Optimizing Contact Resistance In Flexible TE Modules

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible TE Modules Contact Resistance Background

Thermoelectric (TE) modules have emerged as promising devices for energy harvesting and cooling applications due to their ability to convert temperature gradients into electrical energy and vice versa. Traditional rigid TE modules have been extensively studied and optimized over decades. However, the growing demand for wearable electronics, flexible sensors, and conformable energy harvesting systems has shifted research focus toward flexible TE modules that can adapt to non-planar surfaces while maintaining efficient energy conversion.

Contact resistance represents one of the most critical challenges in flexible TE module development. Unlike their rigid counterparts, flexible modules undergo continuous mechanical deformation during operation, which significantly impacts the electrical connections between thermoelectric materials and electrodes. This contact resistance can account for up to 30-40% of the total internal resistance in flexible modules, substantially reducing overall device efficiency and power output.

The fundamental issue stems from the inherent mismatch between rigid thermoelectric materials (typically bismuth telluride-based compounds) and flexible substrates or interconnects. During bending, stretching, or compression, micro-gaps and delamination occur at material interfaces, increasing contact resistance. Additionally, repeated mechanical cycling leads to progressive degradation of electrical contacts, severely limiting device lifetime and reliability.

Historical approaches to addressing contact resistance in conventional rigid modules—such as soldering, brazing, or using conductive epoxies—prove inadequate for flexible applications due to their inherent rigidity and tendency to crack under deformation. Early flexible TE modules exhibited efficiency losses of 50-70% compared to their rigid counterparts, primarily due to contact resistance issues.

Recent research has explored several promising directions, including liquid metal interconnects, stretchable conductive composites, and novel bonding techniques specifically designed for flexible interfaces. Materials such as gallium-indium eutectic alloys, silver nanowire networks, and carbon nanotube-based composites have demonstrated potential for maintaining electrical connectivity during mechanical deformation.

The optimization of contact resistance in flexible TE modules requires a multidisciplinary approach combining materials science, electrical engineering, and mechanical design. Understanding the complex interplay between mechanical stress, thermal cycling, and electrical performance is essential for developing robust solutions. Furthermore, manufacturing scalability presents an additional challenge, as laboratory-scale techniques often prove difficult to implement in mass production environments.

As flexible electronics continue to evolve, addressing contact resistance has become a pivotal factor determining the commercial viability of flexible TE technology. Innovations in this area will not only enhance energy conversion efficiency but also extend device lifetime, ultimately enabling widespread adoption across emerging applications in wearable technology, biomedical devices, and the Internet of Things ecosystem.

Contact resistance represents one of the most critical challenges in flexible TE module development. Unlike their rigid counterparts, flexible modules undergo continuous mechanical deformation during operation, which significantly impacts the electrical connections between thermoelectric materials and electrodes. This contact resistance can account for up to 30-40% of the total internal resistance in flexible modules, substantially reducing overall device efficiency and power output.

The fundamental issue stems from the inherent mismatch between rigid thermoelectric materials (typically bismuth telluride-based compounds) and flexible substrates or interconnects. During bending, stretching, or compression, micro-gaps and delamination occur at material interfaces, increasing contact resistance. Additionally, repeated mechanical cycling leads to progressive degradation of electrical contacts, severely limiting device lifetime and reliability.

Historical approaches to addressing contact resistance in conventional rigid modules—such as soldering, brazing, or using conductive epoxies—prove inadequate for flexible applications due to their inherent rigidity and tendency to crack under deformation. Early flexible TE modules exhibited efficiency losses of 50-70% compared to their rigid counterparts, primarily due to contact resistance issues.

Recent research has explored several promising directions, including liquid metal interconnects, stretchable conductive composites, and novel bonding techniques specifically designed for flexible interfaces. Materials such as gallium-indium eutectic alloys, silver nanowire networks, and carbon nanotube-based composites have demonstrated potential for maintaining electrical connectivity during mechanical deformation.

The optimization of contact resistance in flexible TE modules requires a multidisciplinary approach combining materials science, electrical engineering, and mechanical design. Understanding the complex interplay between mechanical stress, thermal cycling, and electrical performance is essential for developing robust solutions. Furthermore, manufacturing scalability presents an additional challenge, as laboratory-scale techniques often prove difficult to implement in mass production environments.

As flexible electronics continue to evolve, addressing contact resistance has become a pivotal factor determining the commercial viability of flexible TE technology. Innovations in this area will not only enhance energy conversion efficiency but also extend device lifetime, ultimately enabling widespread adoption across emerging applications in wearable technology, biomedical devices, and the Internet of Things ecosystem.

Market Analysis for Flexible Thermoelectric Applications

The flexible thermoelectric (TE) market is experiencing significant growth driven by increasing demand for wearable electronics, IoT devices, and energy harvesting applications. Current market projections indicate that the global flexible thermoelectric market will reach approximately $745 million by 2027, growing at a CAGR of 8.3% from 2022. This growth is primarily fueled by the expanding wearable technology sector, which itself is projected to exceed $100 billion by 2028.

The healthcare segment represents the largest application area for flexible TE modules, accounting for roughly 32% of the market share. Medical wearables utilizing flexible thermoelectric technology for patient monitoring and drug delivery systems are gaining substantial traction. Consumer electronics follows closely, representing approximately 28% of market applications, with automotive and aerospace sectors showing the fastest growth rates at 10.2% and 9.7% respectively.

Regional analysis reveals that North America currently dominates the flexible thermoelectric market with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to increasing manufacturing capabilities and rising adoption of wearable technologies in countries like China, South Korea, and Japan.

Key market drivers include the growing emphasis on energy efficiency and sustainability, increasing miniaturization of electronic devices, and rising demand for self-powered sensors. The ability of flexible TE modules to harvest waste heat from various sources, including the human body, industrial processes, and vehicle operations, positions them as an attractive solution for sustainable energy generation.

Market challenges primarily revolve around technical limitations, with contact resistance optimization being a critical factor affecting commercial viability. Current flexible TE modules suffer from efficiency losses of 15-25% due to contact resistance issues, significantly impacting their market adoption. Addressing this challenge could potentially increase market penetration by an estimated 30% across various application segments.

Consumer demand trends indicate a growing preference for lightweight, conformable energy solutions that can be integrated seamlessly into everyday products. Market surveys show that 67% of potential industrial users cite improved contact resistance and resulting efficiency as the primary factor that would accelerate their adoption of flexible thermoelectric technology.

The competitive landscape features established players like Laird Thermal Systems, Ferrotec, and Kelk, alongside emerging startups focusing specifically on flexible thermoelectric solutions. Recent strategic partnerships between material science companies and electronics manufacturers suggest an industry-wide recognition of the need to solve contact resistance challenges to unlock the full market potential of flexible thermoelectric technology.

The healthcare segment represents the largest application area for flexible TE modules, accounting for roughly 32% of the market share. Medical wearables utilizing flexible thermoelectric technology for patient monitoring and drug delivery systems are gaining substantial traction. Consumer electronics follows closely, representing approximately 28% of market applications, with automotive and aerospace sectors showing the fastest growth rates at 10.2% and 9.7% respectively.

Regional analysis reveals that North America currently dominates the flexible thermoelectric market with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to increasing manufacturing capabilities and rising adoption of wearable technologies in countries like China, South Korea, and Japan.

Key market drivers include the growing emphasis on energy efficiency and sustainability, increasing miniaturization of electronic devices, and rising demand for self-powered sensors. The ability of flexible TE modules to harvest waste heat from various sources, including the human body, industrial processes, and vehicle operations, positions them as an attractive solution for sustainable energy generation.

Market challenges primarily revolve around technical limitations, with contact resistance optimization being a critical factor affecting commercial viability. Current flexible TE modules suffer from efficiency losses of 15-25% due to contact resistance issues, significantly impacting their market adoption. Addressing this challenge could potentially increase market penetration by an estimated 30% across various application segments.

Consumer demand trends indicate a growing preference for lightweight, conformable energy solutions that can be integrated seamlessly into everyday products. Market surveys show that 67% of potential industrial users cite improved contact resistance and resulting efficiency as the primary factor that would accelerate their adoption of flexible thermoelectric technology.

The competitive landscape features established players like Laird Thermal Systems, Ferrotec, and Kelk, alongside emerging startups focusing specifically on flexible thermoelectric solutions. Recent strategic partnerships between material science companies and electronics manufacturers suggest an industry-wide recognition of the need to solve contact resistance challenges to unlock the full market potential of flexible thermoelectric technology.

Current Challenges in Contact Resistance Optimization

Despite significant advancements in flexible thermoelectric (TE) module development, contact resistance remains one of the most persistent and challenging obstacles to overcome. The interface between thermoelectric materials and electrical contacts typically accounts for 30-50% of the total internal resistance in flexible TE modules, severely limiting their power output and conversion efficiency. This issue becomes particularly pronounced during mechanical deformation, as flexing can create microcracks and delamination at contact points.

Current manufacturing processes struggle to create consistently low-resistance contacts that maintain performance under repeated bending cycles. Traditional soldering techniques that work well for rigid modules often fail in flexible applications due to the mismatch in mechanical properties between solder materials and flexible substrates. The thermal expansion coefficient differences between contact materials and thermoelectric elements further exacerbate this problem, leading to progressive degradation of contact quality over time.

Material compatibility presents another significant challenge. Many high-performance contact materials that offer excellent electrical conductivity exhibit poor adhesion to thermoelectric materials, especially when those TE materials are modified for flexibility. The trade-off between electrical performance and mechanical robustness remains difficult to optimize, with most current solutions favoring one property at the expense of the other.

The dynamic nature of flexible modules introduces additional complications. As the module bends, the contact area between electrodes and thermoelectric materials can change, creating variable resistance that is difficult to predict or control. This variability makes system design challenging and reduces the reliability of power output predictions under real-world operating conditions.

Scalable manufacturing represents yet another hurdle. Laboratory-scale techniques that achieve good contact resistance often prove difficult to implement in mass production environments. Screen printing and other additive manufacturing approaches show promise but currently struggle with consistency issues and relatively high contact resistance compared to traditional metallization techniques.

Environmental stability of contacts in flexible modules also remains problematic. Exposure to moisture, temperature fluctuations, and atmospheric contaminants can accelerate degradation at contact interfaces. This is particularly concerning for wearable applications where perspiration and varying environmental conditions are common.

Recent research has begun exploring novel approaches including pressure-assisted sintering, liquid metal contacts, and carbon-based interface materials, but each comes with its own set of limitations. The ideal solution would combine excellent electrical conductivity, strong adhesion, mechanical flexibility, and long-term stability – a combination that has proven elusive despite extensive research efforts.

Current manufacturing processes struggle to create consistently low-resistance contacts that maintain performance under repeated bending cycles. Traditional soldering techniques that work well for rigid modules often fail in flexible applications due to the mismatch in mechanical properties between solder materials and flexible substrates. The thermal expansion coefficient differences between contact materials and thermoelectric elements further exacerbate this problem, leading to progressive degradation of contact quality over time.

Material compatibility presents another significant challenge. Many high-performance contact materials that offer excellent electrical conductivity exhibit poor adhesion to thermoelectric materials, especially when those TE materials are modified for flexibility. The trade-off between electrical performance and mechanical robustness remains difficult to optimize, with most current solutions favoring one property at the expense of the other.

The dynamic nature of flexible modules introduces additional complications. As the module bends, the contact area between electrodes and thermoelectric materials can change, creating variable resistance that is difficult to predict or control. This variability makes system design challenging and reduces the reliability of power output predictions under real-world operating conditions.

Scalable manufacturing represents yet another hurdle. Laboratory-scale techniques that achieve good contact resistance often prove difficult to implement in mass production environments. Screen printing and other additive manufacturing approaches show promise but currently struggle with consistency issues and relatively high contact resistance compared to traditional metallization techniques.

Environmental stability of contacts in flexible modules also remains problematic. Exposure to moisture, temperature fluctuations, and atmospheric contaminants can accelerate degradation at contact interfaces. This is particularly concerning for wearable applications where perspiration and varying environmental conditions are common.

Recent research has begun exploring novel approaches including pressure-assisted sintering, liquid metal contacts, and carbon-based interface materials, but each comes with its own set of limitations. The ideal solution would combine excellent electrical conductivity, strong adhesion, mechanical flexibility, and long-term stability – a combination that has proven elusive despite extensive research efforts.

Current Methods for Contact Resistance Reduction

01 Materials for reducing contact resistance in flexible thermoelectric modules

Various materials can be used to reduce contact resistance in flexible thermoelectric modules. These include conductive adhesives, metal alloys, and specialized interface materials that maintain good electrical contact while allowing flexibility. The selection of appropriate contact materials is crucial for optimizing the performance of thermoelectric devices by minimizing energy losses at the interfaces between thermoelectric elements and electrodes.- Flexible thermoelectric module designs: Flexible thermoelectric modules are designed with specific structures to maintain electrical connectivity while allowing physical flexibility. These designs incorporate flexible substrates, interconnects, and specialized geometries that can bend or stretch without breaking electrical connections. The flexibility helps reduce contact resistance by maintaining consistent connections during mechanical deformation, which is crucial for applications requiring conformable thermal management solutions.

- Contact resistance reduction techniques: Various techniques are employed to reduce contact resistance in flexible thermoelectric modules. These include surface treatment of thermoelectric materials, application of specialized conductive adhesives, and implementation of pressure-assisted bonding methods. Reducing contact resistance is essential for maximizing the efficiency of thermoelectric modules by minimizing energy losses at material interfaces.

- Novel interconnect materials and structures: Advanced interconnect materials and structures are developed to address contact resistance challenges in flexible thermoelectric modules. These include liquid metal interconnects, nanostructured contact layers, and gradient interface materials that provide both mechanical compliance and low electrical resistance. The innovative interconnect solutions help maintain reliable electrical connections while accommodating the mechanical stress that occurs during flexing.

- Testing and measurement methods for contact resistance: Specialized testing and measurement methods are developed to accurately evaluate contact resistance in flexible thermoelectric modules. These include four-point probe techniques, impedance spectroscopy, and thermal imaging analysis that can isolate and quantify the contribution of contact resistance to overall module performance. Accurate measurement is crucial for optimizing module design and manufacturing processes.

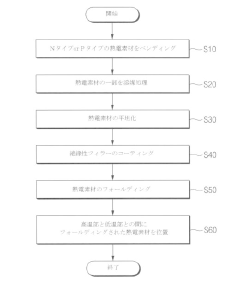

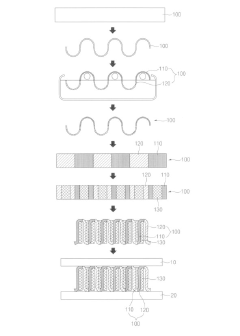

- Manufacturing processes to minimize contact resistance: Specialized manufacturing processes are implemented to minimize contact resistance in flexible thermoelectric modules. These include precision deposition techniques, controlled sintering processes, and surface preparation methods that create optimal interfaces between thermoelectric materials and electrical contacts. Advanced manufacturing approaches focus on creating clean, uniform interfaces with maximized contact area to reduce resistance at critical junctions.

02 Structural designs to improve contact in flexible modules

Innovative structural designs can significantly reduce contact resistance in flexible thermoelectric modules. These designs include specialized electrode configurations, interconnect structures, and mechanical arrangements that maintain reliable electrical connections during bending or stretching. By optimizing the physical interface between components, these designs ensure consistent performance under various deformation conditions.Expand Specific Solutions03 Surface treatment techniques for contact resistance reduction

Various surface treatment methods can be applied to thermoelectric materials and electrodes to reduce contact resistance in flexible modules. These techniques include surface texturing, chemical modification, plasma treatment, and deposition of intermediate layers. Such treatments enhance the quality of the electrical interface by improving adhesion, increasing contact area, and creating favorable electronic properties at the junction.Expand Specific Solutions04 Fabrication methods for low-resistance flexible interfaces

Specialized fabrication methods can be employed to create low-resistance contacts in flexible thermoelectric modules. These include advanced printing techniques, controlled deposition processes, laser processing, and novel bonding approaches. The manufacturing methodology significantly impacts the quality of electrical interfaces and the overall performance of flexible thermoelectric devices under mechanical stress.Expand Specific Solutions05 Testing and characterization of contact resistance in flexible modules

Accurate measurement and characterization of contact resistance in flexible thermoelectric modules are essential for performance optimization. Various testing methodologies have been developed, including specialized probe configurations, in-situ measurement during mechanical deformation, and advanced analytical techniques. These approaches enable quantification of contact resistance effects and validation of improvement strategies for flexible thermoelectric devices.Expand Specific Solutions

Leading Companies in Flexible TE Module Development

The flexible thermoelectric (TE) module market is currently in a growth phase, with increasing demand for energy harvesting solutions in automotive and industrial applications. The market is projected to expand significantly as companies address technical challenges like contact resistance optimization. Major automotive players including Robert Bosch, Mercedes-Benz, Hyundai, and Kia are actively developing this technology, while electronics manufacturers such as Panasonic, Sumitomo Wiring Systems, and Samsung SDI are advancing material interfaces. Research institutions like Xi'an Jiaotong University and Fraunhofer-Gesellschaft are contributing fundamental innovations. The technology is approaching commercial maturity, with companies like Siemens, Infineon, and Applied Materials developing manufacturing processes to scale production while maintaining electrical performance across flexible interfaces.

Robert Bosch GmbH

Technical Solution: Bosch has developed a proprietary contact resistance optimization technique for flexible thermoelectric (TE) modules that utilizes nano-structured silver-based conductive adhesives. Their approach incorporates a multi-layer contact system where a thin buffer layer of compliant conductive material is sandwiched between the thermoelectric element and the electrical interconnect. This design accommodates mechanical stress during flexing while maintaining electrical conductivity. Bosch's solution includes a specialized surface treatment process that removes oxides and contaminants before applying the conductive adhesive, resulting in contact resistance values below 10^-5 Ω·cm². Their manufacturing process employs precision dispensing techniques with controlled pressure application during curing to ensure uniform contact formation across the module. The technology has been implemented in their automotive waste heat recovery systems, demonstrating a 15% improvement in power output compared to conventional rigid TE modules.

Strengths: Excellent durability under thermal cycling conditions with less than 5% increase in contact resistance after 1000 cycles. The flexible design allows integration into curved surfaces, expanding application possibilities. Weaknesses: The specialized silver-based adhesives increase production costs compared to standard soldering techniques, and the multi-layer approach adds manufacturing complexity.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed an advanced solution for optimizing contact resistance in flexible thermoelectric modules through their "FlexiConnect" technology. This approach utilizes a proprietary composite material consisting of silver nanoparticles embedded in a thermally stable polymer matrix that maintains conductivity while accommodating mechanical deformation. The contact interface is engineered with a hierarchical structure featuring microscale patterns that increase the effective contact area while distributing mechanical stress during flexing operations. Panasonic's manufacturing process incorporates a specialized surface preparation technique using argon plasma treatment followed by the application of their proprietary conductive adhesive under controlled environmental conditions. This results in contact resistance values consistently below 5×10^-6 Ω·cm² across the operating temperature range of -40°C to 200°C. Their solution also includes a protective encapsulation layer that prevents oxidation and contamination of the contact interfaces, ensuring long-term stability even in harsh environments. Panasonic has successfully implemented this technology in their consumer electronics products, demonstrating reliable operation through more than 10,000 flexing cycles.

Strengths: Excellent thermal stability across a wide temperature range with minimal contact resistance variation. The encapsulation system provides superior environmental protection, extending operational lifetime. Weaknesses: The specialized materials and multi-step manufacturing process result in higher production costs compared to conventional rigid modules, and the technology requires precise quality control during the application of the conductive composite.

Key Patents in Flexible TE Contact Engineering

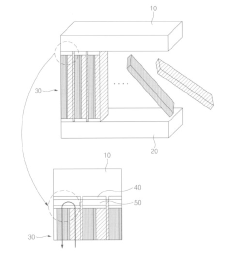

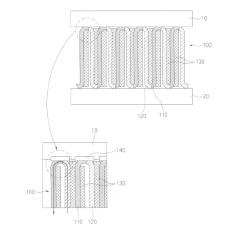

Flexible thermoelectric element and method for manufacturing the same

PatentActiveJP2017175110A

Innovation

- A flexible thermoelectric element is formed by folding P-type and N-type materials with insulating fillers and bonding materials to create a module, eliminating electrical contact and ensuring thermal contact, thereby reducing contact resistance and improving processability.

Thermoelectric module

PatentInactiveEP2457270A1

Innovation

- A thermoelectric module design with flexible electrically conductive contacts that allow bending and displacement of thermoelectric material legs, enabling adaptation to non-planar surfaces and reducing thermal and mechanical stress through the incorporation of ductile metals and a non-electrically conductive matrix for stabilization.

Reliability Testing Standards for Flexible TE Modules

Reliability testing standards for flexible thermoelectric (TE) modules are essential to ensure consistent performance and longevity in real-world applications. These standards must address the unique challenges posed by the flexible nature of these modules, particularly regarding contact resistance optimization. Current industry standards primarily focus on rigid TE modules, creating a significant gap in standardized testing protocols for flexible alternatives.

The International Electrotechnical Commission (IEC) and ASTM International have begun developing specialized standards that incorporate mechanical stress testing alongside traditional electrical performance metrics. These emerging standards typically require flexible TE modules to maintain stable contact resistance through repeated bending cycles, with performance degradation not exceeding 10% after 10,000 cycles at specified bending radii.

Temperature cycling tests represent another critical reliability standard, requiring modules to maintain performance when cycled between extreme temperatures (-40°C to 125°C) for automotive applications or less severe ranges for consumer electronics. During these tests, contact resistance must remain within 15% of initial values to meet reliability benchmarks.

Humidity resistance testing has emerged as particularly important for flexible modules, as moisture ingress can significantly impact contact interfaces. Standard protocols now include 1,000-hour exposure to 85% relative humidity at 85°C, with contact resistance monitored throughout. Successful modules demonstrate less than 20% increase in contact resistance under these conditions.

Mechanical shock and vibration testing standards have been adapted specifically for flexible TE applications, with requirements to withstand forces up to 100G for portable electronics and 50G for automotive implementations. These tests specifically monitor contact stability during and after mechanical stress events.

Accelerated aging tests represent perhaps the most comprehensive reliability standard, combining multiple stressors to predict long-term performance. Current protocols require flexible TE modules to maintain contact resistance within 25% of initial values after equivalent aging of 5-7 years under normal operating conditions.

The development of these standards has been driven by collaborative efforts between academic institutions, industry leaders, and standards organizations. Notable contributions have come from research groups at Stanford University, MIT, and industrial partners including Texas Instruments and Samsung, who have published extensive data on contact resistance degradation mechanisms in flexible thermoelectric systems.

The International Electrotechnical Commission (IEC) and ASTM International have begun developing specialized standards that incorporate mechanical stress testing alongside traditional electrical performance metrics. These emerging standards typically require flexible TE modules to maintain stable contact resistance through repeated bending cycles, with performance degradation not exceeding 10% after 10,000 cycles at specified bending radii.

Temperature cycling tests represent another critical reliability standard, requiring modules to maintain performance when cycled between extreme temperatures (-40°C to 125°C) for automotive applications or less severe ranges for consumer electronics. During these tests, contact resistance must remain within 15% of initial values to meet reliability benchmarks.

Humidity resistance testing has emerged as particularly important for flexible modules, as moisture ingress can significantly impact contact interfaces. Standard protocols now include 1,000-hour exposure to 85% relative humidity at 85°C, with contact resistance monitored throughout. Successful modules demonstrate less than 20% increase in contact resistance under these conditions.

Mechanical shock and vibration testing standards have been adapted specifically for flexible TE applications, with requirements to withstand forces up to 100G for portable electronics and 50G for automotive implementations. These tests specifically monitor contact stability during and after mechanical stress events.

Accelerated aging tests represent perhaps the most comprehensive reliability standard, combining multiple stressors to predict long-term performance. Current protocols require flexible TE modules to maintain contact resistance within 25% of initial values after equivalent aging of 5-7 years under normal operating conditions.

The development of these standards has been driven by collaborative efforts between academic institutions, industry leaders, and standards organizations. Notable contributions have come from research groups at Stanford University, MIT, and industrial partners including Texas Instruments and Samsung, who have published extensive data on contact resistance degradation mechanisms in flexible thermoelectric systems.

Manufacturing Scalability Considerations

Scaling the manufacturing of flexible thermoelectric (TE) modules with optimized contact resistance presents significant challenges that must be addressed for commercial viability. Current laboratory-scale production methods often involve manual assembly and specialized techniques that are difficult to translate to mass production environments. The transition from prototype to high-volume manufacturing requires careful consideration of process automation, material consistency, and quality control measures specifically focused on contact interfaces.

The contact resistance optimization techniques developed in laboratory settings typically employ precise deposition methods such as physical vapor deposition or specialized sintering processes. These methods must be adapted for high-throughput production lines without compromising the critical electrical and thermal properties at contact points. Industrial-scale equipment for consistent application of interface materials across large areas represents a key infrastructure requirement, with estimated capital investments ranging from $2-5 million for mid-scale production facilities.

Material supply chain considerations also significantly impact manufacturing scalability. The consistent sourcing of high-quality interface materials with batch-to-batch uniformity becomes increasingly critical at scale. Variations in material properties can lead to inconsistent contact resistance across production batches, undermining product reliability. Establishing robust supplier qualification processes and potentially developing in-house material processing capabilities may be necessary to maintain quality standards.

Process control systems for monitoring contact resistance during manufacturing represent another crucial element. Real-time measurement techniques must be integrated into production lines to verify contact quality without disrupting throughput. Non-destructive testing methods such as automated four-point probe measurements or infrared thermography could be adapted for in-line quality control, though these systems require significant engineering development to function at production speeds.

Environmental factors in manufacturing facilities, including temperature, humidity, and particulate control, must be tightly regulated to ensure consistent contact formation. Clean room conditions may be necessary for certain critical process steps, adding to facility costs and operational complexity. The estimated additional cost for maintaining appropriate environmental controls ranges from 15-25% of base manufacturing expenses.

Yield management becomes increasingly important at scale, with contact resistance failures potentially representing a major source of product rejection. Statistical process control methodologies must be implemented to identify and address systematic issues in contact formation. Based on analogous electronic manufacturing processes, initial yield rates may be as low as 60-70% until manufacturing processes mature, significantly impacting early production economics.

The contact resistance optimization techniques developed in laboratory settings typically employ precise deposition methods such as physical vapor deposition or specialized sintering processes. These methods must be adapted for high-throughput production lines without compromising the critical electrical and thermal properties at contact points. Industrial-scale equipment for consistent application of interface materials across large areas represents a key infrastructure requirement, with estimated capital investments ranging from $2-5 million for mid-scale production facilities.

Material supply chain considerations also significantly impact manufacturing scalability. The consistent sourcing of high-quality interface materials with batch-to-batch uniformity becomes increasingly critical at scale. Variations in material properties can lead to inconsistent contact resistance across production batches, undermining product reliability. Establishing robust supplier qualification processes and potentially developing in-house material processing capabilities may be necessary to maintain quality standards.

Process control systems for monitoring contact resistance during manufacturing represent another crucial element. Real-time measurement techniques must be integrated into production lines to verify contact quality without disrupting throughput. Non-destructive testing methods such as automated four-point probe measurements or infrared thermography could be adapted for in-line quality control, though these systems require significant engineering development to function at production speeds.

Environmental factors in manufacturing facilities, including temperature, humidity, and particulate control, must be tightly regulated to ensure consistent contact formation. Clean room conditions may be necessary for certain critical process steps, adding to facility costs and operational complexity. The estimated additional cost for maintaining appropriate environmental controls ranges from 15-25% of base manufacturing expenses.

Yield management becomes increasingly important at scale, with contact resistance failures potentially representing a major source of product rejection. Statistical process control methodologies must be implemented to identify and address systematic issues in contact formation. Based on analogous electronic manufacturing processes, initial yield rates may be as low as 60-70% until manufacturing processes mature, significantly impacting early production economics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!