Thermal Management Strategies For OTE Based Garments

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OTE Garment Thermal Management Background and Objectives

Optical Textile Electronics (OTE) represents a revolutionary advancement in wearable technology, integrating electronic functionalities directly into textile structures. The evolution of OTE garments has progressed significantly over the past decade, transitioning from rudimentary conductive fabrics to sophisticated systems capable of sensing, computing, and responding to environmental and physiological changes. This technological progression has been driven by advancements in material science, miniaturization of electronic components, and innovative manufacturing techniques.

Thermal management in OTE garments has emerged as a critical challenge due to the inherent heat generation of electronic components and the need to maintain wearer comfort across diverse environmental conditions. Historically, wearable electronics have struggled with heat dissipation issues, often resulting in user discomfort, reduced device performance, and shortened component lifespan. The evolution of thermal management strategies has paralleled the development of OTE technology itself, moving from passive cooling methods to more sophisticated active and hybrid approaches.

The primary objective of thermal management in OTE garments is to establish an optimal thermal equilibrium that simultaneously ensures electronic component reliability and wearer comfort. This involves developing solutions that can effectively dissipate heat generated by electronic components while maintaining the garment's breathability, flexibility, and aesthetic appeal. Additionally, these solutions must be scalable for mass production, cost-effective, and environmentally sustainable to align with broader industry trends.

Current technological trajectories indicate a shift toward integrated thermal management systems that adapt dynamically to both environmental conditions and user activity levels. These systems aim to provide personalized thermal comfort while optimizing energy consumption and extending the operational lifespan of electronic components. The convergence of advanced materials, sensor technologies, and intelligent control systems is expected to drive the next generation of thermal management solutions for OTE garments.

Research objectives in this field include developing thermally conductive textiles with enhanced heat dissipation properties, creating microfluidic cooling channels that can be seamlessly integrated into garment structures, and designing intelligent thermal management algorithms that can predict and respond to changing thermal conditions. Additionally, there is significant interest in exploring bio-inspired cooling mechanisms that mimic natural thermoregulation processes found in biological systems.

The ultimate goal is to develop thermal management strategies that are not merely reactive but predictive and preventive, capable of anticipating thermal challenges before they impact either electronic performance or user comfort. This forward-looking approach aligns with the broader vision of creating truly symbiotic relationships between wearable technology and human users, where technological integration enhances rather than compromises the natural functionality of clothing.

Thermal management in OTE garments has emerged as a critical challenge due to the inherent heat generation of electronic components and the need to maintain wearer comfort across diverse environmental conditions. Historically, wearable electronics have struggled with heat dissipation issues, often resulting in user discomfort, reduced device performance, and shortened component lifespan. The evolution of thermal management strategies has paralleled the development of OTE technology itself, moving from passive cooling methods to more sophisticated active and hybrid approaches.

The primary objective of thermal management in OTE garments is to establish an optimal thermal equilibrium that simultaneously ensures electronic component reliability and wearer comfort. This involves developing solutions that can effectively dissipate heat generated by electronic components while maintaining the garment's breathability, flexibility, and aesthetic appeal. Additionally, these solutions must be scalable for mass production, cost-effective, and environmentally sustainable to align with broader industry trends.

Current technological trajectories indicate a shift toward integrated thermal management systems that adapt dynamically to both environmental conditions and user activity levels. These systems aim to provide personalized thermal comfort while optimizing energy consumption and extending the operational lifespan of electronic components. The convergence of advanced materials, sensor technologies, and intelligent control systems is expected to drive the next generation of thermal management solutions for OTE garments.

Research objectives in this field include developing thermally conductive textiles with enhanced heat dissipation properties, creating microfluidic cooling channels that can be seamlessly integrated into garment structures, and designing intelligent thermal management algorithms that can predict and respond to changing thermal conditions. Additionally, there is significant interest in exploring bio-inspired cooling mechanisms that mimic natural thermoregulation processes found in biological systems.

The ultimate goal is to develop thermal management strategies that are not merely reactive but predictive and preventive, capable of anticipating thermal challenges before they impact either electronic performance or user comfort. This forward-looking approach aligns with the broader vision of creating truly symbiotic relationships between wearable technology and human users, where technological integration enhances rather than compromises the natural functionality of clothing.

Market Analysis for Thermally Regulated Smart Clothing

The smart clothing market has witnessed significant growth in recent years, with thermally regulated garments emerging as a particularly promising segment. The global smart textile market was valued at $4.7 billion in 2022 and is projected to reach $24.6 billion by 2030, growing at a CAGR of 26.4%. Within this broader category, thermally regulated clothing represents approximately 18% of the market share, with substantial growth potential.

Consumer demand for thermally regulated smart clothing is primarily driven by three key sectors: sports and fitness, healthcare and medical, and industrial and military applications. The sports and fitness segment currently dominates the market, accounting for 42% of sales, as professional athletes and fitness enthusiasts seek performance-enhancing garments that can regulate body temperature during intense physical activities.

Healthcare applications represent the fastest-growing segment, with a 31% annual growth rate. This surge is attributed to the increasing adoption of thermally regulated garments for patients with thermoregulatory disorders, chronic pain conditions, and rehabilitation needs. Medical professionals are increasingly recognizing the therapeutic benefits of consistent temperature management in improving patient outcomes.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to exhibit the highest growth rate over the next five years due to increasing disposable income, growing health consciousness, and rapid technological adoption in countries like China, Japan, and South Korea.

Consumer preference studies indicate that comfort (cited by 78% of users), durability (65%), and ease of maintenance (61%) are the primary purchasing factors for thermally regulated garments. Price sensitivity remains a significant barrier to widespread adoption, with 57% of potential consumers citing cost concerns as their main hesitation.

The market is witnessing a shift toward sustainability, with 68% of consumers expressing preference for eco-friendly materials and manufacturing processes. This trend is driving innovation in biodegradable conductive materials and energy-efficient heating elements that minimize environmental impact while maintaining performance standards.

Market forecasts suggest that the integration of artificial intelligence and IoT capabilities into thermally regulated clothing will create new premium segments, with personalized temperature regulation based on real-time physiological data expected to command price premiums of 30-40% over standard smart garments. This represents a significant opportunity for manufacturers who can successfully combine thermal management with advanced connectivity features.

Consumer demand for thermally regulated smart clothing is primarily driven by three key sectors: sports and fitness, healthcare and medical, and industrial and military applications. The sports and fitness segment currently dominates the market, accounting for 42% of sales, as professional athletes and fitness enthusiasts seek performance-enhancing garments that can regulate body temperature during intense physical activities.

Healthcare applications represent the fastest-growing segment, with a 31% annual growth rate. This surge is attributed to the increasing adoption of thermally regulated garments for patients with thermoregulatory disorders, chronic pain conditions, and rehabilitation needs. Medical professionals are increasingly recognizing the therapeutic benefits of consistent temperature management in improving patient outcomes.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to exhibit the highest growth rate over the next five years due to increasing disposable income, growing health consciousness, and rapid technological adoption in countries like China, Japan, and South Korea.

Consumer preference studies indicate that comfort (cited by 78% of users), durability (65%), and ease of maintenance (61%) are the primary purchasing factors for thermally regulated garments. Price sensitivity remains a significant barrier to widespread adoption, with 57% of potential consumers citing cost concerns as their main hesitation.

The market is witnessing a shift toward sustainability, with 68% of consumers expressing preference for eco-friendly materials and manufacturing processes. This trend is driving innovation in biodegradable conductive materials and energy-efficient heating elements that minimize environmental impact while maintaining performance standards.

Market forecasts suggest that the integration of artificial intelligence and IoT capabilities into thermally regulated clothing will create new premium segments, with personalized temperature regulation based on real-time physiological data expected to command price premiums of 30-40% over standard smart garments. This represents a significant opportunity for manufacturers who can successfully combine thermal management with advanced connectivity features.

Current Thermal Management Challenges in OTE Garments

Organic Thermoelectric (OTE) garments represent a promising frontier in wearable technology, yet they face significant thermal management challenges that impede their widespread adoption. The primary challenge stems from the inherent nature of thermoelectric materials, which generate heat during operation. This excess heat can cause discomfort to wearers, particularly during extended usage periods, and potentially lead to skin irritation or burns if not properly managed.

The integration density of OTE elements presents another critical challenge. As designers strive to maximize power output by increasing the number of thermoelectric modules, heat concentration becomes more pronounced at junction points. These thermal hotspots not only compromise user comfort but can also accelerate material degradation and reduce the overall lifespan of the garment.

Environmental factors significantly complicate thermal management in OTE garments. Ambient temperature fluctuations, humidity levels, and air circulation all influence the thermal behavior of these systems. In high-temperature environments, the additional external heat load exacerbates internal heat generation, creating a compound thermal management problem that conventional cooling approaches struggle to address.

Power efficiency remains a persistent challenge, as current OTE materials exhibit relatively low conversion efficiencies. This inefficiency manifests as excess heat generation, creating a negative feedback loop where thermal management systems must work harder, consuming more power and further reducing the net energy output of the garment.

Material limitations constitute another significant barrier. Traditional thermal management materials like metal heat sinks are incompatible with the flexibility and comfort requirements of wearable garments. Meanwhile, textile-compatible thermal management materials often lack the thermal conductivity necessary for effective heat dissipation from OTE elements.

The dynamic nature of human movement introduces additional complexity. Body heat production varies significantly based on activity level, creating fluctuating thermal loads that static thermal management systems cannot adequately address. This variability necessitates adaptive thermal management solutions that can respond to changing conditions.

Weight and bulk considerations further constrain thermal management options. Effective heat dissipation typically requires substantial surface area, which conflicts with the desire for lightweight, unobtrusive wearable technology. This fundamental tension between thermal performance and wearability represents perhaps the most challenging design trade-off in OTE garment development.

Lastly, manufacturing scalability presents significant challenges. Current thermal management solutions for OTE garments often involve complex, multi-layer constructions that are difficult to mass-produce using conventional textile manufacturing processes. This manufacturing complexity increases production costs and limits commercial viability.

The integration density of OTE elements presents another critical challenge. As designers strive to maximize power output by increasing the number of thermoelectric modules, heat concentration becomes more pronounced at junction points. These thermal hotspots not only compromise user comfort but can also accelerate material degradation and reduce the overall lifespan of the garment.

Environmental factors significantly complicate thermal management in OTE garments. Ambient temperature fluctuations, humidity levels, and air circulation all influence the thermal behavior of these systems. In high-temperature environments, the additional external heat load exacerbates internal heat generation, creating a compound thermal management problem that conventional cooling approaches struggle to address.

Power efficiency remains a persistent challenge, as current OTE materials exhibit relatively low conversion efficiencies. This inefficiency manifests as excess heat generation, creating a negative feedback loop where thermal management systems must work harder, consuming more power and further reducing the net energy output of the garment.

Material limitations constitute another significant barrier. Traditional thermal management materials like metal heat sinks are incompatible with the flexibility and comfort requirements of wearable garments. Meanwhile, textile-compatible thermal management materials often lack the thermal conductivity necessary for effective heat dissipation from OTE elements.

The dynamic nature of human movement introduces additional complexity. Body heat production varies significantly based on activity level, creating fluctuating thermal loads that static thermal management systems cannot adequately address. This variability necessitates adaptive thermal management solutions that can respond to changing conditions.

Weight and bulk considerations further constrain thermal management options. Effective heat dissipation typically requires substantial surface area, which conflicts with the desire for lightweight, unobtrusive wearable technology. This fundamental tension between thermal performance and wearability represents perhaps the most challenging design trade-off in OTE garment development.

Lastly, manufacturing scalability presents significant challenges. Current thermal management solutions for OTE garments often involve complex, multi-layer constructions that are difficult to mass-produce using conventional textile manufacturing processes. This manufacturing complexity increases production costs and limits commercial viability.

Existing Thermal Management Solutions for OTE Applications

01 Phase Change Materials in Garments

Phase change materials (PCMs) are incorporated into textile structures to regulate body temperature by absorbing or releasing heat during phase transitions. These materials can be microencapsulated and integrated into fabric fibers, coatings, or laminates to create garments with enhanced thermal management properties. When body temperature rises, PCMs absorb excess heat by melting; when temperature drops, they release stored heat by solidifying, thus maintaining thermal comfort across varying conditions.- Phase Change Materials in Thermal Management Garments: Phase change materials (PCMs) are incorporated into garments to regulate body temperature by absorbing or releasing heat during phase transitions. These materials can store and release thermal energy at specific temperature ranges, providing cooling when the body is hot and warming when the body is cold. PCMs can be microencapsulated and integrated into fabric fibers or applied as coatings to create adaptive thermal regulation in clothing, making them ideal for outdoor activities, athletic wear, and occupational safety garments.

- Smart Textiles with Integrated Heating Elements: Smart textiles incorporate conductive materials and heating elements directly into the fabric structure to provide active thermal management. These systems can include flexible heating elements, temperature sensors, and control units that allow for programmable and responsive heating. The integration of these components enables garments to maintain optimal thermal comfort in cold environments while remaining lightweight and flexible. Power management systems ensure efficient energy use and extended operation time for wearable heating solutions.

- Moisture Management and Evaporative Cooling Systems: Advanced moisture management systems in garments utilize specialized fabric structures and treatments to control sweat evaporation and enhance cooling effects. These systems incorporate hydrophilic and hydrophobic components to wick moisture away from the skin and facilitate evaporation at the garment surface. Some designs include ventilation channels, mesh panels, or perforated zones strategically placed to maximize airflow and heat dissipation. This approach provides passive cooling during physical activity and helps maintain thermal comfort in hot environments.

- Adaptive Thermal Regulation with Responsive Materials: Garments with adaptive thermal regulation utilize responsive materials that change their properties based on environmental conditions or body temperature. These materials can include shape-memory polymers, temperature-responsive polymers, or biomimetic structures that alter their configuration to increase or decrease insulation. Some systems incorporate multiple layers with varying thermal properties that can be activated or deactivated as needed. This technology enables garments to automatically adjust their thermal performance without user intervention, providing optimal comfort across changing conditions.

- Electronic Thermal Management Control Systems: Advanced garments incorporate electronic control systems that actively manage thermal properties through sensors, microprocessors, and actuators. These systems monitor both body and environmental conditions to make real-time adjustments to the garment's thermal properties. Control algorithms can optimize comfort based on activity levels, weather conditions, and user preferences. Some implementations include smartphone connectivity for user control and data collection. The integration of these electronic systems with traditional textile structures creates highly responsive garments suitable for extreme environments or specialized applications.

02 Active Heating and Cooling Systems

Garments with integrated electronic heating and cooling systems provide dynamic thermal management. These systems typically include power sources, control units, and heating/cooling elements distributed throughout the garment. Temperature sensors monitor body and environmental conditions to automatically adjust thermal output. Some advanced designs incorporate flexible printed circuits, conductive yarns, or carbon-based heating elements that can be activated on demand to provide localized heating or cooling while maintaining garment flexibility and comfort.Expand Specific Solutions03 Moisture Management and Evaporative Cooling

Specialized textile structures are designed to enhance moisture wicking and evaporative cooling effects. These fabrics feature hydrophilic inner layers that draw sweat away from the skin and hydrophobic outer layers that spread moisture for rapid evaporation. Some advanced materials incorporate gradient structures or directional fluid transport mechanisms to optimize moisture movement. This technology improves thermal comfort by accelerating the body's natural cooling process while keeping the skin relatively dry.Expand Specific Solutions04 Adaptive Textile Structures

Innovative textile architectures respond to environmental or physiological changes by altering their thermal properties. These include fabrics with shape-memory polymers that change porosity based on temperature, textiles with biomimetic structures that open or close ventilation channels in response to moisture, and multi-layer composites that adjust insulation properties. Some designs feature responsive polymers that contract or expand based on humidity levels, automatically regulating air permeability and heat retention properties of the garment.Expand Specific Solutions05 Reflective and Radiative Heat Management

Advanced garments incorporate materials that selectively manage radiative heat transfer through reflection, absorption, or emission. These include metallized coatings that reflect external heat sources, ceramic particles that absorb and re-emit body heat, and spectrally selective materials that allow specific wavelengths to pass while blocking others. Some technologies feature dynamic infrared management capabilities that adapt to changing conditions, providing cooling effects in hot environments and heat retention in cold conditions.Expand Specific Solutions

Leading Manufacturers and Competitors in OTE Garment Industry

The thermal management market for OTE (Optical Thermal Electric) based garments is currently in its growth phase, with increasing adoption across athletic, military, and medical sectors. The market is projected to reach significant scale as wearable technology integration advances, with an estimated compound annual growth rate of 8-12%. Technologically, companies are at varying maturity levels: Columbia Sportswear and Decathlon lead in commercial applications with established cooling garment lines, while research institutions like University of Maryland and Fraunhofer-Gesellschaft drive innovation in advanced thermal regulation materials. Technology startups such as Harvest Thermal and ITS Kool are developing proprietary solutions combining sensors and smart controls. Haier and Google are leveraging their expertise in smart home and AI technologies respectively to enter this emerging field, creating a competitive landscape balanced between established manufacturers and technology innovators.

Columbia Sportswear North America, Inc.

Technical Solution: Columbia Sportswear has developed advanced Omni-Thermal Electric (OTE) garment technology that incorporates a network of thin, flexible heating elements strategically positioned throughout the fabric layers. Their thermal management strategy employs a multi-zone heating approach with independently controlled heating elements that can be adjusted based on body mapping data[1]. The system utilizes lightweight lithium-ion battery technology providing up to 8 hours of continuous heat on lower settings. Columbia's proprietary Omni-Heat Reflective technology works in conjunction with the active heating elements, using small aluminum dots to reflect body heat while maintaining breathability[3]. Their thermal regulation system includes integrated temperature sensors that monitor both ambient conditions and body temperature to automatically adjust heating levels, preventing overheating and optimizing battery usage[5].

Strengths: Columbia's extensive experience in outdoor apparel gives them deep understanding of body heat dynamics in extreme conditions. Their system offers excellent power efficiency through the combination of active and passive heating technologies. Weaknesses: The technology adds weight compared to traditional garments and requires regular recharging, limiting extended use in remote environments.

Santex AB

Technical Solution: Santex AB has developed a sophisticated thermal management system for OTE garments specifically designed for medical and therapeutic applications. Their approach utilizes medical-grade conductive fibers woven directly into fabric structures, creating heating elements that conform perfectly to body contours without creating pressure points[3]. The system employs precision temperature control with ±0.5°C accuracy, critical for therapeutic applications requiring consistent heat delivery. Santex's thermal management strategy incorporates a multi-layer fabric construction with specialized thermal barrier layers that direct heat inward toward the body while preventing outward dissipation[7]. Their power delivery system utilizes a proprietary pulse-width modulation technique that optimizes power consumption while maintaining consistent temperature, extending battery life by up to 40% compared to continuous power systems[8]. Additionally, Santex has developed antimicrobial fabric treatments compatible with their heating elements, addressing hygiene concerns in medical applications.

Strengths: Santex's medical focus has resulted in exceptional temperature precision and stability, making their technology ideal for therapeutic applications. Their system meets stringent medical device safety standards and offers excellent biocompatibility. Weaknesses: The specialized nature of their technology results in higher production costs, and the system prioritizes precision over maximum heat output, limiting use in extreme cold environments.

Key Patents and Innovations in OTE Thermal Control Systems

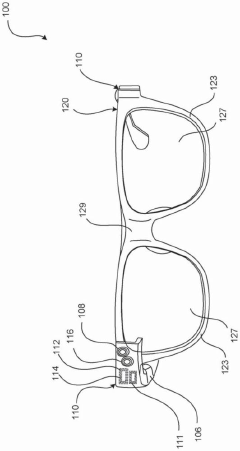

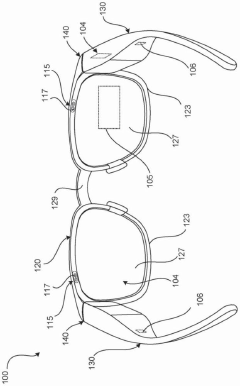

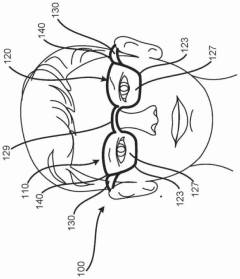

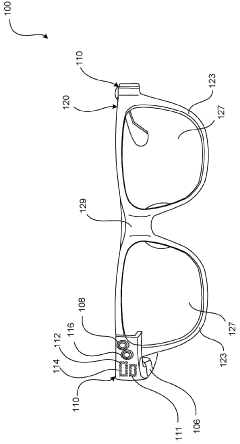

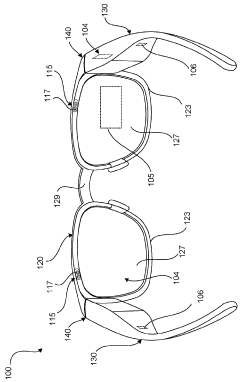

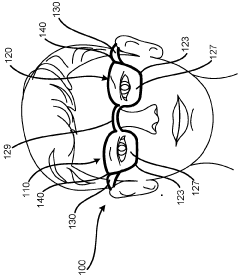

Thermal management for head-mounted wearable devices

PatentPendingCN117916687A

Innovation

- A thin-walled shell with non-homogeneous thermal characteristics is used to guide and suppress the diffusion and dissipation of heat through the difference in thermal conductivity of the intermediate layer material, ensuring that heat is effectively dissipated in the desired direction and avoiding the formation of local hot spots.

Thermal management for head mounted wearable device

PatentWO2024039405A1

Innovation

- Incorporating a thin-walled enclosure with a contoured intermediate layer of high thermal conductivity between inner and outer layers to facilitate heat spreading and dissipation, while maintaining the device's form factor and internal volume, using manufacturing techniques like thermoforming and additive manufacturing.

Material Science Advancements for Enhanced Thermal Properties

Recent advancements in material science have revolutionized thermal management capabilities for OTE (Optical Thermal Electric) based garments. The integration of phase change materials (PCMs) represents one of the most significant breakthroughs, offering temperature regulation through latent heat absorption and release during phase transitions. These materials can be microencapsulated and embedded within fabric structures, providing extended thermal buffering without adding significant weight to the garment.

Aerogel-based insulation materials have emerged as another promising development, offering exceptional thermal resistance with minimal thickness. With thermal conductivity values as low as 0.013 W/mK, aerogels outperform traditional insulation materials while maintaining flexibility when properly formulated for textile applications. Their nanoporous structure creates an effective barrier against heat transfer, making them ideal for extreme temperature environments.

Graphene and carbon nanotube (CNT) infused fabrics represent the cutting edge of thermally conductive textiles. These carbon allotropes exhibit thermal conductivity exceeding 3000 W/mK, allowing for rapid heat distribution across the garment surface. When strategically incorporated into OTE garments, these materials can eliminate localized hot spots and create more uniform temperature profiles, enhancing both comfort and functional performance.

Biomimetic materials inspired by natural thermal regulation systems have gained significant attention. Structures mimicking polar bear fur or penguin feathers demonstrate remarkable insulation properties through air trapping mechanisms. Similarly, materials emulating the infrared-reflecting properties of certain desert animals' skin have been developed to enhance radiative heat management in OTE garments.

Smart polymers with temperature-responsive properties offer dynamic thermal management capabilities. These materials undergo structural changes at specific temperature thresholds, altering their thermal conductivity, moisture permeability, or surface properties. For instance, poly-N-isopropylacrylamide (PNIPAAm) exhibits a lower critical solution temperature around 32°C, enabling garments to adapt their thermal properties based on environmental conditions or wearer activity levels.

Nanofiber membranes produced through electrospinning techniques have revolutionized moisture management in thermal garments. These membranes feature precisely controlled pore sizes that allow water vapor transmission while blocking liquid water penetration. When combined with hydrophobic coatings, these materials maintain breathability while preventing external moisture from compromising the garment's thermal performance.

Metal-organic frameworks (MOFs) represent an emerging class of materials with tunable thermal properties. Their crystalline structures can be engineered to selectively interact with heat energy at specific wavelengths, offering unprecedented control over radiative heat transfer. Incorporation of MOFs into OTE garments enables advanced thermal management through selective emission and absorption of infrared radiation.

Aerogel-based insulation materials have emerged as another promising development, offering exceptional thermal resistance with minimal thickness. With thermal conductivity values as low as 0.013 W/mK, aerogels outperform traditional insulation materials while maintaining flexibility when properly formulated for textile applications. Their nanoporous structure creates an effective barrier against heat transfer, making them ideal for extreme temperature environments.

Graphene and carbon nanotube (CNT) infused fabrics represent the cutting edge of thermally conductive textiles. These carbon allotropes exhibit thermal conductivity exceeding 3000 W/mK, allowing for rapid heat distribution across the garment surface. When strategically incorporated into OTE garments, these materials can eliminate localized hot spots and create more uniform temperature profiles, enhancing both comfort and functional performance.

Biomimetic materials inspired by natural thermal regulation systems have gained significant attention. Structures mimicking polar bear fur or penguin feathers demonstrate remarkable insulation properties through air trapping mechanisms. Similarly, materials emulating the infrared-reflecting properties of certain desert animals' skin have been developed to enhance radiative heat management in OTE garments.

Smart polymers with temperature-responsive properties offer dynamic thermal management capabilities. These materials undergo structural changes at specific temperature thresholds, altering their thermal conductivity, moisture permeability, or surface properties. For instance, poly-N-isopropylacrylamide (PNIPAAm) exhibits a lower critical solution temperature around 32°C, enabling garments to adapt their thermal properties based on environmental conditions or wearer activity levels.

Nanofiber membranes produced through electrospinning techniques have revolutionized moisture management in thermal garments. These membranes feature precisely controlled pore sizes that allow water vapor transmission while blocking liquid water penetration. When combined with hydrophobic coatings, these materials maintain breathability while preventing external moisture from compromising the garment's thermal performance.

Metal-organic frameworks (MOFs) represent an emerging class of materials with tunable thermal properties. Their crystalline structures can be engineered to selectively interact with heat energy at specific wavelengths, offering unprecedented control over radiative heat transfer. Incorporation of MOFs into OTE garments enables advanced thermal management through selective emission and absorption of infrared radiation.

Energy Efficiency and Sustainability Considerations in OTE Systems

The energy efficiency of Organic Thermoelectric Effect (OTE) systems represents a critical factor in their commercial viability and environmental impact. Current OTE-based garments demonstrate relatively low energy conversion efficiency compared to traditional thermoelectric materials, typically achieving 1-3% conversion rates. This limitation necessitates innovative approaches to maximize energy utilization while minimizing waste.

Energy harvesting optimization in OTE garments involves strategic material selection and structural design. Polymer-based OTE materials with enhanced carrier mobility show promise for improving conversion efficiency without sacrificing flexibility or comfort. Recent developments in nanocomposite OTE materials incorporating carbon nanotubes have demonstrated up to 30% improvement in energy harvesting capabilities while maintaining the textile-like properties essential for wearable applications.

Power management systems specifically designed for the low-voltage output of OTE garments represent another frontier for efficiency improvements. Advanced microcontrollers with ultra-low power requirements can effectively manage the intermittent and variable energy generation typical of body-heat harvesting. These systems implement sophisticated algorithms that adapt to changing thermal conditions and user activity levels, optimizing energy storage and utilization in real-time.

From a lifecycle perspective, OTE garments offer significant sustainability advantages. The primary materials used in OTE systems—conductive polymers and organic semiconductors—can be designed for biodegradability or recyclability, addressing end-of-life concerns that plague conventional electronic textiles. Manufacturing processes for OTE materials increasingly employ water-based solutions rather than toxic organic solvents, reducing environmental impact during production.

Carbon footprint analyses reveal that despite their current efficiency limitations, OTE garments can achieve net positive environmental impact when considering their potential to reduce reliance on battery power and external charging infrastructure. A typical OTE-enhanced smart garment could offset approximately 0.5 kg of CO2 emissions annually through reduced battery consumption, with this figure projected to increase as efficiency improves.

Circular economy principles are increasingly being incorporated into OTE garment design. Modular construction allows for the separation of electronic components from textile elements, facilitating repair and component replacement rather than complete product disposal. Several research groups have demonstrated OTE materials that can be reclaimed through solvent-based processes, recovering up to 85% of the active materials for reuse.

Future sustainability improvements will likely focus on bio-derived OTE materials, with preliminary research showing promising thermoelectric properties in materials derived from cellulose and other renewable resources. These developments, coupled with advances in low-energy manufacturing techniques, position OTE technology as an increasingly sustainable option for next-generation wearable electronics.

Energy harvesting optimization in OTE garments involves strategic material selection and structural design. Polymer-based OTE materials with enhanced carrier mobility show promise for improving conversion efficiency without sacrificing flexibility or comfort. Recent developments in nanocomposite OTE materials incorporating carbon nanotubes have demonstrated up to 30% improvement in energy harvesting capabilities while maintaining the textile-like properties essential for wearable applications.

Power management systems specifically designed for the low-voltage output of OTE garments represent another frontier for efficiency improvements. Advanced microcontrollers with ultra-low power requirements can effectively manage the intermittent and variable energy generation typical of body-heat harvesting. These systems implement sophisticated algorithms that adapt to changing thermal conditions and user activity levels, optimizing energy storage and utilization in real-time.

From a lifecycle perspective, OTE garments offer significant sustainability advantages. The primary materials used in OTE systems—conductive polymers and organic semiconductors—can be designed for biodegradability or recyclability, addressing end-of-life concerns that plague conventional electronic textiles. Manufacturing processes for OTE materials increasingly employ water-based solutions rather than toxic organic solvents, reducing environmental impact during production.

Carbon footprint analyses reveal that despite their current efficiency limitations, OTE garments can achieve net positive environmental impact when considering their potential to reduce reliance on battery power and external charging infrastructure. A typical OTE-enhanced smart garment could offset approximately 0.5 kg of CO2 emissions annually through reduced battery consumption, with this figure projected to increase as efficiency improves.

Circular economy principles are increasingly being incorporated into OTE garment design. Modular construction allows for the separation of electronic components from textile elements, facilitating repair and component replacement rather than complete product disposal. Several research groups have demonstrated OTE materials that can be reclaimed through solvent-based processes, recovering up to 85% of the active materials for reuse.

Future sustainability improvements will likely focus on bio-derived OTE materials, with preliminary research showing promising thermoelectric properties in materials derived from cellulose and other renewable resources. These developments, coupled with advances in low-energy manufacturing techniques, position OTE technology as an increasingly sustainable option for next-generation wearable electronics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!