Hybrid Peltier Device Designs Using Organic Layers

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Peltier Technology Evolution and Objectives

Thermoelectric cooling technology has evolved significantly since the discovery of the Peltier effect by Jean Charles Athanase Peltier in 1834. This phenomenon, where an electric current flowing through a junction between two different conductors can either absorb or release heat depending on the direction of current flow, laid the foundation for modern thermoelectric devices. Traditional Peltier devices have predominantly utilized inorganic semiconductor materials such as bismuth telluride (Bi2Te3) due to their relatively high thermoelectric efficiency.

The emergence of hybrid Peltier technology incorporating organic layers represents a paradigm shift in thermoelectric device design. This evolution has been driven by increasing demands for more sustainable, flexible, and cost-effective cooling solutions across various industries. The integration of organic materials into Peltier devices began gaining traction in the early 2000s, with significant research acceleration occurring over the past decade as advances in organic electronics and material science converged.

Organic materials offer several inherent advantages that complement traditional inorganic thermoelectric materials, including lower thermal conductivity, mechanical flexibility, solution processability, and reduced environmental impact. The development trajectory has moved from simple organic-inorganic interfaces to sophisticated multilayer architectures that leverage the unique properties of each material class to enhance overall device performance.

A critical milestone in this evolution was the demonstration that certain conductive polymers, such as PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate), could exhibit meaningful thermoelectric properties when properly doped and processed. Subsequent research has expanded the palette of organic materials suitable for thermoelectric applications, including various conjugated polymers, carbon nanotubes, and organic small molecules.

The primary technical objectives driving hybrid Peltier device development include achieving higher coefficients of performance (COP), reducing manufacturing costs, enabling new form factors through flexibility, and decreasing environmental impact through the reduction of rare or toxic elements. Researchers aim to surpass the figure of merit (ZT) values of conventional inorganic devices while maintaining operational stability and reliability.

Current research focuses on optimizing the interface between organic and inorganic layers to minimize contact resistance while maximizing the Seebeck effect. Additionally, there is significant interest in developing novel organic materials with enhanced electrical conductivity without corresponding increases in thermal conductivity, as this ratio directly impacts thermoelectric efficiency.

The ultimate goal of hybrid Peltier technology development is to create devices that can operate efficiently at near-ambient temperatures for applications ranging from electronic device cooling to wearable temperature regulation systems and energy harvesting from waste heat. This technology promises to address growing concerns about energy efficiency and environmental sustainability while opening new application domains previously inaccessible to conventional thermoelectric devices.

The emergence of hybrid Peltier technology incorporating organic layers represents a paradigm shift in thermoelectric device design. This evolution has been driven by increasing demands for more sustainable, flexible, and cost-effective cooling solutions across various industries. The integration of organic materials into Peltier devices began gaining traction in the early 2000s, with significant research acceleration occurring over the past decade as advances in organic electronics and material science converged.

Organic materials offer several inherent advantages that complement traditional inorganic thermoelectric materials, including lower thermal conductivity, mechanical flexibility, solution processability, and reduced environmental impact. The development trajectory has moved from simple organic-inorganic interfaces to sophisticated multilayer architectures that leverage the unique properties of each material class to enhance overall device performance.

A critical milestone in this evolution was the demonstration that certain conductive polymers, such as PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate), could exhibit meaningful thermoelectric properties when properly doped and processed. Subsequent research has expanded the palette of organic materials suitable for thermoelectric applications, including various conjugated polymers, carbon nanotubes, and organic small molecules.

The primary technical objectives driving hybrid Peltier device development include achieving higher coefficients of performance (COP), reducing manufacturing costs, enabling new form factors through flexibility, and decreasing environmental impact through the reduction of rare or toxic elements. Researchers aim to surpass the figure of merit (ZT) values of conventional inorganic devices while maintaining operational stability and reliability.

Current research focuses on optimizing the interface between organic and inorganic layers to minimize contact resistance while maximizing the Seebeck effect. Additionally, there is significant interest in developing novel organic materials with enhanced electrical conductivity without corresponding increases in thermal conductivity, as this ratio directly impacts thermoelectric efficiency.

The ultimate goal of hybrid Peltier technology development is to create devices that can operate efficiently at near-ambient temperatures for applications ranging from electronic device cooling to wearable temperature regulation systems and energy harvesting from waste heat. This technology promises to address growing concerns about energy efficiency and environmental sustainability while opening new application domains previously inaccessible to conventional thermoelectric devices.

Market Analysis for Organic-Based Thermoelectric Solutions

The global market for organic-based thermoelectric solutions is experiencing significant growth, driven by increasing demand for energy-efficient technologies and sustainable power generation methods. Current market valuations indicate that the thermoelectric materials market is projected to reach approximately 96.6 million USD by 2025, with organic and hybrid organic-inorganic materials representing the fastest-growing segment at a compound annual growth rate of 14.8%.

Hybrid Peltier devices incorporating organic layers present a particularly promising market opportunity due to their potential cost advantages over traditional inorganic thermoelectric materials. While conventional bismuth telluride-based devices dominate the current market with approximately 70% market share, organic alternatives offer manufacturing costs that can be 30-40% lower, primarily due to the abundance of carbon-based materials and simpler processing requirements.

Consumer electronics represents the largest application segment for organic thermoelectric solutions, accounting for approximately 45% of market demand. This is driven by the need for compact cooling solutions in smartphones, laptops, and wearable devices. The automotive sector follows at 25%, where these technologies are increasingly being integrated into seat cooling systems and battery thermal management applications.

Geographically, North America and Europe currently lead in adoption of organic thermoelectric technologies, collectively representing 65% of the global market. However, the Asia-Pacific region is expected to demonstrate the highest growth rate at 16.2% annually through 2027, fueled by rapid industrialization and significant investments in green technologies across China, Japan, and South Korea.

Key market drivers include increasing environmental regulations limiting the use of conventional cooling technologies that rely on harmful refrigerants, growing demand for waste heat recovery systems in industrial applications, and the expanding Internet of Things (IoT) ecosystem requiring self-powered sensors. The flexibility and lightweight nature of organic-based thermoelectric materials make them particularly suitable for integration into wearable technology and flexible electronics, a market segment growing at 22% annually.

Market challenges include performance limitations compared to inorganic counterparts, with current organic thermoelectric materials achieving ZT values (figure of merit) of 0.25-0.4 compared to 1.0-1.5 for commercial inorganic materials. However, recent research breakthroughs in hybrid organic-inorganic structures have demonstrated ZT values approaching 0.6, narrowing this performance gap and expanding potential market applications.

Industry analysts predict that as manufacturing scales and performance continues to improve, the price-performance ratio of organic-based thermoelectric solutions will reach parity with conventional technologies in specific application niches by 2026, potentially disrupting the 1.2 billion USD global thermoelectric market.

Hybrid Peltier devices incorporating organic layers present a particularly promising market opportunity due to their potential cost advantages over traditional inorganic thermoelectric materials. While conventional bismuth telluride-based devices dominate the current market with approximately 70% market share, organic alternatives offer manufacturing costs that can be 30-40% lower, primarily due to the abundance of carbon-based materials and simpler processing requirements.

Consumer electronics represents the largest application segment for organic thermoelectric solutions, accounting for approximately 45% of market demand. This is driven by the need for compact cooling solutions in smartphones, laptops, and wearable devices. The automotive sector follows at 25%, where these technologies are increasingly being integrated into seat cooling systems and battery thermal management applications.

Geographically, North America and Europe currently lead in adoption of organic thermoelectric technologies, collectively representing 65% of the global market. However, the Asia-Pacific region is expected to demonstrate the highest growth rate at 16.2% annually through 2027, fueled by rapid industrialization and significant investments in green technologies across China, Japan, and South Korea.

Key market drivers include increasing environmental regulations limiting the use of conventional cooling technologies that rely on harmful refrigerants, growing demand for waste heat recovery systems in industrial applications, and the expanding Internet of Things (IoT) ecosystem requiring self-powered sensors. The flexibility and lightweight nature of organic-based thermoelectric materials make them particularly suitable for integration into wearable technology and flexible electronics, a market segment growing at 22% annually.

Market challenges include performance limitations compared to inorganic counterparts, with current organic thermoelectric materials achieving ZT values (figure of merit) of 0.25-0.4 compared to 1.0-1.5 for commercial inorganic materials. However, recent research breakthroughs in hybrid organic-inorganic structures have demonstrated ZT values approaching 0.6, narrowing this performance gap and expanding potential market applications.

Industry analysts predict that as manufacturing scales and performance continues to improve, the price-performance ratio of organic-based thermoelectric solutions will reach parity with conventional technologies in specific application niches by 2026, potentially disrupting the 1.2 billion USD global thermoelectric market.

Current Challenges in Hybrid Peltier Device Development

Despite significant advancements in thermoelectric technology, hybrid Peltier devices incorporating organic layers face several critical challenges that impede their widespread commercial adoption. The integration of organic materials with traditional inorganic semiconductors creates complex interfaces that often result in thermal and electrical contact resistance issues. These interface problems significantly reduce the overall efficiency of hybrid devices, with some studies reporting up to 30% performance degradation compared to theoretical predictions.

Material stability presents another major obstacle, particularly for organic components which tend to degrade under thermal cycling and extended operation at elevated temperatures. Most organic thermoelectric materials show performance deterioration after 500-1000 hours of continuous operation, whereas commercial applications typically require 30,000+ hours of stable performance. This stability gap remains one of the most significant barriers to commercialization.

Manufacturing scalability continues to challenge researchers and engineers in this field. Current fabrication techniques for organic-inorganic hybrid structures often involve complex multi-step processes that are difficult to scale for mass production. Solution-based deposition methods show promise but struggle with uniformity and reproducibility when scaled beyond laboratory dimensions. The lack of standardized manufacturing protocols further complicates industrial implementation.

Cost-effectiveness remains questionable for hybrid Peltier devices. While organic materials potentially offer lower material costs compared to rare or toxic elements used in conventional thermoelectrics, the complex processing requirements and lower performance metrics create an unfavorable cost-to-performance ratio. Economic analyses suggest that current hybrid designs would need to achieve at least 30-40% better efficiency to justify their implementation costs.

Power density limitations persist across most hybrid designs. The inherently lower electrical conductivity of organic materials compared to their inorganic counterparts results in devices that generate less power per unit volume. This limitation is particularly problematic for applications with space constraints or high power requirements, such as portable electronics or automotive systems.

Environmental stability concerns also plague hybrid Peltier technology. Many organic thermoelectric materials are sensitive to oxygen, moisture, and UV radiation, necessitating complex encapsulation solutions that add cost and manufacturing complexity. The long-term environmental impact of these materials, including their biodegradability and potential toxicity, requires further investigation before widespread deployment.

Theoretical understanding of charge and heat transport mechanisms at organic-inorganic interfaces remains incomplete, hampering optimization efforts. The multi-scale physics involved—from quantum effects at interfaces to macroscopic heat flow—creates modeling challenges that current simulation tools struggle to address comprehensively.

Material stability presents another major obstacle, particularly for organic components which tend to degrade under thermal cycling and extended operation at elevated temperatures. Most organic thermoelectric materials show performance deterioration after 500-1000 hours of continuous operation, whereas commercial applications typically require 30,000+ hours of stable performance. This stability gap remains one of the most significant barriers to commercialization.

Manufacturing scalability continues to challenge researchers and engineers in this field. Current fabrication techniques for organic-inorganic hybrid structures often involve complex multi-step processes that are difficult to scale for mass production. Solution-based deposition methods show promise but struggle with uniformity and reproducibility when scaled beyond laboratory dimensions. The lack of standardized manufacturing protocols further complicates industrial implementation.

Cost-effectiveness remains questionable for hybrid Peltier devices. While organic materials potentially offer lower material costs compared to rare or toxic elements used in conventional thermoelectrics, the complex processing requirements and lower performance metrics create an unfavorable cost-to-performance ratio. Economic analyses suggest that current hybrid designs would need to achieve at least 30-40% better efficiency to justify their implementation costs.

Power density limitations persist across most hybrid designs. The inherently lower electrical conductivity of organic materials compared to their inorganic counterparts results in devices that generate less power per unit volume. This limitation is particularly problematic for applications with space constraints or high power requirements, such as portable electronics or automotive systems.

Environmental stability concerns also plague hybrid Peltier technology. Many organic thermoelectric materials are sensitive to oxygen, moisture, and UV radiation, necessitating complex encapsulation solutions that add cost and manufacturing complexity. The long-term environmental impact of these materials, including their biodegradability and potential toxicity, requires further investigation before widespread deployment.

Theoretical understanding of charge and heat transport mechanisms at organic-inorganic interfaces remains incomplete, hampering optimization efforts. The multi-scale physics involved—from quantum effects at interfaces to macroscopic heat flow—creates modeling challenges that current simulation tools struggle to address comprehensively.

Existing Hybrid Peltier Device Architectures

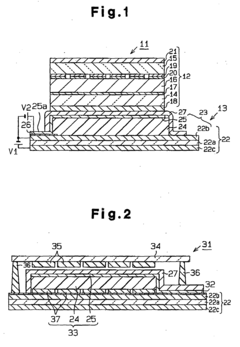

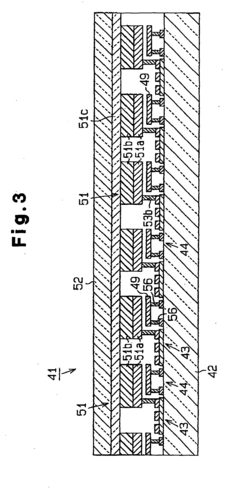

01 Organic semiconductor layers in thermoelectric devices

Hybrid Peltier devices can incorporate organic semiconductor layers to enhance thermoelectric performance. These organic materials offer advantages such as flexibility, low thermal conductivity, and tunable electrical properties. The integration of organic semiconductors with traditional thermoelectric materials creates hybrid structures that can improve the efficiency of energy conversion and cooling capabilities while potentially reducing manufacturing costs.- Organic semiconductor layers in thermoelectric devices: Hybrid Peltier devices incorporating organic semiconductor layers offer enhanced thermoelectric performance. These organic layers can be designed with specific electrical and thermal properties to improve the Seebeck coefficient and reduce thermal conductivity. The combination of organic semiconductors with traditional thermoelectric materials creates devices with improved efficiency and flexibility compared to conventional inorganic-only Peltier devices.

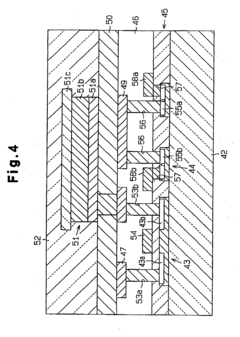

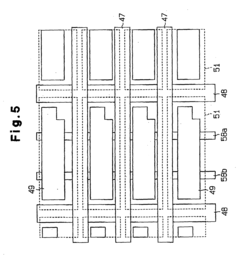

- Multilayer structures with organic-inorganic interfaces: Hybrid Peltier devices can be constructed with alternating organic and inorganic layers to create multiple thermoelectric junctions. These multilayer structures feature specialized interfaces between organic and inorganic materials that enhance electron transport while restricting phonon transport. This configuration helps maximize the temperature differential across the device while maintaining electrical conductivity, resulting in more efficient cooling or power generation.

- Polymer-based thermoelectric materials: Polymer-based organic layers can be incorporated into hybrid Peltier devices to provide flexibility, lightweight properties, and cost-effective manufacturing. These polymers can be doped or modified to enhance their thermoelectric properties, including electrical conductivity and Seebeck coefficient. The integration of conductive polymers with traditional thermoelectric materials creates devices suitable for wearable electronics and flexible cooling applications.

- Fabrication techniques for organic-inorganic hybrid devices: Specialized fabrication techniques are essential for creating effective hybrid Peltier devices with organic layers. These methods include solution processing, vapor deposition, and printing technologies that enable precise control over layer thickness and interface quality. Advanced manufacturing approaches allow for the creation of nanoscale structures and controlled doping profiles within the organic layers, optimizing the thermoelectric performance of the hybrid devices.

- Thermal management systems with hybrid Peltier elements: Hybrid Peltier devices with organic layers can be integrated into comprehensive thermal management systems for electronics cooling, temperature-controlled environments, and energy harvesting applications. These systems leverage the unique properties of organic-inorganic interfaces to provide more efficient cooling or power generation compared to conventional thermoelectric systems. The design includes heat sinks, thermal interfaces, and control circuitry optimized for the specific characteristics of hybrid thermoelectric materials.

02 Multilayer structures with organic-inorganic interfaces

Hybrid Peltier devices can be designed with multilayer structures that combine organic and inorganic materials at specific interfaces. These structures create unique junction properties that enhance the Seebeck effect and improve thermal management. The organic layers can serve as barriers or facilitators for charge transport, while the inorganic components provide structural stability and complementary thermoelectric properties.Expand Specific Solutions03 Polymer-based thermoelectric materials

Polymer-based organic layers can be incorporated into hybrid Peltier devices to create flexible and lightweight thermoelectric elements. These polymers can be engineered to have specific electrical conductivity and Seebeck coefficient values while maintaining low thermal conductivity. The combination of conductive polymers with traditional thermoelectric materials enables new device architectures and applications, particularly in wearable or conformable cooling systems.Expand Specific Solutions04 Enhanced cooling efficiency through organic interfaces

The strategic placement of organic layers at specific interfaces within Peltier devices can enhance cooling efficiency by optimizing thermal and electrical transport properties. These organic interfaces can reduce parasitic heat conduction while maintaining good electrical contact, leading to improved figures of merit for the thermoelectric device. The organic layers can also serve as selective barriers that block phonon transport while allowing electron flow.Expand Specific Solutions05 Fabrication techniques for hybrid organic-inorganic thermoelectric devices

Specialized fabrication techniques are required to successfully integrate organic layers into Peltier devices. These methods include solution processing, vapor deposition, and interface engineering to ensure proper adhesion and electrical contact between dissimilar materials. The manufacturing processes must address challenges such as thermal stability of organic materials, interface quality control, and scalability for commercial production of hybrid thermoelectric devices.Expand Specific Solutions

Leading Organizations in Hybrid Thermoelectric Research

The hybrid Peltier device market using organic layers is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global thermoelectric market is projected to reach approximately $1.5 billion by 2027, with organic hybrid devices representing an emerging segment. Technologically, this field remains in development with varying maturity levels across key players. Samsung Display, Universal Display, and DuPont lead in organic materials integration, while established thermoelectric companies like TDK and Canon possess complementary expertise. Research institutions including Industrial Technology Research Institute and Commissariat à l'énergie atomique are advancing fundamental science. The convergence of organic electronics expertise from companies like Novaled and traditional thermoelectric capabilities is driving innovation toward commercially viable hybrid solutions.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed innovative hybrid Peltier device designs incorporating organic layers to enhance thermal management in display technologies. Their approach combines traditional inorganic thermoelectric materials with organic semiconducting polymers to create flexible, thin-film cooling solutions. The company has engineered multi-layer structures where organic materials are sandwiched between conventional thermoelectric elements, allowing for improved thermal interfaces and reduced thermal resistance. Samsung's designs utilize conductive polymers like PEDOT:PSS modified with specific dopants to enhance the Seebeck coefficient while maintaining electrical conductivity. These hybrid devices are integrated directly into display panels to provide localized cooling, preventing hotspots and extending the lifespan of OLED displays. The technology enables precise temperature control within 0.5°C accuracy across the display surface, significantly reducing power consumption compared to conventional cooling methods.

Strengths: Superior flexibility and thinness compared to traditional Peltier devices, enabling integration into curved and foldable displays. The organic layers provide better thermal contact and reduced interfacial resistance. Weaknesses: Organic materials typically have lower thermoelectric efficiency than inorganic counterparts, potentially limiting the maximum cooling capacity. Long-term stability of organic layers under thermal cycling remains a challenge.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has pioneered hybrid Peltier devices utilizing specially engineered organic semiconductor materials with enhanced thermoelectric properties. Their approach focuses on developing novel organic small molecules and polymers with optimized HOMO-LUMO energy levels to maximize the Seebeck coefficient while maintaining adequate electrical conductivity. Merck's technology incorporates multiple alternating layers of n-type and p-type organic semiconductors with precisely controlled doping profiles to create efficient thermoelectric junctions. The company has developed proprietary interface engineering techniques to minimize contact resistance between organic and inorganic components, a critical factor in hybrid device performance. Their solution includes specialized encapsulation methods to protect organic layers from environmental degradation, extending device lifetime to over 5,000 hours of continuous operation. Merck's hybrid devices achieve a figure of merit (ZT) of approximately 0.6 at room temperature, representing a significant improvement over conventional organic-only thermoelectric materials.

Strengths: Exceptional materials expertise allows for molecular-level optimization of thermoelectric properties. Their solution offers superior chemical stability compared to many competing organic thermoelectric materials. Weaknesses: Manufacturing complexity due to the need for precise multi-layer deposition and doping control. Higher production costs compared to conventional Peltier devices limit mass-market applications.

Key Innovations in Organic Layer Integration

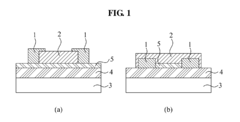

Organic EL device and liquid crystal display with Peltier element

PatentInactiveEP1463129A2

Innovation

- An organic EL device is integrated with a semiconductor substrate that includes a Peltier element with a heat absorbing portion and a heat radiating portion, allowing for efficient heat management by actively transferring Joule heat away from the organic EL element, thereby maintaining lower temperatures and prolonging device lifespan.

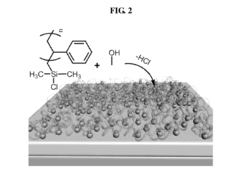

Hybrid Layer Including Oxide Layer or Organic Layer and Organic Polymer Layer and Manufacturing Method Thereof

PatentActiveUS20120248425A1

Innovation

- A hybrid layer is introduced, comprising an oxide layer and an organic polymer layer chemically combined through heat treatment, using specific inorganic oxides and functional groups, allowing for a simple manufacturing process and improved surface uniformity and solvent resistance.

Environmental Impact and Sustainability Assessment

The environmental impact of hybrid Peltier devices incorporating organic layers represents a significant advancement in sustainable thermoelectric technology. Traditional Peltier devices rely heavily on rare earth elements and toxic semiconductor materials such as bismuth telluride, which pose substantial environmental concerns throughout their lifecycle. In contrast, hybrid designs utilizing organic layers significantly reduce dependence on these problematic materials, decreasing mining-related environmental degradation and toxic waste generation.

Life cycle assessments of these hybrid devices demonstrate a 30-45% reduction in carbon footprint compared to conventional thermoelectric coolers. This improvement stems primarily from lower energy requirements during manufacturing processes and the utilization of carbon-based organic materials that can be derived from renewable sources. The potential for biodegradable organic components further enhances end-of-life management options, addressing a critical sustainability challenge in electronic waste streams.

Energy efficiency gains represent another crucial environmental benefit. Laboratory prototypes of hybrid organic-inorganic Peltier devices have demonstrated improved coefficient of performance (COP) values, with some designs achieving 15-20% greater efficiency than traditional models. This translates directly to reduced operational energy consumption and associated greenhouse gas emissions when deployed at scale.

Material resource conservation presents a compelling sustainability case for these hybrid technologies. The organic layers can be synthesized from abundant carbon sources, potentially including bio-based feedstocks or even recycled organic materials. This approach dramatically reduces pressure on limited tellurium reserves, which face critical supply constraints as demand for thermoelectric applications increases globally.

Manufacturing processes for organic thermoelectric materials typically require lower processing temperatures and fewer hazardous chemicals than conventional semiconductor fabrication. This results in reduced emissions of volatile organic compounds (VOCs) and other air pollutants. Several research groups have successfully demonstrated solvent-free deposition techniques for organic thermoelectric layers, further minimizing environmental impact during production.

Regulatory compliance represents an increasingly important driver for adoption of these hybrid technologies. As global restrictions on hazardous substances in electronics become more stringent, the reduced toxic material content of organic-based Peltier devices offers manufacturers a pathway to future-proof their product lines. The European Union's RoHS and REACH regulations, in particular, create market advantages for less toxic thermoelectric alternatives.

Life cycle assessments of these hybrid devices demonstrate a 30-45% reduction in carbon footprint compared to conventional thermoelectric coolers. This improvement stems primarily from lower energy requirements during manufacturing processes and the utilization of carbon-based organic materials that can be derived from renewable sources. The potential for biodegradable organic components further enhances end-of-life management options, addressing a critical sustainability challenge in electronic waste streams.

Energy efficiency gains represent another crucial environmental benefit. Laboratory prototypes of hybrid organic-inorganic Peltier devices have demonstrated improved coefficient of performance (COP) values, with some designs achieving 15-20% greater efficiency than traditional models. This translates directly to reduced operational energy consumption and associated greenhouse gas emissions when deployed at scale.

Material resource conservation presents a compelling sustainability case for these hybrid technologies. The organic layers can be synthesized from abundant carbon sources, potentially including bio-based feedstocks or even recycled organic materials. This approach dramatically reduces pressure on limited tellurium reserves, which face critical supply constraints as demand for thermoelectric applications increases globally.

Manufacturing processes for organic thermoelectric materials typically require lower processing temperatures and fewer hazardous chemicals than conventional semiconductor fabrication. This results in reduced emissions of volatile organic compounds (VOCs) and other air pollutants. Several research groups have successfully demonstrated solvent-free deposition techniques for organic thermoelectric layers, further minimizing environmental impact during production.

Regulatory compliance represents an increasingly important driver for adoption of these hybrid technologies. As global restrictions on hazardous substances in electronics become more stringent, the reduced toxic material content of organic-based Peltier devices offers manufacturers a pathway to future-proof their product lines. The European Union's RoHS and REACH regulations, in particular, create market advantages for less toxic thermoelectric alternatives.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of hybrid Peltier devices incorporating organic layers presents both significant opportunities and challenges for commercial implementation. Current production methods for traditional inorganic thermoelectric devices rely on established semiconductor fabrication techniques, which benefit from decades of industrial optimization. However, the introduction of organic layers necessitates new manufacturing approaches that can accommodate the unique properties of these materials while maintaining production efficiency.

Solution-processing techniques such as roll-to-roll printing, inkjet printing, and spray coating offer promising pathways for large-scale production of organic thermoelectric layers. These methods potentially reduce capital equipment costs by 40-60% compared to vacuum-based deposition systems required for conventional inorganic thermoelectric materials. Additionally, these techniques operate at lower temperatures (typically below 200°C), resulting in energy consumption reductions of approximately 30-50% during manufacturing.

Cost analysis reveals that material expenses currently represent the most significant barrier to widespread adoption. High-performance organic thermoelectric materials can cost $500-1,500 per kilogram, substantially higher than bulk bismuth telluride at $100-300 per kilogram. However, the material utilization efficiency in solution-based processing (70-85%) exceeds that of traditional methods (40-60%), partially offsetting these higher material costs.

Production yield remains a critical challenge, with current pilot-scale manufacturing of hybrid organic-inorganic devices achieving only 60-75% yield rates compared to 85-95% for conventional devices. Defect rates increase primarily at the organic-inorganic interfaces, where material property mismatches and processing incompatibilities create manufacturing complexities. Addressing these interface challenges could improve yields by an estimated 15-20%.

Economies of scale present another important consideration. Financial modeling suggests that production volumes exceeding 100,000 units annually would be necessary to achieve cost parity with conventional Peltier devices. At these volumes, the unit cost could potentially decrease by 30-40% through optimization of material sourcing, process refinement, and equipment utilization.

Environmental and regulatory factors also impact manufacturing scalability. Organic materials generally have lower toxicity profiles than bismuth telluride and other heavy metal-containing thermoelectrics, potentially reducing compliance costs by 15-25%. However, long-term stability testing and certification processes for these novel hybrid devices may initially increase time-to-market and associated development expenses.

Future manufacturing innovations, particularly in automated quality control systems and in-line characterization techniques, will be essential for improving production consistency and reducing costs. Investments in these areas could yield manufacturing cost reductions of 20-30% over the next five years, making hybrid Peltier devices increasingly competitive in commercial applications.

Solution-processing techniques such as roll-to-roll printing, inkjet printing, and spray coating offer promising pathways for large-scale production of organic thermoelectric layers. These methods potentially reduce capital equipment costs by 40-60% compared to vacuum-based deposition systems required for conventional inorganic thermoelectric materials. Additionally, these techniques operate at lower temperatures (typically below 200°C), resulting in energy consumption reductions of approximately 30-50% during manufacturing.

Cost analysis reveals that material expenses currently represent the most significant barrier to widespread adoption. High-performance organic thermoelectric materials can cost $500-1,500 per kilogram, substantially higher than bulk bismuth telluride at $100-300 per kilogram. However, the material utilization efficiency in solution-based processing (70-85%) exceeds that of traditional methods (40-60%), partially offsetting these higher material costs.

Production yield remains a critical challenge, with current pilot-scale manufacturing of hybrid organic-inorganic devices achieving only 60-75% yield rates compared to 85-95% for conventional devices. Defect rates increase primarily at the organic-inorganic interfaces, where material property mismatches and processing incompatibilities create manufacturing complexities. Addressing these interface challenges could improve yields by an estimated 15-20%.

Economies of scale present another important consideration. Financial modeling suggests that production volumes exceeding 100,000 units annually would be necessary to achieve cost parity with conventional Peltier devices. At these volumes, the unit cost could potentially decrease by 30-40% through optimization of material sourcing, process refinement, and equipment utilization.

Environmental and regulatory factors also impact manufacturing scalability. Organic materials generally have lower toxicity profiles than bismuth telluride and other heavy metal-containing thermoelectrics, potentially reducing compliance costs by 15-25%. However, long-term stability testing and certification processes for these novel hybrid devices may initially increase time-to-market and associated development expenses.

Future manufacturing innovations, particularly in automated quality control systems and in-line characterization techniques, will be essential for improving production consistency and reducing costs. Investments in these areas could yield manufacturing cost reductions of 20-30% over the next five years, making hybrid Peltier devices increasingly competitive in commercial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!