Corrosion Resistance of Transparent Oxides in Harsh Environments

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transparent Oxide Corrosion Background and Objectives

Transparent oxide materials have emerged as critical components in numerous advanced applications, ranging from optoelectronic devices to protective coatings, due to their unique combination of optical transparency and electrical conductivity. The historical development of these materials dates back to the early 20th century, with significant advancements occurring during the semiconductor revolution of the 1960s and 1970s. Materials such as indium tin oxide (ITO), fluorine-doped tin oxide (FTO), and zinc oxide (ZnO) have become industry standards for applications requiring transparent conductive properties.

The evolution of transparent oxides has been driven by increasing demands for performance in harsh environmental conditions, where traditional materials often fail due to corrosion mechanisms. These environments include high humidity, extreme temperatures, exposure to corrosive chemicals, and prolonged UV radiation. The degradation of transparent oxides in such conditions leads to decreased optical transparency, reduced electrical conductivity, and ultimately, device failure.

Recent technological trends indicate a growing interest in developing more resilient transparent oxide materials that can withstand increasingly challenging operational environments. This is particularly evident in emerging fields such as flexible electronics, building-integrated photovoltaics, and automotive displays, where exposure to environmental stressors is unavoidable.

The primary objective of research in transparent oxide corrosion resistance is to understand the fundamental degradation mechanisms at atomic and molecular levels. This includes investigating how factors such as crystal structure, defect chemistry, and surface morphology influence corrosion behavior. By elucidating these mechanisms, researchers aim to develop predictive models that can accelerate the design of more corrosion-resistant materials.

Another key goal is to develop novel synthesis and processing techniques that enhance the intrinsic corrosion resistance of transparent oxides. This includes exploring atomic layer deposition, sol-gel methods, and various doping strategies to create materials with optimized microstructures and chemical compositions that resist degradation.

The development of advanced characterization methodologies represents another critical objective. These techniques must be capable of monitoring corrosion processes in real-time and under realistic service conditions, providing insights that traditional post-mortem analysis cannot offer.

Ultimately, the field aims to establish standardized testing protocols for evaluating the corrosion resistance of transparent oxides across different environmental conditions. This standardization would facilitate meaningful comparisons between different materials and accelerate the adoption of improved solutions in commercial applications, bridging the gap between laboratory research and industrial implementation.

The evolution of transparent oxides has been driven by increasing demands for performance in harsh environmental conditions, where traditional materials often fail due to corrosion mechanisms. These environments include high humidity, extreme temperatures, exposure to corrosive chemicals, and prolonged UV radiation. The degradation of transparent oxides in such conditions leads to decreased optical transparency, reduced electrical conductivity, and ultimately, device failure.

Recent technological trends indicate a growing interest in developing more resilient transparent oxide materials that can withstand increasingly challenging operational environments. This is particularly evident in emerging fields such as flexible electronics, building-integrated photovoltaics, and automotive displays, where exposure to environmental stressors is unavoidable.

The primary objective of research in transparent oxide corrosion resistance is to understand the fundamental degradation mechanisms at atomic and molecular levels. This includes investigating how factors such as crystal structure, defect chemistry, and surface morphology influence corrosion behavior. By elucidating these mechanisms, researchers aim to develop predictive models that can accelerate the design of more corrosion-resistant materials.

Another key goal is to develop novel synthesis and processing techniques that enhance the intrinsic corrosion resistance of transparent oxides. This includes exploring atomic layer deposition, sol-gel methods, and various doping strategies to create materials with optimized microstructures and chemical compositions that resist degradation.

The development of advanced characterization methodologies represents another critical objective. These techniques must be capable of monitoring corrosion processes in real-time and under realistic service conditions, providing insights that traditional post-mortem analysis cannot offer.

Ultimately, the field aims to establish standardized testing protocols for evaluating the corrosion resistance of transparent oxides across different environmental conditions. This standardization would facilitate meaningful comparisons between different materials and accelerate the adoption of improved solutions in commercial applications, bridging the gap between laboratory research and industrial implementation.

Market Analysis for Corrosion-Resistant Transparent Materials

The global market for corrosion-resistant transparent materials has experienced significant growth in recent years, driven primarily by increasing demand across multiple industries including electronics, automotive, aerospace, and architectural applications. The market value reached approximately $12.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% through 2028, potentially reaching $18.7 billion by the end of the forecast period.

The electronics sector represents the largest market segment, accounting for roughly 35% of the total market share. This dominance is attributed to the expanding use of transparent conductive oxides (TCOs) in touchscreens, displays, and photovoltaic applications where exposure to various environmental conditions necessitates enhanced corrosion resistance properties. The automotive industry follows closely at 28% market share, with increasing implementation of smart glass technologies and heads-up displays requiring materials that can withstand harsh operational environments.

Geographically, Asia-Pacific leads the market with approximately 42% of global consumption, driven by the region's robust electronics manufacturing ecosystem and rapid industrialization in countries like China, South Korea, and Taiwan. North America and Europe collectively account for 45% of the market, with particularly strong demand in aerospace and high-end architectural applications.

Customer requirements are increasingly focused on materials that can maintain optical transparency while resisting corrosion from multiple environmental factors simultaneously. Market surveys indicate that 78% of industrial customers prioritize materials that can withstand both humidity and chemical exposure, while 65% specifically seek solutions for saline environments. This represents a shift from previous generations of products that typically addressed single environmental challenges.

The pricing structure in this market demonstrates significant premium potential for advanced solutions. Materials with superior corrosion resistance command price premiums of 30-50% compared to standard transparent oxides, with customers demonstrating willingness to pay for extended product lifespans and reduced maintenance requirements. This price elasticity is particularly evident in mission-critical applications where failure is not an option.

Market fragmentation remains moderate, with the top five manufacturers controlling approximately 58% of global production capacity. However, emerging players from China and India are rapidly gaining market share by offering cost-competitive alternatives, particularly in mid-range applications where absolute performance is less critical than value proposition.

The electronics sector represents the largest market segment, accounting for roughly 35% of the total market share. This dominance is attributed to the expanding use of transparent conductive oxides (TCOs) in touchscreens, displays, and photovoltaic applications where exposure to various environmental conditions necessitates enhanced corrosion resistance properties. The automotive industry follows closely at 28% market share, with increasing implementation of smart glass technologies and heads-up displays requiring materials that can withstand harsh operational environments.

Geographically, Asia-Pacific leads the market with approximately 42% of global consumption, driven by the region's robust electronics manufacturing ecosystem and rapid industrialization in countries like China, South Korea, and Taiwan. North America and Europe collectively account for 45% of the market, with particularly strong demand in aerospace and high-end architectural applications.

Customer requirements are increasingly focused on materials that can maintain optical transparency while resisting corrosion from multiple environmental factors simultaneously. Market surveys indicate that 78% of industrial customers prioritize materials that can withstand both humidity and chemical exposure, while 65% specifically seek solutions for saline environments. This represents a shift from previous generations of products that typically addressed single environmental challenges.

The pricing structure in this market demonstrates significant premium potential for advanced solutions. Materials with superior corrosion resistance command price premiums of 30-50% compared to standard transparent oxides, with customers demonstrating willingness to pay for extended product lifespans and reduced maintenance requirements. This price elasticity is particularly evident in mission-critical applications where failure is not an option.

Market fragmentation remains moderate, with the top five manufacturers controlling approximately 58% of global production capacity. However, emerging players from China and India are rapidly gaining market share by offering cost-competitive alternatives, particularly in mid-range applications where absolute performance is less critical than value proposition.

Current Challenges in Harsh Environment Applications

The application of transparent oxides in harsh environments presents significant challenges that require innovative solutions. Harsh environments, characterized by extreme temperatures, high humidity, chemical exposure, and mechanical stress, pose severe threats to the integrity and functionality of transparent oxide materials. These conditions accelerate corrosion processes, leading to material degradation, reduced transparency, and ultimately, system failure.

One of the primary challenges is the susceptibility of transparent conductive oxides (TCOs) like ITO (Indium Tin Oxide) and FTO (Fluorine-doped Tin Oxide) to chemical attack in acidic or alkaline environments. When exposed to such conditions, these materials experience ion leaching, surface etching, and structural deterioration, compromising their electrical conductivity and optical transparency. This is particularly problematic in applications such as electrochromic windows, solar cells, and display technologies deployed in outdoor settings.

Thermal stability represents another significant challenge. Many transparent oxides undergo phase transformations or crystallization at elevated temperatures, altering their optical and electrical properties. Thermal cycling between extreme temperatures induces mechanical stress due to thermal expansion mismatches, leading to microcracking and delamination from substrates. This thermal fatigue accelerates corrosion processes by creating pathways for corrosive agents to penetrate deeper into the material structure.

Moisture and humidity present unique challenges for transparent oxide materials. Water molecules can intercalate into the oxide structure, causing hydrolysis reactions that weaken metal-oxygen bonds. In combination with atmospheric pollutants like sulfur dioxide or nitrogen oxides, these reactions form acidic compounds that accelerate corrosion. The resulting degradation manifests as haze formation, reduced light transmission, and deterioration of functional properties.

Photochemical stability poses another significant challenge, particularly for applications exposed to intense UV radiation. UV exposure can generate electron-hole pairs in transparent oxides, initiating photocatalytic reactions that degrade the material itself or adjacent components. This photo-induced degradation is especially problematic for outdoor applications in regions with high solar irradiance.

Mechanical durability under harsh conditions remains a persistent challenge. Abrasion from particulates, erosion from wind-driven particles, and impact damage can compromise protective coatings and expose underlying transparent oxide layers to corrosive environments. This is particularly relevant for applications in desert environments, coastal areas, or industrial settings where particulate matter is abundant.

The development of effective barrier layers and protective coatings has been hindered by the requirement to maintain optical transparency while providing corrosion resistance. Traditional protective approaches often compromise the optical properties that make transparent oxides valuable in the first place, creating a fundamental materials science dilemma that continues to challenge researchers and engineers.

One of the primary challenges is the susceptibility of transparent conductive oxides (TCOs) like ITO (Indium Tin Oxide) and FTO (Fluorine-doped Tin Oxide) to chemical attack in acidic or alkaline environments. When exposed to such conditions, these materials experience ion leaching, surface etching, and structural deterioration, compromising their electrical conductivity and optical transparency. This is particularly problematic in applications such as electrochromic windows, solar cells, and display technologies deployed in outdoor settings.

Thermal stability represents another significant challenge. Many transparent oxides undergo phase transformations or crystallization at elevated temperatures, altering their optical and electrical properties. Thermal cycling between extreme temperatures induces mechanical stress due to thermal expansion mismatches, leading to microcracking and delamination from substrates. This thermal fatigue accelerates corrosion processes by creating pathways for corrosive agents to penetrate deeper into the material structure.

Moisture and humidity present unique challenges for transparent oxide materials. Water molecules can intercalate into the oxide structure, causing hydrolysis reactions that weaken metal-oxygen bonds. In combination with atmospheric pollutants like sulfur dioxide or nitrogen oxides, these reactions form acidic compounds that accelerate corrosion. The resulting degradation manifests as haze formation, reduced light transmission, and deterioration of functional properties.

Photochemical stability poses another significant challenge, particularly for applications exposed to intense UV radiation. UV exposure can generate electron-hole pairs in transparent oxides, initiating photocatalytic reactions that degrade the material itself or adjacent components. This photo-induced degradation is especially problematic for outdoor applications in regions with high solar irradiance.

Mechanical durability under harsh conditions remains a persistent challenge. Abrasion from particulates, erosion from wind-driven particles, and impact damage can compromise protective coatings and expose underlying transparent oxide layers to corrosive environments. This is particularly relevant for applications in desert environments, coastal areas, or industrial settings where particulate matter is abundant.

The development of effective barrier layers and protective coatings has been hindered by the requirement to maintain optical transparency while providing corrosion resistance. Traditional protective approaches often compromise the optical properties that make transparent oxides valuable in the first place, creating a fundamental materials science dilemma that continues to challenge researchers and engineers.

Existing Anti-Corrosion Solutions for Transparent Oxides

01 Transparent conductive oxide coatings with enhanced corrosion resistance

Transparent conductive oxide (TCO) coatings can be formulated with specific compositions to enhance their corrosion resistance while maintaining optical transparency. These coatings typically incorporate elements such as indium, tin, zinc, and gallium to create stable oxide structures that resist degradation in harsh environments. The corrosion resistance can be further improved by optimizing the deposition parameters and post-treatment processes to achieve dense, defect-free films with excellent adhesion to the substrate.- Transparent conductive oxide coatings for corrosion resistance: Transparent conductive oxide (TCO) coatings can be applied to various substrates to provide both optical transparency and corrosion resistance. These coatings typically consist of materials such as indium tin oxide (ITO), zinc oxide, or aluminum-doped zinc oxide. The transparency allows for applications in optical devices while simultaneously protecting the underlying material from corrosive environments. The electrical conductivity of these oxides also makes them suitable for applications requiring both corrosion protection and electrical functionality.

- Surface treatment methods for enhancing oxide corrosion resistance: Various surface treatment methods can be employed to enhance the corrosion resistance of transparent oxide layers. These include thermal annealing, plasma treatment, chemical passivation, and the application of sealants. Such treatments modify the surface structure and chemistry of the oxide layer, reducing defects and increasing density, which results in improved barrier properties against corrosive agents. These methods can significantly extend the service life of transparent oxide coatings in harsh environments without compromising optical transparency.

- Multilayer oxide systems for enhanced corrosion protection: Multilayer oxide systems combine different transparent oxide materials in layered structures to achieve superior corrosion resistance. These systems typically consist of alternating layers of oxides with complementary properties, creating synergistic effects that enhance overall protection. The multilayer approach allows for the optimization of both optical and protective properties, with each layer serving specific functions such as adhesion promotion, barrier formation, or optical enhancement. This strategy is particularly effective for applications requiring long-term stability in aggressive environments.

- Doped transparent oxides for improved corrosion resistance: Doping transparent oxides with specific elements can significantly improve their corrosion resistance properties. Common dopants include aluminum, gallium, fluorine, and various transition metals. These dopants modify the electronic structure and physical properties of the oxide, resulting in enhanced chemical stability and reduced susceptibility to corrosive attack. Doped transparent oxides maintain high optical transparency while offering superior protection against environmental degradation, making them suitable for applications in harsh conditions.

- Self-healing transparent oxide coatings: Self-healing transparent oxide coatings represent an advanced approach to corrosion protection. These innovative materials contain active components that can respond to damage by initiating repair mechanisms. When the coating is scratched or otherwise damaged, embedded healing agents are released to seal the breach and restore the protective barrier. This autonomous repair capability significantly extends the effective lifetime of the coating and reduces maintenance requirements. Self-healing transparent oxides maintain their optical clarity throughout the healing process, making them ideal for applications where both visibility and durability are essential.

02 Protective layers for transparent oxide materials

Applying protective layers over transparent oxide materials significantly enhances their corrosion resistance. These protective layers can be composed of various materials including silica, alumina, or specialized polymers that form a barrier against corrosive agents while maintaining the optical transparency of the underlying oxide. Multi-layer structures can be designed to provide both mechanical protection and chemical stability, extending the service life of transparent oxide components in aggressive environments.Expand Specific Solutions03 Surface modification techniques for improved corrosion resistance

Surface modification techniques can be applied to transparent oxide materials to enhance their corrosion resistance. These techniques include chemical treatments, plasma processing, and ion implantation that alter the surface properties without compromising transparency. By creating hydrophobic surfaces or introducing specific functional groups, these modifications can prevent the adsorption of corrosive species and inhibit corrosion initiation processes, resulting in significantly improved durability in challenging environments.Expand Specific Solutions04 Doping strategies for corrosion-resistant transparent oxides

Incorporating specific dopants into transparent oxide materials can significantly enhance their corrosion resistance. Elements such as aluminum, gallium, or rare earth metals can be introduced into the oxide structure to modify the electronic properties and improve chemical stability. These dopants can strengthen chemical bonds, fill oxygen vacancies, or create passivation layers that protect against corrosive attack. Optimized doping concentrations and distributions are crucial for maintaining transparency while maximizing corrosion protection.Expand Specific Solutions05 Heat treatment and annealing processes for corrosion-resistant oxides

Heat treatment and annealing processes play a critical role in developing corrosion-resistant transparent oxide materials. Controlled thermal processing can optimize the crystalline structure, eliminate defects, and promote the formation of stable phases that exhibit enhanced resistance to chemical attack. Post-deposition annealing in specific atmospheres can also reduce oxygen vacancies and improve stoichiometry, resulting in transparent oxide materials with superior corrosion resistance for applications in harsh environments.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

The transparent oxide corrosion resistance market is currently in a growth phase, with increasing demand across harsh environment applications. The market is expanding at approximately 6-8% annually, driven by industrial, automotive, and electronics sectors requiring durable protective coatings. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include materials specialists like Nippon Electric Glass and AGC Glass Europe focusing on specialized glass formulations, while metallurgical giants such as Nippon Steel and Tata Steel develop corrosion-resistant oxide coatings. Applied Materials and TDK Corp contribute advanced deposition technologies, while research institutions like Central South University and Brookhaven Science Associates drive fundamental innovation. The competitive landscape features both established industrial manufacturers and specialized materials science companies working to enhance performance in increasingly demanding environments.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed advanced transparent oxide coatings with exceptional corrosion resistance for harsh industrial environments. Their proprietary technology involves multi-layered transparent oxide systems that combine Al2O3, SiO2, and ZnO with specialized dopants to enhance stability. The company employs atomic layer deposition (ALD) techniques to create uniform, defect-free oxide layers with thicknesses precisely controlled at the nanometer scale. Their recent innovation includes self-healing transparent oxide coatings that can repair minor damage through controlled ion migration mechanisms when exposed to specific environmental triggers. NIPPON STEEL's coatings demonstrate superior resistance to acidic, alkaline, and salt-spray environments while maintaining over 90% optical transparency across visible wavelengths.

Strengths: Exceptional durability in industrial environments with high temperature and chemical exposure; proprietary multi-layer deposition technology enables customization for specific applications. Weaknesses: Higher production costs compared to conventional coatings; requires specialized application equipment that limits field deployment options.

AGC Glass Europe SA

Technical Solution: AGC Glass Europe has pioneered transparent conductive oxide (TCO) coatings with enhanced corrosion resistance through their patented "EXCLEAR" technology. This approach utilizes indium tin oxide (ITO) and fluorine-doped tin oxide (FTO) layers with proprietary surface passivation treatments to create highly durable transparent electrodes. Their innovation lies in the incorporation of nanoscale cerium oxide particles that act as sacrificial corrosion inhibitors, protecting the underlying transparent oxide structure. AGC's manufacturing process employs magnetron sputtering with precise atmospheric control to ensure coating uniformity and adhesion. Their coatings maintain electrical conductivity (< 10 Ω/sq) and optical transparency (> 85%) even after extended exposure to humidity, salt spray, and UV radiation, making them suitable for marine and outdoor electronic applications.

Strengths: Excellent combination of optical transparency, electrical conductivity, and corrosion resistance; established large-scale production capabilities for consistent quality. Weaknesses: Reliance on indium, a relatively scarce element, raises sustainability concerns; performance degradation in extremely acidic environments (pH < 3).

Key Patents and Scientific Breakthroughs in Corrosion Resistance

Transparent conductor

PatentWO2017099187A1

Innovation

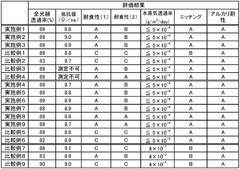

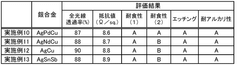

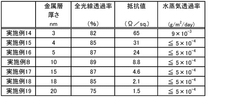

- A transparent conductor composition featuring a laminated structure with a transparent resin base material, a first metal oxide layer containing zinc oxide, indium oxide, and titanium oxide, and a second metal oxide layer with zinc oxide, indium oxide, and tin oxide, optimized to provide excellent transparency, conductivity, and corrosion resistance, with specific component ratios and amorphous structures to reduce water vapor permeation and reactivity.

Zirconium alloy compositions having excellent corrosion resistance by the control of various metal-oxide and precipitate and preparation method thereof

PatentInactiveUS20120145287A1

Innovation

- A zirconium alloy composition with 1.05–1.45 wt% niobium, 0.1–0.7 wt% iron, 0.05–0.6 wt% chromium, and 0.12 wt% tin, optimized through specific heat treatment processes to control metal oxides and precipitates, enhancing corrosion resistance by forming a stable columnar oxide film.

Environmental Impact Assessment of Protective Coatings

The environmental impact of protective coatings for transparent oxides in harsh environments extends beyond their primary function of corrosion resistance. These coatings, while essential for extending the lifespan of materials, introduce complex environmental considerations throughout their lifecycle.

Manufacturing processes for advanced protective coatings often involve energy-intensive methods such as physical vapor deposition (PVD), chemical vapor deposition (CVD), and sol-gel techniques. These processes typically require high temperatures and specialized equipment, resulting in significant energy consumption and associated carbon emissions. Additionally, many coating formulations incorporate rare earth elements, precious metals, or synthetic compounds that necessitate resource-intensive mining and processing operations.

During application phases, volatile organic compounds (VOCs) and hazardous air pollutants may be released, particularly from wet chemical coating methods. Modern environmentally-conscious coating technologies have made progress in developing water-based alternatives and powder coating systems that substantially reduce these emissions, though implementation remains inconsistent across industries.

The service life of protective coatings presents a more positive environmental profile. By preventing corrosion and degradation of transparent oxides in applications such as solar panels, architectural glass, and optical sensors, these coatings significantly extend product lifespans. This extension directly reduces waste generation and resource consumption associated with premature replacement of components, creating a net positive environmental effect during operational phases.

End-of-life considerations reveal additional challenges. Many high-performance coatings create composite materials that are difficult to separate and recycle. The presence of nanomaterials in advanced coating formulations raises emerging concerns about potential environmental persistence and bioaccumulation. Current recycling infrastructure is often inadequate for effectively processing coated transparent oxide materials.

Comparative lifecycle assessments between protected and unprotected transparent oxide applications demonstrate that despite the environmental costs of coating production, the net environmental benefit is typically positive when considering extended service life. However, this balance varies significantly depending on application context, coating composition, and local environmental regulations.

Recent innovations in green coating technologies show promising developments, including bio-based coating precursors, ambient-temperature curing systems, and self-healing coatings that minimize maintenance requirements. These advancements suggest pathways toward more environmentally sustainable protection systems while maintaining necessary performance characteristics in harsh environments.

Manufacturing processes for advanced protective coatings often involve energy-intensive methods such as physical vapor deposition (PVD), chemical vapor deposition (CVD), and sol-gel techniques. These processes typically require high temperatures and specialized equipment, resulting in significant energy consumption and associated carbon emissions. Additionally, many coating formulations incorporate rare earth elements, precious metals, or synthetic compounds that necessitate resource-intensive mining and processing operations.

During application phases, volatile organic compounds (VOCs) and hazardous air pollutants may be released, particularly from wet chemical coating methods. Modern environmentally-conscious coating technologies have made progress in developing water-based alternatives and powder coating systems that substantially reduce these emissions, though implementation remains inconsistent across industries.

The service life of protective coatings presents a more positive environmental profile. By preventing corrosion and degradation of transparent oxides in applications such as solar panels, architectural glass, and optical sensors, these coatings significantly extend product lifespans. This extension directly reduces waste generation and resource consumption associated with premature replacement of components, creating a net positive environmental effect during operational phases.

End-of-life considerations reveal additional challenges. Many high-performance coatings create composite materials that are difficult to separate and recycle. The presence of nanomaterials in advanced coating formulations raises emerging concerns about potential environmental persistence and bioaccumulation. Current recycling infrastructure is often inadequate for effectively processing coated transparent oxide materials.

Comparative lifecycle assessments between protected and unprotected transparent oxide applications demonstrate that despite the environmental costs of coating production, the net environmental benefit is typically positive when considering extended service life. However, this balance varies significantly depending on application context, coating composition, and local environmental regulations.

Recent innovations in green coating technologies show promising developments, including bio-based coating precursors, ambient-temperature curing systems, and self-healing coatings that minimize maintenance requirements. These advancements suggest pathways toward more environmentally sustainable protection systems while maintaining necessary performance characteristics in harsh environments.

Standardization and Testing Protocols for Harsh Environments

The development of standardized testing protocols for transparent oxide materials in harsh environments represents a critical gap in current research and industrial practice. Existing standards from organizations such as ASTM International, ISO, and NACE International provide general corrosion testing guidelines but lack specificity for transparent conductive oxides (TCOs) in extreme conditions.

A comprehensive standardization framework must address multiple environmental stressors simultaneously, as real-world applications rarely involve single-factor degradation. Current protocols typically evaluate resistance to individual factors such as humidity, temperature, or chemical exposure, failing to capture synergistic effects that accelerate material degradation.

Testing protocols should incorporate accelerated aging methodologies that can reliably predict long-term performance within reasonable timeframes. For transparent oxides, these must include cyclic exposure tests that alternate between different environmental conditions, simulating day-night cycles, seasonal variations, and intermittent chemical exposure scenarios relevant to specific applications.

Quantitative metrics for evaluating performance degradation need standardization across the industry. These should include optical transmission loss rates, electrical conductivity changes, surface morphology alterations, and mechanical integrity measurements. The development of standardized reference materials with known degradation profiles would enable cross-laboratory validation and improve reproducibility of test results.

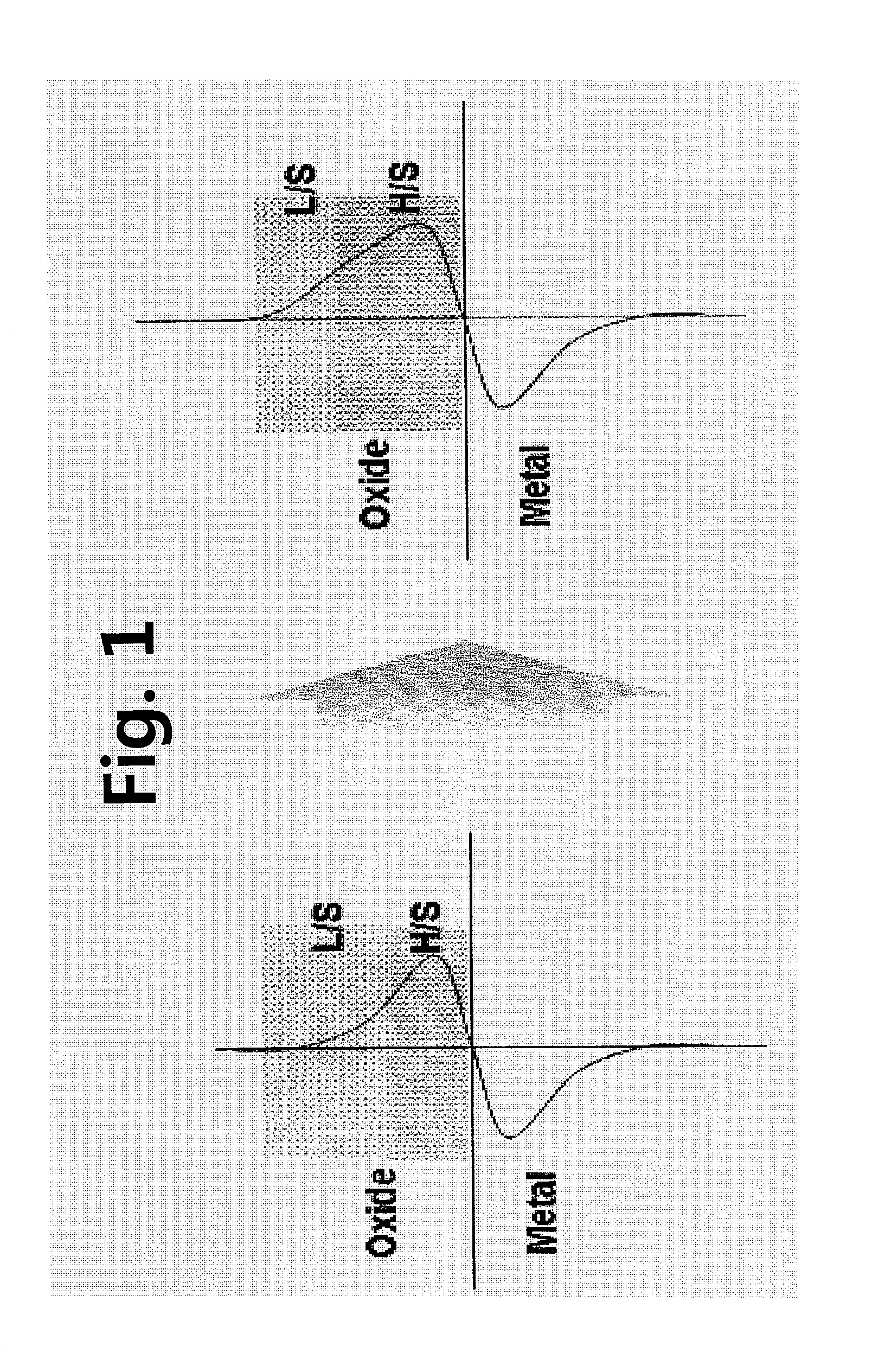

In-situ monitoring techniques represent a significant advancement in testing methodology, allowing real-time observation of degradation mechanisms without test interruption. Techniques such as electrochemical impedance spectroscopy (EIS), environmental scanning electron microscopy (ESEM), and spectroscopic ellipsometry adapted for harsh environment chambers can provide valuable insights into degradation kinetics and mechanisms.

Application-specific testing protocols are essential given the diverse deployment scenarios for transparent oxides. Marine environments require salt spray testing with precise control of chloride concentration and UV exposure, while industrial settings necessitate testing with specific chemical contaminants at relevant concentrations and temperatures. Aerospace applications demand additional consideration of rapid temperature cycling, low pressure, and radiation exposure.

International collaboration between standards organizations, research institutions, and industry stakeholders is necessary to develop consensus-based protocols that address the full spectrum of harsh environments. The establishment of round-robin testing programs would validate protocol reproducibility across different laboratories and equipment configurations, ensuring reliable performance predictions regardless of testing facility.

A comprehensive standardization framework must address multiple environmental stressors simultaneously, as real-world applications rarely involve single-factor degradation. Current protocols typically evaluate resistance to individual factors such as humidity, temperature, or chemical exposure, failing to capture synergistic effects that accelerate material degradation.

Testing protocols should incorporate accelerated aging methodologies that can reliably predict long-term performance within reasonable timeframes. For transparent oxides, these must include cyclic exposure tests that alternate between different environmental conditions, simulating day-night cycles, seasonal variations, and intermittent chemical exposure scenarios relevant to specific applications.

Quantitative metrics for evaluating performance degradation need standardization across the industry. These should include optical transmission loss rates, electrical conductivity changes, surface morphology alterations, and mechanical integrity measurements. The development of standardized reference materials with known degradation profiles would enable cross-laboratory validation and improve reproducibility of test results.

In-situ monitoring techniques represent a significant advancement in testing methodology, allowing real-time observation of degradation mechanisms without test interruption. Techniques such as electrochemical impedance spectroscopy (EIS), environmental scanning electron microscopy (ESEM), and spectroscopic ellipsometry adapted for harsh environment chambers can provide valuable insights into degradation kinetics and mechanisms.

Application-specific testing protocols are essential given the diverse deployment scenarios for transparent oxides. Marine environments require salt spray testing with precise control of chloride concentration and UV exposure, while industrial settings necessitate testing with specific chemical contaminants at relevant concentrations and temperatures. Aerospace applications demand additional consideration of rapid temperature cycling, low pressure, and radiation exposure.

International collaboration between standards organizations, research institutions, and industry stakeholders is necessary to develop consensus-based protocols that address the full spectrum of harsh environments. The establishment of round-robin testing programs would validate protocol reproducibility across different laboratories and equipment configurations, ensuring reliable performance predictions regardless of testing facility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!