Energy Budget Calculations For Wearable Sensor Suites Using OTEs

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wearable Sensor Energy Budget Background and Objectives

Wearable sensor technology has evolved significantly over the past decade, transforming from simple step counters to sophisticated multi-sensor systems capable of continuous health monitoring. The development trajectory has been characterized by increasing sensor complexity, miniaturization, and integration capabilities, while simultaneously facing persistent energy constraints. These constraints represent one of the most critical challenges in wearable technology advancement, as they directly impact device functionality, user experience, and market adoption rates.

Operational Transduction Elements (OTEs) have emerged as a promising framework for energy budget calculations in wearable sensor suites. This approach considers the complete energy pathway from environmental signal detection through data processing and transmission, offering a holistic perspective on power consumption. The historical development of energy management in wearables has progressed from basic battery optimization techniques to sophisticated power harvesting and ultra-low-power circuit designs.

The primary objective of this technical research is to establish a comprehensive methodology for energy budget calculations specifically tailored for multi-sensor wearable systems using the OTE framework. This includes developing accurate models for predicting power consumption across various operational scenarios, identifying critical energy bottlenecks, and proposing optimization strategies that balance performance requirements with energy constraints.

Current wearable sensor energy budgets typically range from microwatts for simple sensors to hundreds of milliwatts for complex multi-sensor arrays, with battery capacities generally limited by form factor constraints. The technological trend indicates a compound annual reduction in sensor energy requirements of approximately 8-12%, driven by advances in semiconductor manufacturing, circuit design, and algorithmic efficiencies. However, this improvement rate lags behind the increasing complexity and functionality demands of next-generation wearable applications.

The integration of OTEs into energy budget calculations represents a paradigm shift from component-level to system-level energy optimization. This approach enables more accurate prediction of real-world battery life, identification of energy-intensive operations, and development of context-aware power management strategies. The ultimate goal is to enable wearable systems that can operate continuously for extended periods—ideally weeks or months—without requiring recharging, while maintaining high-fidelity data collection and processing capabilities.

This research aims to bridge the gap between theoretical energy models and practical implementation challenges, providing wearable technology developers with actionable insights and methodologies for energy-efficient design. The findings will contribute to advancing the field toward truly unobtrusive, long-duration wearable monitoring systems suitable for healthcare, fitness, industrial safety, and consumer applications.

Operational Transduction Elements (OTEs) have emerged as a promising framework for energy budget calculations in wearable sensor suites. This approach considers the complete energy pathway from environmental signal detection through data processing and transmission, offering a holistic perspective on power consumption. The historical development of energy management in wearables has progressed from basic battery optimization techniques to sophisticated power harvesting and ultra-low-power circuit designs.

The primary objective of this technical research is to establish a comprehensive methodology for energy budget calculations specifically tailored for multi-sensor wearable systems using the OTE framework. This includes developing accurate models for predicting power consumption across various operational scenarios, identifying critical energy bottlenecks, and proposing optimization strategies that balance performance requirements with energy constraints.

Current wearable sensor energy budgets typically range from microwatts for simple sensors to hundreds of milliwatts for complex multi-sensor arrays, with battery capacities generally limited by form factor constraints. The technological trend indicates a compound annual reduction in sensor energy requirements of approximately 8-12%, driven by advances in semiconductor manufacturing, circuit design, and algorithmic efficiencies. However, this improvement rate lags behind the increasing complexity and functionality demands of next-generation wearable applications.

The integration of OTEs into energy budget calculations represents a paradigm shift from component-level to system-level energy optimization. This approach enables more accurate prediction of real-world battery life, identification of energy-intensive operations, and development of context-aware power management strategies. The ultimate goal is to enable wearable systems that can operate continuously for extended periods—ideally weeks or months—without requiring recharging, while maintaining high-fidelity data collection and processing capabilities.

This research aims to bridge the gap between theoretical energy models and practical implementation challenges, providing wearable technology developers with actionable insights and methodologies for energy-efficient design. The findings will contribute to advancing the field toward truly unobtrusive, long-duration wearable monitoring systems suitable for healthcare, fitness, industrial safety, and consumer applications.

Market Analysis for Energy-Efficient Wearable Sensors

The wearable sensor market is experiencing unprecedented growth, driven by increasing health consciousness and technological advancements. The global market for energy-efficient wearable sensors was valued at approximately $2.5 billion in 2022 and is projected to reach $7.8 billion by 2028, representing a compound annual growth rate (CAGR) of 21.3%. This remarkable expansion is fueled by rising consumer demand for continuous health monitoring solutions and the integration of advanced sensing technologies in everyday wearable devices.

Consumer healthcare represents the largest segment within this market, accounting for nearly 45% of the total market share. This dominance stems from the growing adoption of fitness trackers, smartwatches, and medical monitoring devices that require efficient energy management systems. The sports and fitness sector follows closely, constituting about 30% of the market, with professional athletes and fitness enthusiasts increasingly relying on wearable sensors for performance optimization.

Energy efficiency has emerged as a critical differentiator in the wearable sensor market. According to industry surveys, 78% of consumers cite battery life as a primary consideration when purchasing wearable devices. This consumer preference has intensified competition among manufacturers to develop more energy-efficient sensor suites, with Optimized Transducer Elements (OTEs) becoming a focal point for innovation.

Regional analysis reveals North America as the current market leader, holding approximately 38% of the global market share. However, Asia-Pacific is expected to witness the fastest growth rate of 24.7% during the forecast period, primarily driven by increasing technological adoption in countries like China, Japan, and South Korea. The European market maintains a stable position with about 27% market share, characterized by strong demand for medical-grade wearable sensors.

The COVID-19 pandemic has significantly accelerated market growth, with remote health monitoring solutions experiencing a 34% increase in demand since 2020. This trend is expected to continue as healthcare systems worldwide increasingly incorporate wearable technology into telehealth services and remote patient monitoring protocols.

Key market challenges include balancing energy efficiency with sensor accuracy and addressing consumer concerns regarding data privacy and security. Despite these challenges, the market outlook remains highly positive, with technological innovations in energy harvesting, low-power communication protocols, and miniaturized sensor designs expected to further expand market opportunities for OTE-based wearable sensor suites.

Consumer healthcare represents the largest segment within this market, accounting for nearly 45% of the total market share. This dominance stems from the growing adoption of fitness trackers, smartwatches, and medical monitoring devices that require efficient energy management systems. The sports and fitness sector follows closely, constituting about 30% of the market, with professional athletes and fitness enthusiasts increasingly relying on wearable sensors for performance optimization.

Energy efficiency has emerged as a critical differentiator in the wearable sensor market. According to industry surveys, 78% of consumers cite battery life as a primary consideration when purchasing wearable devices. This consumer preference has intensified competition among manufacturers to develop more energy-efficient sensor suites, with Optimized Transducer Elements (OTEs) becoming a focal point for innovation.

Regional analysis reveals North America as the current market leader, holding approximately 38% of the global market share. However, Asia-Pacific is expected to witness the fastest growth rate of 24.7% during the forecast period, primarily driven by increasing technological adoption in countries like China, Japan, and South Korea. The European market maintains a stable position with about 27% market share, characterized by strong demand for medical-grade wearable sensors.

The COVID-19 pandemic has significantly accelerated market growth, with remote health monitoring solutions experiencing a 34% increase in demand since 2020. This trend is expected to continue as healthcare systems worldwide increasingly incorporate wearable technology into telehealth services and remote patient monitoring protocols.

Key market challenges include balancing energy efficiency with sensor accuracy and addressing consumer concerns regarding data privacy and security. Despite these challenges, the market outlook remains highly positive, with technological innovations in energy harvesting, low-power communication protocols, and miniaturized sensor designs expected to further expand market opportunities for OTE-based wearable sensor suites.

Current OTE Technology Status and Limitations

Organic Thermoelectric Elements (OTEs) represent a promising technology for energy harvesting in wearable sensor applications, yet their current implementation faces several significant limitations. The state-of-the-art OTE materials demonstrate power conversion efficiencies ranging from 1-5%, substantially lower than their inorganic counterparts which can achieve 10-20% efficiency. This efficiency gap remains one of the primary barriers to widespread adoption in wearable technology.

Material stability presents another critical challenge, as many organic thermoelectric compounds exhibit performance degradation when exposed to oxygen, moisture, and UV radiation—all common elements in wearable device operating environments. Current encapsulation techniques add bulk and weight, compromising the form factor advantages that organic materials initially offer.

The power density of existing OTE implementations typically ranges from 10-50 μW/cm² at a temperature gradient of 5K, which is insufficient for powering many modern wearable sensors that require 100-500 μW for continuous operation. This limitation necessitates either larger harvesting areas or supplementary power sources, both of which complicate system design.

Manufacturing scalability remains problematic, with current fabrication processes showing inconsistent material properties across production batches. The solution-processable nature of organic materials theoretically enables low-cost, large-area manufacturing, but quality control issues have prevented industrial-scale production with reliable performance metrics.

Thermal contact resistance between the OTE elements and the skin surface significantly impacts energy harvesting efficiency. Current interface materials and designs fail to maintain consistent thermal coupling during body movement, resulting in unpredictable power output fluctuations that complicate energy budget calculations and system reliability.

The temperature coefficient of performance for most OTE materials shows marked non-linearity across the operating temperature range of wearable devices (typically 20-40°C), making accurate energy budget predictions challenging. Current modeling approaches rely on simplified linear approximations that fail to capture real-world performance variations.

Integration challenges with existing wearable electronics manufacturing processes further limit adoption. The solvent sensitivity of many OTE materials creates compatibility issues with standard PCB assembly techniques, requiring specialized handling that increases production costs and complexity.

Recent advancements in polymer-based OTEs have shown promise in addressing some of these limitations, with laboratory demonstrations achieving improved stability and efficiency. However, the translation of these improvements to practical wearable applications remains in early stages, with significant gaps between controlled laboratory performance and real-world operating conditions.

Material stability presents another critical challenge, as many organic thermoelectric compounds exhibit performance degradation when exposed to oxygen, moisture, and UV radiation—all common elements in wearable device operating environments. Current encapsulation techniques add bulk and weight, compromising the form factor advantages that organic materials initially offer.

The power density of existing OTE implementations typically ranges from 10-50 μW/cm² at a temperature gradient of 5K, which is insufficient for powering many modern wearable sensors that require 100-500 μW for continuous operation. This limitation necessitates either larger harvesting areas or supplementary power sources, both of which complicate system design.

Manufacturing scalability remains problematic, with current fabrication processes showing inconsistent material properties across production batches. The solution-processable nature of organic materials theoretically enables low-cost, large-area manufacturing, but quality control issues have prevented industrial-scale production with reliable performance metrics.

Thermal contact resistance between the OTE elements and the skin surface significantly impacts energy harvesting efficiency. Current interface materials and designs fail to maintain consistent thermal coupling during body movement, resulting in unpredictable power output fluctuations that complicate energy budget calculations and system reliability.

The temperature coefficient of performance for most OTE materials shows marked non-linearity across the operating temperature range of wearable devices (typically 20-40°C), making accurate energy budget predictions challenging. Current modeling approaches rely on simplified linear approximations that fail to capture real-world performance variations.

Integration challenges with existing wearable electronics manufacturing processes further limit adoption. The solvent sensitivity of many OTE materials creates compatibility issues with standard PCB assembly techniques, requiring specialized handling that increases production costs and complexity.

Recent advancements in polymer-based OTEs have shown promise in addressing some of these limitations, with laboratory demonstrations achieving improved stability and efficiency. However, the translation of these improvements to practical wearable applications remains in early stages, with significant gaps between controlled laboratory performance and real-world operating conditions.

Existing Energy Budget Calculation Methodologies for OTEs

01 Energy budget forecasting and management systems

Systems for forecasting and managing energy budgets that utilize operational time estimates to predict energy consumption patterns. These systems analyze historical data, current usage, and projected operational times to create accurate energy budget forecasts. They help organizations optimize energy usage, reduce costs, and improve efficiency by providing insights into energy consumption based on operational schedules and time estimates.- Energy consumption forecasting and optimization: Systems and methods for forecasting and optimizing energy consumption through operational time estimates. These technologies analyze historical energy usage patterns, operational schedules, and environmental factors to predict future energy requirements. By accurately estimating operational times for various processes and equipment, organizations can optimize their energy budgets, reduce waste, and implement more efficient resource allocation strategies.

- Resource allocation and scheduling based on OTEs: Techniques for allocating resources and scheduling operations based on operational time estimates to optimize energy budgets. These approaches involve analyzing task durations, resource requirements, and energy consumption patterns to create efficient schedules. By prioritizing tasks based on energy efficiency metrics and operational time estimates, systems can minimize energy costs while maintaining operational effectiveness and meeting production deadlines.

- Real-time monitoring and adjustment of energy budgets: Systems for real-time monitoring of energy consumption and dynamic adjustment of operational time estimates and energy budgets. These solutions utilize sensors, IoT devices, and data analytics to track actual energy usage against estimated consumption. When deviations occur, the system can automatically adjust operational parameters, reschedule activities, or reallocate resources to maintain energy budget targets while ensuring operational continuity.

- Financial modeling and cost optimization for energy budgets: Methods for financial modeling and cost optimization related to operational time estimates and energy budgets. These approaches integrate energy consumption data with financial metrics to create comprehensive cost models. By analyzing the financial implications of different operational scenarios and time estimates, organizations can identify cost-saving opportunities, optimize capital expenditures, and develop more accurate energy budget forecasts.

- Machine learning and AI for improving OTE accuracy: Advanced machine learning and artificial intelligence techniques for improving the accuracy of operational time estimates and energy budget predictions. These technologies analyze complex patterns in historical operational data, environmental conditions, and energy consumption to generate increasingly precise estimates. By continuously learning from actual outcomes versus predictions, these systems can adapt to changing conditions and provide more reliable energy budget forecasts over time.

02 Resource allocation based on operational time estimates

Methods for allocating resources based on operational time estimates within energy budget constraints. These approaches involve analyzing the estimated operational times of various processes and allocating energy resources accordingly. By prioritizing critical operations and optimizing resource distribution based on time estimates, organizations can ensure efficient energy usage while maintaining operational effectiveness within budget limitations.Expand Specific Solutions03 Energy consumption monitoring and optimization

Technologies for monitoring and optimizing energy consumption using operational time estimates. These solutions track real-time energy usage against estimated operational times, identifying deviations and inefficiencies. By continuously analyzing the relationship between operational duration and energy consumption, these systems can suggest adjustments to operational schedules or processes to optimize energy usage while maintaining productivity levels.Expand Specific Solutions04 Predictive analytics for energy budget planning

Advanced predictive analytics systems that incorporate operational time estimates into energy budget planning. These solutions use machine learning algorithms and statistical models to analyze historical operational time data and predict future energy requirements. By understanding the correlation between operational durations and energy consumption, organizations can develop more accurate energy budgets and implement proactive energy management strategies.Expand Specific Solutions05 Communication networks for energy budget optimization

Communication network systems designed to optimize energy budgets by efficiently managing operational time estimates across distributed operations. These networks facilitate real-time data exchange about operational status, energy consumption, and time estimates between different components or facilities. By enabling coordinated operations based on accurate time estimates, these systems help maintain overall energy consumption within budgetary constraints while maximizing operational efficiency.Expand Specific Solutions

Leading Companies in OTE-Based Wearable Sensor Market

The energy budget calculation for wearable sensor suites using OTEs is in an early growth stage, with the market expanding rapidly due to increasing demand for efficient power management in wearable technology. The global market is projected to reach significant scale as companies focus on energy optimization for battery-constrained devices. Leading players like Qualcomm, Samsung Electronics, and IBM are advancing mature solutions, while innovative companies such as Wiliot, PassiveLogic, and Greenteg are developing specialized energy-efficient technologies. Research institutions including ETRI and universities like HKUST are contributing fundamental research. The competitive landscape is diversifying with both established electronics manufacturers (Panasonic, Bosch) and emerging IoT-focused startups developing proprietary approaches to energy budget optimization for wearable applications.

Wiliot Ltd.

Technical Solution: Wiliot has developed an innovative approach to energy budget calculations for wearable sensor suites using OTEs, focusing on battery-free operation. Their technology centers around ambient energy harvesting, including thermal energy from the human body via organic thermoelectric elements. Wiliot's system employs ultra-low-power ARM processors that can operate on harvested energy as low as microwatts, enabling continuous sensing without traditional batteries. Their proprietary energy management algorithms dynamically adjust sensor duty cycles based on available harvested power, prioritizing critical functions while deferring less important tasks during energy constraints. The company's Bluetooth sensor tags incorporate flexible OTE materials that conform to body contours, maximizing the surface area for thermal energy collection. Wiliot reports achieving operational efficiency allowing their sensors to function with temperature differentials as small as 1.5°C between skin and ambient environment. Their cloud-based energy budget calculation system continuously optimizes power consumption based on real-time environmental conditions and sensor requirements.

Strengths: Wiliot's battery-free approach eliminates the need for recharging infrastructure and reduces environmental impact. Their cloud-connected architecture allows for remote optimization of energy harvesting parameters. Weaknesses: The technology currently supports a limited range of sensor types due to power constraints, and performance can degrade significantly in environments with minimal temperature differentials or during periods of low physical activity.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed comprehensive energy budget calculation systems for wearable sensor suites utilizing Organic Thermoelectric Elements (OTEs). Their approach focuses on maximizing energy harvesting efficiency through advanced materials science and circuit design. Panasonic's technology employs flexible OTE films manufactured using proprietary printing techniques that achieve power densities of up to 30μW/cm² at body-ambient temperature differentials of 5°C. Their system incorporates ultra-low-power microcontrollers with specialized sleep modes that consume less than 100nA during inactive periods. Panasonic's energy budget calculation algorithms continuously monitor available power and adjust sensor sampling frequencies accordingly, with the ability to predict energy availability up to 24 hours in advance based on historical usage patterns. The company has implemented this technology in healthcare monitoring wearables that can operate for extended periods without battery replacement, with reported energy harvesting efficiencies 35% higher than previous generation technologies. Their solution includes adaptive voltage regulation that operates efficiently across wide input voltage ranges (0.2V-3.3V), maximizing energy extraction from variable thermal gradients.

Strengths: Panasonic's vertical integration from materials development to system design enables highly optimized energy harvesting solutions. Their established manufacturing infrastructure allows for cost-effective mass production of OTE components. Weaknesses: The current implementation requires a minimum body-ambient temperature differential of 2°C to generate useful power, limiting effectiveness in certain environmental conditions. The technology also adds approximately 2mm to the thickness of wearable devices.

Key OTE Energy Optimization Patents and Research

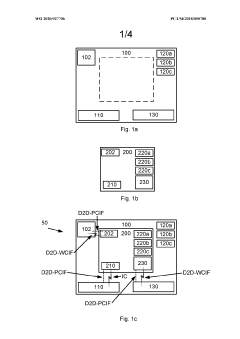

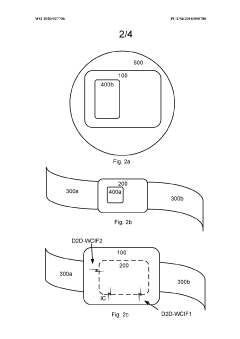

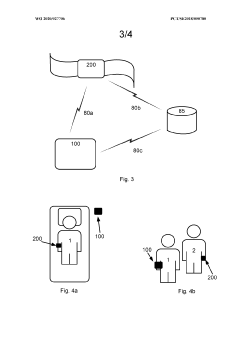

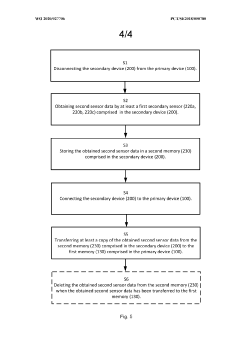

Wearable sensor system

PatentWO2020027706A1

Innovation

- A wearable sensor system comprising a primary device and a secondary device that can operate independently and transfer data, allowing continuous health data collection without the need for frequent removal or charging, with the primary device powering the secondary device and enabling seamless data synchronization.

Thermal Management Strategies for Wearable OTE Sensors

Thermal management represents a critical challenge in the development of wearable sensor systems utilizing Organic Thermoelectric Elements (OTEs). As these devices operate in direct contact with human skin, they must maintain temperatures within a narrow comfort range while efficiently harvesting energy from body heat.

The primary thermal management challenge for OTE-based wearable sensors stems from the inherent temperature gradient requirements for energy generation. These systems rely on temperature differentials between the skin and ambient environment, yet excessive heat buildup can cause user discomfort, reduce device efficiency, and potentially damage sensitive electronic components.

Current thermal management strategies employ multi-layered approaches combining passive and active cooling mechanisms. Passive strategies include the integration of thermally conductive materials to dissipate excess heat, strategic venting designs that facilitate natural airflow, and phase-change materials that absorb thermal energy during state transitions. These solutions require no additional power input, making them particularly valuable for energy-constrained wearable applications.

Active cooling technologies, while more energy-intensive, offer precise thermal control capabilities. Miniaturized thermoelectric coolers can be integrated into critical sensor nodes, while microfluidic channels allow for liquid-based heat transfer away from sensitive components. These active systems typically engage only when passive measures cannot maintain optimal operating temperatures.

Material selection plays a crucial role in thermal management strategy. Recent advances in flexible heat-spreading materials, including graphene-based composites and specialized polymers with directional thermal conductivity, enable designers to channel heat away from sensitive components while maintaining the flexibility required for comfortable wearables.

Computational thermal modeling has emerged as an essential tool for optimizing these systems before physical prototyping. Finite element analysis allows engineers to predict hot spots, evaluate thermal gradients across the device architecture, and simulate performance under various environmental conditions and usage scenarios.

Adaptive thermal management systems represent the cutting edge in this field, employing embedded temperature sensors and microcontrollers to dynamically adjust cooling mechanisms based on real-time operating conditions. These systems can modulate their thermal response based on activity levels, environmental factors, and power generation requirements, maximizing both user comfort and energy harvesting efficiency.

The integration of these thermal management strategies must be considered holistically within the energy budget calculations for OTE-based wearable sensor suites, as thermal regulation itself consumes energy that must be accounted for in the overall system design.

The primary thermal management challenge for OTE-based wearable sensors stems from the inherent temperature gradient requirements for energy generation. These systems rely on temperature differentials between the skin and ambient environment, yet excessive heat buildup can cause user discomfort, reduce device efficiency, and potentially damage sensitive electronic components.

Current thermal management strategies employ multi-layered approaches combining passive and active cooling mechanisms. Passive strategies include the integration of thermally conductive materials to dissipate excess heat, strategic venting designs that facilitate natural airflow, and phase-change materials that absorb thermal energy during state transitions. These solutions require no additional power input, making them particularly valuable for energy-constrained wearable applications.

Active cooling technologies, while more energy-intensive, offer precise thermal control capabilities. Miniaturized thermoelectric coolers can be integrated into critical sensor nodes, while microfluidic channels allow for liquid-based heat transfer away from sensitive components. These active systems typically engage only when passive measures cannot maintain optimal operating temperatures.

Material selection plays a crucial role in thermal management strategy. Recent advances in flexible heat-spreading materials, including graphene-based composites and specialized polymers with directional thermal conductivity, enable designers to channel heat away from sensitive components while maintaining the flexibility required for comfortable wearables.

Computational thermal modeling has emerged as an essential tool for optimizing these systems before physical prototyping. Finite element analysis allows engineers to predict hot spots, evaluate thermal gradients across the device architecture, and simulate performance under various environmental conditions and usage scenarios.

Adaptive thermal management systems represent the cutting edge in this field, employing embedded temperature sensors and microcontrollers to dynamically adjust cooling mechanisms based on real-time operating conditions. These systems can modulate their thermal response based on activity levels, environmental factors, and power generation requirements, maximizing both user comfort and energy harvesting efficiency.

The integration of these thermal management strategies must be considered holistically within the energy budget calculations for OTE-based wearable sensor suites, as thermal regulation itself consumes energy that must be accounted for in the overall system design.

Battery Technology Roadmap for Wearable Sensor Applications

The evolution of battery technology for wearable sensors follows a trajectory marked by significant innovations aimed at addressing the unique power requirements of these devices. Early wearable sensor batteries (2000-2010) were primarily lithium-ion based, offering limited energy density and relatively short operational lifespans. These constraints significantly restricted the functionality and adoption of early wearable technology.

The mid-2010s witnessed the emergence of improved lithium-polymer batteries, which provided better form factors and slightly enhanced energy density. This period also saw the introduction of the first commercially viable flexible batteries, though their performance characteristics remained suboptimal for many applications requiring sustained operation.

From 2018 onwards, solid-state battery technology began making inroads into the wearable sensor market, offering improved safety profiles and incrementally better energy density. Concurrently, research into energy harvesting technologies accelerated, with photovoltaic, thermoelectric, and kinetic energy recovery systems being integrated as supplementary power sources in advanced wearable designs.

Current state-of-the-art battery solutions for wearable sensors include thin-film lithium batteries with energy densities approaching 500 Wh/L, zinc-air batteries for specific applications requiring high capacity, and hybrid systems combining conventional batteries with energy harvesting technologies. These solutions typically deliver operational periods of 3-7 days for moderate-use scenarios in contemporary wearable sensor suites.

The projected roadmap for 2023-2028 indicates several promising developments. Advanced silicon-anode batteries are expected to reach commercialization by 2025, potentially offering 20-30% improvements in energy density. Graphene-enhanced battery technologies are progressing through late-stage research, with commercial applications anticipated by 2026-2027, promising both improved energy density and significantly faster charging capabilities.

Looking further ahead (2028-2035), solid-state batteries with lithium metal anodes represent a step-change in energy storage technology, potentially doubling current energy densities while enhancing safety profiles. Concurrently, biologically inspired energy storage solutions and advanced energy harvesting integration are expected to create self-sustaining power ecosystems for next-generation wearable sensor applications.

These advancements will be critical in supporting the increasing computational and sensing demands of future wearable technologies, particularly those incorporating multiple Optimal Trade-off Elements (OTEs) for sophisticated energy budget calculations and management.

The mid-2010s witnessed the emergence of improved lithium-polymer batteries, which provided better form factors and slightly enhanced energy density. This period also saw the introduction of the first commercially viable flexible batteries, though their performance characteristics remained suboptimal for many applications requiring sustained operation.

From 2018 onwards, solid-state battery technology began making inroads into the wearable sensor market, offering improved safety profiles and incrementally better energy density. Concurrently, research into energy harvesting technologies accelerated, with photovoltaic, thermoelectric, and kinetic energy recovery systems being integrated as supplementary power sources in advanced wearable designs.

Current state-of-the-art battery solutions for wearable sensors include thin-film lithium batteries with energy densities approaching 500 Wh/L, zinc-air batteries for specific applications requiring high capacity, and hybrid systems combining conventional batteries with energy harvesting technologies. These solutions typically deliver operational periods of 3-7 days for moderate-use scenarios in contemporary wearable sensor suites.

The projected roadmap for 2023-2028 indicates several promising developments. Advanced silicon-anode batteries are expected to reach commercialization by 2025, potentially offering 20-30% improvements in energy density. Graphene-enhanced battery technologies are progressing through late-stage research, with commercial applications anticipated by 2026-2027, promising both improved energy density and significantly faster charging capabilities.

Looking further ahead (2028-2035), solid-state batteries with lithium metal anodes represent a step-change in energy storage technology, potentially doubling current energy densities while enhancing safety profiles. Concurrently, biologically inspired energy storage solutions and advanced energy harvesting integration are expected to create self-sustaining power ecosystems for next-generation wearable sensor applications.

These advancements will be critical in supporting the increasing computational and sensing demands of future wearable technologies, particularly those incorporating multiple Optimal Trade-off Elements (OTEs) for sophisticated energy budget calculations and management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!