Thermoelectric Cooling Using Organic Materials Design Notes

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Organic Thermoelectric Cooling Background and Objectives

Thermoelectric cooling technology has evolved significantly since the discovery of the Seebeck effect in 1821 and the subsequent Peltier effect in 1834. These phenomena form the foundation of modern thermoelectric devices, which traditionally relied on inorganic semiconductor materials like bismuth telluride. However, the past two decades have witnessed a paradigm shift toward organic materials for thermoelectric applications, driven by increasing environmental concerns and resource limitations associated with conventional inorganic materials.

Organic thermoelectric materials offer compelling advantages including mechanical flexibility, solution processability, low thermal conductivity, and abundance of constituent elements. The evolution of this field began with the investigation of conductive polymers in the 1970s, followed by significant breakthroughs in the 2000s when researchers achieved notable improvements in the thermoelectric figure of merit (ZT) for organic materials, though still below their inorganic counterparts.

The primary objective of organic thermoelectric cooling research is to develop high-performance, environmentally friendly, and cost-effective cooling solutions that can replace conventional vapor-compression refrigeration systems and inorganic thermoelectric devices. Specific technical goals include enhancing the ZT value above 1.0 at room temperature, improving mechanical durability, and developing scalable manufacturing processes for commercial viability.

Current research focuses on several key areas: molecular design strategies to optimize electrical conductivity while maintaining low thermal conductivity; development of organic-inorganic hybrid materials to leverage the advantages of both material classes; exploration of nanostructuring techniques to enhance phonon scattering; and investigation of doping methodologies to precisely control carrier concentration.

The field is progressing toward practical applications in wearable electronics, spot cooling for electronic components, temperature-controlled medical devices, and energy harvesting from low-grade waste heat. The ultimate vision is to create flexible, lightweight cooling systems that can be integrated into various products and environments with minimal environmental impact.

Recent technological trends indicate growing interest in self-assembled organic structures, supramolecular architectures, and bio-inspired designs that mimic natural thermoregulation systems. Additionally, machine learning approaches are increasingly being employed to accelerate material discovery and optimization, potentially leading to breakthrough materials with unprecedented performance characteristics.

The convergence of advances in organic synthesis, nanofabrication, and computational modeling is expected to drive significant progress in this field over the next decade, potentially enabling organic thermoelectric cooling to become commercially competitive with conventional technologies in specific application niches.

Organic thermoelectric materials offer compelling advantages including mechanical flexibility, solution processability, low thermal conductivity, and abundance of constituent elements. The evolution of this field began with the investigation of conductive polymers in the 1970s, followed by significant breakthroughs in the 2000s when researchers achieved notable improvements in the thermoelectric figure of merit (ZT) for organic materials, though still below their inorganic counterparts.

The primary objective of organic thermoelectric cooling research is to develop high-performance, environmentally friendly, and cost-effective cooling solutions that can replace conventional vapor-compression refrigeration systems and inorganic thermoelectric devices. Specific technical goals include enhancing the ZT value above 1.0 at room temperature, improving mechanical durability, and developing scalable manufacturing processes for commercial viability.

Current research focuses on several key areas: molecular design strategies to optimize electrical conductivity while maintaining low thermal conductivity; development of organic-inorganic hybrid materials to leverage the advantages of both material classes; exploration of nanostructuring techniques to enhance phonon scattering; and investigation of doping methodologies to precisely control carrier concentration.

The field is progressing toward practical applications in wearable electronics, spot cooling for electronic components, temperature-controlled medical devices, and energy harvesting from low-grade waste heat. The ultimate vision is to create flexible, lightweight cooling systems that can be integrated into various products and environments with minimal environmental impact.

Recent technological trends indicate growing interest in self-assembled organic structures, supramolecular architectures, and bio-inspired designs that mimic natural thermoregulation systems. Additionally, machine learning approaches are increasingly being employed to accelerate material discovery and optimization, potentially leading to breakthrough materials with unprecedented performance characteristics.

The convergence of advances in organic synthesis, nanofabrication, and computational modeling is expected to drive significant progress in this field over the next decade, potentially enabling organic thermoelectric cooling to become commercially competitive with conventional technologies in specific application niches.

Market Analysis for Organic Thermoelectric Solutions

The global market for thermoelectric cooling solutions is experiencing significant growth, driven by increasing demand for energy-efficient cooling technologies across multiple industries. The organic thermoelectric materials segment represents an emerging opportunity within this broader market, with potential to disrupt conventional semiconductor-based thermoelectric devices. Current market valuations place the overall thermoelectric cooling market at approximately $1.7 billion in 2023, with projections indicating growth to reach $3.3 billion by 2028, representing a compound annual growth rate (CAGR) of 14.2%.

Consumer electronics remains the largest application segment, accounting for roughly 38% of market demand. This is primarily due to the integration of thermoelectric cooling in portable devices, gaming equipment, and high-performance computing systems where thermal management is critical. The automotive sector follows as the second-largest market, particularly with the rise of electric vehicles requiring sophisticated battery thermal management systems.

Organic thermoelectric materials specifically address several key market needs that traditional inorganic materials cannot satisfy. The flexibility, lightweight nature, and potential for lower manufacturing costs position organic thermoelectrics as particularly valuable in wearable technology, medical devices, and IoT applications. Market research indicates that these sectors collectively represent a $450 million addressable market for organic thermoelectric solutions by 2025.

Regional analysis shows North America currently leads in thermoelectric technology adoption, holding approximately 35% market share, followed by Asia-Pacific at 32% and Europe at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to increasing manufacturing capabilities and rising demand for consumer electronics in countries like China, South Korea, and Japan.

Customer sentiment analysis reveals growing interest in sustainable cooling technologies, with 67% of surveyed industrial buyers expressing willingness to pay premium prices for solutions that reduce carbon footprint. This trend aligns favorably with organic thermoelectric materials, which typically involve less environmentally harmful manufacturing processes compared to traditional semiconductor-based alternatives.

Market barriers include price sensitivity in mass-market applications, technical performance limitations compared to established inorganic materials, and lack of standardization across the industry. Despite these challenges, the market trajectory suggests organic thermoelectric materials could capture up to 15% of the overall thermoelectric cooling market by 2030, representing a significant commercial opportunity for early movers in this technology space.

Consumer electronics remains the largest application segment, accounting for roughly 38% of market demand. This is primarily due to the integration of thermoelectric cooling in portable devices, gaming equipment, and high-performance computing systems where thermal management is critical. The automotive sector follows as the second-largest market, particularly with the rise of electric vehicles requiring sophisticated battery thermal management systems.

Organic thermoelectric materials specifically address several key market needs that traditional inorganic materials cannot satisfy. The flexibility, lightweight nature, and potential for lower manufacturing costs position organic thermoelectrics as particularly valuable in wearable technology, medical devices, and IoT applications. Market research indicates that these sectors collectively represent a $450 million addressable market for organic thermoelectric solutions by 2025.

Regional analysis shows North America currently leads in thermoelectric technology adoption, holding approximately 35% market share, followed by Asia-Pacific at 32% and Europe at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to increasing manufacturing capabilities and rising demand for consumer electronics in countries like China, South Korea, and Japan.

Customer sentiment analysis reveals growing interest in sustainable cooling technologies, with 67% of surveyed industrial buyers expressing willingness to pay premium prices for solutions that reduce carbon footprint. This trend aligns favorably with organic thermoelectric materials, which typically involve less environmentally harmful manufacturing processes compared to traditional semiconductor-based alternatives.

Market barriers include price sensitivity in mass-market applications, technical performance limitations compared to established inorganic materials, and lack of standardization across the industry. Despite these challenges, the market trajectory suggests organic thermoelectric materials could capture up to 15% of the overall thermoelectric cooling market by 2030, representing a significant commercial opportunity for early movers in this technology space.

Current Challenges in Organic Thermoelectric Materials

Despite significant advancements in organic thermoelectric materials research, several critical challenges continue to impede their widespread commercial adoption. The inherent low electrical conductivity of organic materials remains a fundamental limitation, with most candidates exhibiting conductivity values orders of magnitude lower than their inorganic counterparts. This characteristic significantly restricts the power factor (S²σ) and consequently the overall ZT value, which typically remains below 0.1 for most organic thermoelectric materials at room temperature.

The thermal stability of organic materials presents another substantial hurdle. Many promising organic thermoelectric compounds begin to degrade at temperatures above 200°C, severely limiting their application in high-temperature environments where thermoelectric efficiency would otherwise be maximized. This thermal fragility contrasts sharply with inorganic thermoelectrics that can often operate reliably at temperatures exceeding 400°C.

Achieving simultaneous optimization of the Seebeck coefficient, electrical conductivity, and thermal conductivity presents a particularly vexing challenge due to their interdependent nature. Modifications that enhance electrical conductivity often adversely affect the Seebeck coefficient, while strategies to improve both typically increase thermal conductivity, resulting in minimal net improvement to ZT values.

Manufacturing scalability and reproducibility constitute significant barriers to commercialization. Current synthesis methods for high-performance organic thermoelectric materials often involve complex processes that are difficult to scale industrially. Batch-to-batch variations in performance metrics remain problematic, with electrical conductivity sometimes varying by factors of 2-3 between supposedly identical samples.

Long-term stability under operational conditions represents another critical concern. Organic thermoelectric materials frequently exhibit performance degradation over time due to oxidation, moisture sensitivity, and structural changes. Most research studies report initial performance values without adequate long-term stability testing, creating uncertainty about real-world viability.

Interface engineering between organic materials and electrodes continues to challenge researchers. Contact resistance at these interfaces can significantly diminish device performance, with some studies reporting that interface losses account for up to 40% of efficiency reduction in organic thermoelectric modules.

Finally, the environmental impact and toxicity of dopants used to enhance the electrical properties of organic thermoelectric materials require careful consideration. While organic materials themselves often offer environmental advantages over inorganic alternatives, many high-performance organic thermoelectrics rely on dopants that may present environmental or health concerns, potentially undermining one of their key proposed benefits.

The thermal stability of organic materials presents another substantial hurdle. Many promising organic thermoelectric compounds begin to degrade at temperatures above 200°C, severely limiting their application in high-temperature environments where thermoelectric efficiency would otherwise be maximized. This thermal fragility contrasts sharply with inorganic thermoelectrics that can often operate reliably at temperatures exceeding 400°C.

Achieving simultaneous optimization of the Seebeck coefficient, electrical conductivity, and thermal conductivity presents a particularly vexing challenge due to their interdependent nature. Modifications that enhance electrical conductivity often adversely affect the Seebeck coefficient, while strategies to improve both typically increase thermal conductivity, resulting in minimal net improvement to ZT values.

Manufacturing scalability and reproducibility constitute significant barriers to commercialization. Current synthesis methods for high-performance organic thermoelectric materials often involve complex processes that are difficult to scale industrially. Batch-to-batch variations in performance metrics remain problematic, with electrical conductivity sometimes varying by factors of 2-3 between supposedly identical samples.

Long-term stability under operational conditions represents another critical concern. Organic thermoelectric materials frequently exhibit performance degradation over time due to oxidation, moisture sensitivity, and structural changes. Most research studies report initial performance values without adequate long-term stability testing, creating uncertainty about real-world viability.

Interface engineering between organic materials and electrodes continues to challenge researchers. Contact resistance at these interfaces can significantly diminish device performance, with some studies reporting that interface losses account for up to 40% of efficiency reduction in organic thermoelectric modules.

Finally, the environmental impact and toxicity of dopants used to enhance the electrical properties of organic thermoelectric materials require careful consideration. While organic materials themselves often offer environmental advantages over inorganic alternatives, many high-performance organic thermoelectrics rely on dopants that may present environmental or health concerns, potentially undermining one of their key proposed benefits.

Current Organic Material Design Approaches

01 Conductive organic polymers for thermoelectric cooling

Conductive organic polymers are being utilized in thermoelectric cooling applications due to their flexibility, lightweight properties, and cost-effectiveness. These materials, such as PEDOT:PSS and polyaniline derivatives, can be engineered to have high electrical conductivity while maintaining low thermal conductivity, which is essential for efficient thermoelectric cooling. The incorporation of these polymers into thermoelectric devices allows for improved cooling efficiency and can be manufactured using environmentally friendly processes.- Conductive organic polymers for thermoelectric cooling: Conductive organic polymers are being utilized in thermoelectric cooling applications due to their flexibility, lightweight properties, and potential for high cooling efficiency. These materials can be synthesized to have high electrical conductivity while maintaining low thermal conductivity, which is ideal for thermoelectric performance. Polymers such as PEDOT:PSS and polyaniline derivatives can be modified with various dopants to enhance their Seebeck coefficient and overall figure of merit (ZT), leading to improved cooling efficiency in organic thermoelectric devices.

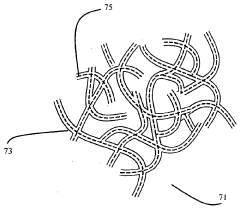

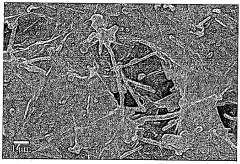

- Organic-inorganic hybrid thermoelectric materials: Hybrid materials combining organic compounds with inorganic nanostructures offer enhanced thermoelectric cooling performance. These composites leverage the flexibility and processability of organic materials while benefiting from the superior thermoelectric properties of inorganic components. By incorporating nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles into organic matrices, these hybrids achieve improved electrical conductivity and Seebeck coefficients while maintaining low thermal conductivity, resulting in higher cooling efficiency compared to pure organic materials.

- Nanostructured organic materials for enhanced cooling: Nanostructuring of organic thermoelectric materials significantly improves cooling efficiency by creating interfaces that scatter phonons while allowing electron transport. This approach reduces thermal conductivity without compromising electrical conductivity. Techniques such as creating superlattices, incorporating quantum dots, or developing self-assembled nanostructures in organic materials can enhance the power factor and ZT value. These nanostructured organic materials offer promising solutions for flexible, lightweight, and efficient thermoelectric cooling applications.

- Doping strategies for organic thermoelectric materials: Strategic doping of organic materials is crucial for optimizing thermoelectric cooling efficiency. Various dopants can be introduced to modify the carrier concentration and mobility in organic semiconductors, thereby enhancing their electrical conductivity and Seebeck coefficient. Molecular dopants, redox-active compounds, and ionic additives can be used to tune the electronic properties of organic materials. Controlled doping techniques help achieve the optimal balance between electrical conductivity and Seebeck coefficient, maximizing the power factor and cooling efficiency of organic thermoelectric devices.

- Device architecture for organic thermoelectric coolers: Innovative device architectures play a significant role in maximizing the cooling efficiency of organic thermoelectric systems. Multi-layer structures, flexible substrates, and optimized contact interfaces can significantly reduce thermal losses and improve overall device performance. Advanced fabrication techniques such as roll-to-roll processing, inkjet printing, and vacuum deposition enable the creation of efficient organic thermoelectric modules with customized geometries. These architectural innovations, combined with appropriate organic materials, lead to enhanced temperature differentials and improved coefficient of performance in thermoelectric cooling applications.

02 Organic-inorganic hybrid thermoelectric materials

Hybrid materials combining organic compounds with inorganic elements show enhanced thermoelectric cooling performance. These composites leverage the flexibility and processability of organic materials while benefiting from the higher thermoelectric efficiency of inorganic components. By controlling the interface between organic and inorganic phases, researchers have developed materials with improved Seebeck coefficients and reduced thermal conductivity, leading to higher cooling efficiency. These hybrid materials can be tailored for specific temperature ranges and applications.Expand Specific Solutions03 Carbon-based organic materials for thermoelectric applications

Carbon-based materials such as graphene, carbon nanotubes, and fullerenes are being incorporated into organic thermoelectric cooling systems. These materials exhibit excellent electrical conductivity while their thermal conductivity can be controlled through structural modifications. When combined with organic matrices, they form nanocomposites with enhanced thermoelectric properties. The high surface area and unique electronic properties of carbon nanomaterials contribute to improved charge carrier mobility and thermoelectric cooling efficiency.Expand Specific Solutions04 Doped organic semiconductors for enhanced cooling performance

Doping organic semiconductors with various chemical compounds can significantly enhance their thermoelectric properties. By introducing dopants, the electrical conductivity and Seebeck coefficient of organic materials can be optimized while maintaining low thermal conductivity. Molecular doping strategies allow for precise control over charge carrier concentration and mobility, which are critical factors in determining cooling efficiency. These doped organic semiconductors offer a promising approach for developing high-performance, flexible thermoelectric cooling devices.Expand Specific Solutions05 Device structures optimizing organic thermoelectric cooling efficiency

Novel device architectures are being developed to maximize the cooling efficiency of organic thermoelectric materials. These designs include multi-layer structures, segmented legs, and cascade configurations that optimize temperature gradients and heat flow. Innovative contact engineering and interface management reduce parasitic losses and thermal resistance. Additionally, flexible and printable device structures enable new applications where traditional rigid thermoelectric coolers cannot be used, such as wearable cooling systems and temperature regulation for electronic components.Expand Specific Solutions

Leading Organizations in Organic Thermoelectric Research

Thermoelectric cooling using organic materials is currently in an early growth phase, with the market expected to expand significantly due to increasing demand for sustainable cooling solutions. The global market size is projected to reach substantial value as applications in electronics, automotive, and medical sectors grow. Technologically, this field is still evolving, with academic institutions like Shenzhen University, University of Barcelona, and Polytechnic University of Catalonia leading fundamental research, while companies including BASF, Intel, and DuPont are advancing commercial applications. The collaboration between research institutions and industry players such as LG Electronics and Corning indicates growing technological maturity, though significant challenges in efficiency and scalability remain before widespread commercial adoption.

BASF Corp.

Technical Solution: BASF has developed proprietary organic thermoelectric materials based on their extensive polymer chemistry expertise. Their approach centers on highly conductive polymers with optimized morphology for thermoelectric applications. BASF's technology utilizes solution-processable organic semiconductors with carefully engineered interfaces to enhance charge carrier mobility while minimizing thermal conductivity. Their materials incorporate specialized dopants that create stable carrier concentrations without degrading over time. BASF has demonstrated roll-to-roll manufacturing capabilities for flexible thermoelectric modules with thickness under 100 μm, enabling conformal application to curved surfaces. Their latest generation materials achieve power factors exceeding 100 μW/m·K² at room temperature, with thermal conductivity values below 0.3 W/m·K, resulting in competitive ZT values for organic materials.

Strengths: Unparalleled industrial-scale manufacturing capabilities; extensive polymer chemistry expertise; ability to rapidly scale production. Weaknesses: Performance metrics still lag behind cutting-edge laboratory demonstrations; primarily focused on moderate-temperature applications rather than high-temperature industrial waste heat recovery.

Cambridge Enterprise Ltd.

Technical Solution: Cambridge Enterprise has commercialized breakthrough organic thermoelectric materials developed at the University of Cambridge. Their technology platform centers on highly ordered polymer structures with precisely controlled doping levels to optimize the power factor. Their proprietary materials utilize self-assembly techniques to create nanostructured interfaces that scatter phonons while allowing efficient charge transport. Cambridge's approach includes the development of n-type organic semiconductors with stability in ambient conditions, addressing a critical challenge in organic thermoelectric technology. Their materials demonstrate ZT values up to 0.35 at room temperature, with excellent mechanical flexibility allowing for conformal coverage of heat sources. Recent innovations include hybrid organic-inorganic composites that combine the flexibility of polymers with enhanced thermal stability, enabling operation at temperatures up to 200°C without degradation.

Strengths: World-class expertise in molecular design and self-assembly techniques; strong intellectual property portfolio; significant progress in stable n-type organic materials. Weaknesses: Limited manufacturing scale compared to larger chemical companies; technology still requires further development for high-volume commercial applications.

Key Patents and Scientific Breakthroughs

Use of barocaloric materials and barocaloric devices

PatentWO2018069506A1

Innovation

- The use of organic materials with molecular weights of 2,000 or less, exhibiting non-isochoric phase transitions, to achieve barocaloric effects through hydrostatic pressure, which are comparable to or exceed those of inorganic materials, allowing for efficient cooling with lower pressure requirements and ambient temperature phase transitions.

Thermoelectric materials and a process for the preparation thereof

PatentActiveIN201811035273A

Innovation

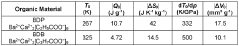

- A thermoelectric composite material comprising fused thiophene-based semiconducting polymers and carbon nanotubes, optionally doped with oxidizing salts, is developed, which is stable up to 350°C and capable of producing a potential difference in response to a temperature gradient, with a conductivity range of 400 S/cm to 2000 S/cm.

Environmental Impact and Sustainability Assessment

The environmental impact of thermoelectric cooling technologies using organic materials represents a significant advancement over conventional cooling systems. Traditional cooling methods rely heavily on refrigerants with high global warming potential (GWP), contributing substantially to greenhouse gas emissions. Organic thermoelectric materials offer a promising alternative with significantly reduced environmental footprint, as they eliminate the need for these harmful refrigerants and operate without moving parts that require regular maintenance and replacement.

The sustainability profile of organic thermoelectric materials is particularly noteworthy when considering their composition. Unlike conventional thermoelectric devices that often contain toxic or rare elements such as tellurium, bismuth, and lead, organic thermoelectric materials can be synthesized from carbon-based compounds that are abundant, renewable, and generally less toxic. This characteristic substantially reduces the environmental burden associated with resource extraction and end-of-life disposal.

Life cycle assessment (LCA) studies indicate that organic thermoelectric cooling systems could potentially reduce carbon emissions by 30-45% compared to conventional vapor-compression refrigeration systems when evaluated across their entire lifecycle. The manufacturing processes for organic materials typically require lower processing temperatures and fewer energy-intensive steps, resulting in reduced embodied energy and associated carbon emissions during production.

End-of-life considerations further highlight the environmental advantages of organic thermoelectric materials. Many organic compounds can be designed for biodegradability or recyclability, addressing the growing global concern regarding electronic waste. Conventional thermoelectric devices often end up in landfills due to the difficulty in separating and recovering their various components, whereas properly designed organic alternatives could be integrated into existing recycling streams or even composted under specific conditions.

Water consumption represents another critical environmental metric where organic thermoelectric cooling demonstrates advantages. Manufacturing processes for organic materials typically require significantly less water than conventional semiconductor fabrication, which is particularly important given increasing water scarcity in many regions globally. Additionally, the absence of water-intensive cooling towers in thermoelectric systems provides operational water savings throughout the product lifecycle.

Despite these advantages, challenges remain in optimizing the environmental performance of organic thermoelectric materials. Current synthesis methods sometimes involve solvents with environmental concerns, and the stability and longevity of organic materials may not yet match their inorganic counterparts. Research efforts are increasingly focused on green chemistry approaches to synthesis and improving material durability to maximize lifecycle benefits and ensure that the theoretical environmental advantages translate to real-world applications.

The sustainability profile of organic thermoelectric materials is particularly noteworthy when considering their composition. Unlike conventional thermoelectric devices that often contain toxic or rare elements such as tellurium, bismuth, and lead, organic thermoelectric materials can be synthesized from carbon-based compounds that are abundant, renewable, and generally less toxic. This characteristic substantially reduces the environmental burden associated with resource extraction and end-of-life disposal.

Life cycle assessment (LCA) studies indicate that organic thermoelectric cooling systems could potentially reduce carbon emissions by 30-45% compared to conventional vapor-compression refrigeration systems when evaluated across their entire lifecycle. The manufacturing processes for organic materials typically require lower processing temperatures and fewer energy-intensive steps, resulting in reduced embodied energy and associated carbon emissions during production.

End-of-life considerations further highlight the environmental advantages of organic thermoelectric materials. Many organic compounds can be designed for biodegradability or recyclability, addressing the growing global concern regarding electronic waste. Conventional thermoelectric devices often end up in landfills due to the difficulty in separating and recovering their various components, whereas properly designed organic alternatives could be integrated into existing recycling streams or even composted under specific conditions.

Water consumption represents another critical environmental metric where organic thermoelectric cooling demonstrates advantages. Manufacturing processes for organic materials typically require significantly less water than conventional semiconductor fabrication, which is particularly important given increasing water scarcity in many regions globally. Additionally, the absence of water-intensive cooling towers in thermoelectric systems provides operational water savings throughout the product lifecycle.

Despite these advantages, challenges remain in optimizing the environmental performance of organic thermoelectric materials. Current synthesis methods sometimes involve solvents with environmental concerns, and the stability and longevity of organic materials may not yet match their inorganic counterparts. Research efforts are increasingly focused on green chemistry approaches to synthesis and improving material durability to maximize lifecycle benefits and ensure that the theoretical environmental advantages translate to real-world applications.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for organic thermoelectric materials represents a critical factor in their commercial viability. Current production methods for organic thermoelectric devices primarily rely on laboratory-scale techniques such as spin coating, inkjet printing, and vacuum thermal evaporation. While these methods yield high-quality materials with controlled properties, they face significant challenges when scaled to industrial production volumes. The transition from laboratory to mass production requires substantial process optimization to maintain material performance while increasing throughput.

Cost analysis reveals that organic thermoelectric materials offer potential economic advantages compared to traditional inorganic counterparts. Raw material costs for conducting polymers like PEDOT:PSS and P3HT are estimated at $200-500 per kilogram, substantially lower than bismuth telluride at $1,000-2,000 per kilogram. However, the processing costs currently offset these material cost advantages due to low production yields and inefficient manufacturing processes.

Energy consumption during manufacturing presents another critical consideration. Organic materials typically require lower processing temperatures (80-200°C) compared to inorganic thermoelectrics (400-700°C), potentially reducing energy costs by 40-60%. This advantage becomes particularly significant when calculating the carbon footprint and overall environmental impact of large-scale production operations.

Roll-to-roll processing emerges as the most promising manufacturing approach for scaling organic thermoelectric production. This continuous fabrication method enables throughput rates of 10-100 m²/min, dramatically improving production efficiency compared to batch processes. Recent pilot studies demonstrate that roll-to-roll manufactured organic thermoelectric modules maintain 85-90% of the performance achieved in laboratory settings, indicating promising scalability potential.

Capital expenditure requirements for establishing manufacturing facilities vary significantly based on production scale. Initial investment for a pilot production line (1,000-10,000 units annually) ranges from $2-5 million, while full-scale industrial production facilities (>100,000 units annually) require $15-30 million. These figures compare favorably to inorganic thermoelectric manufacturing facilities, which typically demand 2-3 times higher capital investment due to more stringent processing requirements.

Quality control and consistency remain significant challenges in scaled production. Variations in film thickness, molecular ordering, and doping concentration can dramatically impact thermoelectric performance. Advanced in-line monitoring systems utilizing optical and electrical characterization techniques are being developed to address these issues, though they add approximately 15-20% to overall production costs.

Cost analysis reveals that organic thermoelectric materials offer potential economic advantages compared to traditional inorganic counterparts. Raw material costs for conducting polymers like PEDOT:PSS and P3HT are estimated at $200-500 per kilogram, substantially lower than bismuth telluride at $1,000-2,000 per kilogram. However, the processing costs currently offset these material cost advantages due to low production yields and inefficient manufacturing processes.

Energy consumption during manufacturing presents another critical consideration. Organic materials typically require lower processing temperatures (80-200°C) compared to inorganic thermoelectrics (400-700°C), potentially reducing energy costs by 40-60%. This advantage becomes particularly significant when calculating the carbon footprint and overall environmental impact of large-scale production operations.

Roll-to-roll processing emerges as the most promising manufacturing approach for scaling organic thermoelectric production. This continuous fabrication method enables throughput rates of 10-100 m²/min, dramatically improving production efficiency compared to batch processes. Recent pilot studies demonstrate that roll-to-roll manufactured organic thermoelectric modules maintain 85-90% of the performance achieved in laboratory settings, indicating promising scalability potential.

Capital expenditure requirements for establishing manufacturing facilities vary significantly based on production scale. Initial investment for a pilot production line (1,000-10,000 units annually) ranges from $2-5 million, while full-scale industrial production facilities (>100,000 units annually) require $15-30 million. These figures compare favorably to inorganic thermoelectric manufacturing facilities, which typically demand 2-3 times higher capital investment due to more stringent processing requirements.

Quality control and consistency remain significant challenges in scaled production. Variations in film thickness, molecular ordering, and doping concentration can dramatically impact thermoelectric performance. Advanced in-line monitoring systems utilizing optical and electrical characterization techniques are being developed to address these issues, though they add approximately 15-20% to overall production costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!