Low Temperature Characterization Methods For OTE Materials

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OTE Materials Cryogenic Testing Background and Objectives

Optical-to-electrical (OTE) materials have emerged as critical components in advanced sensing, quantum computing, and space exploration technologies. The characterization of these materials under extreme low temperature conditions has become increasingly important as applications extend into cryogenic environments. Historically, OTE material testing has evolved from basic electrical conductivity measurements in the early 20th century to sophisticated multi-parameter characterization techniques in recent decades.

The evolution of cryogenic testing for OTE materials has been closely linked to advancements in superconductivity research, with significant milestones including the development of liquid helium cooling systems in the 1950s and the introduction of closed-cycle cryostats in the 1980s. These technological breakthroughs have enabled more precise and controlled testing environments, allowing researchers to observe quantum effects and material behaviors that only manifest at temperatures approaching absolute zero.

Current technological trends in this field include the miniaturization of testing apparatus, integration of in-situ measurement capabilities, and development of non-destructive characterization methods. The push toward quantum technologies has accelerated the need for understanding how OTE materials behave at millikelvin temperatures, where quantum effects dominate classical behaviors.

The primary objectives of low temperature characterization for OTE materials include quantifying conversion efficiency under cryogenic conditions, measuring response time variations across temperature gradients, determining thermal stability during operational cycles, and identifying potential failure mechanisms specific to extreme cold environments. Additionally, researchers aim to establish standardized testing protocols that enable meaningful comparisons between different OTE materials and technologies.

Another critical goal is to bridge the gap between laboratory testing and real-world application requirements, particularly for space-based systems where materials must function reliably in the vacuum and extreme cold of outer space. This includes developing accelerated testing methodologies that can accurately predict long-term performance and degradation patterns without requiring decades of observation.

The scientific community also seeks to establish correlations between molecular structure and cryogenic performance, potentially enabling the design of new OTE materials specifically optimized for low-temperature applications. This requires sophisticated characterization techniques that can probe both electronic and structural properties simultaneously under cryogenic conditions.

As industries from quantum computing to deep space exploration increasingly rely on OTE materials functioning at cryogenic temperatures, the development of comprehensive, accurate, and efficient characterization methods has become not just a scientific pursuit but an economic and strategic imperative for technological leadership.

The evolution of cryogenic testing for OTE materials has been closely linked to advancements in superconductivity research, with significant milestones including the development of liquid helium cooling systems in the 1950s and the introduction of closed-cycle cryostats in the 1980s. These technological breakthroughs have enabled more precise and controlled testing environments, allowing researchers to observe quantum effects and material behaviors that only manifest at temperatures approaching absolute zero.

Current technological trends in this field include the miniaturization of testing apparatus, integration of in-situ measurement capabilities, and development of non-destructive characterization methods. The push toward quantum technologies has accelerated the need for understanding how OTE materials behave at millikelvin temperatures, where quantum effects dominate classical behaviors.

The primary objectives of low temperature characterization for OTE materials include quantifying conversion efficiency under cryogenic conditions, measuring response time variations across temperature gradients, determining thermal stability during operational cycles, and identifying potential failure mechanisms specific to extreme cold environments. Additionally, researchers aim to establish standardized testing protocols that enable meaningful comparisons between different OTE materials and technologies.

Another critical goal is to bridge the gap between laboratory testing and real-world application requirements, particularly for space-based systems where materials must function reliably in the vacuum and extreme cold of outer space. This includes developing accelerated testing methodologies that can accurately predict long-term performance and degradation patterns without requiring decades of observation.

The scientific community also seeks to establish correlations between molecular structure and cryogenic performance, potentially enabling the design of new OTE materials specifically optimized for low-temperature applications. This requires sophisticated characterization techniques that can probe both electronic and structural properties simultaneously under cryogenic conditions.

As industries from quantum computing to deep space exploration increasingly rely on OTE materials functioning at cryogenic temperatures, the development of comprehensive, accurate, and efficient characterization methods has become not just a scientific pursuit but an economic and strategic imperative for technological leadership.

Market Analysis for Low Temperature OTE Material Applications

The global market for Organic Thermoelectric (OTE) materials operating at low temperatures has been experiencing significant growth, driven by increasing demand for energy harvesting solutions in various applications. The market is primarily segmented into consumer electronics, healthcare devices, automotive systems, and industrial IoT applications, with each sector presenting unique opportunities for OTE material implementation.

Consumer electronics represents the largest market segment, with wearable technology and portable devices leading the adoption of low-temperature OTE materials. These materials enable the harvesting of body heat to power small electronic devices, addressing the persistent challenge of battery limitations in wearable technology. Market research indicates that the wearable technology sector alone is projected to grow at a compound annual growth rate of 15% through 2028, creating substantial opportunities for OTE material applications.

The healthcare sector presents another promising market for low-temperature OTE materials, particularly in implantable medical devices and remote patient monitoring systems. The ability to harvest body heat to power medical devices eliminates the need for battery replacement surgeries, significantly improving patient comfort and reducing healthcare costs. This application area is expected to witness rapid growth as healthcare systems worldwide increasingly adopt remote monitoring solutions.

Automotive applications represent an emerging market for low-temperature OTE materials, with potential uses in seat heating/cooling systems, climate control optimization, and sensor networks. As vehicles become increasingly electrified and autonomous, the demand for efficient energy management solutions continues to rise, creating new opportunities for thermoelectric materials that can operate effectively at lower temperature differentials.

Industrial IoT applications constitute another significant market segment, where low-temperature OTE materials can power wireless sensor networks in environments where traditional power sources are impractical. This includes remote monitoring systems, predictive maintenance sensors, and environmental monitoring devices deployed in challenging locations.

Geographically, North America and Europe currently lead in OTE material adoption, primarily due to strong research infrastructure and higher investment in emerging technologies. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing electronic manufacturing capabilities, and growing consumer electronics markets in countries like China, Japan, and South Korea.

Market challenges include competition from alternative energy harvesting technologies such as piezoelectric and photovoltaic systems, cost considerations for mass production, and the need for improved efficiency in real-world applications. Despite these challenges, the unique advantages of OTE materials in low-temperature applications, including flexibility, lightweight properties, and ability to operate with small temperature gradients, position them favorably for continued market expansion.

Consumer electronics represents the largest market segment, with wearable technology and portable devices leading the adoption of low-temperature OTE materials. These materials enable the harvesting of body heat to power small electronic devices, addressing the persistent challenge of battery limitations in wearable technology. Market research indicates that the wearable technology sector alone is projected to grow at a compound annual growth rate of 15% through 2028, creating substantial opportunities for OTE material applications.

The healthcare sector presents another promising market for low-temperature OTE materials, particularly in implantable medical devices and remote patient monitoring systems. The ability to harvest body heat to power medical devices eliminates the need for battery replacement surgeries, significantly improving patient comfort and reducing healthcare costs. This application area is expected to witness rapid growth as healthcare systems worldwide increasingly adopt remote monitoring solutions.

Automotive applications represent an emerging market for low-temperature OTE materials, with potential uses in seat heating/cooling systems, climate control optimization, and sensor networks. As vehicles become increasingly electrified and autonomous, the demand for efficient energy management solutions continues to rise, creating new opportunities for thermoelectric materials that can operate effectively at lower temperature differentials.

Industrial IoT applications constitute another significant market segment, where low-temperature OTE materials can power wireless sensor networks in environments where traditional power sources are impractical. This includes remote monitoring systems, predictive maintenance sensors, and environmental monitoring devices deployed in challenging locations.

Geographically, North America and Europe currently lead in OTE material adoption, primarily due to strong research infrastructure and higher investment in emerging technologies. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing electronic manufacturing capabilities, and growing consumer electronics markets in countries like China, Japan, and South Korea.

Market challenges include competition from alternative energy harvesting technologies such as piezoelectric and photovoltaic systems, cost considerations for mass production, and the need for improved efficiency in real-world applications. Despite these challenges, the unique advantages of OTE materials in low-temperature applications, including flexibility, lightweight properties, and ability to operate with small temperature gradients, position them favorably for continued market expansion.

Current Challenges in Sub-Kelvin Characterization Techniques

Despite significant advancements in cryogenic measurement technologies, characterizing Optically Transparent and Electrically conductive (OTE) materials at sub-Kelvin temperatures presents formidable challenges that impede research progress. The primary obstacle remains thermal management during optical measurements, as even minimal light exposure can induce substantial temperature fluctuations in the sub-Kelvin regime, compromising measurement accuracy and stability.

Signal-to-noise ratio deterioration becomes particularly problematic at these extreme temperatures, where thermal noise reduction should theoretically improve measurement sensitivity. However, the electrical connections required for conductivity measurements often introduce thermal pathways that disrupt the delicate temperature equilibrium. This creates a fundamental paradox where the very act of measurement disturbs the system being measured.

Mechanical stability presents another significant challenge, as materials undergo differential thermal contraction when cooled to sub-Kelvin temperatures. This can cause misalignment of optical components, stress-induced property changes in OTE materials, and unreliable electrical contacts. Current solutions involving rigid mounting structures often transfer unwanted vibrations to the sample, further complicating precise measurements.

The integration of optical and electrical measurement capabilities within the same cryogenic environment remains technically demanding. Conventional cryostats designed for electrical measurements typically lack adequate optical access, while optically-optimized systems often sacrifice electrical measurement capabilities. This forces researchers to make compromises that limit comprehensive material characterization.

Sample preparation techniques suitable for sub-Kelvin environments represent another unresolved challenge. Standard mounting methods using conductive epoxies or mechanical clamps often fail at extremely low temperatures due to differential thermal contraction or introduce unwanted thermal gradients across the sample. Additionally, surface contamination becomes increasingly problematic as even molecular-scale impurities can significantly alter OTE material properties at these temperatures.

Calibration and standardization across different measurement systems remain inconsistent, making direct comparison between research results difficult. The lack of universally accepted reference materials specifically designed for sub-Kelvin OTE characterization further compounds this problem, leading to potential misinterpretation of experimental data and hindering collaborative research efforts.

Finally, the prohibitive cost and operational complexity of sub-Kelvin measurement systems restrict widespread access to these technologies. Most systems require specialized infrastructure, including liquid helium supply chains and highly trained personnel, creating significant barriers to entry for many research institutions and limiting the pace of innovation in this critical field.

Signal-to-noise ratio deterioration becomes particularly problematic at these extreme temperatures, where thermal noise reduction should theoretically improve measurement sensitivity. However, the electrical connections required for conductivity measurements often introduce thermal pathways that disrupt the delicate temperature equilibrium. This creates a fundamental paradox where the very act of measurement disturbs the system being measured.

Mechanical stability presents another significant challenge, as materials undergo differential thermal contraction when cooled to sub-Kelvin temperatures. This can cause misalignment of optical components, stress-induced property changes in OTE materials, and unreliable electrical contacts. Current solutions involving rigid mounting structures often transfer unwanted vibrations to the sample, further complicating precise measurements.

The integration of optical and electrical measurement capabilities within the same cryogenic environment remains technically demanding. Conventional cryostats designed for electrical measurements typically lack adequate optical access, while optically-optimized systems often sacrifice electrical measurement capabilities. This forces researchers to make compromises that limit comprehensive material characterization.

Sample preparation techniques suitable for sub-Kelvin environments represent another unresolved challenge. Standard mounting methods using conductive epoxies or mechanical clamps often fail at extremely low temperatures due to differential thermal contraction or introduce unwanted thermal gradients across the sample. Additionally, surface contamination becomes increasingly problematic as even molecular-scale impurities can significantly alter OTE material properties at these temperatures.

Calibration and standardization across different measurement systems remain inconsistent, making direct comparison between research results difficult. The lack of universally accepted reference materials specifically designed for sub-Kelvin OTE characterization further compounds this problem, leading to potential misinterpretation of experimental data and hindering collaborative research efforts.

Finally, the prohibitive cost and operational complexity of sub-Kelvin measurement systems restrict widespread access to these technologies. Most systems require specialized infrastructure, including liquid helium supply chains and highly trained personnel, creating significant barriers to entry for many research institutions and limiting the pace of innovation in this critical field.

State-of-the-Art Cryogenic Characterization Methods

01 Low temperature testing methods for OTE materials

Various testing methods are employed to characterize Optical, Thermal, and Electrical (OTE) materials at low temperatures. These methods include thermal conductivity measurements, electrical resistance testing, and optical property analysis under cryogenic conditions. Advanced equipment such as cryostats and specialized sensors are used to maintain stable low-temperature environments while collecting precise data on material performance.- Low temperature testing methods for OTE materials: Various testing methods have been developed to characterize Optical, Thermal, and Electrical (OTE) materials at low temperatures. These methods include specialized equipment and procedures to measure material properties under cryogenic conditions. The testing approaches allow for accurate assessment of how material properties change as temperature decreases, which is crucial for applications in extreme environments.

- Cryogenic performance of semiconductor OTE materials: Semiconductor materials used in optical, thermal, and electrical applications exhibit unique characteristics at low temperatures. The characterization of these materials involves measuring parameters such as conductivity, band gap changes, and carrier mobility at cryogenic conditions. These measurements help in understanding how semiconductor performance improves or degrades at extremely low temperatures, which is essential for space, quantum computing, and superconducting applications.

- Thermal conductivity measurement techniques at low temperatures: Specialized techniques have been developed to measure the thermal conductivity of OTE materials at low temperatures. These include modified transient plane source methods, laser flash analysis, and steady-state heat flow measurements adapted for cryogenic environments. The accurate measurement of thermal properties at low temperatures is critical for designing materials for applications such as space exploration, superconducting devices, and cryogenic equipment.

- Optical property changes of materials at cryogenic temperatures: The optical properties of materials, including transmittance, reflectance, and refractive index, can significantly change at low temperatures. Characterization methods for these properties involve specialized spectroscopic techniques and optical testing equipment designed to operate in cryogenic environments. Understanding these changes is crucial for applications in astronomy, space-based optical systems, and quantum optical devices where materials must maintain specific optical properties at extremely low temperatures.

- Novel composite materials for enhanced low temperature performance: Research has led to the development of novel composite materials specifically designed to maintain or enhance their optical, thermal, and electrical properties at low temperatures. These materials often combine different substances to achieve superior performance characteristics under cryogenic conditions. The characterization of these composites involves comprehensive testing of their mechanical stability, thermal expansion coefficients, and electrical conductivity at various low temperature points to ensure reliability in extreme environments.

02 Cryogenic performance of semiconductor OTE materials

Semiconductor materials used in optical, thermal, and electrical applications exhibit unique properties at low temperatures. The characterization focuses on changes in bandgap, carrier mobility, and thermal conductivity as temperatures approach cryogenic levels. These materials often show improved electrical conductivity and reduced thermal noise at low temperatures, making them valuable for specialized applications in quantum computing, space technology, and scientific instrumentation.Expand Specific Solutions03 Composite OTE materials for extreme temperature applications

Composite materials combining multiple functional components are developed specifically for low-temperature environments. These composites often integrate ceramic, metallic, and polymer materials to achieve balanced optical, thermal, and electrical properties. Characterization techniques focus on interface behavior, structural integrity, and performance stability across temperature gradients, particularly for applications in aerospace, cryogenic storage, and superconducting systems.Expand Specific Solutions04 Imaging and visualization techniques for low-temperature OTE characterization

Advanced imaging methods are employed to visualize and analyze OTE material properties at low temperatures. These techniques include thermal imaging, electron microscopy at cryogenic temperatures, and spectroscopic analysis. The visualization approaches help researchers understand phase transitions, structural changes, and performance characteristics that occur specifically at low temperatures, providing crucial data for material optimization.Expand Specific Solutions05 Novel equipment and apparatus for OTE material testing at low temperatures

Specialized equipment has been developed specifically for characterizing optical, thermal, and electrical properties of materials at low temperatures. These include custom-designed cryostats, temperature-controlled test chambers, and integrated measurement systems that can simultaneously assess multiple material properties. The equipment often features precise temperature control, vibration isolation, and automated data collection to ensure accurate and reproducible characterization results.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The low temperature characterization of OTE materials is currently in a growth phase, with increasing market demand driven by semiconductor and optoelectronic applications. The global market is expanding as industries seek advanced materials with superior performance at low temperatures. Technologically, research institutions like Shanghai Institute of Ceramics and Max Planck Society are advancing fundamental understanding, while companies including Applied Materials, Samsung Electronics, and Tokyo Electron are developing commercial applications. SCHOTT AG and Nippon Electric Glass lead in specialized glass materials, while semiconductor manufacturers like UMC and BOE Technology are integrating these materials into devices. University collaborations with industry partners are accelerating innovation, particularly in cryogenic testing methodologies and standardization of characterization techniques.

Max Planck Gesellschaft zur Förderung der Wissenschaften eV

Technical Solution: Max Planck Society has developed advanced low temperature characterization methods for OTE (Optically Transparent Electronics) materials using specialized cryogenic systems that operate at temperatures as low as 4K. Their approach combines multiple characterization techniques including low-temperature Hall effect measurements, temperature-dependent photoluminescence spectroscopy, and cryogenic X-ray diffraction to comprehensively analyze carrier transport mechanisms in transparent conducting oxides. Their methodology employs custom-designed vacuum chambers with optical access windows that allow simultaneous optical and electrical measurements while maintaining ultra-low temperatures. The institute has pioneered the use of synchrotron radiation for temperature-dependent structural analysis of amorphous and crystalline OTE materials, revealing critical phase transitions and structural changes that occur at cryogenic temperatures. Their characterization platform integrates automated temperature control systems that enable precise temperature ramping profiles (0.1K resolution) for detecting subtle changes in material properties across the full temperature range.

Strengths: Exceptional precision in temperature control and measurement stability; comprehensive multi-technique approach provides correlative data between structural, optical, and electrical properties; access to world-class synchrotron facilities. Weaknesses: Highly specialized equipment requirements limit widespread adoption; characterization process is time-intensive and requires significant expertise to interpret complex multi-parameter datasets.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has developed a comprehensive low-temperature characterization platform specifically for OTE (Optically Transparent Electronics) materials that integrates multiple measurement techniques. Their system employs a closed-cycle helium cryostat capable of reaching temperatures as low as 2K with temperature stability of ±0.01K, allowing for precise measurements of temperature-dependent electrical and optical properties. The institute has pioneered a novel approach combining low-temperature impedance spectroscopy with in-situ optical transmission measurements to simultaneously track changes in electrical conductivity and optical transparency. Their methodology includes specialized sample holders designed to minimize thermal gradients and reduce contact resistance issues that typically plague low-temperature measurements of high-resistance transparent materials. The institute has also developed custom software algorithms for separating bulk and interface contributions to electrical properties at low temperatures, enabling more accurate characterization of intrinsic material properties. Their recent publications demonstrate successful application of these techniques to various transparent conducting oxides including ITO, AZO, and emerging amorphous oxide semiconductors, revealing previously unobserved quantum transport phenomena at temperatures below 30K.

Strengths: Exceptional integration of multiple measurement techniques in a single platform; specialized sample holders designed specifically for transparent materials; advanced data analysis algorithms for separating intrinsic and extrinsic effects. Weaknesses: System complexity requires significant expertise to operate effectively; measurements are time-consuming due to the need for careful temperature stabilization at each measurement point; limited throughput compared to room-temperature characterization methods.

Critical Patents and Literature in OTE Material Testing

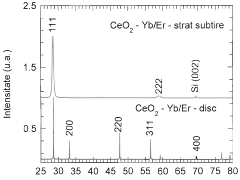

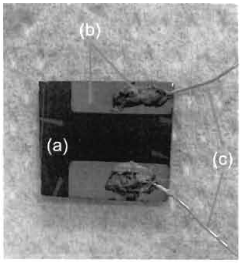

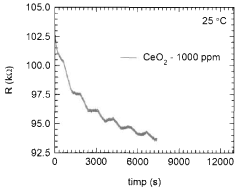

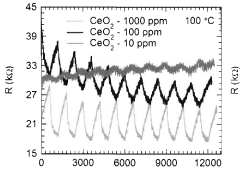

OPTICAL MATERIAL SENSITIVE TO NO<sub>2</sub> GAS AT LOW TEMPERATURE

PatentUndeterminedRO134631A0

Innovation

- Development of a CeO2-based thin film doped with Yb and Er oxides that exhibits sensitivity to NO2 gas at low temperatures (25-200°C), enabling detection at concentrations of 10-1000 ppm.

- Utilization of plasma deposition technique to create thin films (0.2-1 μm) on monocrystalline silicon substrates, resulting in materials with both active and passive optical activity in the visible-infrared range.

- Implementation of a specific sintering process at 1400°C in air to create the target material from CeO2, Yb2O3, and Er2O3 powders before plasma deposition.

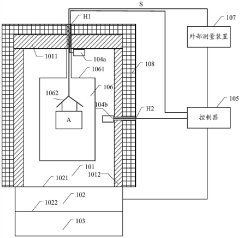

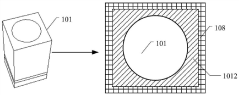

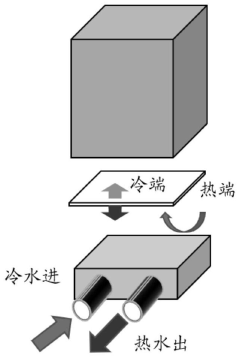

Device and method for measuring low-temperature characteristics of electrical parameters

PatentActiveCN112285452A

Innovation

- A measurement chamber device including a semiconductor refrigeration piece, a radiator, a temperature sensor and a controller is designed. The semiconductor refrigeration piece is used for cooling, and the temperature sensor and controller are used to achieve closed-loop temperature control to avoid uneven cooling and ensure the measurement chamber. room reaches target temperature.

Standardization Efforts for Cryogenic Testing Protocols

The standardization of cryogenic testing protocols for Optical, Thermal, and Electrical (OTE) materials represents a critical advancement in ensuring reliable performance characterization at low temperatures. Currently, several international organizations are actively developing comprehensive standards to address the unique challenges posed by cryogenic environments.

The International Electrotechnical Commission (IEC) has established Technical Committee 90, which focuses specifically on superconductivity and includes working groups dedicated to standardizing measurement methods for materials at cryogenic temperatures. Their recent publication IEC 61788-17 outlines specific protocols for electronic and thermal property measurements below 10K, with particular attention to quantum computing applications.

ASTM International has also made significant contributions through Committee E37 on Thermal Measurements, which has developed standards such as ASTM E1952 for thermal conductivity measurements that have been adapted for cryogenic applications. These standards provide detailed guidelines on sample preparation, measurement procedures, and uncertainty analysis specifically tailored for low-temperature regimes.

The National Institute of Standards and Technology (NIST) has been instrumental in establishing reference materials and calibration procedures for cryogenic testing. Their Cryogenic Materials Program has developed Standard Reference Materials (SRMs) that serve as calibration benchmarks for thermal conductivity, electrical resistivity, and optical properties at temperatures ranging from 4K to 300K.

In Europe, the European Committee for Standardization (CEN) has formed Technical Committee CEN/TC 352, which collaborates with the European Space Agency to develop standards specifically for materials used in space applications requiring cryogenic performance characterization. Their recent standard EN 16615 addresses optical property measurements at temperatures below 20K.

Industry consortia have also emerged to address application-specific standardization needs. The Quantum Economic Development Consortium (QED-C) has established working groups focused on developing testing protocols for materials used in quantum computing systems, where consistent characterization at millikelvin temperatures is essential for predicting qubit performance.

Despite these efforts, significant gaps remain in standardization coverage. Current protocols often lack specific guidance for testing composite materials, thin films, and nanoscale structures at cryogenic temperatures. Additionally, there is limited standardization for dynamic property measurements under thermal cycling conditions, which are crucial for materials subjected to repeated cooling and warming cycles in practical applications.

The International Electrotechnical Commission (IEC) has established Technical Committee 90, which focuses specifically on superconductivity and includes working groups dedicated to standardizing measurement methods for materials at cryogenic temperatures. Their recent publication IEC 61788-17 outlines specific protocols for electronic and thermal property measurements below 10K, with particular attention to quantum computing applications.

ASTM International has also made significant contributions through Committee E37 on Thermal Measurements, which has developed standards such as ASTM E1952 for thermal conductivity measurements that have been adapted for cryogenic applications. These standards provide detailed guidelines on sample preparation, measurement procedures, and uncertainty analysis specifically tailored for low-temperature regimes.

The National Institute of Standards and Technology (NIST) has been instrumental in establishing reference materials and calibration procedures for cryogenic testing. Their Cryogenic Materials Program has developed Standard Reference Materials (SRMs) that serve as calibration benchmarks for thermal conductivity, electrical resistivity, and optical properties at temperatures ranging from 4K to 300K.

In Europe, the European Committee for Standardization (CEN) has formed Technical Committee CEN/TC 352, which collaborates with the European Space Agency to develop standards specifically for materials used in space applications requiring cryogenic performance characterization. Their recent standard EN 16615 addresses optical property measurements at temperatures below 20K.

Industry consortia have also emerged to address application-specific standardization needs. The Quantum Economic Development Consortium (QED-C) has established working groups focused on developing testing protocols for materials used in quantum computing systems, where consistent characterization at millikelvin temperatures is essential for predicting qubit performance.

Despite these efforts, significant gaps remain in standardization coverage. Current protocols often lack specific guidance for testing composite materials, thin films, and nanoscale structures at cryogenic temperatures. Additionally, there is limited standardization for dynamic property measurements under thermal cycling conditions, which are crucial for materials subjected to repeated cooling and warming cycles in practical applications.

Environmental Impact of Cryogenic Cooling Technologies

The environmental impact of cryogenic cooling technologies used in low temperature characterization of OTE (Optical, Thermal, and Electrical) materials presents significant sustainability challenges. Traditional cryogenic systems rely heavily on liquid helium and nitrogen, both of which have considerable environmental footprints. Helium, a non-renewable resource extracted primarily from natural gas, faces global supply constraints with reserves potentially depleting within the next century. Its production and purification processes are energy-intensive, contributing to greenhouse gas emissions.

Nitrogen liquefaction, while less resource-constrained, still requires substantial energy input—approximately 0.5 kWh per liter of liquid nitrogen produced. Large-scale characterization facilities utilizing these coolants can consume thousands of liters annually, translating to significant carbon emissions when powered by non-renewable energy sources.

The operation of cryogenic systems presents additional environmental concerns. Inefficient thermal insulation leads to coolant losses through evaporation, necessitating more frequent replenishment and increasing the overall environmental burden. Furthermore, many systems employ hydrofluorocarbons (HFCs) and other high global warming potential (GWP) gases in their refrigeration cycles, contributing to climate change when leaked.

Recent technological developments have begun addressing these environmental challenges. Closed-cycle refrigeration systems, particularly those using pulse tube and Gifford-McMahon technologies, significantly reduce helium consumption by recycling the working gas. These systems can achieve temperatures below 4K without continuous cryogen replenishment, though they require substantial electrical power and often contain environmentally problematic refrigerants.

Emerging technologies show promise for further environmental improvements. Magnetic refrigeration using magnetocaloric materials offers an alternative cooling mechanism potentially free from harmful refrigerants. Similarly, thermoelectric cooling systems, when optimized for cryogenic temperatures, could provide localized cooling with minimal environmental impact, though currently limited to modest temperature differentials.

The waste heat management from cryogenic systems presents another environmental consideration. Most facilities simply vent this thermal energy, but integrated approaches that capture and repurpose this heat for building climate control or other processes could significantly improve overall energy efficiency. Such heat recovery systems could reduce the net environmental impact of low-temperature characterization facilities by 15-30% according to recent studies.

Nitrogen liquefaction, while less resource-constrained, still requires substantial energy input—approximately 0.5 kWh per liter of liquid nitrogen produced. Large-scale characterization facilities utilizing these coolants can consume thousands of liters annually, translating to significant carbon emissions when powered by non-renewable energy sources.

The operation of cryogenic systems presents additional environmental concerns. Inefficient thermal insulation leads to coolant losses through evaporation, necessitating more frequent replenishment and increasing the overall environmental burden. Furthermore, many systems employ hydrofluorocarbons (HFCs) and other high global warming potential (GWP) gases in their refrigeration cycles, contributing to climate change when leaked.

Recent technological developments have begun addressing these environmental challenges. Closed-cycle refrigeration systems, particularly those using pulse tube and Gifford-McMahon technologies, significantly reduce helium consumption by recycling the working gas. These systems can achieve temperatures below 4K without continuous cryogen replenishment, though they require substantial electrical power and often contain environmentally problematic refrigerants.

Emerging technologies show promise for further environmental improvements. Magnetic refrigeration using magnetocaloric materials offers an alternative cooling mechanism potentially free from harmful refrigerants. Similarly, thermoelectric cooling systems, when optimized for cryogenic temperatures, could provide localized cooling with minimal environmental impact, though currently limited to modest temperature differentials.

The waste heat management from cryogenic systems presents another environmental consideration. Most facilities simply vent this thermal energy, but integrated approaches that capture and repurpose this heat for building climate control or other processes could significantly improve overall energy efficiency. Such heat recovery systems could reduce the net environmental impact of low-temperature characterization facilities by 15-30% according to recent studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!