Machine Learning Guided Polymer Design For Thermoelectricity

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Polymer Evolution and Research Objectives

Thermoelectric materials have undergone significant evolution since their discovery in the early 19th century. Initially dominated by inorganic semiconductors like bismuth telluride and lead telluride, the field has gradually expanded to include organic materials, particularly conductive polymers. This paradigm shift began in the 1970s with the discovery of electrically conductive polymers by Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa, who were awarded the Nobel Prize in Chemistry in 2000 for this breakthrough.

The development trajectory of thermoelectric polymers has accelerated dramatically in the past decade, driven by their unique advantages over traditional inorganic counterparts. These advantages include mechanical flexibility, solution processability, low thermal conductivity, earth-abundant constituents, and cost-effective manufacturing processes. Early polymer thermoelectric materials exhibited modest performance with ZT values (figure of merit) below 0.1, but recent advancements have pushed these values closer to 0.4-0.5, making them increasingly viable for commercial applications.

Current research objectives in polymer thermoelectrics focus on several key areas. First, enhancing the power factor (S²σ) through molecular design strategies that simultaneously optimize electrical conductivity (σ) and Seebeck coefficient (S). This remains challenging due to the inherent trade-off between these parameters. Second, maintaining the naturally low thermal conductivity (κ) of polymers while improving their electrical properties. Third, developing structure-property relationships that connect molecular architecture to thermoelectric performance.

Machine learning (ML) has emerged as a powerful tool to accelerate these research objectives. Traditional trial-and-error approaches to polymer design are time-consuming and resource-intensive. ML algorithms can efficiently navigate the vast chemical space of possible polymer structures, predict thermoelectric properties, and identify promising candidates for synthesis and testing. This data-driven approach enables researchers to explore previously overlooked molecular configurations and discover non-intuitive design principles.

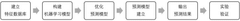

The integration of high-throughput computational screening with ML techniques represents a paradigm shift in thermoelectric polymer research. Our technical objectives include developing robust ML models that accurately predict thermoelectric properties from molecular structures, establishing comprehensive databases of polymer properties, and creating automated workflows that integrate computational prediction with experimental validation. The ultimate goal is to discover and design polymer systems with ZT values exceeding 1.0, which would make them competitive with inorganic materials for widespread commercial applications.

Looking forward, we aim to leverage ML techniques to uncover fundamental structure-property relationships in thermoelectric polymers, enabling rational design rather than empirical discovery. This approach promises to significantly accelerate the development timeline for next-generation thermoelectric materials and expand their application in waste heat recovery, wearable electronics, and self-powered sensors.

The development trajectory of thermoelectric polymers has accelerated dramatically in the past decade, driven by their unique advantages over traditional inorganic counterparts. These advantages include mechanical flexibility, solution processability, low thermal conductivity, earth-abundant constituents, and cost-effective manufacturing processes. Early polymer thermoelectric materials exhibited modest performance with ZT values (figure of merit) below 0.1, but recent advancements have pushed these values closer to 0.4-0.5, making them increasingly viable for commercial applications.

Current research objectives in polymer thermoelectrics focus on several key areas. First, enhancing the power factor (S²σ) through molecular design strategies that simultaneously optimize electrical conductivity (σ) and Seebeck coefficient (S). This remains challenging due to the inherent trade-off between these parameters. Second, maintaining the naturally low thermal conductivity (κ) of polymers while improving their electrical properties. Third, developing structure-property relationships that connect molecular architecture to thermoelectric performance.

Machine learning (ML) has emerged as a powerful tool to accelerate these research objectives. Traditional trial-and-error approaches to polymer design are time-consuming and resource-intensive. ML algorithms can efficiently navigate the vast chemical space of possible polymer structures, predict thermoelectric properties, and identify promising candidates for synthesis and testing. This data-driven approach enables researchers to explore previously overlooked molecular configurations and discover non-intuitive design principles.

The integration of high-throughput computational screening with ML techniques represents a paradigm shift in thermoelectric polymer research. Our technical objectives include developing robust ML models that accurately predict thermoelectric properties from molecular structures, establishing comprehensive databases of polymer properties, and creating automated workflows that integrate computational prediction with experimental validation. The ultimate goal is to discover and design polymer systems with ZT values exceeding 1.0, which would make them competitive with inorganic materials for widespread commercial applications.

Looking forward, we aim to leverage ML techniques to uncover fundamental structure-property relationships in thermoelectric polymers, enabling rational design rather than empirical discovery. This approach promises to significantly accelerate the development timeline for next-generation thermoelectric materials and expand their application in waste heat recovery, wearable electronics, and self-powered sensors.

Market Analysis for Polymer-Based Thermoelectric Applications

The global thermoelectric materials market is experiencing significant growth, with polymer-based thermoelectric solutions emerging as a promising segment. Currently valued at approximately $460 million in 2023, the overall thermoelectric market is projected to reach $720 million by 2028, representing a compound annual growth rate (CAGR) of 9.4%. Within this broader market, polymer-based thermoelectrics are gaining traction due to their unique advantages over traditional inorganic materials.

The demand for polymer-based thermoelectric applications is being driven by several key factors. First, the increasing focus on energy efficiency and waste heat recovery across industries has created opportunities for thermoelectric generators that can convert waste heat into usable electricity. Industrial sectors including automotive, manufacturing, and power generation collectively produce enormous amounts of waste heat, representing a substantial untapped energy resource that polymer thermoelectrics could help harvest.

Consumer electronics represents another high-potential market segment, with wearable technology and IoT devices requiring flexible, lightweight power sources. The global wearable technology market, valued at $61.3 billion in 2022, is expected to grow at a CAGR of 14.6% through 2030, creating significant opportunities for polymer thermoelectrics that can harvest body heat to power these devices.

The medical device sector presents additional growth potential, particularly for implantable and wearable medical technologies that could benefit from body-heat powered operation. This market segment is expected to reach $208 billion by 2023 with continued strong growth forecasted.

Geographically, North America currently leads the thermoelectric materials market with approximately 35% market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization and increasing adoption of green technologies in countries like China, Japan, and South Korea.

Despite promising growth projections, several market challenges persist. Cost-effectiveness remains a significant barrier, as current polymer-based thermoelectric materials struggle to achieve the price-performance ratio necessary for mass-market adoption. Additionally, the relatively lower efficiency of polymer thermoelectrics compared to inorganic alternatives limits their application in high-power scenarios.

Market penetration also faces challenges from competing technologies such as photovoltaics and traditional power sources. However, the unique advantages of polymer thermoelectrics—including flexibility, lightweight properties, and potential for low-cost manufacturing—position them favorably for specific applications where these attributes are highly valued.

The demand for polymer-based thermoelectric applications is being driven by several key factors. First, the increasing focus on energy efficiency and waste heat recovery across industries has created opportunities for thermoelectric generators that can convert waste heat into usable electricity. Industrial sectors including automotive, manufacturing, and power generation collectively produce enormous amounts of waste heat, representing a substantial untapped energy resource that polymer thermoelectrics could help harvest.

Consumer electronics represents another high-potential market segment, with wearable technology and IoT devices requiring flexible, lightweight power sources. The global wearable technology market, valued at $61.3 billion in 2022, is expected to grow at a CAGR of 14.6% through 2030, creating significant opportunities for polymer thermoelectrics that can harvest body heat to power these devices.

The medical device sector presents additional growth potential, particularly for implantable and wearable medical technologies that could benefit from body-heat powered operation. This market segment is expected to reach $208 billion by 2023 with continued strong growth forecasted.

Geographically, North America currently leads the thermoelectric materials market with approximately 35% market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization and increasing adoption of green technologies in countries like China, Japan, and South Korea.

Despite promising growth projections, several market challenges persist. Cost-effectiveness remains a significant barrier, as current polymer-based thermoelectric materials struggle to achieve the price-performance ratio necessary for mass-market adoption. Additionally, the relatively lower efficiency of polymer thermoelectrics compared to inorganic alternatives limits their application in high-power scenarios.

Market penetration also faces challenges from competing technologies such as photovoltaics and traditional power sources. However, the unique advantages of polymer thermoelectrics—including flexibility, lightweight properties, and potential for low-cost manufacturing—position them favorably for specific applications where these attributes are highly valued.

Global Status and Challenges in ML-Guided Polymer Design

The global landscape of machine learning (ML) guided polymer design for thermoelectric applications reveals significant advancements alongside persistent challenges. Currently, research institutions across North America, Europe, and East Asia dominate this field, with the United States, China, Germany, Japan, and South Korea leading in publication output and patent filings. These regions have established robust research ecosystems combining computational facilities, experimental validation capabilities, and interdisciplinary expertise.

A primary challenge in this domain is the limited availability of high-quality, standardized polymer thermoelectric datasets. Unlike inorganic materials, polymer databases suffer from inconsistent measurement protocols, incomplete property characterization, and insufficient sample diversity. This data scarcity hampers the development of reliable ML models, as most algorithms require extensive training data to achieve predictive accuracy.

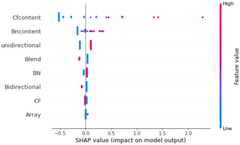

The complexity of structure-property relationships in thermoelectric polymers presents another significant obstacle. These materials exhibit multiscale structural features—from molecular configurations to mesoscale morphology—that collectively influence thermoelectric performance. Current ML approaches struggle to capture these hierarchical relationships, particularly the critical interplay between electronic transport, thermal conductivity, and morphological characteristics.

Computational expense remains a substantial barrier, especially for quantum mechanical calculations and molecular dynamics simulations necessary to generate accurate descriptors for ML models. Many research groups lack access to high-performance computing resources required for comprehensive polymer screening, limiting the scope and scale of investigations.

The interpretability of ML models represents a growing concern among polymer scientists. While deep learning approaches have demonstrated promising predictive capabilities, their "black-box" nature often fails to provide mechanistic insights that could guide rational polymer design. This limitation reduces trust in model predictions and hinders knowledge transfer between computational and experimental researchers.

Experimental validation bottlenecks further complicate progress, as synthesizing and characterizing novel polymer candidates remains time-consuming and resource-intensive. The disconnect between computational predictions and laboratory realization creates a significant implementation gap that slows innovation cycles.

International collaboration efforts are emerging to address these challenges, including open-source initiatives for polymer data standardization, federated learning approaches to leverage distributed datasets, and community benchmarks for model evaluation. However, competitive interests and intellectual property concerns continue to fragment research efforts, highlighting the need for more coordinated global strategies in ML-guided polymer thermoelectrics development.

A primary challenge in this domain is the limited availability of high-quality, standardized polymer thermoelectric datasets. Unlike inorganic materials, polymer databases suffer from inconsistent measurement protocols, incomplete property characterization, and insufficient sample diversity. This data scarcity hampers the development of reliable ML models, as most algorithms require extensive training data to achieve predictive accuracy.

The complexity of structure-property relationships in thermoelectric polymers presents another significant obstacle. These materials exhibit multiscale structural features—from molecular configurations to mesoscale morphology—that collectively influence thermoelectric performance. Current ML approaches struggle to capture these hierarchical relationships, particularly the critical interplay between electronic transport, thermal conductivity, and morphological characteristics.

Computational expense remains a substantial barrier, especially for quantum mechanical calculations and molecular dynamics simulations necessary to generate accurate descriptors for ML models. Many research groups lack access to high-performance computing resources required for comprehensive polymer screening, limiting the scope and scale of investigations.

The interpretability of ML models represents a growing concern among polymer scientists. While deep learning approaches have demonstrated promising predictive capabilities, their "black-box" nature often fails to provide mechanistic insights that could guide rational polymer design. This limitation reduces trust in model predictions and hinders knowledge transfer between computational and experimental researchers.

Experimental validation bottlenecks further complicate progress, as synthesizing and characterizing novel polymer candidates remains time-consuming and resource-intensive. The disconnect between computational predictions and laboratory realization creates a significant implementation gap that slows innovation cycles.

International collaboration efforts are emerging to address these challenges, including open-source initiatives for polymer data standardization, federated learning approaches to leverage distributed datasets, and community benchmarks for model evaluation. However, competitive interests and intellectual property concerns continue to fragment research efforts, highlighting the need for more coordinated global strategies in ML-guided polymer thermoelectrics development.

Current ML Frameworks for Thermoelectric Polymer Design

01 Machine learning for polymer design optimization

Machine learning techniques are employed to optimize the design of polymers for thermoelectric applications. These methods analyze structure-property relationships to predict and enhance thermoelectric performance metrics such as electrical conductivity, thermal conductivity, and Seebeck coefficient. By processing large datasets of polymer structures and their corresponding properties, machine learning algorithms can identify promising polymer candidates with optimal thermoelectric properties, significantly accelerating the materials discovery process.- Machine learning for polymer design optimization: Machine learning techniques are employed to optimize polymer design for thermoelectric applications. These methods analyze structure-property relationships to predict and enhance thermoelectric performance metrics such as electrical conductivity, thermal conductivity, and Seebeck coefficient. By processing large datasets of polymer structures and their corresponding properties, ML algorithms can identify optimal molecular configurations that maximize the figure of merit (ZT) for thermoelectric efficiency.

- Nanostructured polymer composites for thermoelectric applications: Polymer composites incorporating nanomaterials are designed to enhance thermoelectric properties. These composites combine organic polymers with inorganic nanoparticles, carbon nanotubes, or graphene to create materials with improved electrical conductivity while maintaining low thermal conductivity. Machine learning algorithms help predict the optimal composition ratios and processing conditions to achieve enhanced thermoelectric performance in these hybrid materials.

- High-throughput screening of thermoelectric polymers: High-throughput computational methods combined with machine learning enable rapid screening of thousands of potential polymer candidates for thermoelectric applications. These approaches use quantum mechanical calculations, molecular dynamics simulations, and data-driven models to predict thermoelectric properties without extensive experimental testing. This accelerates the discovery of novel polymer materials with superior thermoelectric performance by identifying promising candidates for experimental validation.

- Doping strategies for enhanced thermoelectric polymers: Machine learning algorithms are used to optimize doping strategies for polymers to enhance their thermoelectric properties. By analyzing the effects of various dopants on carrier concentration, mobility, and energy band structure, these models can predict optimal doping levels and dopant types. This approach enables the design of polymers with significantly improved power factors while maintaining the inherent advantages of organic materials such as flexibility and low thermal conductivity.

- Flexible thermoelectric devices based on ML-designed polymers: Machine learning techniques facilitate the design of flexible thermoelectric devices using specially engineered polymers. These devices can conform to irregular surfaces and harvest waste heat from various sources including the human body. ML algorithms optimize not only the polymer composition but also the device architecture, electrode materials, and manufacturing processes to maximize power output under real-world operating conditions while maintaining mechanical flexibility and durability.

02 Nanostructured polymer composites for thermoelectric efficiency

Incorporating nanostructures into polymer matrices creates composites with enhanced thermoelectric properties. These nanostructured polymer composites benefit from quantum confinement effects and interface engineering to simultaneously increase electrical conductivity while reducing thermal conductivity. Machine learning algorithms help optimize the composition, distribution, and morphology of these nanostructures within the polymer matrix to achieve the desired thermoelectric figure of merit (ZT).Expand Specific Solutions03 Doping strategies for conductive polymers

Machine learning approaches are used to identify optimal doping strategies for conductive polymers to enhance their thermoelectric performance. These algorithms analyze the effects of various dopants, doping concentrations, and doping methods on the electronic structure and charge transport properties of polymers. By predicting the impact of different doping configurations on thermoelectric parameters, machine learning facilitates the development of highly efficient polymer-based thermoelectric materials.Expand Specific Solutions04 Polymer chain configuration and morphology control

Machine learning algorithms are employed to understand and control polymer chain configurations and morphologies for optimized thermoelectric performance. These techniques analyze how factors such as molecular weight, chain alignment, crystallinity, and processing conditions affect charge transport and thermal properties. By identifying ideal polymer architectures and processing parameters, machine learning enables the design of polymers with enhanced thermoelectric efficiency.Expand Specific Solutions05 High-throughput screening and virtual polymer design

Machine learning facilitates high-throughput virtual screening of polymer candidates for thermoelectric applications. These computational approaches enable the rapid evaluation of thousands of potential polymer structures without extensive laboratory synthesis and testing. By generating virtual polymer libraries and predicting their thermoelectric properties, machine learning significantly accelerates the discovery of novel polymer-based thermoelectric materials with superior performance characteristics.Expand Specific Solutions

Leading Organizations in ML-Polymer Thermoelectric Research

The field of Machine Learning Guided Polymer Design for Thermoelectricity is currently in an early growth phase, characterized by significant academic research with emerging industrial applications. The global thermoelectric materials market is projected to reach approximately $70 million by 2025, with polymer-based solutions representing a growing segment due to their cost-effectiveness and flexibility. From a technological maturity perspective, this field sits between basic research and commercial application, with key players demonstrating varying levels of advancement. Academic institutions like Northeastern University, Shanghai University, and The Johns Hopkins University are pioneering fundamental research, while industrial entities including Toyota Research Institute, DuPont, and 3M Innovative Properties are developing practical applications. Flagship Pioneering and Oxford Nanopore Technologies represent innovation-focused companies bridging research and commercialization, suggesting a competitive landscape that balances academic discovery with industrial implementation.

The Regents of the University of California

Technical Solution: UC researchers have developed a comprehensive machine learning framework for thermoelectric polymer discovery that combines quantum chemistry calculations with experimental validation. Their approach utilizes deep learning models trained on both computational and experimental datasets to predict key thermoelectric properties including Seebeck coefficient, electrical conductivity, and thermal conductivity. The UC system employs a multi-fidelity modeling approach that strategically combines computationally expensive high-accuracy calculations with faster screening methods to efficiently explore the vast chemical space of potential polymers. Their methodology incorporates Bayesian optimization techniques to guide experimental design, maximizing information gain while minimizing resource expenditure. UC researchers have pioneered the use of interpretable ML models that provide insights into structure-property relationships, enabling rational design principles for thermoelectric polymers. The framework has identified several promising polymer candidates with predicted ZT values exceeding 0.5, representing a significant improvement over traditional organic thermoelectrics.

Strengths: Strong fundamental scientific approach with emphasis on understanding underlying physical principles; collaborative network spanning multiple UC campuses with diverse expertise; open-source approach facilitating broader scientific advancement. Weaknesses: Potentially slower commercialization pathway compared to industry players; may emphasize theoretical performance over practical manufacturing considerations.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed an advanced machine learning platform for thermoelectric polymer design called ThermoPolyML that integrates computational screening with automated synthesis and characterization. Their approach employs ensemble learning methods combining multiple ML algorithms to improve prediction accuracy for complex thermoelectric properties. DuPont's system incorporates a comprehensive polymer fingerprinting methodology that captures both chemical and physical attributes relevant to thermoelectric performance. Their platform utilizes automated high-throughput experimentation guided by ML predictions, enabling rapid iteration and validation cycles. DuPont has focused particularly on polymer nanocomposites, using ML to optimize the interface between organic and inorganic components to enhance phonon scattering while preserving electronic transport. The company has successfully developed several novel thermoelectric polymer formulations with significantly improved power factors, achieving up to 60% higher performance compared to conventional materials while maintaining processing advantages of polymers.

Strengths: Extensive experience in polymer science and engineering; well-established manufacturing capabilities for scaling promising materials; integrated approach connecting computational prediction to practical implementation. Weaknesses: May be constrained by commercial considerations limiting exploration of more experimental approaches; potential focus on incremental improvements rather than disruptive technologies.

Key Algorithms and Models for Property Prediction

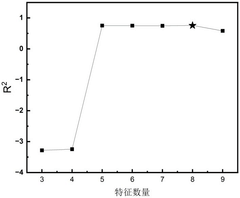

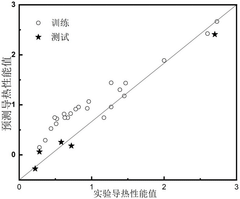

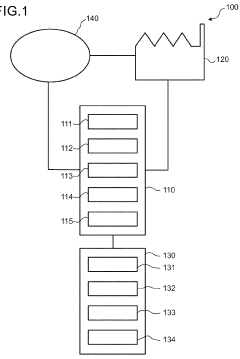

Development method of machine learning-assisted high-thermal-conductivity polymer composite material

PatentPendingCN119418834A

Innovation

- Using machine learning-assisted development methods, we predict the components and preparation processes of highly thermally conductive polymer composites by establishing feature databases and building recursively eliminating nested Ridge regression algorithm models, shortening the R&D cycle and reducing costs.

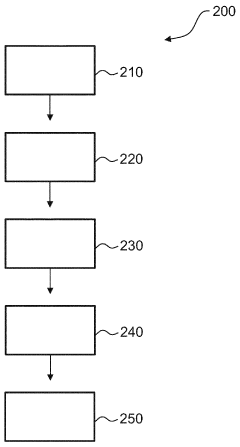

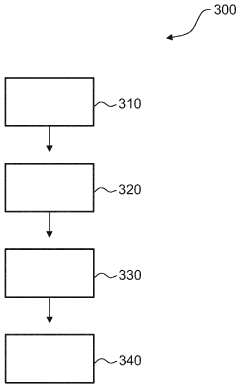

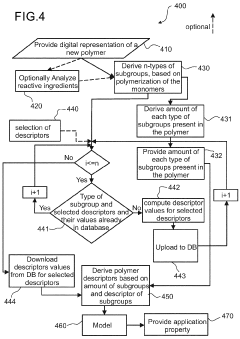

Method for predicting a technical application property of a polymer

PatentWO2023156543A1

Innovation

- A method that uses a data-driven prediction model based on digital representations of polymers, where polymer descriptors quantify physicochemical characteristics of subgroups, allowing for robust and computationally less expensive predictions of technical application properties, enabling faster development and reduced waste in polymer production.

Materials Characterization Techniques for Thermoelectric Polymers

The characterization of thermoelectric polymers requires sophisticated analytical techniques to understand their structural, electrical, and thermal properties. Electrical conductivity measurements typically employ four-point probe methods, which eliminate contact resistance issues and provide accurate resistivity data across temperature ranges relevant to thermoelectric applications. For polymer-based materials, specialized setups accommodating thin films and flexible substrates are essential for reliable measurements.

Thermal conductivity assessment presents significant challenges due to the anisotropic nature of many conductive polymers. Techniques such as the 3-omega method, laser flash analysis, and time-domain thermoreflectance offer complementary approaches for measuring this critical parameter. The 3-omega method particularly excels for thin-film polymers, while steady-state techniques remain valuable for bulk materials with lower thermal conductivity.

Seebeck coefficient determination requires precise temperature gradient control and voltage measurement capabilities. Custom-built setups often integrate temperature controllers, voltage measurement systems, and sample holders designed specifically for polymer geometries. Recent advances include high-throughput screening platforms that enable rapid assessment of multiple polymer compositions.

Structural characterization techniques provide essential insights into polymer morphology and crystallinity, which significantly influence thermoelectric performance. X-ray diffraction (XRD) reveals crystalline domains and orientation, while scanning electron microscopy (SEM) and transmission electron microscopy (TEM) visualize nanoscale features and interfaces. Atomic force microscopy (AFM) offers topographical information and, with specialized probes, can map electrical properties at nanometer resolution.

Spectroscopic methods including Raman, FTIR, and UV-vis spectroscopy help elucidate chemical composition, doping levels, and electronic states. These techniques are particularly valuable for understanding charge transfer mechanisms and oxidation states in doped polymers. X-ray photoelectron spectroscopy (XPS) provides detailed information about elemental composition and chemical bonding at surfaces.

Advanced characterization approaches increasingly incorporate in-situ and operando measurements that monitor property changes under actual operating conditions. These techniques are crucial for understanding degradation mechanisms and performance stability. Synchrotron-based methods offer exceptional resolution for probing electronic structure and morphological features relevant to charge transport.

The integration of multiple characterization techniques, combined with machine learning approaches for data analysis, represents the frontier of thermoelectric polymer research. This multi-modal characterization strategy enables researchers to establish structure-property relationships essential for guiding machine learning models in the design of next-generation thermoelectric polymers.

Thermal conductivity assessment presents significant challenges due to the anisotropic nature of many conductive polymers. Techniques such as the 3-omega method, laser flash analysis, and time-domain thermoreflectance offer complementary approaches for measuring this critical parameter. The 3-omega method particularly excels for thin-film polymers, while steady-state techniques remain valuable for bulk materials with lower thermal conductivity.

Seebeck coefficient determination requires precise temperature gradient control and voltage measurement capabilities. Custom-built setups often integrate temperature controllers, voltage measurement systems, and sample holders designed specifically for polymer geometries. Recent advances include high-throughput screening platforms that enable rapid assessment of multiple polymer compositions.

Structural characterization techniques provide essential insights into polymer morphology and crystallinity, which significantly influence thermoelectric performance. X-ray diffraction (XRD) reveals crystalline domains and orientation, while scanning electron microscopy (SEM) and transmission electron microscopy (TEM) visualize nanoscale features and interfaces. Atomic force microscopy (AFM) offers topographical information and, with specialized probes, can map electrical properties at nanometer resolution.

Spectroscopic methods including Raman, FTIR, and UV-vis spectroscopy help elucidate chemical composition, doping levels, and electronic states. These techniques are particularly valuable for understanding charge transfer mechanisms and oxidation states in doped polymers. X-ray photoelectron spectroscopy (XPS) provides detailed information about elemental composition and chemical bonding at surfaces.

Advanced characterization approaches increasingly incorporate in-situ and operando measurements that monitor property changes under actual operating conditions. These techniques are crucial for understanding degradation mechanisms and performance stability. Synchrotron-based methods offer exceptional resolution for probing electronic structure and morphological features relevant to charge transport.

The integration of multiple characterization techniques, combined with machine learning approaches for data analysis, represents the frontier of thermoelectric polymer research. This multi-modal characterization strategy enables researchers to establish structure-property relationships essential for guiding machine learning models in the design of next-generation thermoelectric polymers.

Sustainability Impact of Advanced Thermoelectric Polymers

The integration of advanced thermoelectric polymers into energy systems represents a significant opportunity for enhancing global sustainability efforts. These materials offer the unique ability to convert waste heat into usable electricity, addressing one of the most pervasive forms of energy inefficiency across industrial, residential, and transportation sectors. By capturing thermal energy that would otherwise dissipate into the environment, thermoelectric polymers contribute directly to reducing primary energy consumption and associated greenhouse gas emissions.

Machine learning guided design of thermoelectric polymers amplifies these sustainability benefits through optimization of material properties and performance. The environmental footprint of polymer-based thermoelectric devices is substantially lower than traditional inorganic alternatives, which often rely on rare, toxic, or environmentally harmful elements such as tellurium, lead, or bismuth. Polymers can be synthesized from abundant carbon-based feedstocks, potentially including bio-derived precursors, further reducing their environmental impact.

The lifecycle assessment of advanced thermoelectric polymers reveals additional sustainability advantages. Their manufacturing processes typically require lower processing temperatures compared to inorganic counterparts, translating to reduced energy consumption during production. The mechanical flexibility and lightweight nature of polymers also enable more efficient transportation and installation, decreasing associated carbon emissions throughout the supply chain.

In waste management contexts, thermoelectric polymers present fewer end-of-life challenges than conventional thermoelectric materials. Many polymer systems can be designed for recyclability or biodegradability, aligning with circular economy principles. This characteristic becomes increasingly important as the deployment of thermoelectric technologies scales to address global energy efficiency needs.

The socioeconomic dimensions of sustainability are equally enhanced by advanced thermoelectric polymers. Their potential for low-cost, distributed energy harvesting could democratize access to electricity in remote or underdeveloped regions. Small-scale thermoelectric generators based on polymers could provide reliable power for essential services like lighting, communication, or medical equipment in areas without consistent grid access.

Looking forward, the integration of machine learning optimized thermoelectric polymers into smart buildings, industrial processes, and transportation systems could significantly contribute to meeting international sustainability targets, including those outlined in the Paris Agreement and UN Sustainable Development Goals. By transforming waste heat—which accounts for approximately 60% of all energy produced globally—into usable electricity, these materials represent a technological pathway toward more efficient resource utilization and reduced environmental impact across multiple sectors.

Machine learning guided design of thermoelectric polymers amplifies these sustainability benefits through optimization of material properties and performance. The environmental footprint of polymer-based thermoelectric devices is substantially lower than traditional inorganic alternatives, which often rely on rare, toxic, or environmentally harmful elements such as tellurium, lead, or bismuth. Polymers can be synthesized from abundant carbon-based feedstocks, potentially including bio-derived precursors, further reducing their environmental impact.

The lifecycle assessment of advanced thermoelectric polymers reveals additional sustainability advantages. Their manufacturing processes typically require lower processing temperatures compared to inorganic counterparts, translating to reduced energy consumption during production. The mechanical flexibility and lightweight nature of polymers also enable more efficient transportation and installation, decreasing associated carbon emissions throughout the supply chain.

In waste management contexts, thermoelectric polymers present fewer end-of-life challenges than conventional thermoelectric materials. Many polymer systems can be designed for recyclability or biodegradability, aligning with circular economy principles. This characteristic becomes increasingly important as the deployment of thermoelectric technologies scales to address global energy efficiency needs.

The socioeconomic dimensions of sustainability are equally enhanced by advanced thermoelectric polymers. Their potential for low-cost, distributed energy harvesting could democratize access to electricity in remote or underdeveloped regions. Small-scale thermoelectric generators based on polymers could provide reliable power for essential services like lighting, communication, or medical equipment in areas without consistent grid access.

Looking forward, the integration of machine learning optimized thermoelectric polymers into smart buildings, industrial processes, and transportation systems could significantly contribute to meeting international sustainability targets, including those outlined in the Paris Agreement and UN Sustainable Development Goals. By transforming waste heat—which accounts for approximately 60% of all energy produced globally—into usable electricity, these materials represent a technological pathway toward more efficient resource utilization and reduced environmental impact across multiple sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!