Encapsulation And Reliability Engineering For Wearable TEGs

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Encapsulation Background and Objectives

Thermoelectric generators (TEGs) have emerged as a promising technology for harvesting waste heat and converting it into usable electrical energy. The evolution of wearable TEGs represents a significant advancement in this field, offering potential applications in powering personal electronic devices, medical monitoring systems, and Internet of Things (IoT) sensors. The development trajectory of wearable TEGs has been characterized by continuous improvements in materials, design configurations, and manufacturing techniques aimed at enhancing energy conversion efficiency and practical applicability.

The fundamental principle behind TEGs is the Seebeck effect, discovered in the early 19th century, which describes the generation of an electrical voltage in response to a temperature gradient across certain materials. While traditional TEGs have been rigid and bulky, recent technological breakthroughs have enabled the creation of flexible, lightweight, and conformable devices suitable for integration into wearable systems. This transition has been facilitated by innovations in nanomaterials, thin-film deposition techniques, and flexible substrate technologies.

Encapsulation represents a critical aspect of wearable TEG development, serving as the protective barrier between sensitive thermoelectric materials and the harsh external environment. Effective encapsulation must address multiple challenges including moisture resistance, mechanical durability, thermal management, and biocompatibility while maintaining optimal thermoelectric performance. The historical progression of encapsulation technologies has evolved from basic polymer coatings to sophisticated multi-layer systems incorporating advanced materials such as parylene, polyimide, and specialized silicones.

The primary technical objectives for wearable TEG encapsulation include developing solutions that provide comprehensive environmental protection while maintaining thermal conductivity pathways essential for device operation. Specifically, encapsulation systems must facilitate efficient heat transfer between the human body and the TEG's hot side while allowing effective heat dissipation from the cold side. Additionally, these systems must accommodate the mechanical stresses associated with body movement and daily wear conditions without compromising electrical connections or thermoelectric performance.

Current research trends in TEG encapsulation focus on achieving longer operational lifetimes under real-world conditions, enhancing resistance to sweat and other bodily fluids, minimizing thermal resistance at material interfaces, and developing manufacturing processes suitable for mass production. The integration of self-healing materials, breathable membranes, and adaptive thermal management systems represents emerging directions in this field. These innovations aim to address the persistent reliability challenges that have limited widespread commercial adoption of wearable TEG technology.

The ultimate goal of wearable TEG encapsulation research is to enable devices that can maintain stable performance for extended periods (years rather than months) while being subjected to the variable conditions of daily human activity. This requires interdisciplinary approaches combining materials science, thermal engineering, and human factors considerations to create solutions that are both technically effective and practically viable for end-users.

The fundamental principle behind TEGs is the Seebeck effect, discovered in the early 19th century, which describes the generation of an electrical voltage in response to a temperature gradient across certain materials. While traditional TEGs have been rigid and bulky, recent technological breakthroughs have enabled the creation of flexible, lightweight, and conformable devices suitable for integration into wearable systems. This transition has been facilitated by innovations in nanomaterials, thin-film deposition techniques, and flexible substrate technologies.

Encapsulation represents a critical aspect of wearable TEG development, serving as the protective barrier between sensitive thermoelectric materials and the harsh external environment. Effective encapsulation must address multiple challenges including moisture resistance, mechanical durability, thermal management, and biocompatibility while maintaining optimal thermoelectric performance. The historical progression of encapsulation technologies has evolved from basic polymer coatings to sophisticated multi-layer systems incorporating advanced materials such as parylene, polyimide, and specialized silicones.

The primary technical objectives for wearable TEG encapsulation include developing solutions that provide comprehensive environmental protection while maintaining thermal conductivity pathways essential for device operation. Specifically, encapsulation systems must facilitate efficient heat transfer between the human body and the TEG's hot side while allowing effective heat dissipation from the cold side. Additionally, these systems must accommodate the mechanical stresses associated with body movement and daily wear conditions without compromising electrical connections or thermoelectric performance.

Current research trends in TEG encapsulation focus on achieving longer operational lifetimes under real-world conditions, enhancing resistance to sweat and other bodily fluids, minimizing thermal resistance at material interfaces, and developing manufacturing processes suitable for mass production. The integration of self-healing materials, breathable membranes, and adaptive thermal management systems represents emerging directions in this field. These innovations aim to address the persistent reliability challenges that have limited widespread commercial adoption of wearable TEG technology.

The ultimate goal of wearable TEG encapsulation research is to enable devices that can maintain stable performance for extended periods (years rather than months) while being subjected to the variable conditions of daily human activity. This requires interdisciplinary approaches combining materials science, thermal engineering, and human factors considerations to create solutions that are both technically effective and practically viable for end-users.

Market Analysis for Wearable Energy Harvesting Solutions

The wearable energy harvesting market is experiencing significant growth, driven by the increasing adoption of wearable devices across consumer electronics, healthcare, and industrial sectors. The global market for wearable energy harvesting solutions was valued at approximately $400 million in 2022 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate of 20.3%. Thermoelectric generators (TEGs) constitute a substantial segment of this market, accounting for roughly 25% of the total revenue.

Consumer demand for extended battery life and reduced charging frequency in wearable devices represents the primary market driver. End-users increasingly prioritize devices that can operate for extended periods without requiring frequent recharging, creating a strong market pull for efficient energy harvesting technologies like TEGs. Healthcare applications, particularly continuous health monitoring devices, represent the fastest-growing segment with a 24.7% CAGR, as these applications benefit significantly from the consistent power generation capabilities of body heat-powered TEGs.

Regional analysis indicates North America currently leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to increasing manufacturing capabilities and rising consumer adoption of wearable technologies in countries like China, South Korea, and Japan.

Market segmentation by application reveals diverse opportunities for wearable TEGs. Smartwatches and fitness trackers represent the largest current application segment (42%), followed by medical monitoring devices (27%), industrial wearables (18%), and military applications (13%). The medical segment is projected to overtake consumer electronics by 2027 due to the critical need for reliable power sources in healthcare monitoring devices.

Key market challenges include price sensitivity among consumers, with current TEG solutions adding $15-30 to device costs, and competition from alternative energy harvesting technologies such as photovoltaic, piezoelectric, and RF energy harvesting solutions. The market also faces technical barriers related to power density limitations, with current commercial wearable TEGs typically generating only 10-50 μW/cm² under normal body-ambient temperature differentials.

Despite these challenges, market forecasts remain optimistic due to ongoing technological advancements in TEG materials and encapsulation techniques. The increasing integration of IoT functionality in wearables and the growing demand for sustainable power solutions are expected to sustain market growth through 2030, with particular expansion in healthcare, sports performance monitoring, and industrial safety applications.

Consumer demand for extended battery life and reduced charging frequency in wearable devices represents the primary market driver. End-users increasingly prioritize devices that can operate for extended periods without requiring frequent recharging, creating a strong market pull for efficient energy harvesting technologies like TEGs. Healthcare applications, particularly continuous health monitoring devices, represent the fastest-growing segment with a 24.7% CAGR, as these applications benefit significantly from the consistent power generation capabilities of body heat-powered TEGs.

Regional analysis indicates North America currently leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to increasing manufacturing capabilities and rising consumer adoption of wearable technologies in countries like China, South Korea, and Japan.

Market segmentation by application reveals diverse opportunities for wearable TEGs. Smartwatches and fitness trackers represent the largest current application segment (42%), followed by medical monitoring devices (27%), industrial wearables (18%), and military applications (13%). The medical segment is projected to overtake consumer electronics by 2027 due to the critical need for reliable power sources in healthcare monitoring devices.

Key market challenges include price sensitivity among consumers, with current TEG solutions adding $15-30 to device costs, and competition from alternative energy harvesting technologies such as photovoltaic, piezoelectric, and RF energy harvesting solutions. The market also faces technical barriers related to power density limitations, with current commercial wearable TEGs typically generating only 10-50 μW/cm² under normal body-ambient temperature differentials.

Despite these challenges, market forecasts remain optimistic due to ongoing technological advancements in TEG materials and encapsulation techniques. The increasing integration of IoT functionality in wearables and the growing demand for sustainable power solutions are expected to sustain market growth through 2030, with particular expansion in healthcare, sports performance monitoring, and industrial safety applications.

Current Challenges in TEG Encapsulation Technology

Despite significant advancements in thermoelectric generator (TEG) technology, encapsulation remains one of the most critical challenges for wearable applications. The primary difficulty lies in creating encapsulation solutions that simultaneously provide mechanical protection while maintaining optimal thermal performance. Current encapsulation materials often create thermal barriers that significantly reduce the temperature gradient across the TEG, directly diminishing power output. This fundamental trade-off between protection and performance represents the central challenge in the field.

Moisture ingress presents another substantial obstacle for wearable TEG encapsulation. Human perspiration and environmental humidity can penetrate inadequately sealed devices, leading to electrical shorts, corrosion of thermoelectric materials, and degradation of internal connections. While hermetic sealing would solve this issue, implementing such solutions in flexible, body-conforming devices remains technically challenging and cost-prohibitive for mass production.

Mechanical stress resistance poses a significant challenge as wearable TEGs must withstand continuous flexing, compression, and torsional forces during normal use. Current encapsulation materials often fail to provide sufficient protection against these mechanical stresses without becoming excessively rigid, which compromises wearability and user comfort. The development of materials that can absorb mechanical energy while remaining thermally conductive represents an ongoing research priority.

Biocompatibility and skin-contact safety requirements add another layer of complexity. Encapsulation materials must not only protect the device but also ensure user safety through non-toxicity, hypoallergenic properties, and prevention of skin irritation. Many high-performance encapsulation materials that excel in thermal or mechanical properties fail to meet these biocompatibility standards, limiting material selection options.

Long-term reliability under varying environmental conditions remains problematic. Wearable TEGs experience significant temperature fluctuations, exposure to UV radiation, and contact with various chemicals (including cosmetics, lotions, and cleaning agents). Current encapsulation technologies show accelerated degradation under these conditions, with most solutions failing to maintain performance beyond 6-12 months of regular use.

Manufacturing scalability presents additional challenges, as many laboratory-developed encapsulation techniques involve complex multi-step processes that are difficult to implement in mass production. The precision required for effective encapsulation while maintaining thermal performance often necessitates specialized equipment and tight quality control, driving up production costs and limiting commercial viability.

Moisture ingress presents another substantial obstacle for wearable TEG encapsulation. Human perspiration and environmental humidity can penetrate inadequately sealed devices, leading to electrical shorts, corrosion of thermoelectric materials, and degradation of internal connections. While hermetic sealing would solve this issue, implementing such solutions in flexible, body-conforming devices remains technically challenging and cost-prohibitive for mass production.

Mechanical stress resistance poses a significant challenge as wearable TEGs must withstand continuous flexing, compression, and torsional forces during normal use. Current encapsulation materials often fail to provide sufficient protection against these mechanical stresses without becoming excessively rigid, which compromises wearability and user comfort. The development of materials that can absorb mechanical energy while remaining thermally conductive represents an ongoing research priority.

Biocompatibility and skin-contact safety requirements add another layer of complexity. Encapsulation materials must not only protect the device but also ensure user safety through non-toxicity, hypoallergenic properties, and prevention of skin irritation. Many high-performance encapsulation materials that excel in thermal or mechanical properties fail to meet these biocompatibility standards, limiting material selection options.

Long-term reliability under varying environmental conditions remains problematic. Wearable TEGs experience significant temperature fluctuations, exposure to UV radiation, and contact with various chemicals (including cosmetics, lotions, and cleaning agents). Current encapsulation technologies show accelerated degradation under these conditions, with most solutions failing to maintain performance beyond 6-12 months of regular use.

Manufacturing scalability presents additional challenges, as many laboratory-developed encapsulation techniques involve complex multi-step processes that are difficult to implement in mass production. The precision required for effective encapsulation while maintaining thermal performance often necessitates specialized equipment and tight quality control, driving up production costs and limiting commercial viability.

Existing Encapsulation Methods for Wearable TEGs

01 Flexible encapsulation materials for wearable TEGs

Flexible encapsulation materials are crucial for wearable thermoelectric generators to ensure both comfort and durability. These materials protect the TEG components from environmental factors while maintaining flexibility for body movement. Polymers such as PDMS, polyimide, and silicone elastomers are commonly used as they provide waterproofing, thermal stability, and mechanical flexibility. These encapsulation materials also help in maintaining the thermal gradient necessary for efficient energy harvesting while being comfortable for long-term wear.- Encapsulation materials for wearable TEGs: Various materials are used for encapsulating wearable thermoelectric generators to protect them from environmental factors while maintaining flexibility and comfort. These materials include polymers, elastomers, and composite materials that provide waterproofing, mechanical protection, and thermal insulation. The encapsulation materials must be biocompatible for skin contact and maintain their properties during repeated mechanical deformation when worn on the body.

- Reliability testing methods for wearable TEGs: Specific testing protocols have been developed to evaluate the reliability of wearable thermoelectric generators under various conditions. These include accelerated aging tests, mechanical stress tests (bending, stretching, twisting), thermal cycling tests, and humidity resistance tests. Long-term performance evaluation methods assess power output stability, material degradation, and connection integrity over extended periods of use in conditions that simulate real-world wearable applications.

- Flexible interconnection technologies: Advanced interconnection technologies are crucial for maintaining electrical connections in wearable TEGs during movement and deformation. These include stretchable conductive materials, liquid metal interconnects, and serpentine wire patterns that can withstand repeated bending and stretching. The reliability of these connections directly impacts the overall performance and lifespan of wearable TEGs, with innovations focusing on minimizing resistance changes during mechanical deformation.

- Thermal management systems for wearable TEGs: Specialized thermal management systems are designed to optimize the temperature gradient across wearable TEGs while maintaining user comfort. These systems include heat spreaders, thermal interface materials, and innovative heat sink designs that can conform to body contours. Effective thermal management is essential for maximizing power generation efficiency while preventing overheating or uncomfortable temperature sensations for the wearer.

- Self-healing and fault-tolerant designs: Advanced wearable TEGs incorporate self-healing materials and fault-tolerant circuit designs to improve long-term reliability. These innovations include self-repairing polymers that can recover from minor damage, redundant circuit paths that maintain functionality even when some components fail, and adaptive power management systems that can reconfigure to optimize performance under changing conditions or partial damage. These approaches significantly extend the operational lifetime of wearable TEGs in challenging environments.

02 Reliability enhancement techniques for wearable TEGs

Various techniques are employed to enhance the reliability of wearable thermoelectric generators under real-world conditions. These include strain-resistant interconnects, redundant circuit designs, and self-healing materials that can withstand repeated mechanical deformation. Advanced testing protocols simulate washing, bending, and stretching to ensure durability. Thermal cycling resistance is particularly important as TEGs operate across temperature gradients. Reliability enhancement also involves protection against sweat, moisture, and other bodily fluids that could degrade performance over time.Expand Specific Solutions03 Thermal management systems for wearable TEGs

Effective thermal management is essential for maximizing the efficiency and reliability of wearable thermoelectric generators. These systems include heat spreaders, thermal interface materials, and heat sinks designed specifically for body-worn applications. Proper thermal management ensures optimal temperature gradients between the hot and cold sides of the TEG, which directly impacts power generation. Advanced designs incorporate phase change materials to stabilize temperature fluctuations and maintain consistent performance during various physical activities and environmental conditions.Expand Specific Solutions04 Integration of TEGs with wearable electronics and textiles

Integration methods for combining thermoelectric generators with textiles and wearable electronics focus on maintaining comfort while ensuring electrical connectivity. Techniques include conductive thread stitching, direct printing of thermoelectric materials onto fabrics, and modular designs that allow for removal before washing. Advanced integration approaches use stretchable interconnects and textile-compatible substrates to create seamless wearable power systems. These integration methods also address challenges of weight distribution, breathability, and user comfort while maintaining reliable electrical connections.Expand Specific Solutions05 Environmental and mechanical durability solutions

Specialized solutions for environmental and mechanical durability ensure wearable thermoelectric generators can withstand daily use conditions. These include multi-layer barrier films that protect against moisture while allowing heat transfer, abrasion-resistant coatings, and shock-absorbing structures. Designs incorporate strain-relief features at connection points to prevent failure during movement. Some solutions use hermetic sealing techniques adapted for flexible applications, while others employ breathable membranes that block water while allowing vapor transmission to prevent internal condensation that could damage sensitive components.Expand Specific Solutions

Leading Companies in Wearable TEG Development

The wearable thermoelectric generator (TEG) market is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market for wearable TEGs is projected to expand significantly as energy harvesting technologies gain traction in consumer electronics and medical devices. Technologically, the field remains in development with challenges in encapsulation and reliability engineering being addressed by key players. École Polytechnique Fédérale de Lausanne and Beijing Institute of Nanoenergy & Nanosystems lead academic research, while companies like Fitbit and Intel explore integration possibilities. Established manufacturers including Siemens, LG Chem, and Medtronic are investing in reliability improvements, while specialized firms like I-TEN SA and Capical GmbH focus on novel encapsulation techniques to enhance durability and performance in wearable applications.

École Polytechnique Fédérale de Lausanne

Technical Solution: École Polytechnique Fédérale de Lausanne (EPFL) has pioneered advanced encapsulation technologies for wearable TEGs using atomic layer deposition (ALD) techniques that create ultra-thin barrier films with exceptional impermeability to moisture and oxygen. Their approach combines nanoscale inorganic barrier layers with biocompatible polymer substrates to achieve flexibility while maintaining thermal gradient efficiency. EPFL researchers have developed a novel thermal interface material that adapts to skin contours while efficiently transferring body heat to the TEG hot side. Their reliability engineering methodology incorporates accelerated environmental testing under combined stressors (temperature cycling, humidity, mechanical strain) with in-situ performance monitoring. Long-term reliability studies demonstrate less than 5% performance degradation after equivalent of 3 years of daily use, with encapsulation maintaining integrity through over 10,000 flexing cycles. EPFL has also developed specialized edge sealing techniques that prevent delamination at material interfaces, a common failure point in flexible TEGs.

Strengths: Exceptional barrier properties with minimal thickness, maximizing thermal transfer efficiency; scientifically rigorous reliability testing protocols; biocompatible materials suitable for extended skin contact. Weaknesses: Complex manufacturing process with high precision requirements; higher initial production costs; limited scalability for mass production without industrial partnerships.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research (A*STAR) has developed a comprehensive encapsulation solution for wearable TEGs that addresses both environmental protection and long-term reliability. Their approach utilizes a multi-functional composite encapsulation system with gradient properties - hydrophobic and thermally conductive at the skin interface, while providing thermal insulation at the cold side to maximize temperature differential. A*STAR's technology incorporates graphene-enhanced polymer composites that improve thermal conductivity while maintaining flexibility and mechanical durability. Their reliability engineering framework includes environmental chamber testing across temperature ranges from -40°C to 85°C and humidity cycling from 20% to 95% RH. The encapsulation system has demonstrated resistance to common chemicals found in personal care products and maintains performance after exposure to artificial sweat for over 1,000 hours. A*STAR has also developed specialized accelerated life testing protocols that correlate with real-world wearable device usage patterns, allowing for accurate lifetime predictions of 5+ years under normal use conditions.

Strengths: Optimized thermal management through gradient material properties; comprehensive chemical resistance suitable for diverse user environments; scientifically validated lifetime predictions. Weaknesses: Complex material system requires precise manufacturing controls; higher material costs compared to conventional encapsulants; potential challenges in recycling at end-of-life.

Key Patents in TEG Protection and Durability

Thermogenerator for generating electrical energy from thermal energy and method for producing same

PatentWO2014139721A1

Innovation

- A thermogenerator with thermoelectric elements made from half-Heusler compounds or silicides, partially covered with easily produced passivation layers of oxides, nitrides, or carbides, allowing for simplified integration and reduced encapsulation costs, enabling immediate use with preconfigured electronics.

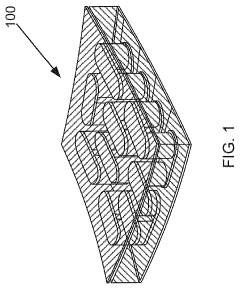

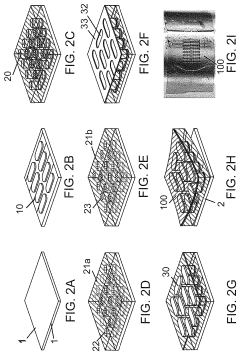

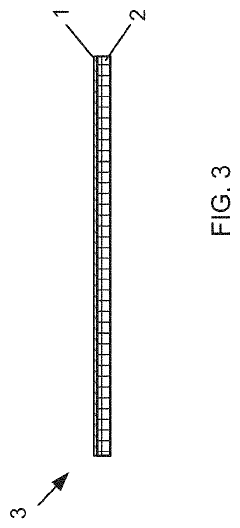

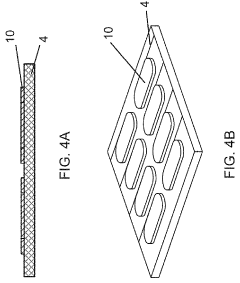

Methods of fabrication of flexible micro-thermoelectric generators

PatentActiveUS10680155B2

Innovation

- A method involving electroplating and microfabrication processes on a semi-rigid or rigid substrate, followed by substrate transferring, to form cross-plane flexible micro-TEGs with low internal resistance, using a bottom-up approach with polyimide layers and electroplating of thermoelectric pillars, allowing for high power density and commercial viability.

Materials Science Advancements for TEG Reliability

Recent advancements in materials science have significantly contributed to enhancing the reliability and performance of wearable thermoelectric generators (TEGs). The development of flexible substrate materials with superior thermal conductivity properties has been a breakthrough in addressing the thermal management challenges that previously limited TEG efficiency. These materials, including modified polymers and nanocomposites, enable better heat transfer while maintaining the flexibility required for wearable applications.

Encapsulation technologies have evolved from basic polymer coatings to sophisticated multi-layer systems that provide comprehensive protection against environmental factors. Modern encapsulation materials incorporate hydrophobic properties, offering improved water resistance without compromising the thermal conductivity necessary for TEG operation. Silicone-based compounds with modified surface properties have emerged as particularly promising for maintaining device integrity in high-moisture environments.

Nanomaterial integration represents another significant advancement, with carbon nanotubes and graphene-based materials demonstrating exceptional thermal and electrical properties when incorporated into TEG structures. These materials provide enhanced mechanical stability while improving the power output of wearable TEGs. Research indicates that graphene-enhanced thermoelectric materials can maintain performance even after thousands of bending cycles, addressing a critical reliability concern for wearable applications.

Self-healing materials represent a cutting-edge development in TEG reliability engineering. These materials can autonomously repair microcracks and damage that occur during normal wear, significantly extending device lifespan. Polymers with embedded microcapsules containing healing agents have shown promising results in laboratory testing, with some prototypes demonstrating up to 85% recovery of original performance after mechanical damage.

Interface engineering between different materials in TEG structures has also advanced considerably. Novel bonding techniques and interface materials that accommodate the different thermal expansion coefficients of TEG components have reduced delamination issues that previously plagued wearable devices. These techniques include gradient material transitions and specialized adhesives that maintain bond strength across wide temperature ranges.

Accelerated aging test protocols have been developed specifically for wearable TEGs, allowing researchers to better predict long-term reliability under real-world conditions. These standardized testing methodologies have enabled more accurate comparison between different material solutions and have accelerated the development cycle for new materials by providing rapid feedback on performance degradation mechanisms.

Encapsulation technologies have evolved from basic polymer coatings to sophisticated multi-layer systems that provide comprehensive protection against environmental factors. Modern encapsulation materials incorporate hydrophobic properties, offering improved water resistance without compromising the thermal conductivity necessary for TEG operation. Silicone-based compounds with modified surface properties have emerged as particularly promising for maintaining device integrity in high-moisture environments.

Nanomaterial integration represents another significant advancement, with carbon nanotubes and graphene-based materials demonstrating exceptional thermal and electrical properties when incorporated into TEG structures. These materials provide enhanced mechanical stability while improving the power output of wearable TEGs. Research indicates that graphene-enhanced thermoelectric materials can maintain performance even after thousands of bending cycles, addressing a critical reliability concern for wearable applications.

Self-healing materials represent a cutting-edge development in TEG reliability engineering. These materials can autonomously repair microcracks and damage that occur during normal wear, significantly extending device lifespan. Polymers with embedded microcapsules containing healing agents have shown promising results in laboratory testing, with some prototypes demonstrating up to 85% recovery of original performance after mechanical damage.

Interface engineering between different materials in TEG structures has also advanced considerably. Novel bonding techniques and interface materials that accommodate the different thermal expansion coefficients of TEG components have reduced delamination issues that previously plagued wearable devices. These techniques include gradient material transitions and specialized adhesives that maintain bond strength across wide temperature ranges.

Accelerated aging test protocols have been developed specifically for wearable TEGs, allowing researchers to better predict long-term reliability under real-world conditions. These standardized testing methodologies have enabled more accurate comparison between different material solutions and have accelerated the development cycle for new materials by providing rapid feedback on performance degradation mechanisms.

Environmental Impact of TEG Manufacturing Processes

The manufacturing processes of Thermoelectric Generators (TEGs) for wearable applications present significant environmental considerations that warrant thorough examination. Traditional TEG production involves several materials with varying environmental footprints, including bismuth telluride, antimony, selenium, and various rare earth elements. The extraction of these materials often requires extensive mining operations that contribute to habitat destruction, soil erosion, and water pollution. Particularly concerning is the mining of tellurium, which typically occurs as a byproduct of copper refining, resulting in substantial energy consumption and greenhouse gas emissions.

Chemical processes employed in TEG manufacturing introduce additional environmental challenges. The etching and cleaning procedures commonly utilize hazardous chemicals such as hydrofluoric acid, sulfuric acid, and various organic solvents. These substances can lead to air pollution, water contamination, and potential health risks for workers if not properly managed. Furthermore, the encapsulation materials for wearable TEGs, including polymers and elastomers, often derive from petroleum-based sources, contributing to carbon emissions and resource depletion.

Energy consumption represents another significant environmental factor in TEG production. The high-temperature processes required for material synthesis, including zone melting and hot pressing techniques, demand substantial energy inputs. Additionally, the precision manufacturing equipment necessary for miniaturized wearable TEGs requires clean room environments with continuous climate control systems, further increasing the energy footprint of production facilities.

Waste management presents ongoing challenges in TEG manufacturing. Production inefficiencies can result in material wastage, while the complex composition of TEGs complicates end-of-life recycling efforts. The integration of multiple materials in encapsulated wearable TEGs creates particular difficulties in material separation and recovery, potentially leading to increased electronic waste if proper recycling protocols are not established.

Recent industry developments show promising trends toward more sustainable manufacturing approaches. Several manufacturers have begun implementing closed-loop water systems to minimize water consumption and contamination. Others are exploring alternative material compositions that reduce dependence on rare or toxic elements while maintaining thermoelectric performance. Additionally, advanced manufacturing techniques such as additive manufacturing and precision deposition methods are being developed to minimize material waste and energy consumption.

The environmental impact assessment of wearable TEG manufacturing must also consider the potential positive effects of the technology. By enabling energy harvesting from waste heat, TEGs can contribute to reduced battery consumption and extended device lifespans, potentially offsetting some of their manufacturing impacts through operational benefits. A comprehensive life cycle assessment approach is essential for accurately evaluating the net environmental impact of wearable TEG technologies.

Chemical processes employed in TEG manufacturing introduce additional environmental challenges. The etching and cleaning procedures commonly utilize hazardous chemicals such as hydrofluoric acid, sulfuric acid, and various organic solvents. These substances can lead to air pollution, water contamination, and potential health risks for workers if not properly managed. Furthermore, the encapsulation materials for wearable TEGs, including polymers and elastomers, often derive from petroleum-based sources, contributing to carbon emissions and resource depletion.

Energy consumption represents another significant environmental factor in TEG production. The high-temperature processes required for material synthesis, including zone melting and hot pressing techniques, demand substantial energy inputs. Additionally, the precision manufacturing equipment necessary for miniaturized wearable TEGs requires clean room environments with continuous climate control systems, further increasing the energy footprint of production facilities.

Waste management presents ongoing challenges in TEG manufacturing. Production inefficiencies can result in material wastage, while the complex composition of TEGs complicates end-of-life recycling efforts. The integration of multiple materials in encapsulated wearable TEGs creates particular difficulties in material separation and recovery, potentially leading to increased electronic waste if proper recycling protocols are not established.

Recent industry developments show promising trends toward more sustainable manufacturing approaches. Several manufacturers have begun implementing closed-loop water systems to minimize water consumption and contamination. Others are exploring alternative material compositions that reduce dependence on rare or toxic elements while maintaining thermoelectric performance. Additionally, advanced manufacturing techniques such as additive manufacturing and precision deposition methods are being developed to minimize material waste and energy consumption.

The environmental impact assessment of wearable TEG manufacturing must also consider the potential positive effects of the technology. By enabling energy harvesting from waste heat, TEGs can contribute to reduced battery consumption and extended device lifespans, potentially offsetting some of their manufacturing impacts through operational benefits. A comprehensive life cycle assessment approach is essential for accurately evaluating the net environmental impact of wearable TEG technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!