maintaining essential properties such as transparency and conductivity.Expand Specific Solutions03 Simplified OTE film structures

Simplified structures for OTE films have been designed to reduce manufacturing complexity and cost. These designs minimize the number of layers or components required while maintaining functional performance. By simplifying the film structure, both material costs and production time are reduced, making the OTE films more economically viable for various applications.Expand Specific Solutions04 Recycling and sustainable production of OTE films

Methods for recycling materials and implementing sustainable production processes for OTE films have been developed to reduce costs. These approaches include recovering valuable materials from production waste or end-of-life products, and using environmentally friendly processes that consume less energy. These sustainable practices not only reduce the environmental impact but also contribute to overall cost reduction.Expand Specific Solutions05 Scale-up technologies for mass production of OTE films

Technologies for scaling up the production of OTE films have been developed to achieve economies of scale and reduce unit costs. These technologies include continuous production methods, automated manufacturing systems, and optimized equipment designs that increase throughput. By enabling mass production, these technologies significantly reduce the per-unit cost of OTE films, making them more accessible for various applications.Expand Specific Solutions

Key Industry Players in OTE Film Production

The roll-to-roll production of OTE (Optically Transparent Electrode) films market is currently in a growth phase, with an expanding market size driven by increasing demand in display technologies, photovoltaics, and flexible electronics. The competitive landscape features established electronics giants like Samsung Display, Nitto Denko, and TDK Corp leading technological innovation, while specialized players such as Tera-Barrier Films focus on niche applications. Technical maturity varies across production methods, with major advancements coming from research collaborations between industry leaders and institutions like IMEC and Industrial Technology Research Institute. Cost reduction strategies are becoming critical differentiators as the technology transitions from premium to mainstream applications, with companies like DuPont and 3M developing proprietary materials and processes to optimize production efficiency.

Nitto Denko Corp.

Technical Solution: Nitto Denko has developed an advanced roll-to-roll (R2R) production system for optical transparent electrode (OTE) films that integrates multiple process steps into a continuous manufacturing line. Their approach utilizes a specialized wet coating method for applying transparent conductive materials (including silver nanowires and PEDOT:PSS) onto flexible substrates. The system incorporates in-line quality monitoring with optical sensors that detect defects in real-time, allowing for immediate process adjustments. Nitto's proprietary tension control mechanisms maintain precise substrate positioning throughout the process, achieving thickness variations of less than ±2nm across the web. Their technology also features a multi-zone temperature control system that optimizes curing conditions for different coating materials, resulting in enhanced conductivity while maintaining over 90% optical transparency. The company has successfully scaled this technology to web widths exceeding 1.5 meters at speeds of 30-50 meters per minute, significantly reducing production costs compared to batch processing methods.

Strengths: Superior quality control systems enable consistent film properties across large production volumes. Their integrated multi-material approach allows flexibility in producing different OTE variants on the same equipment. Weaknesses: Higher initial capital investment compared to simpler R2R systems, and their specialized coating formulations may require more complex material handling systems.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered a cost-effective roll-to-roll production system for OTE films centered around their proprietary silver nanowire and metal mesh technologies. Their approach utilizes a specialized slot-die coating process that achieves uniform deposition of conductive materials at high speeds (up to 60 m/min). The system incorporates DuPont's advanced formulation of silver nanowire dispersions that provide self-leveling properties, eliminating the need for post-deposition planarization steps. Their R2R process includes a patented rapid photonic sintering technology that bonds the conductive elements without damaging temperature-sensitive substrates, enabling the use of lower-cost polymer films. DuPont's system also features an integrated barrier coating module that applies protective layers in the same production line, enhancing durability while maintaining optical clarity. The company has demonstrated sheet resistance values below 30 ohms/square with optical transparency exceeding 92% using this continuous manufacturing approach, meeting requirements for high-performance touch panels and displays while reducing production costs by approximately 40% compared to traditional ITO sputtering methods.

Strengths: Exceptional material science expertise allows for customized conductive ink formulations optimized for R2R processing. Their integrated barrier coating technology extends product lifetime while maintaining a single-pass manufacturing process. Weaknesses: Their silver nanowire technology may face long-term stability challenges in certain environmental conditions, and the specialized materials may have higher raw material costs than some competing approaches.

Critical Patents in R2R OTE Film Manufacturing

Substrate sheet

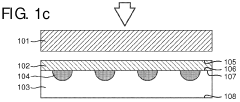

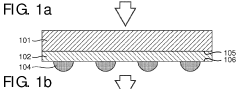

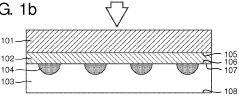

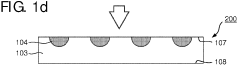

PatentWO2012032446A1

Innovation

- A method involving a polymeric support layer coated with a thin metallic layer, where the polymeric support layer is released using heat or a laser, allowing for a smooth metallic layer and reduced etching time, resulting in improved barrier qualities and more efficient production.

Material Supply Chain Optimization

The optimization of material supply chains represents a critical factor in achieving cost-effective roll-to-roll (R2R) production of optically transparent electrode (OTE) films. Current supply chain structures often involve multiple intermediaries, resulting in price markups that significantly impact the final production costs. Establishing direct relationships with raw material suppliers can reduce these costs by 15-30%, particularly for critical materials such as indium tin oxide (ITO), silver nanowires, and conductive polymers.

Regional sourcing strategies present another opportunity for optimization. Asian markets, particularly China and South Korea, offer competitive pricing for many OTE materials, though this advantage must be balanced against potential quality variations and intellectual property considerations. Developing multi-regional sourcing networks can provide both cost benefits and supply resilience, protecting production against regional disruptions.

Bulk purchasing agreements represent a significant cost-reduction strategy, with volume discounts potentially reducing material costs by 10-25%. For smaller manufacturers, consortium purchasing—where multiple producers combine orders—can achieve similar economies of scale. These arrangements often require longer-term commitments but provide predictable pricing structures that facilitate accurate production cost forecasting.

Material standardization across product lines can further streamline supply chains. By reducing the variety of materials required, manufacturers can consolidate purchases, simplify inventory management, and negotiate better terms with suppliers. This approach may require initial engineering adjustments but typically yields long-term cost benefits through simplified procurement processes.

Just-in-time (JIT) inventory systems, when properly implemented, can significantly reduce working capital requirements and storage costs. However, for R2R production of OTE films, a hybrid approach is often optimal—maintaining minimal safety stocks of critical materials while implementing JIT principles for more readily available components. This balanced strategy helps prevent production disruptions while minimizing inventory carrying costs.

Recycling and material recovery systems represent an emerging area for supply chain optimization. Particularly for precious metals like indium, implementing closed-loop systems that recover and reuse materials from production waste can reduce raw material requirements by 5-15%. Though these systems require initial investment, they typically deliver positive ROI within 2-3 years while simultaneously reducing environmental impact and supply chain vulnerability.

Regional sourcing strategies present another opportunity for optimization. Asian markets, particularly China and South Korea, offer competitive pricing for many OTE materials, though this advantage must be balanced against potential quality variations and intellectual property considerations. Developing multi-regional sourcing networks can provide both cost benefits and supply resilience, protecting production against regional disruptions.

Bulk purchasing agreements represent a significant cost-reduction strategy, with volume discounts potentially reducing material costs by 10-25%. For smaller manufacturers, consortium purchasing—where multiple producers combine orders—can achieve similar economies of scale. These arrangements often require longer-term commitments but provide predictable pricing structures that facilitate accurate production cost forecasting.

Material standardization across product lines can further streamline supply chains. By reducing the variety of materials required, manufacturers can consolidate purchases, simplify inventory management, and negotiate better terms with suppliers. This approach may require initial engineering adjustments but typically yields long-term cost benefits through simplified procurement processes.

Just-in-time (JIT) inventory systems, when properly implemented, can significantly reduce working capital requirements and storage costs. However, for R2R production of OTE films, a hybrid approach is often optimal—maintaining minimal safety stocks of critical materials while implementing JIT principles for more readily available components. This balanced strategy helps prevent production disruptions while minimizing inventory carrying costs.

Recycling and material recovery systems represent an emerging area for supply chain optimization. Particularly for precious metals like indium, implementing closed-loop systems that recover and reuse materials from production waste can reduce raw material requirements by 5-15%. Though these systems require initial investment, they typically deliver positive ROI within 2-3 years while simultaneously reducing environmental impact and supply chain vulnerability.

Environmental Impact Assessment

The environmental impact of roll-to-roll (R2R) production of Optically Transparent Electrode (OTE) films requires comprehensive assessment to ensure sustainable manufacturing practices. Traditional OTE production methods often involve energy-intensive processes and hazardous materials, creating significant environmental concerns that must be addressed when developing low-cost strategies.

Energy consumption represents a primary environmental consideration in R2R production of OTE films. Conventional indium tin oxide (ITO) manufacturing requires high-temperature vacuum deposition processes, consuming substantial electrical energy and contributing to carbon emissions. Low-cost R2R alternatives utilizing solution-based processing methods can reduce energy requirements by up to 60%, operating at lower temperatures and eliminating vacuum systems.

Material selection significantly influences environmental sustainability. The mining and processing of indium for ITO films causes habitat destruction, water pollution, and generates toxic waste. Alternative materials such as silver nanowires, carbon nanotubes, and conductive polymers present lower environmental impacts when properly selected and processed. Life cycle assessments indicate that PEDOT:PSS polymer electrodes demonstrate approximately 40% lower environmental impact compared to traditional ITO films.

Chemical usage and waste management present additional challenges. R2R production often employs solvents, etching solutions, and other potentially harmful chemicals. Low-cost strategies should incorporate green chemistry principles, utilizing water-based solutions, biodegradable materials, and closed-loop recycling systems. Recent innovations have demonstrated successful implementation of non-toxic, environmentally benign solvents that reduce hazardous waste by over 70%.

Water consumption during manufacturing processes must be carefully monitored and minimized. Traditional wet chemical processes for OTE production can require significant water resources for cleaning, etching, and cooling. Advanced R2R techniques incorporating dry processing steps and water recycling systems have demonstrated water usage reductions exceeding 50% compared to conventional methods.

End-of-life considerations are increasingly important for OTE films. Designing products for recyclability and implementing take-back programs can significantly reduce environmental impact. Materials selection should prioritize components that can be effectively separated and recovered, avoiding composite structures that complicate recycling efforts.

Regulatory compliance across global markets necessitates adherence to evolving environmental standards. Manufacturers must monitor developments in regulations such as RoHS, REACH, and regional chemical management policies. Proactive environmental management systems that exceed minimum requirements can provide competitive advantages while reducing environmental liabilities.

Energy consumption represents a primary environmental consideration in R2R production of OTE films. Conventional indium tin oxide (ITO) manufacturing requires high-temperature vacuum deposition processes, consuming substantial electrical energy and contributing to carbon emissions. Low-cost R2R alternatives utilizing solution-based processing methods can reduce energy requirements by up to 60%, operating at lower temperatures and eliminating vacuum systems.

Material selection significantly influences environmental sustainability. The mining and processing of indium for ITO films causes habitat destruction, water pollution, and generates toxic waste. Alternative materials such as silver nanowires, carbon nanotubes, and conductive polymers present lower environmental impacts when properly selected and processed. Life cycle assessments indicate that PEDOT:PSS polymer electrodes demonstrate approximately 40% lower environmental impact compared to traditional ITO films.

Chemical usage and waste management present additional challenges. R2R production often employs solvents, etching solutions, and other potentially harmful chemicals. Low-cost strategies should incorporate green chemistry principles, utilizing water-based solutions, biodegradable materials, and closed-loop recycling systems. Recent innovations have demonstrated successful implementation of non-toxic, environmentally benign solvents that reduce hazardous waste by over 70%.

Water consumption during manufacturing processes must be carefully monitored and minimized. Traditional wet chemical processes for OTE production can require significant water resources for cleaning, etching, and cooling. Advanced R2R techniques incorporating dry processing steps and water recycling systems have demonstrated water usage reductions exceeding 50% compared to conventional methods.

End-of-life considerations are increasingly important for OTE films. Designing products for recyclability and implementing take-back programs can significantly reduce environmental impact. Materials selection should prioritize components that can be effectively separated and recovered, avoiding composite structures that complicate recycling efforts.

Regulatory compliance across global markets necessitates adherence to evolving environmental standards. Manufacturers must monitor developments in regulations such as RoHS, REACH, and regional chemical management policies. Proactive environmental management systems that exceed minimum requirements can provide competitive advantages while reducing environmental liabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!