Control Strategies For Managing Exothermic Reactions In Flow

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flow Chemistry Exothermic Control Background and Objectives

Flow chemistry has emerged as a transformative approach in chemical synthesis over the past two decades, offering significant advantages over traditional batch processing. The evolution of this technology began in the early 2000s with pioneering work in microreactor technology and has since expanded into a diverse field encompassing various reactor designs, process control strategies, and industrial applications. The management of exothermic reactions represents one of the most critical challenges in this domain, as these reactions pose substantial safety risks and process control difficulties.

Exothermic reactions in flow chemistry involve the release of heat during chemical transformations, which, if not properly controlled, can lead to thermal runaway scenarios, degradation of product quality, and even catastrophic equipment failures. The historical development of control strategies has progressed from basic passive cooling approaches to sophisticated integrated systems combining real-time monitoring, predictive modeling, and automated response mechanisms.

The primary technical objectives in this field center on achieving precise thermal management while maintaining reaction efficiency and product quality. This includes developing methods for rapid heat dissipation, implementing accurate temperature monitoring systems, designing fail-safe mechanisms, and creating predictive models for reaction behavior under various conditions. Additionally, there is a growing emphasis on scalability, ensuring that control strategies effective at laboratory scale can be successfully implemented in industrial production environments.

Current research trends indicate a shift toward more integrated approaches that combine multiple control strategies, including microstructured devices for enhanced heat transfer, advanced process analytical technology (PAT) for real-time monitoring, and artificial intelligence for predictive control. The convergence of these technologies promises to enable safer handling of increasingly challenging chemical transformations.

The global research landscape shows concentrated efforts in academic institutions across Europe, North America, and East Asia, with industrial adoption following closely behind academic innovations. Collaborative initiatives between academia and industry have accelerated the translation of theoretical advances into practical applications, particularly in pharmaceutical and fine chemical manufacturing sectors.

The ultimate goal of research in this domain is to develop robust, scalable, and universally applicable control strategies that can safely harness the full potential of exothermic reactions in flow chemistry. This would enable the implementation of previously challenging or impossible chemical transformations, expanding the synthetic toolkit available to chemists and chemical engineers while maintaining the highest standards of safety and efficiency.

Exothermic reactions in flow chemistry involve the release of heat during chemical transformations, which, if not properly controlled, can lead to thermal runaway scenarios, degradation of product quality, and even catastrophic equipment failures. The historical development of control strategies has progressed from basic passive cooling approaches to sophisticated integrated systems combining real-time monitoring, predictive modeling, and automated response mechanisms.

The primary technical objectives in this field center on achieving precise thermal management while maintaining reaction efficiency and product quality. This includes developing methods for rapid heat dissipation, implementing accurate temperature monitoring systems, designing fail-safe mechanisms, and creating predictive models for reaction behavior under various conditions. Additionally, there is a growing emphasis on scalability, ensuring that control strategies effective at laboratory scale can be successfully implemented in industrial production environments.

Current research trends indicate a shift toward more integrated approaches that combine multiple control strategies, including microstructured devices for enhanced heat transfer, advanced process analytical technology (PAT) for real-time monitoring, and artificial intelligence for predictive control. The convergence of these technologies promises to enable safer handling of increasingly challenging chemical transformations.

The global research landscape shows concentrated efforts in academic institutions across Europe, North America, and East Asia, with industrial adoption following closely behind academic innovations. Collaborative initiatives between academia and industry have accelerated the translation of theoretical advances into practical applications, particularly in pharmaceutical and fine chemical manufacturing sectors.

The ultimate goal of research in this domain is to develop robust, scalable, and universally applicable control strategies that can safely harness the full potential of exothermic reactions in flow chemistry. This would enable the implementation of previously challenging or impossible chemical transformations, expanding the synthetic toolkit available to chemists and chemical engineers while maintaining the highest standards of safety and efficiency.

Market Analysis for Flow Chemistry Safety Solutions

The flow chemistry safety solutions market is experiencing significant growth driven by increasing adoption of continuous flow processes across pharmaceutical, chemical, and petrochemical industries. Current market valuation stands at approximately 450 million USD with projections indicating growth to reach 820 million USD by 2028, representing a compound annual growth rate of 12.7%. This growth trajectory is primarily fueled by stringent safety regulations, particularly in developed regions, and the pharmaceutical industry's shift toward continuous manufacturing processes.

Demand analysis reveals that pharmaceutical companies constitute the largest market segment, accounting for nearly 42% of the total market share. This dominance stems from the industry's need for precise control over exothermic reactions during drug synthesis and scale-up processes. Chemical manufacturers represent the second-largest segment at 28%, followed by academic and research institutions at 17%, with the remaining market distributed among specialty chemical producers and contract manufacturing organizations.

Geographically, North America leads the market with 38% share, followed closely by Europe at 35%. The Asia-Pacific region, while currently representing 22% of the market, is expected to demonstrate the highest growth rate in the coming years due to rapid industrialization and increasing investment in pharmaceutical manufacturing infrastructure, particularly in China, India, and Singapore.

Customer needs assessment indicates that end-users prioritize several key features in flow chemistry safety solutions: real-time monitoring capabilities, automated shutdown systems, scalability, integration with existing manufacturing systems, and compliance with regulatory standards. The demand for integrated solutions that combine hardware, software, and services is growing at 15% annually, outpacing the overall market growth rate.

Market segmentation by solution type shows that hardware components (reactors, sensors, controllers) constitute 55% of the market, software solutions (monitoring, data analysis, predictive maintenance) account for 30%, and services (installation, training, maintenance) make up the remaining 15%. The software segment is projected to grow at the fastest rate due to increasing emphasis on data-driven decision making and process optimization.

Price sensitivity analysis reveals that while initial investment costs remain a barrier for small and medium enterprises, the total cost of ownership calculations increasingly favor flow chemistry safety solutions due to reduced waste generation, lower energy consumption, and minimized risk of catastrophic events compared to batch processing methods.

Demand analysis reveals that pharmaceutical companies constitute the largest market segment, accounting for nearly 42% of the total market share. This dominance stems from the industry's need for precise control over exothermic reactions during drug synthesis and scale-up processes. Chemical manufacturers represent the second-largest segment at 28%, followed by academic and research institutions at 17%, with the remaining market distributed among specialty chemical producers and contract manufacturing organizations.

Geographically, North America leads the market with 38% share, followed closely by Europe at 35%. The Asia-Pacific region, while currently representing 22% of the market, is expected to demonstrate the highest growth rate in the coming years due to rapid industrialization and increasing investment in pharmaceutical manufacturing infrastructure, particularly in China, India, and Singapore.

Customer needs assessment indicates that end-users prioritize several key features in flow chemistry safety solutions: real-time monitoring capabilities, automated shutdown systems, scalability, integration with existing manufacturing systems, and compliance with regulatory standards. The demand for integrated solutions that combine hardware, software, and services is growing at 15% annually, outpacing the overall market growth rate.

Market segmentation by solution type shows that hardware components (reactors, sensors, controllers) constitute 55% of the market, software solutions (monitoring, data analysis, predictive maintenance) account for 30%, and services (installation, training, maintenance) make up the remaining 15%. The software segment is projected to grow at the fastest rate due to increasing emphasis on data-driven decision making and process optimization.

Price sensitivity analysis reveals that while initial investment costs remain a barrier for small and medium enterprises, the total cost of ownership calculations increasingly favor flow chemistry safety solutions due to reduced waste generation, lower energy consumption, and minimized risk of catastrophic events compared to batch processing methods.

Current Challenges in Exothermic Reaction Management

Despite significant advancements in flow chemistry, managing exothermic reactions remains one of the most challenging aspects in continuous processing. The primary challenge stems from the inherent nature of exothermic reactions - they release heat that can rapidly accumulate, potentially leading to thermal runaway scenarios if not properly controlled. This risk is particularly pronounced in microreactor and flow systems where reaction volumes are small but surface-to-volume ratios are high.

Temperature control presents a formidable challenge in flow systems. While the enhanced heat transfer capabilities of microreactors offer advantages over batch processes, maintaining precise temperature profiles throughout the reaction pathway remains difficult. Hot spots can develop at mixing points or in regions where reaction kinetics accelerate, creating localized areas of elevated temperature that may compromise product quality or safety.

Scale-up considerations introduce another layer of complexity. As flow systems increase in size to meet production demands, the heat transfer characteristics change significantly. What works effectively at laboratory scale may not translate directly to production scale, necessitating sophisticated modeling and often redesign of heat management strategies.

Mixing efficiency directly impacts heat distribution in flow reactors. Inadequate mixing can create concentration gradients that lead to unpredictable reaction rates and localized heat generation. This is especially problematic for fast exothermic reactions where mixing times must be shorter than reaction times to ensure uniform heat distribution.

Real-time monitoring and control systems face significant technical hurdles. Current sensor technologies often struggle with the speed requirements for detecting rapid temperature changes in flow environments. The latency between detection, data processing, and control response can be problematic when dealing with reactions that release heat on millisecond timescales.

Material limitations further constrain available solutions. Reactor materials must simultaneously provide excellent heat transfer properties while withstanding potentially corrosive reaction media and high pressure conditions. The trade-offs between thermal conductivity, chemical resistance, and mechanical strength often force compromises in reactor design.

Multiphase reactions introduce additional complications for heat management. Gas-liquid or liquid-liquid reactions in flow systems create complex hydrodynamic patterns that affect heat transfer coefficients and can lead to unpredictable thermal behavior. These systems require specialized approaches to ensure consistent heat removal across phase boundaries.

Regulatory and safety considerations add further constraints to exothermic reaction management strategies. As industrial adoption of flow chemistry increases, regulatory frameworks are still evolving to address the unique safety considerations of continuous processing of energetic materials.

Temperature control presents a formidable challenge in flow systems. While the enhanced heat transfer capabilities of microreactors offer advantages over batch processes, maintaining precise temperature profiles throughout the reaction pathway remains difficult. Hot spots can develop at mixing points or in regions where reaction kinetics accelerate, creating localized areas of elevated temperature that may compromise product quality or safety.

Scale-up considerations introduce another layer of complexity. As flow systems increase in size to meet production demands, the heat transfer characteristics change significantly. What works effectively at laboratory scale may not translate directly to production scale, necessitating sophisticated modeling and often redesign of heat management strategies.

Mixing efficiency directly impacts heat distribution in flow reactors. Inadequate mixing can create concentration gradients that lead to unpredictable reaction rates and localized heat generation. This is especially problematic for fast exothermic reactions where mixing times must be shorter than reaction times to ensure uniform heat distribution.

Real-time monitoring and control systems face significant technical hurdles. Current sensor technologies often struggle with the speed requirements for detecting rapid temperature changes in flow environments. The latency between detection, data processing, and control response can be problematic when dealing with reactions that release heat on millisecond timescales.

Material limitations further constrain available solutions. Reactor materials must simultaneously provide excellent heat transfer properties while withstanding potentially corrosive reaction media and high pressure conditions. The trade-offs between thermal conductivity, chemical resistance, and mechanical strength often force compromises in reactor design.

Multiphase reactions introduce additional complications for heat management. Gas-liquid or liquid-liquid reactions in flow systems create complex hydrodynamic patterns that affect heat transfer coefficients and can lead to unpredictable thermal behavior. These systems require specialized approaches to ensure consistent heat removal across phase boundaries.

Regulatory and safety considerations add further constraints to exothermic reaction management strategies. As industrial adoption of flow chemistry increases, regulatory frameworks are still evolving to address the unique safety considerations of continuous processing of energetic materials.

Current Control Strategies for Exothermic Flow Reactions

01 Temperature control mechanisms for exothermic reactions

Various temperature control mechanisms can be employed to manage exothermic reactions in flow systems. These include heat exchangers, cooling jackets, and temperature sensors that provide real-time monitoring. By maintaining optimal temperature conditions, these mechanisms prevent runaway reactions and ensure process safety while maximizing yield and product quality. Advanced control algorithms can adjust cooling rates based on reaction progression.- Temperature control mechanisms for exothermic reactions: Various temperature control mechanisms can be employed to manage exothermic reactions in flow systems. These include heat exchangers, cooling jackets, and temperature sensors that provide real-time monitoring. By maintaining optimal temperature conditions, these mechanisms prevent runaway reactions and ensure process safety. Advanced control systems can automatically adjust cooling parameters based on reaction progression, allowing for precise thermal management in continuous flow processes.

- Flow rate modulation for reaction control: Controlling the flow rate of reactants is a critical strategy for managing exothermic reactions in continuous flow systems. By adjusting the flow rate, the residence time and heat generation can be regulated, preventing excessive heat accumulation. Automated flow control systems can respond to temperature changes by reducing flow when temperatures rise beyond set thresholds. This approach allows for safer handling of highly exothermic reactions while maintaining production efficiency.

- Reactor design optimization for heat dissipation: Specialized reactor designs can significantly improve heat dissipation in exothermic flow reactions. Microreactors with high surface-to-volume ratios facilitate efficient heat transfer, while segmented flow reactors create controlled reaction zones. Materials with high thermal conductivity can be incorporated into reactor construction to enhance heat removal. Some designs include internal structures that promote turbulence, improving mixing and heat transfer characteristics while maintaining controlled reaction conditions.

- Dilution and staged addition techniques: Dilution and staged addition of reactants are effective strategies for controlling exothermic reactions in flow systems. By introducing one reactant gradually or in a diluted form, the heat generation rate can be managed more effectively. This approach prevents localized hot spots and reduces the risk of thermal runaway. Advanced flow systems may incorporate multiple injection points along the reactor length, allowing for precise control over concentration gradients and reaction progression.

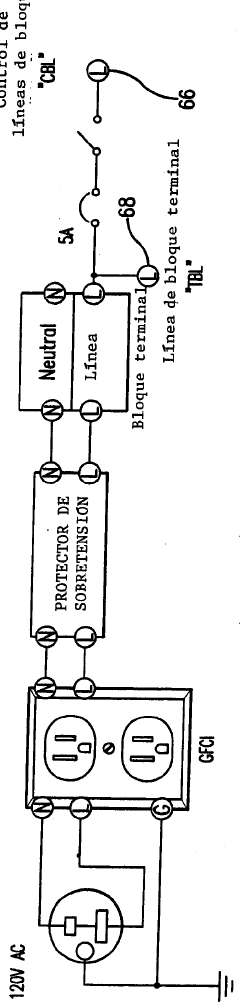

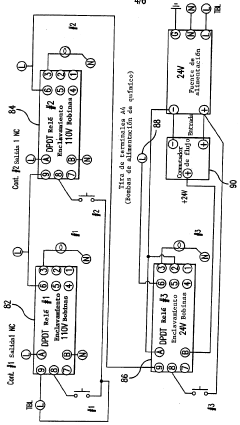

- Monitoring and feedback control systems: Advanced monitoring and feedback control systems play a crucial role in managing exothermic reactions in flow processes. These systems utilize sensors to continuously measure parameters such as temperature, pressure, and flow rate. When deviations from optimal conditions are detected, automated control mechanisms make real-time adjustments to maintain safety and efficiency. Some systems incorporate predictive modeling capabilities that anticipate reaction behavior and proactively adjust process parameters to prevent potential issues.

02 Flow rate modulation for reaction control

Controlling the flow rate of reactants is a critical strategy for managing exothermic reactions in continuous flow systems. By adjusting the flow rate, the residence time and heat generation can be precisely regulated. This approach allows for better control of reaction kinetics and prevents localized hot spots. Automated flow control systems can respond to temperature or pressure changes by adjusting input rates to maintain safe operating conditions.Expand Specific Solutions03 Reactor design optimization for heat management

Specialized reactor designs can significantly improve heat management in exothermic flow reactions. These include microreactors with high surface-to-volume ratios, plate heat exchangers, and structured reactors with enhanced heat transfer capabilities. Some designs incorporate segmented flow or static mixers to improve mixing efficiency while facilitating heat removal. Materials with high thermal conductivity are often used in critical components to enhance heat dissipation.Expand Specific Solutions04 Process monitoring and feedback control systems

Advanced monitoring and feedback control systems are essential for managing exothermic reactions in flow processes. These systems utilize sensors for real-time measurement of temperature, pressure, flow rate, and reaction progress. The collected data feeds into control algorithms that can make automatic adjustments to maintain optimal conditions. Some systems incorporate predictive models to anticipate potential issues before they occur, enabling proactive control strategies rather than reactive responses.Expand Specific Solutions05 Diluent and solvent selection strategies

The strategic selection of diluents and solvents plays a crucial role in controlling exothermic reactions in flow systems. Inert diluents can absorb excess heat and moderate reaction rates, while appropriate solvents can influence reaction kinetics and heat transfer properties. Some approaches involve the use of phase-change materials that absorb heat through endothermic transitions. The careful selection of these components can provide an additional layer of safety and control for highly exothermic processes.Expand Specific Solutions

Leading Companies in Flow Chemistry Equipment

The flow chemistry market for exothermic reaction control is currently in a growth phase, with increasing adoption across pharmaceutical and chemical industries. The market size is expanding rapidly, projected to reach significant value as continuous manufacturing gains traction over batch processing. Technologically, the field shows varying maturity levels, with companies like Johnson Matthey Davy Technologies and BASF leading with advanced catalytic and reactor technologies. Haldor Topsøe and Casale SA have developed specialized solutions for managing thermal challenges in flow systems, while pharmaceutical players including Janssen Pharmaceutica and Wyeth are implementing these technologies for safer production processes. Emerging players like Precision Combustion are introducing innovative microreactor designs, creating a competitive landscape balanced between established chemical engineering firms and specialized technology providers focused on process intensification and safety enhancement.

Casale SA

Technical Solution: Casale SA has developed the ExoFlow™ control system specifically designed for managing highly exothermic reactions in continuous flow processes, particularly for ammonia and methanol synthesis applications. Their technology employs a multi-tubular reactor design with specialized heat transfer enhancement features, including helical inserts that create controlled turbulence patterns, increasing heat transfer coefficients by up to 60% compared to conventional designs[6]. Casale's control strategy incorporates a comprehensive thermal mapping system using distributed temperature sensors with spatial resolution of 2cm, enabling precise identification of reaction hotspots. Their approach includes adaptive feed modulation where reactant concentrations are automatically adjusted based on thermal profiles to maintain optimal reaction conditions. The company has pioneered the use of dynamic pressure swing techniques where controlled pressure fluctuations are introduced to temporarily shift equilibrium conditions and moderate reaction rates during potential thermal excursions. Casale's system features a predictive safety module that continuously calculates the distance to thermal runaway conditions based on real-time process data and thermodynamic models, triggering preventive interventions when safety margins decrease below threshold values.

Strengths: Specialized expertise in handling highly exothermic industrial reactions like ammonia synthesis; innovative heat transfer enhancement through engineered turbulence; sophisticated thermal mapping capabilities; proven reliability in continuous 24/7 industrial operations. Weaknesses: Systems primarily optimized for specific chemical processes with less flexibility for diverse applications; higher pressure drop due to turbulence-enhancing features increasing energy costs; complex control systems require specialized training; significant capital investment requirements for implementation.

BASF Corp.

Technical Solution: BASF has developed advanced microreactor technology for managing exothermic reactions in flow processes. Their plate reactor systems incorporate precise temperature control through integrated heat exchangers that maintain isothermal conditions even during highly exothermic reactions. The company employs a multi-zone cooling approach where different temperature zones are established along the flow path to accommodate reaction profile changes. BASF's systems utilize real-time monitoring with embedded temperature and pressure sensors that feed into predictive control algorithms, allowing for automated adjustments to flow rates, cooling intensity, and residence times based on reaction parameters. Their FlowSafe™ technology includes emergency shutdown protocols that activate when parameters exceed safety thresholds, rapidly quenching reactions through coolant flooding and reactant diversion systems[1][3]. BASF has also pioneered the use of structured reactor internals that enhance mixing while improving heat transfer coefficients by up to 40% compared to conventional systems.

Strengths: Superior heat transfer efficiency through innovative microreactor design; integrated safety systems with predictive capabilities; scalable technology applicable from lab to production scale. Weaknesses: Higher capital investment required compared to batch systems; complex control systems require specialized expertise; potential for channel clogging in certain reaction types requiring additional maintenance protocols.

Key Innovations in Heat Management Technologies

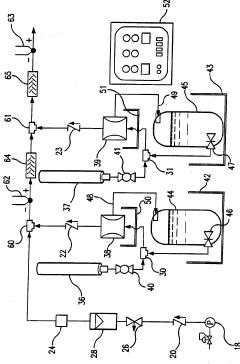

Method and apparatus for monitoring and controlling exothermic and endothermic chemical reactions.

PatentActiveMX2015004295A

Innovation

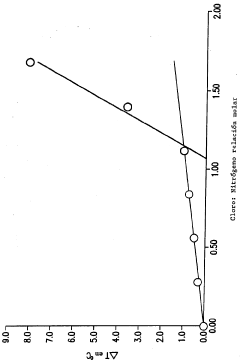

- A method and apparatus using differential temperature measurement to monitor and control exothermic or endothermic reactions by adjusting reactant flow rates based on temperature differences, ensuring safe and efficient production of desired products.

EXOTHERMAL REACTION CONTROL METHOD AND DEVICE INTENDED FOR ITS IMPLEMENTATION

PatentInactiveRU2010140901A

Innovation

- Introduction of an inert product (previously obtained from the same exothermic reaction) into the reactor when temperature/pressure exceeds critical values to control the reaction.

- Maintaining the inert product in the storage container at a higher pressure than inside the reactor, enabling rapid introduction when needed without additional pumping systems.

- The ability to simultaneously stop the introduction of reactants while introducing the inert product to quickly halt the exothermic reaction progression.

Scale-up Considerations for Industrial Implementation

Scaling up exothermic flow reactions from laboratory to industrial scale presents significant engineering challenges that must be addressed systematically. The transition requires careful consideration of heat transfer capabilities, as the surface-to-volume ratio decreases substantially with increasing reactor dimensions. Industrial implementation necessitates specialized heat exchange equipment, including intensified plate heat exchangers, multi-tubular reactors, or specialized microstructured devices that can maintain efficient thermal management at larger scales.

Material selection becomes increasingly critical during scale-up operations. Construction materials must withstand not only the chemical environment but also thermal cycling and mechanical stress associated with larger production volumes. Stainless steel alloys, specialized polymers, or ceramic-coated systems are often employed depending on the specific reaction conditions and corrosivity of the process streams.

Process control systems require substantial enhancement when scaling up exothermic flow reactions. Advanced distributed control systems (DCS) with multiple temperature monitoring points throughout the flow path become essential. Implementation of cascade control loops that integrate temperature, flow rate, and pressure measurements allows for responsive adjustments to maintain safe operating conditions. Predictive control algorithms that anticipate temperature excursions based on reaction kinetics data significantly improve safety margins.

Risk assessment methodologies must be rigorously applied during scale-up. This includes Hazard and Operability Studies (HAZOP), Layer of Protection Analysis (LOPA), and Failure Mode and Effects Analysis (FEMA) to identify potential failure points and establish appropriate safeguards. Particular attention must be paid to the increased consequences of thermal runaway at industrial scales, necessitating redundant safety systems and emergency shutdown protocols.

Economic considerations also influence scale-up strategies. The capital investment in sophisticated control systems and heat exchange equipment must be balanced against operational benefits such as improved yield, reduced waste, and enhanced safety. Modular approaches to scale-up, utilizing multiple parallel smaller-scale units rather than a single large reactor, often provide an optimal balance between safety, control precision, and economic viability.

Regulatory compliance becomes more stringent at industrial scales, particularly for pharmaceutical and fine chemical applications. Documentation of control strategy validation, demonstration of consistent thermal management across production batches, and establishment of clear operational boundaries are essential components of regulatory submissions for commercial manufacturing processes involving exothermic flow reactions.

Material selection becomes increasingly critical during scale-up operations. Construction materials must withstand not only the chemical environment but also thermal cycling and mechanical stress associated with larger production volumes. Stainless steel alloys, specialized polymers, or ceramic-coated systems are often employed depending on the specific reaction conditions and corrosivity of the process streams.

Process control systems require substantial enhancement when scaling up exothermic flow reactions. Advanced distributed control systems (DCS) with multiple temperature monitoring points throughout the flow path become essential. Implementation of cascade control loops that integrate temperature, flow rate, and pressure measurements allows for responsive adjustments to maintain safe operating conditions. Predictive control algorithms that anticipate temperature excursions based on reaction kinetics data significantly improve safety margins.

Risk assessment methodologies must be rigorously applied during scale-up. This includes Hazard and Operability Studies (HAZOP), Layer of Protection Analysis (LOPA), and Failure Mode and Effects Analysis (FEMA) to identify potential failure points and establish appropriate safeguards. Particular attention must be paid to the increased consequences of thermal runaway at industrial scales, necessitating redundant safety systems and emergency shutdown protocols.

Economic considerations also influence scale-up strategies. The capital investment in sophisticated control systems and heat exchange equipment must be balanced against operational benefits such as improved yield, reduced waste, and enhanced safety. Modular approaches to scale-up, utilizing multiple parallel smaller-scale units rather than a single large reactor, often provide an optimal balance between safety, control precision, and economic viability.

Regulatory compliance becomes more stringent at industrial scales, particularly for pharmaceutical and fine chemical applications. Documentation of control strategy validation, demonstration of consistent thermal management across production batches, and establishment of clear operational boundaries are essential components of regulatory submissions for commercial manufacturing processes involving exothermic flow reactions.

Risk Assessment and Safety Protocol Development

Risk assessment for exothermic flow reactions requires a systematic approach to identify, evaluate, and mitigate potential hazards. The inherent risks of managing heat-generating reactions in continuous flow systems stem from the possibility of thermal runaway, pressure build-up, and subsequent equipment failure. A comprehensive risk assessment framework begins with hazard identification through techniques such as HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis), specifically adapted for flow chemistry operations.

Temperature and pressure monitoring represent critical control points in exothermic flow reactions. Real-time monitoring systems with redundant sensors should be implemented at strategic locations throughout the flow path, particularly at reaction zones where heat generation is most intense. These systems must be integrated with automated shutdown protocols that activate when parameters exceed predetermined safety thresholds.

Safety protocol development for exothermic flow reactions should incorporate both preventive and responsive measures. Preventive protocols include proper reactor design with adequate heat exchange capacity, precise control of reactant concentrations, and implementation of flow rate limitations based on heat transfer capabilities. The establishment of safe operating windows through reaction calorimetry data provides essential boundaries for process parameters.

Emergency response procedures constitute a vital component of safety protocols. These should detail specific actions for various scenarios, including cooling system failures, unexpected pressure increases, or reactant delivery malfunctions. Automated safety systems such as emergency coolant injection, flow diversion to quench tanks, and rapid system depressurization mechanisms should be engineered into the flow setup.

Personnel training represents another crucial aspect of safety protocol development. Operators must be thoroughly trained in normal operating procedures, recognition of warning signs, and emergency response actions. Regular drills and simulations of potential failure scenarios ensure preparedness and minimize response time during actual emergencies.

Documentation and continuous improvement processes complete the safety framework. All risk assessments, safety protocols, incident reports, and near-miss analyses should be systematically documented and periodically reviewed. This information forms the foundation for iterative improvements to both risk assessment methodologies and safety protocols, creating a cycle of continuous enhancement in managing exothermic reactions in flow systems.

Temperature and pressure monitoring represent critical control points in exothermic flow reactions. Real-time monitoring systems with redundant sensors should be implemented at strategic locations throughout the flow path, particularly at reaction zones where heat generation is most intense. These systems must be integrated with automated shutdown protocols that activate when parameters exceed predetermined safety thresholds.

Safety protocol development for exothermic flow reactions should incorporate both preventive and responsive measures. Preventive protocols include proper reactor design with adequate heat exchange capacity, precise control of reactant concentrations, and implementation of flow rate limitations based on heat transfer capabilities. The establishment of safe operating windows through reaction calorimetry data provides essential boundaries for process parameters.

Emergency response procedures constitute a vital component of safety protocols. These should detail specific actions for various scenarios, including cooling system failures, unexpected pressure increases, or reactant delivery malfunctions. Automated safety systems such as emergency coolant injection, flow diversion to quench tanks, and rapid system depressurization mechanisms should be engineered into the flow setup.

Personnel training represents another crucial aspect of safety protocol development. Operators must be thoroughly trained in normal operating procedures, recognition of warning signs, and emergency response actions. Regular drills and simulations of potential failure scenarios ensure preparedness and minimize response time during actual emergencies.

Documentation and continuous improvement processes complete the safety framework. All risk assessments, safety protocols, incident reports, and near-miss analyses should be systematically documented and periodically reviewed. This information forms the foundation for iterative improvements to both risk assessment methodologies and safety protocols, creating a cycle of continuous enhancement in managing exothermic reactions in flow systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!