Material Selection Guide For Wearable Thermoelectric Generators

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Material Evolution and Objectives

Thermoelectric generators (TEGs) have evolved significantly since their inception in the early 19th century with the discovery of the Seebeck effect. The journey of TEG materials has progressed from simple metallic junctions to complex semiconductor compounds, with each advancement aimed at improving efficiency, reducing costs, and enhancing applicability in various domains, particularly in wearable technology.

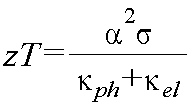

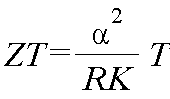

The initial thermoelectric materials were primarily metal-based, utilizing the inherent properties of metals like bismuth, antimony, and their alloys. These materials offered limited efficiency with ZT values (figure of merit for thermoelectric performance) below 1. The mid-20th century witnessed a paradigm shift with the introduction of semiconductor-based thermoelectric materials, notably bismuth telluride (Bi2Te3) and lead telluride (PbTe), which demonstrated improved ZT values around 1-1.5 at room temperature.

Recent decades have seen remarkable advancements in nanostructured thermoelectric materials, including quantum dots, superlattices, and nanowires, which exploit quantum confinement effects to enhance thermoelectric properties. These materials have achieved ZT values exceeding 2, representing a significant improvement over conventional bulk materials. Additionally, organic and polymer-based thermoelectric materials have emerged as promising candidates for wearable applications due to their flexibility, lightweight nature, and biocompatibility.

For wearable TEGs specifically, the material evolution has been guided by unique requirements including flexibility, comfort, durability, and biocompatibility, alongside traditional performance metrics. This has led to the development of composite materials that combine inorganic thermoelectric elements with flexible substrates and interconnects, as well as fully organic thermoelectric materials based on conducting polymers like PEDOT:PSS and carbon nanotubes.

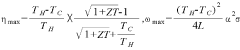

The primary objectives for wearable TEG materials research include achieving higher power density at low temperature gradients (typically 1-5K for body-ambient differentials), enhancing mechanical flexibility without compromising electrical performance, improving long-term stability under repeated mechanical stress and exposure to bodily fluids, and developing scalable, cost-effective manufacturing processes suitable for mass production.

Future research aims to develop materials with ZT values exceeding 3 at room temperature, create fully textile-integrated thermoelectric systems with washability and breathability, and establish environmentally sustainable materials that reduce or eliminate toxic elements like tellurium and lead while maintaining high performance. The ultimate goal is to enable self-powered wearable electronics that can operate continuously using only body heat, eliminating the need for battery replacement or external charging.

The initial thermoelectric materials were primarily metal-based, utilizing the inherent properties of metals like bismuth, antimony, and their alloys. These materials offered limited efficiency with ZT values (figure of merit for thermoelectric performance) below 1. The mid-20th century witnessed a paradigm shift with the introduction of semiconductor-based thermoelectric materials, notably bismuth telluride (Bi2Te3) and lead telluride (PbTe), which demonstrated improved ZT values around 1-1.5 at room temperature.

Recent decades have seen remarkable advancements in nanostructured thermoelectric materials, including quantum dots, superlattices, and nanowires, which exploit quantum confinement effects to enhance thermoelectric properties. These materials have achieved ZT values exceeding 2, representing a significant improvement over conventional bulk materials. Additionally, organic and polymer-based thermoelectric materials have emerged as promising candidates for wearable applications due to their flexibility, lightweight nature, and biocompatibility.

For wearable TEGs specifically, the material evolution has been guided by unique requirements including flexibility, comfort, durability, and biocompatibility, alongside traditional performance metrics. This has led to the development of composite materials that combine inorganic thermoelectric elements with flexible substrates and interconnects, as well as fully organic thermoelectric materials based on conducting polymers like PEDOT:PSS and carbon nanotubes.

The primary objectives for wearable TEG materials research include achieving higher power density at low temperature gradients (typically 1-5K for body-ambient differentials), enhancing mechanical flexibility without compromising electrical performance, improving long-term stability under repeated mechanical stress and exposure to bodily fluids, and developing scalable, cost-effective manufacturing processes suitable for mass production.

Future research aims to develop materials with ZT values exceeding 3 at room temperature, create fully textile-integrated thermoelectric systems with washability and breathability, and establish environmentally sustainable materials that reduce or eliminate toxic elements like tellurium and lead while maintaining high performance. The ultimate goal is to enable self-powered wearable electronics that can operate continuously using only body heat, eliminating the need for battery replacement or external charging.

Market Analysis for Wearable TEG Applications

The wearable thermoelectric generator (TEG) market is experiencing significant growth driven by the expanding wearable technology ecosystem and increasing demand for sustainable power sources. Current market valuations place the global wearable TEG sector at approximately 450 million USD in 2023, with projections indicating a compound annual growth rate of 13.7% through 2030, potentially reaching 1.2 billion USD by the end of the decade.

Healthcare applications represent the largest market segment for wearable TEGs, accounting for roughly 38% of current market share. The integration of TEGs into medical monitoring devices enables continuous power generation for vital sign tracking, medication delivery systems, and implantable medical devices. This segment is particularly valuable due to the critical nature of uninterrupted power supply in medical applications and the premium pricing these solutions command.

Consumer electronics constitutes the second-largest application segment at 29% market share, with fitness trackers, smartwatches, and hearables being primary integration targets. The appeal in this sector stems from the potential to extend battery life or enable battery-free operation for certain low-power functions, addressing a key pain point for consumers regarding device charging frequency.

Industrial and military applications collectively represent approximately 22% of the market, with emphasis on personnel monitoring systems, environmental sensors, and specialized equipment operating in remote or harsh conditions where conventional power sources are impractical.

Geographic distribution of market demand shows North America leading with 36% market share, followed by Europe (28%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the highest growth rate at 15.2% annually, driven by expanding manufacturing capabilities and increasing adoption of wearable technology in countries like China, South Korea, and Japan.

Key market drivers include miniaturization of TEG components, improving power conversion efficiencies, and growing consumer preference for sustainable technology solutions. The integration potential with emerging technologies such as 5G, IoT, and AI-powered wearables further expands the addressable market.

Market challenges primarily revolve around cost considerations, with current wearable TEG solutions commanding a premium of 30-45% over conventional power sources. Additionally, performance limitations in low-temperature differential environments and competition from improving battery technologies represent significant market constraints that material innovation must address to unlock broader commercial adoption.

Healthcare applications represent the largest market segment for wearable TEGs, accounting for roughly 38% of current market share. The integration of TEGs into medical monitoring devices enables continuous power generation for vital sign tracking, medication delivery systems, and implantable medical devices. This segment is particularly valuable due to the critical nature of uninterrupted power supply in medical applications and the premium pricing these solutions command.

Consumer electronics constitutes the second-largest application segment at 29% market share, with fitness trackers, smartwatches, and hearables being primary integration targets. The appeal in this sector stems from the potential to extend battery life or enable battery-free operation for certain low-power functions, addressing a key pain point for consumers regarding device charging frequency.

Industrial and military applications collectively represent approximately 22% of the market, with emphasis on personnel monitoring systems, environmental sensors, and specialized equipment operating in remote or harsh conditions where conventional power sources are impractical.

Geographic distribution of market demand shows North America leading with 36% market share, followed by Europe (28%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the highest growth rate at 15.2% annually, driven by expanding manufacturing capabilities and increasing adoption of wearable technology in countries like China, South Korea, and Japan.

Key market drivers include miniaturization of TEG components, improving power conversion efficiencies, and growing consumer preference for sustainable technology solutions. The integration potential with emerging technologies such as 5G, IoT, and AI-powered wearables further expands the addressable market.

Market challenges primarily revolve around cost considerations, with current wearable TEG solutions commanding a premium of 30-45% over conventional power sources. Additionally, performance limitations in low-temperature differential environments and competition from improving battery technologies represent significant market constraints that material innovation must address to unlock broader commercial adoption.

Current TEG Materials Landscape and Challenges

The thermoelectric generator (TEG) materials landscape is currently dominated by several key material classes, each with distinct advantages and limitations for wearable applications. Traditional inorganic semiconductors, particularly bismuth telluride (Bi2Te3) and its alloys, remain the industry standard due to their relatively high figure of merit (ZT) values ranging from 0.8 to 1.2 at room temperature. These materials demonstrate excellent power conversion efficiency but present significant challenges for wearable integration due to their inherent rigidity, toxicity concerns, and high manufacturing costs.

Emerging alternatives include skutterudites and half-Heusler alloys, which offer improved high-temperature performance but remain suboptimal for body-heat harvesting applications due to their peak efficiency occurring well above human body temperature ranges. Silicon-germanium (SiGe) alloys, while established in space applications, are similarly unsuitable for wearable TEGs due to their high optimal operating temperatures exceeding 600°C.

Organic thermoelectric materials represent a promising frontier, with conducting polymers like PEDOT:PSS and P3HT showing increasing ZT values through recent advancements. These materials offer mechanical flexibility, low-cost solution processing, and reduced toxicity compared to inorganic counterparts. However, they currently suffer from substantially lower ZT values (typically below 0.2) and long-term stability issues that limit commercial viability.

Hybrid organic-inorganic composites are emerging as a compelling compromise, combining the flexibility and processability of polymers with the superior thermoelectric performance of inorganic materials. Notable examples include PEDOT:PSS/tellurium nanowire composites and carbon nanotube/Bi2Te3 hybrids, which have demonstrated ZT values approaching 0.5 while maintaining reasonable flexibility.

The primary technical challenges facing wearable TEG materials development include the fundamental trade-off between electrical conductivity and thermal conductivity, which limits ZT enhancement. Additionally, achieving mechanical flexibility without compromising thermoelectric performance remains difficult, particularly for inorganic materials. Interface engineering between different material components in composite systems presents another significant hurdle, as poor interfaces lead to electrical resistance and reduced overall performance.

Manufacturing scalability represents a critical bottleneck, with many high-performance materials requiring complex fabrication processes incompatible with large-scale production. Environmental stability is another major concern, as many promising materials degrade when exposed to oxygen, moisture, or mechanical stress during regular wear. Finally, biocompatibility and safety considerations limit material selection, particularly for direct skin-contact applications where leaching of toxic elements must be prevented.

Emerging alternatives include skutterudites and half-Heusler alloys, which offer improved high-temperature performance but remain suboptimal for body-heat harvesting applications due to their peak efficiency occurring well above human body temperature ranges. Silicon-germanium (SiGe) alloys, while established in space applications, are similarly unsuitable for wearable TEGs due to their high optimal operating temperatures exceeding 600°C.

Organic thermoelectric materials represent a promising frontier, with conducting polymers like PEDOT:PSS and P3HT showing increasing ZT values through recent advancements. These materials offer mechanical flexibility, low-cost solution processing, and reduced toxicity compared to inorganic counterparts. However, they currently suffer from substantially lower ZT values (typically below 0.2) and long-term stability issues that limit commercial viability.

Hybrid organic-inorganic composites are emerging as a compelling compromise, combining the flexibility and processability of polymers with the superior thermoelectric performance of inorganic materials. Notable examples include PEDOT:PSS/tellurium nanowire composites and carbon nanotube/Bi2Te3 hybrids, which have demonstrated ZT values approaching 0.5 while maintaining reasonable flexibility.

The primary technical challenges facing wearable TEG materials development include the fundamental trade-off between electrical conductivity and thermal conductivity, which limits ZT enhancement. Additionally, achieving mechanical flexibility without compromising thermoelectric performance remains difficult, particularly for inorganic materials. Interface engineering between different material components in composite systems presents another significant hurdle, as poor interfaces lead to electrical resistance and reduced overall performance.

Manufacturing scalability represents a critical bottleneck, with many high-performance materials requiring complex fabrication processes incompatible with large-scale production. Environmental stability is another major concern, as many promising materials degrade when exposed to oxygen, moisture, or mechanical stress during regular wear. Finally, biocompatibility and safety considerations limit material selection, particularly for direct skin-contact applications where leaching of toxic elements must be prevented.

Contemporary Material Solutions for Wearable TEGs

01 Bismuth telluride-based materials for thermoelectric generators

Bismuth telluride and its alloys are widely used in thermoelectric generators due to their high figure of merit at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. The performance of bismuth telluride-based materials can be further improved through nanostructuring techniques, which reduce thermal conductivity while maintaining electrical conductivity. These materials are particularly suitable for low to medium temperature applications in thermoelectric power generation.- Bismuth telluride-based materials for thermoelectric generators: Bismuth telluride and its alloys are widely used in thermoelectric generators due to their high figure of merit (ZT) at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. The performance of bismuth telluride-based materials can be further improved through nanostructuring techniques, which reduce thermal conductivity while maintaining electrical conductivity. These materials are particularly suitable for low to medium temperature applications in thermoelectric power generation.

- Skutterudite and half-Heusler compounds for medium to high temperature applications: Skutterudite and half-Heusler compounds are promising thermoelectric materials for medium to high temperature applications. These materials exhibit good thermal stability and relatively high ZT values at elevated temperatures. Skutterudites can be filled with guest atoms to reduce thermal conductivity, while half-Heusler compounds can be optimized through elemental substitution. Both material classes offer a good balance between performance and material cost for thermoelectric generators operating in the 400-700°C range.

- Silicon-germanium alloys for high temperature thermoelectric applications: Silicon-germanium (SiGe) alloys are suitable for high-temperature thermoelectric applications, particularly in space missions and industrial waste heat recovery. These materials demonstrate excellent thermal stability and reasonable thermoelectric performance at temperatures above 700°C. The thermoelectric properties of SiGe alloys can be enhanced through nanostructuring, compositional optimization, and controlled doping. Their ability to withstand extreme conditions makes them valuable for specialized high-temperature thermoelectric generators.

- Organic and polymer-based thermoelectric materials: Organic and polymer-based thermoelectric materials offer advantages such as flexibility, low cost, and environmental friendliness. These materials can be processed using solution-based techniques, enabling large-area and flexible thermoelectric generators. While their ZT values are generally lower than inorganic counterparts, recent advances in molecular design and doping strategies have significantly improved their performance. These materials are particularly promising for wearable electronics, IoT devices, and low-grade waste heat recovery applications.

- Nanostructured and composite thermoelectric materials: Nanostructuring and composite approaches can significantly enhance the performance of thermoelectric materials by decoupling electrical and thermal transport properties. Techniques such as quantum dot superlattices, nanowire arrays, and nanocomposites create interfaces that scatter phonons more effectively than electrons, reducing thermal conductivity while maintaining electrical conductivity. These advanced material engineering approaches can be applied to various material systems to achieve higher ZT values and improved thermoelectric generator efficiency across different temperature ranges.

02 Skutterudite and half-Heusler compounds for high-temperature applications

Skutterudite and half-Heusler compounds are promising materials for thermoelectric generators operating at high temperatures. These materials exhibit good thermal stability and relatively high thermoelectric efficiency at elevated temperatures. Skutterudites can be filled with atoms to reduce thermal conductivity, while half-Heusler compounds can be optimized through compositional tuning. Both material classes offer advantages for waste heat recovery applications in industrial processes and automotive exhaust systems.Expand Specific Solutions03 Organic and polymer-based thermoelectric materials

Organic and polymer-based thermoelectric materials represent an emerging class of materials for flexible and low-cost thermoelectric generators. These materials offer advantages such as abundance, low toxicity, and ease of processing. While their thermoelectric efficiency is generally lower than inorganic counterparts, they can be advantageous for specific applications requiring flexibility or conformability. Research focuses on enhancing the power factor of these materials through molecular design and doping strategies.Expand Specific Solutions04 Nanostructured and composite thermoelectric materials

Nanostructuring and composite approaches are effective strategies to enhance the performance of thermoelectric materials. By introducing nanoscale features or combining different materials, thermal conductivity can be reduced while maintaining electrical properties. Techniques such as ball milling, hot pressing, and spark plasma sintering are used to create these advanced materials. Nanocomposites can achieve higher ZT values compared to their bulk counterparts, making them promising for efficient thermoelectric power generation.Expand Specific Solutions05 Silicon-germanium and oxide-based thermoelectric materials

Silicon-germanium alloys and oxide-based materials are important classes of thermoelectric materials for specific applications. Silicon-germanium alloys perform well at high temperatures and have been used in space applications. Oxide-based thermoelectrics offer advantages in terms of stability, abundance, and environmental friendliness, though they typically have lower efficiency. Both material classes can be modified through doping and microstructural engineering to enhance their thermoelectric properties for power generation applications.Expand Specific Solutions

Leading Companies in Wearable TEG Industry

The wearable thermoelectric generator (TEG) market is currently in its growth phase, characterized by increasing research activities and early commercial applications. The global market is projected to reach approximately $750 million by 2027, driven by rising demand for self-powered wearable electronics. Technologically, the field is advancing from laboratory prototypes toward commercial viability, with material selection remaining a critical challenge. Leading academic institutions like MIT, Caltech, and KAIST are conducting fundamental research, while companies including Siemens, BASF, and International ThermoDyne are developing commercial applications. Specialized firms such as KELK Ltd. and Liquid X Printed Metals are advancing material innovations specifically for flexible TEGs. The competitive landscape features collaboration between research institutions and industrial partners to overcome efficiency, flexibility, and cost barriers.

Massachusetts Institute of Technology

Technical Solution: MIT has developed groundbreaking PEDOT:PSS-based organic thermoelectric materials specifically engineered for wearable TEGs. Their research has achieved significant enhancements in the thermoelectric properties of conducting polymers through controlled doping strategies and nanostructuring. MIT's approach combines solution-processable polymers with carbon nanomaterials (graphene and carbon nanotubes) to create hybrid composites with improved electrical conductivity while maintaining low thermal conductivity. Their materials demonstrate ZT values approaching 0.42 at room temperature, representing a substantial improvement over conventional organic thermoelectrics. MIT researchers have pioneered post-processing techniques including solvent treatments and sequential doping that enhance the power factor by up to 100%. Their materials can be directly printed or coated onto textiles and flexible substrates, enabling seamless integration with existing garment manufacturing processes. MIT has also developed specialized interface engineering approaches that reduce contact resistance between organic thermoelectric materials and metallic interconnects, addressing a key limitation in flexible TEG performance.

Strengths: Exceptional mechanical flexibility and conformability to body contours; solution-processable manufacturing compatible with roll-to-roll production; non-toxic and environmentally friendly compared to inorganic alternatives; potential for low-cost mass production. Weaknesses: Lower ZT values compared to inorganic thermoelectric materials; potential degradation under prolonged exposure to moisture and oxygen; challenges in achieving consistent electrical properties across large-area manufacturing.

Purdue Research Foundation

Technical Solution: Purdue Research Foundation has developed innovative nanostructured thermoelectric materials specifically designed for wearable energy harvesting applications. Their approach focuses on skutterudite-based materials with controlled nano-inclusions that significantly reduce thermal conductivity while maintaining electrical performance. Purdue's materials incorporate phase boundaries and interfaces at multiple length scales, creating phonon scattering centers that improve the ZT value to approximately 1.4 at temperatures relevant for wearable applications. Their technology includes a proprietary synthesis method that allows for precise control of material composition and nanostructure, resulting in consistent performance across manufacturing batches. Purdue has pioneered flexible thermoelectric composites that combine high-performance inorganic thermoelectric materials with elastomeric matrices, creating materials that can withstand repeated bending and stretching while maintaining electrical connectivity. Their materials also feature specialized surface treatments that improve adhesion to various substrate materials, facilitating integration with textiles and flexible electronics platforms.

Strengths: Excellent thermoelectric performance with ZT values exceeding many commercial materials; engineered specifically for the temperature range relevant to body-heat harvesting; scalable manufacturing processes compatible with existing production infrastructure. Weaknesses: Higher material costs compared to bulk thermoelectric materials; complex manufacturing process requiring precise control of nanostructures; potential challenges with long-term stability of nanostructured features under thermal cycling.

Key Thermoelectric Material Properties Analysis

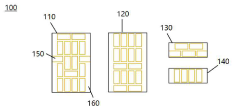

Wearable Thermoelectric Generator Using Thermoelectric Materials

PatentInactiveKR1020200070585A

Innovation

- A thermoelectric generator design comprising A-type and B-type modules with P-type and N-type thermoelectric materials, polymer layers, ceramic substrates, electrodes, and conductive connections, allowing adjustable length and reduced thermal contact resistance.

Thermoelectric device and method of manufacturing the same

PatentInactiveEP3373335A3

Innovation

- A thermoelectric device with a zigzag configuration featuring peaks and valleys on a flexible substrate, using a solution process for large-area production, incorporating a p-type and n-type thermoelectric material alternately disposed with an electrode material, and a thermal insulator to achieve a vertical temperature difference and enhance flexibility and lightness.

Sustainability Aspects of TEG Materials

The sustainability of materials used in wearable thermoelectric generators (TEGs) has become increasingly important as these devices gain traction in the consumer electronics and medical monitoring sectors. Environmental considerations must be balanced with performance requirements when selecting TEG materials. Traditional thermoelectric materials such as bismuth telluride (Bi2Te3) contain rare and potentially toxic elements that raise significant sustainability concerns regarding resource depletion and end-of-life disposal.

Life cycle assessment (LCA) studies reveal that the environmental impact of TEG materials extends beyond their operational phase to include extraction, processing, and disposal. Mining tellurium, for instance, often results in significant land degradation and water pollution. Additionally, the energy-intensive manufacturing processes for conventional thermoelectric materials contribute substantially to their carbon footprint, offsetting some of the clean energy benefits these generators provide.

Recent research has focused on developing alternative, more sustainable thermoelectric materials. Organic thermoelectric materials, including conducting polymers like PEDOT:PSS and carbon-based composites, offer promising environmental advantages. These materials typically require less energy-intensive production methods and utilize more abundant elements, reducing supply chain vulnerabilities and extraction-related environmental damage.

Recyclability represents another critical sustainability aspect of TEG materials. Silicon-based and oxide-based thermoelectric materials demonstrate superior recyclability compared to traditional options. Furthermore, emerging research into biodegradable thermoelectric materials could revolutionize the field, particularly for temporary wearable applications in healthcare monitoring where device disposal presents significant environmental challenges.

Material toxicity must be carefully evaluated when designing wearable TEGs that maintain direct contact with skin. Lead-based thermoelectric materials, despite their excellent performance characteristics, pose serious health and environmental risks. Consequently, regulatory frameworks worldwide are increasingly restricting the use of hazardous substances in electronic devices, driving the development of lead-free alternatives with comparable efficiency.

Supply chain sustainability also factors into material selection decisions. Rare earth elements commonly used in high-performance TEGs face geopolitical supply constraints and ethical mining concerns. Diversifying material compositions to incorporate more abundant elements can mitigate these risks while promoting more equitable global resource distribution.

The energy payback period—the time required for a TEG to generate the energy consumed during its production—serves as a crucial sustainability metric. Materials requiring less energy-intensive processing generally offer shorter payback periods, enhancing their overall environmental value proposition in wearable applications where operational lifetimes may be relatively short.

Life cycle assessment (LCA) studies reveal that the environmental impact of TEG materials extends beyond their operational phase to include extraction, processing, and disposal. Mining tellurium, for instance, often results in significant land degradation and water pollution. Additionally, the energy-intensive manufacturing processes for conventional thermoelectric materials contribute substantially to their carbon footprint, offsetting some of the clean energy benefits these generators provide.

Recent research has focused on developing alternative, more sustainable thermoelectric materials. Organic thermoelectric materials, including conducting polymers like PEDOT:PSS and carbon-based composites, offer promising environmental advantages. These materials typically require less energy-intensive production methods and utilize more abundant elements, reducing supply chain vulnerabilities and extraction-related environmental damage.

Recyclability represents another critical sustainability aspect of TEG materials. Silicon-based and oxide-based thermoelectric materials demonstrate superior recyclability compared to traditional options. Furthermore, emerging research into biodegradable thermoelectric materials could revolutionize the field, particularly for temporary wearable applications in healthcare monitoring where device disposal presents significant environmental challenges.

Material toxicity must be carefully evaluated when designing wearable TEGs that maintain direct contact with skin. Lead-based thermoelectric materials, despite their excellent performance characteristics, pose serious health and environmental risks. Consequently, regulatory frameworks worldwide are increasingly restricting the use of hazardous substances in electronic devices, driving the development of lead-free alternatives with comparable efficiency.

Supply chain sustainability also factors into material selection decisions. Rare earth elements commonly used in high-performance TEGs face geopolitical supply constraints and ethical mining concerns. Diversifying material compositions to incorporate more abundant elements can mitigate these risks while promoting more equitable global resource distribution.

The energy payback period—the time required for a TEG to generate the energy consumed during its production—serves as a crucial sustainability metric. Materials requiring less energy-intensive processing generally offer shorter payback periods, enhancing their overall environmental value proposition in wearable applications where operational lifetimes may be relatively short.

Wearable TEG Integration Considerations

The integration of wearable thermoelectric generators (TEGs) into functional devices requires careful consideration of multiple factors beyond material selection alone. Successful implementation demands a holistic approach that addresses mechanical, electrical, and thermal interface challenges while maintaining user comfort and device functionality.

Mechanical integration represents a primary consideration, as wearable TEGs must conform to body contours while maintaining consistent thermal contact. Flexible substrates such as polyimide or silicone elastomers can serve as mounting platforms, allowing TEGs to adapt to body movement without compromising performance. The attachment mechanism must balance secure positioning with user comfort, utilizing medical-grade adhesives, elastic bands, or integration into existing garments depending on the application context.

Thermal interface management critically impacts TEG efficiency. The implementation of thermal interface materials (TIMs) with high thermal conductivity yet mechanical compliance is essential for maximizing temperature differential across the device. Materials such as graphene-based thermal pads, phase change materials, or specialized thermal greases can minimize contact resistance while accommodating the irregular surfaces of human skin.

Electrical integration considerations include power management circuitry design that can effectively handle the low-voltage, variable output characteristic of wearable TEGs. This typically necessitates DC-DC converters with high efficiency at low input voltages, maximum power point tracking (MPPT) capabilities, and energy storage solutions such as thin-film batteries or supercapacitors to manage intermittent power generation.

Environmental protection represents another crucial integration factor. Wearable TEGs must withstand exposure to moisture, sweat, mechanical stress, and temperature fluctuations. Encapsulation strategies using biocompatible, waterproof materials like parylene or medical-grade silicones can protect sensitive components while maintaining breathability where needed.

Miniaturization and weight considerations directly impact user acceptance. Integration approaches must minimize bulk through techniques such as flexible printed circuit boards, component stacking, and strategic placement of TEG modules at locations that balance thermal gradient availability with user comfort. The total system weight should ideally remain below 5% of the weight of the garment or accessory into which it is integrated.

Manufacturing scalability must be addressed early in the integration design process. Assembly techniques should be compatible with existing electronics manufacturing infrastructure while accommodating the unique requirements of thermoelectric materials. Automated placement of TEG modules, reliable interconnection methods, and quality control processes specific to thermoelectric performance are essential for commercial viability.

Mechanical integration represents a primary consideration, as wearable TEGs must conform to body contours while maintaining consistent thermal contact. Flexible substrates such as polyimide or silicone elastomers can serve as mounting platforms, allowing TEGs to adapt to body movement without compromising performance. The attachment mechanism must balance secure positioning with user comfort, utilizing medical-grade adhesives, elastic bands, or integration into existing garments depending on the application context.

Thermal interface management critically impacts TEG efficiency. The implementation of thermal interface materials (TIMs) with high thermal conductivity yet mechanical compliance is essential for maximizing temperature differential across the device. Materials such as graphene-based thermal pads, phase change materials, or specialized thermal greases can minimize contact resistance while accommodating the irregular surfaces of human skin.

Electrical integration considerations include power management circuitry design that can effectively handle the low-voltage, variable output characteristic of wearable TEGs. This typically necessitates DC-DC converters with high efficiency at low input voltages, maximum power point tracking (MPPT) capabilities, and energy storage solutions such as thin-film batteries or supercapacitors to manage intermittent power generation.

Environmental protection represents another crucial integration factor. Wearable TEGs must withstand exposure to moisture, sweat, mechanical stress, and temperature fluctuations. Encapsulation strategies using biocompatible, waterproof materials like parylene or medical-grade silicones can protect sensitive components while maintaining breathability where needed.

Miniaturization and weight considerations directly impact user acceptance. Integration approaches must minimize bulk through techniques such as flexible printed circuit boards, component stacking, and strategic placement of TEG modules at locations that balance thermal gradient availability with user comfort. The total system weight should ideally remain below 5% of the weight of the garment or accessory into which it is integrated.

Manufacturing scalability must be addressed early in the integration design process. Assembly techniques should be compatible with existing electronics manufacturing infrastructure while accommodating the unique requirements of thermoelectric materials. Automated placement of TEG modules, reliable interconnection methods, and quality control processes specific to thermoelectric performance are essential for commercial viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!