The Thermal Performance of Transparent Oxides in Cooling Applications

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transparent Oxide Thermal Technology Background and Objectives

Transparent oxide materials have emerged as a significant technological advancement in thermal management systems, particularly for cooling applications. The evolution of these materials spans several decades, beginning with basic research into oxide semiconductors in the 1950s and accelerating with the development of transparent conducting oxides (TCOs) for electronic applications in the 1970s. The thermal properties of these materials remained relatively unexplored until the early 2000s when increasing demands for energy-efficient building materials and advanced cooling systems prompted renewed interest in their thermal characteristics.

The technological trajectory has been marked by progressive improvements in material synthesis techniques, allowing for precise control over optical transparency and thermal conductivity. Key milestones include the development of indium tin oxide (ITO) with enhanced thermal properties in the 1990s, the emergence of aluminum-doped zinc oxide (AZO) as a cost-effective alternative in the early 2000s, and recent breakthroughs in gallium-doped zinc oxide (GZO) systems with optimized thermal performance while maintaining high visible light transmission.

Current research focuses on understanding the fundamental relationship between material structure and thermal behavior in transparent oxides. This includes investigating phonon transport mechanisms, thermal boundary resistance at interfaces, and the impact of defects and dopants on thermal conductivity. The interplay between optical transparency and thermal properties presents a unique challenge, as modifications that enhance thermal performance often compromise transparency, creating a critical optimization problem.

The primary technical objectives in this field include developing transparent oxide materials with thermal conductivity exceeding 10 W/m·K while maintaining visible light transmission above 85%. Additionally, researchers aim to create materials with tunable thermal properties that can respond to environmental conditions, potentially enabling smart cooling systems. Durability under thermal cycling and resistance to environmental degradation represent additional technical goals essential for practical applications.

Another significant objective is the development of scalable, cost-effective manufacturing processes that can transition these advanced materials from laboratory settings to commercial production. Current techniques such as magnetron sputtering and sol-gel processes face challenges in maintaining consistent properties across large surface areas, limiting widespread adoption in building-scale cooling applications.

The convergence of nanotechnology with transparent oxide research has opened new avenues for innovation, including nanostructured oxide films with engineered thermal pathways and hybrid materials combining oxides with other thermally conductive components. These approaches show promise for breaking traditional performance trade-offs between optical and thermal properties, potentially enabling next-generation cooling technologies with unprecedented efficiency.

The technological trajectory has been marked by progressive improvements in material synthesis techniques, allowing for precise control over optical transparency and thermal conductivity. Key milestones include the development of indium tin oxide (ITO) with enhanced thermal properties in the 1990s, the emergence of aluminum-doped zinc oxide (AZO) as a cost-effective alternative in the early 2000s, and recent breakthroughs in gallium-doped zinc oxide (GZO) systems with optimized thermal performance while maintaining high visible light transmission.

Current research focuses on understanding the fundamental relationship between material structure and thermal behavior in transparent oxides. This includes investigating phonon transport mechanisms, thermal boundary resistance at interfaces, and the impact of defects and dopants on thermal conductivity. The interplay between optical transparency and thermal properties presents a unique challenge, as modifications that enhance thermal performance often compromise transparency, creating a critical optimization problem.

The primary technical objectives in this field include developing transparent oxide materials with thermal conductivity exceeding 10 W/m·K while maintaining visible light transmission above 85%. Additionally, researchers aim to create materials with tunable thermal properties that can respond to environmental conditions, potentially enabling smart cooling systems. Durability under thermal cycling and resistance to environmental degradation represent additional technical goals essential for practical applications.

Another significant objective is the development of scalable, cost-effective manufacturing processes that can transition these advanced materials from laboratory settings to commercial production. Current techniques such as magnetron sputtering and sol-gel processes face challenges in maintaining consistent properties across large surface areas, limiting widespread adoption in building-scale cooling applications.

The convergence of nanotechnology with transparent oxide research has opened new avenues for innovation, including nanostructured oxide films with engineered thermal pathways and hybrid materials combining oxides with other thermally conductive components. These approaches show promise for breaking traditional performance trade-offs between optical and thermal properties, potentially enabling next-generation cooling technologies with unprecedented efficiency.

Market Analysis for Transparent Cooling Solutions

The transparent cooling materials market is experiencing significant growth, driven by increasing demand for energy-efficient building solutions and sustainable cooling technologies. Current market valuations indicate that the global transparent thermal management materials sector reached approximately 3.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 8.7% through 2030. This growth trajectory is primarily fueled by escalating energy costs and stringent building efficiency regulations across developed economies.

The construction sector represents the largest application segment, accounting for nearly 45% of market demand. Within this segment, commercial buildings constitute the primary end-users, as corporations increasingly prioritize both aesthetic appeal and energy efficiency in their facilities. Residential applications are growing rapidly as well, particularly in regions experiencing extreme heat conditions due to climate change.

Automotive applications form the second-largest market segment, with transparent thermal oxides being integrated into windshields and sunroofs to reduce cabin temperatures and decrease air conditioning loads. This segment is expected to grow at 10.2% annually, outpacing the overall market as electric vehicle manufacturers seek to maximize range by reducing cooling energy requirements.

Geographically, North America and Europe currently dominate market consumption, collectively representing approximately 62% of global demand. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading adoption rates due to rapid urbanization and increasing disposable incomes. These markets are projected to grow at 12.5% annually over the next five years.

Consumer willingness to pay premiums for transparent cooling solutions varies significantly by application. In premium automotive and luxury commercial construction, customers demonstrate price tolerance up to 30% above conventional materials. However, in mass-market residential applications, this premium acceptance drops to 5-10%, creating a significant barrier to widespread adoption.

Market penetration remains relatively low, with transparent cooling oxides present in less than 8% of eligible applications globally. This indicates substantial growth potential but also highlights challenges in cost reduction and performance optimization that must be addressed to achieve mass-market adoption.

The competitive landscape features both established materials science corporations and innovative startups. Major chemical companies have begun acquiring specialized transparent oxide technology firms, signaling industry consolidation and recognition of the technology's strategic importance in addressing global cooling challenges.

The construction sector represents the largest application segment, accounting for nearly 45% of market demand. Within this segment, commercial buildings constitute the primary end-users, as corporations increasingly prioritize both aesthetic appeal and energy efficiency in their facilities. Residential applications are growing rapidly as well, particularly in regions experiencing extreme heat conditions due to climate change.

Automotive applications form the second-largest market segment, with transparent thermal oxides being integrated into windshields and sunroofs to reduce cabin temperatures and decrease air conditioning loads. This segment is expected to grow at 10.2% annually, outpacing the overall market as electric vehicle manufacturers seek to maximize range by reducing cooling energy requirements.

Geographically, North America and Europe currently dominate market consumption, collectively representing approximately 62% of global demand. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading adoption rates due to rapid urbanization and increasing disposable incomes. These markets are projected to grow at 12.5% annually over the next five years.

Consumer willingness to pay premiums for transparent cooling solutions varies significantly by application. In premium automotive and luxury commercial construction, customers demonstrate price tolerance up to 30% above conventional materials. However, in mass-market residential applications, this premium acceptance drops to 5-10%, creating a significant barrier to widespread adoption.

Market penetration remains relatively low, with transparent cooling oxides present in less than 8% of eligible applications globally. This indicates substantial growth potential but also highlights challenges in cost reduction and performance optimization that must be addressed to achieve mass-market adoption.

The competitive landscape features both established materials science corporations and innovative startups. Major chemical companies have begun acquiring specialized transparent oxide technology firms, signaling industry consolidation and recognition of the technology's strategic importance in addressing global cooling challenges.

Current Challenges in Transparent Oxide Thermal Performance

Despite significant advancements in transparent oxide materials for cooling applications, several critical challenges continue to impede their optimal thermal performance. The inherent trade-off between optical transparency and thermal conductivity represents the most fundamental obstacle. As transparency increases, thermal conductivity often decreases, creating a performance ceiling that limits application efficiency. This inverse relationship stems from the atomic structure and electron behavior in these materials, where modifications that enhance optical properties frequently disrupt phonon transport pathways.

Material stability under thermal cycling presents another significant challenge. Transparent oxides in cooling applications typically experience repeated temperature fluctuations, leading to thermal expansion and contraction cycles. These cycles can induce microcracks, delamination, and gradual performance degradation. For instance, indium tin oxide (ITO) and aluminum-doped zinc oxide (AZO) show notable performance deterioration after extended thermal cycling, particularly at temperature differentials exceeding 100°C.

Interface thermal resistance between transparent oxides and adjacent materials constitutes a major bottleneck in system-level thermal management. Poor thermal coupling at these interfaces creates heat transfer barriers that significantly reduce overall cooling efficiency. Current deposition techniques struggle to create atomically smooth interfaces with minimal defects, resulting in phonon scattering and reduced heat transfer across boundaries.

Manufacturing scalability remains problematic for high-performance transparent oxide cooling systems. Laboratory-scale processes that produce materials with excellent thermal properties often fail to translate to industrial-scale production. Techniques like atomic layer deposition (ALD) and pulsed laser deposition (PLD) yield superior quality films but face significant challenges in scaling to commercially viable dimensions and production rates.

Environmental stability poses additional concerns, particularly in outdoor applications where transparent oxides must withstand humidity, UV radiation, and atmospheric pollutants. Many promising materials exhibit accelerated degradation under these conditions, with water vapor infiltration being especially problematic for materials like vanadium dioxide (VO₂) and tungsten-doped VO₂, which are otherwise promising for thermochromic cooling applications.

Cost factors further constrain widespread adoption, as high-performance transparent oxides often incorporate expensive elements like indium or specialized dopants. The complex processing requirements and high-purity precursors needed for optimal thermal performance significantly increase production costs, limiting commercial viability despite technical promise.

Material stability under thermal cycling presents another significant challenge. Transparent oxides in cooling applications typically experience repeated temperature fluctuations, leading to thermal expansion and contraction cycles. These cycles can induce microcracks, delamination, and gradual performance degradation. For instance, indium tin oxide (ITO) and aluminum-doped zinc oxide (AZO) show notable performance deterioration after extended thermal cycling, particularly at temperature differentials exceeding 100°C.

Interface thermal resistance between transparent oxides and adjacent materials constitutes a major bottleneck in system-level thermal management. Poor thermal coupling at these interfaces creates heat transfer barriers that significantly reduce overall cooling efficiency. Current deposition techniques struggle to create atomically smooth interfaces with minimal defects, resulting in phonon scattering and reduced heat transfer across boundaries.

Manufacturing scalability remains problematic for high-performance transparent oxide cooling systems. Laboratory-scale processes that produce materials with excellent thermal properties often fail to translate to industrial-scale production. Techniques like atomic layer deposition (ALD) and pulsed laser deposition (PLD) yield superior quality films but face significant challenges in scaling to commercially viable dimensions and production rates.

Environmental stability poses additional concerns, particularly in outdoor applications where transparent oxides must withstand humidity, UV radiation, and atmospheric pollutants. Many promising materials exhibit accelerated degradation under these conditions, with water vapor infiltration being especially problematic for materials like vanadium dioxide (VO₂) and tungsten-doped VO₂, which are otherwise promising for thermochromic cooling applications.

Cost factors further constrain widespread adoption, as high-performance transparent oxides often incorporate expensive elements like indium or specialized dopants. The complex processing requirements and high-purity precursors needed for optimal thermal performance significantly increase production costs, limiting commercial viability despite technical promise.

Current Technical Solutions for Transparent Thermal Management

01 Transparent conductive oxide films with enhanced thermal properties

Transparent conductive oxide (TCO) films can be engineered to exhibit improved thermal performance while maintaining optical transparency. These films typically incorporate materials such as indium tin oxide (ITO), zinc oxide, or aluminum-doped zinc oxide. By controlling the deposition parameters, doping levels, and film thickness, the thermal conductivity and stability of these oxides can be significantly enhanced, making them suitable for applications requiring both optical transparency and heat management.- Transparent conductive oxide films with enhanced thermal properties: Transparent conductive oxide (TCO) films can be engineered to exhibit improved thermal performance while maintaining optical transparency. These materials typically incorporate elements like indium, tin, zinc, or gallium to create oxides with both electrical conductivity and thermal stability. Various deposition techniques such as sputtering, chemical vapor deposition, or sol-gel methods can be used to optimize the thermal conductivity and heat dissipation properties while preserving transparency.

- Thermal management in transparent oxide semiconductor devices: Transparent oxide semiconductors require effective thermal management strategies to maintain performance and reliability. This includes the development of heat dissipation structures, thermal interface materials, and device architectures that minimize thermal resistance. Advanced cooling techniques and thermally conductive substrates can be integrated with transparent oxide layers to improve overall thermal performance in applications such as displays, solar cells, and electronic devices.

- Doping strategies for improved thermal conductivity in transparent oxides: Strategic doping of transparent oxide materials can significantly enhance their thermal conductivity while maintaining optical transparency. By introducing specific dopants at controlled concentrations, the phonon transport properties can be modified to improve heat transfer. Common dopants include aluminum, gallium, and rare earth elements, which can create optimized crystal structures that facilitate better thermal performance without compromising the transparency required for optical applications.

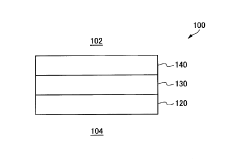

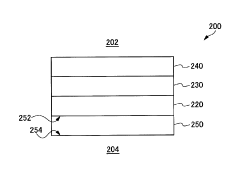

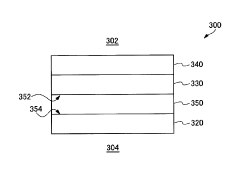

- Multilayer transparent oxide structures for thermal insulation: Multilayer structures incorporating transparent oxide materials can be designed to provide thermal insulation properties while maintaining optical transparency. These structures typically consist of alternating layers of different oxide materials with varying thermal conductivities, creating thermal barriers that reduce heat transfer. Such multilayer systems can be optimized for specific wavelength transmission while providing effective thermal management in applications such as energy-efficient windows, solar thermal collectors, and electronic displays.

- Nanostructured transparent oxides for enhanced thermal stability: Nanostructuring of transparent oxide materials can significantly improve their thermal stability and performance. By controlling the material at the nanoscale through techniques such as nanoparticle incorporation, nanoporous structures, or nanolaminates, the thermal properties can be tailored while maintaining optical transparency. These nanostructured transparent oxides exhibit enhanced resistance to thermal degradation, improved thermal shock resistance, and better long-term stability under thermal cycling conditions, making them suitable for high-temperature applications.

02 Thermal barrier properties of transparent oxide coatings

Certain transparent oxide coatings can function as effective thermal barriers while allowing visible light transmission. These coatings can be designed with specific microstructures and compositions to minimize heat transfer through radiation, conduction, and convection. Multi-layer oxide structures can be particularly effective, creating interfaces that scatter phonons and reduce thermal conductivity while maintaining high visible light transmittance. These materials are valuable for energy-efficient windows, solar panels, and electronic displays.Expand Specific Solutions03 Nanostructured transparent oxides for improved thermal management

Nanostructuring of transparent oxide materials can significantly alter their thermal performance characteristics. By incorporating nanoparticles, nanowires, or creating nanoporous structures within transparent oxides, thermal conductivity can be precisely controlled. These nanostructured materials can exhibit enhanced phonon scattering, leading to reduced thermal conductivity while maintaining optical transparency. Additionally, the high surface area of nanostructured oxides can improve heat dissipation in certain applications, making them valuable for thermal management in optoelectronic devices.Expand Specific Solutions04 Temperature-dependent properties of transparent oxide semiconductors

Transparent oxide semiconductors exhibit temperature-dependent electrical and optical properties that can be leveraged for various applications. The thermal performance of these materials, including their thermal expansion coefficient, thermal stability, and temperature-dependent conductivity, can be tuned through composition and processing. Understanding and controlling these temperature-dependent properties is crucial for applications in high-temperature environments, temperature sensing, and devices requiring stable performance across wide temperature ranges.Expand Specific Solutions05 Transparent oxide thin films for solar thermal applications

Transparent oxide thin films can be optimized for solar thermal applications by engineering their spectral selectivity and thermal stability. These films can be designed to transmit visible light while reflecting or absorbing infrared radiation, effectively managing heat gain and loss. By controlling the composition, thickness, and microstructure of the oxide layers, their thermal emissivity and absorption properties can be tailored for specific solar thermal applications, including solar collectors, smart windows, and building-integrated photovoltaics.Expand Specific Solutions

Leading Companies and Research Institutions in Transparent Oxides

The thermal performance of transparent oxides in cooling applications is currently in an early growth phase, with increasing market interest driven by energy efficiency demands. The market size is expanding rapidly, projected to reach significant scale as sustainable cooling solutions become critical in addressing climate change. Technologically, the field is advancing from experimental to commercial applications, with key players demonstrating varying levels of maturity. Semiconductor Energy Laboratory and Applied Materials lead in innovative oxide-based cooling technologies, while LG Chem and 3M Innovative Properties focus on material optimization. Academic institutions like Oregon State University and Tokyo Institute of Technology contribute fundamental research, creating a competitive landscape where industrial-academic partnerships are accelerating development of high-performance transparent cooling materials.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive thermal management solution utilizing transparent oxide materials for next-generation cooling applications. Their approach centers on nanostructured transparent conductive oxides (TCOs) that combine high thermal conductivity with excellent optical transparency. The company has engineered composite materials incorporating indium zinc oxide (IZO) and fluorine-doped tin oxide (FTO) with specialized dopants to enhance thermal transport properties. These materials achieve thermal conductivity values of 15-20 W/mK while maintaining visible light transmission above 85%. LG Chem's technology employs a proprietary sol-gel synthesis method followed by controlled annealing processes to optimize the crystallinity and grain boundary characteristics of the oxide films, which are critical factors affecting thermal performance. The company has successfully implemented these materials in flexible electronics cooling systems, where traditional metal-based heat sinks are impractical. Their transparent oxide cooling films have demonstrated the ability to reduce hotspot temperatures by up to 30% in OLED display applications, addressing one of the key challenges in advanced display technologies. LG Chem has also developed scalable manufacturing processes for these materials, enabling cost-effective production for commercial applications.

Strengths: Excellent balance between thermal conductivity and optical transparency; compatibility with flexible substrates; established large-scale manufacturing capabilities; strong integration with existing LG display technologies. Weaknesses: Higher material costs compared to conventional cooling solutions; performance degradation under extreme humidity conditions; limited long-term stability data in certain application environments.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced transparent oxide materials with enhanced thermal performance for cooling applications. Their technology focuses on atomic layer deposition (ALD) and physical vapor deposition (PVD) processes to create high-quality transparent oxide films with optimized thermal conductivity. The company's approach involves engineering the microstructure of materials like indium tin oxide (ITO) and aluminum-doped zinc oxide (AZO) to maximize heat dissipation while maintaining optical transparency. Their proprietary deposition techniques allow precise control over film thickness and composition, resulting in materials that can efficiently transfer heat while allowing visible light transmission above 80%. Applied Materials has also pioneered the integration of these materials into cooling systems for electronics, particularly in display technologies and photovoltaic applications where heat management and transparency are equally critical. Their research has demonstrated that optimized transparent oxide layers can reduce operating temperatures by up to 15°C compared to conventional materials, significantly extending device lifetimes and improving performance reliability.

Strengths: Industry-leading deposition technology allowing precise control of material properties; extensive manufacturing infrastructure enabling scale-up; strong integration capabilities with existing semiconductor and display production lines. Weaknesses: Higher production costs compared to conventional cooling solutions; limited flexibility in post-deposition processing; requires specialized equipment for optimal implementation.

Key Patents and Innovations in Transparent Oxide Cooling

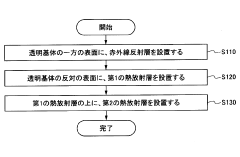

Transparent unpowered cooling device

PatentInactiveJP2023037040A

Innovation

- A transparent, unpowered cooling device with an infrared reflective layer, a first heat emitting layer, and a second heat emitting layer, each with specific absorption peaks and reflectance properties, to enhance radiative cooling by effectively emitting heat as infrared radiation through atmospheric windows.

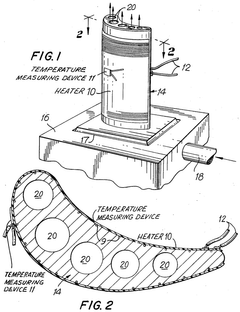

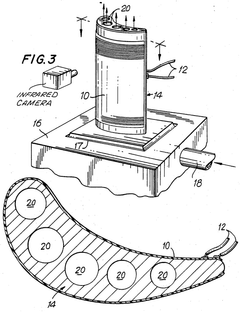

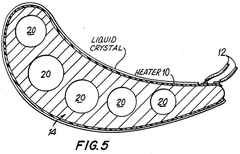

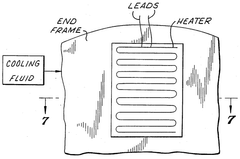

Apparatus and method for measuring the thermal performance of a heated or cooled component

PatentInactiveUS4902139A

Innovation

- An apparatus and method that applies a predetermined heat flux to a component's surface and exposes it to cooling or heating fluid with specific characteristics, using temperature measuring devices to assess the thermal performance by measuring temperature distribution, allowing for pre-installation verification of thermal performance.

Environmental Impact and Sustainability Considerations

The integration of transparent oxides in cooling applications presents significant environmental implications that warrant careful consideration. These materials, while offering promising thermal performance benefits, must be evaluated within a broader sustainability framework to ensure their long-term viability and ecological compatibility.

The manufacturing processes for transparent oxide materials often involve energy-intensive procedures and potentially hazardous chemicals. Production methods such as chemical vapor deposition, sputtering, and sol-gel techniques require substantial energy inputs, contributing to carbon emissions when powered by non-renewable energy sources. A life cycle assessment of indium tin oxide (ITO) and aluminum-doped zinc oxide (AZO) reveals that their production can generate between 15-30 kg CO2 equivalent per square meter of material, depending on manufacturing efficiency and energy sources.

Resource scarcity represents another critical environmental concern. Several transparent conducting oxides rely on rare or strategic elements like indium, which faces supply constraints due to limited global reserves and geopolitical factors affecting extraction. The environmental degradation associated with mining these materials, including habitat destruction, water pollution, and soil contamination, further compounds their ecological footprint.

End-of-life management for transparent oxide-based cooling systems presents both challenges and opportunities. The complex material compositions can complicate recycling efforts, potentially leading to increased electronic waste if proper recovery systems are not implemented. However, emerging technologies for urban mining and advanced separation techniques show promise for reclaiming valuable elements from discarded cooling applications, potentially creating closed-loop material cycles.

The operational environmental benefits of transparent oxide cooling technologies must be weighed against these production and disposal concerns. When properly implemented, these materials can significantly reduce energy consumption in buildings and electronic devices through passive cooling effects, potentially offsetting their initial environmental costs over their operational lifetime. Studies indicate that radiative cooling applications using transparent oxides can reduce cooling energy requirements by 10-40% in appropriate climates.

Water conservation represents an additional sustainability advantage, as these passive cooling technologies typically require minimal or no water compared to conventional cooling systems. This aspect becomes increasingly valuable in water-stressed regions where traditional cooling approaches place additional pressure on limited water resources.

Future research directions should prioritize developing transparent oxides with reduced environmental impact through green chemistry principles, renewable energy manufacturing, and design for recyclability. Biomimetic approaches and exploration of abundant, non-toxic alternative materials may provide pathways to more sustainable cooling solutions while maintaining or enhancing thermal performance characteristics.

The manufacturing processes for transparent oxide materials often involve energy-intensive procedures and potentially hazardous chemicals. Production methods such as chemical vapor deposition, sputtering, and sol-gel techniques require substantial energy inputs, contributing to carbon emissions when powered by non-renewable energy sources. A life cycle assessment of indium tin oxide (ITO) and aluminum-doped zinc oxide (AZO) reveals that their production can generate between 15-30 kg CO2 equivalent per square meter of material, depending on manufacturing efficiency and energy sources.

Resource scarcity represents another critical environmental concern. Several transparent conducting oxides rely on rare or strategic elements like indium, which faces supply constraints due to limited global reserves and geopolitical factors affecting extraction. The environmental degradation associated with mining these materials, including habitat destruction, water pollution, and soil contamination, further compounds their ecological footprint.

End-of-life management for transparent oxide-based cooling systems presents both challenges and opportunities. The complex material compositions can complicate recycling efforts, potentially leading to increased electronic waste if proper recovery systems are not implemented. However, emerging technologies for urban mining and advanced separation techniques show promise for reclaiming valuable elements from discarded cooling applications, potentially creating closed-loop material cycles.

The operational environmental benefits of transparent oxide cooling technologies must be weighed against these production and disposal concerns. When properly implemented, these materials can significantly reduce energy consumption in buildings and electronic devices through passive cooling effects, potentially offsetting their initial environmental costs over their operational lifetime. Studies indicate that radiative cooling applications using transparent oxides can reduce cooling energy requirements by 10-40% in appropriate climates.

Water conservation represents an additional sustainability advantage, as these passive cooling technologies typically require minimal or no water compared to conventional cooling systems. This aspect becomes increasingly valuable in water-stressed regions where traditional cooling approaches place additional pressure on limited water resources.

Future research directions should prioritize developing transparent oxides with reduced environmental impact through green chemistry principles, renewable energy manufacturing, and design for recyclability. Biomimetic approaches and exploration of abundant, non-toxic alternative materials may provide pathways to more sustainable cooling solutions while maintaining or enhancing thermal performance characteristics.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of transparent oxide materials for cooling applications presents both significant opportunities and challenges for industrial implementation. Current production methods for high-performance transparent oxides include physical vapor deposition (PVD), chemical vapor deposition (CVD), sol-gel processes, and magnetron sputtering. Among these, magnetron sputtering demonstrates the most promising balance between quality and scalability, with production capacities reaching up to 3 million square meters annually in advanced facilities. However, the capital expenditure for establishing such production lines remains substantial, typically ranging from $5-15 million depending on capacity and precision requirements.

Cost analysis reveals that material expenses constitute approximately 30-40% of total production costs, with indium tin oxide (ITO) being particularly expensive due to indium's limited global supply. Alternative materials such as aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO) offer more cost-effective options, reducing material costs by 40-60% compared to ITO while maintaining acceptable thermal performance. Energy consumption during manufacturing represents another significant cost factor, accounting for 15-25% of production expenses, particularly for high-temperature deposition processes.

Production yield rates significantly impact economic viability, with current industry standards achieving 80-90% for established processes. Defect rates directly correlate with production scale, with larger facilities typically experiencing 2-5% higher defect rates than smaller, more controlled environments. This quality-scale tradeoff must be carefully managed through advanced process control systems and in-line quality monitoring.

The economies of scale follow a non-linear progression, with production costs decreasing by approximately 15-20% when scaling from pilot to medium production, and an additional 10-15% when advancing to mass production levels. However, these cost reductions plateau at very large scales due to increasing complexity in quality control and logistics management.

Recent innovations in roll-to-roll processing technology show promise for dramatically improving manufacturing scalability, potentially reducing production costs by 30-40% compared to traditional batch processing methods. Several manufacturers have demonstrated pilot-scale roll-to-roll production of transparent oxide coatings with thermal performance comparable to conventional methods, though consistency across large areas remains challenging.

For market viability, production costs must decrease to below $10 per square meter for building applications and under $5 per square meter for automotive applications. Current production costs range from $12-25 per square meter depending on performance specifications and production volume, indicating that further technological advancement and scale optimization are necessary to achieve widespread commercial adoption.

Cost analysis reveals that material expenses constitute approximately 30-40% of total production costs, with indium tin oxide (ITO) being particularly expensive due to indium's limited global supply. Alternative materials such as aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO) offer more cost-effective options, reducing material costs by 40-60% compared to ITO while maintaining acceptable thermal performance. Energy consumption during manufacturing represents another significant cost factor, accounting for 15-25% of production expenses, particularly for high-temperature deposition processes.

Production yield rates significantly impact economic viability, with current industry standards achieving 80-90% for established processes. Defect rates directly correlate with production scale, with larger facilities typically experiencing 2-5% higher defect rates than smaller, more controlled environments. This quality-scale tradeoff must be carefully managed through advanced process control systems and in-line quality monitoring.

The economies of scale follow a non-linear progression, with production costs decreasing by approximately 15-20% when scaling from pilot to medium production, and an additional 10-15% when advancing to mass production levels. However, these cost reductions plateau at very large scales due to increasing complexity in quality control and logistics management.

Recent innovations in roll-to-roll processing technology show promise for dramatically improving manufacturing scalability, potentially reducing production costs by 30-40% compared to traditional batch processing methods. Several manufacturers have demonstrated pilot-scale roll-to-roll production of transparent oxide coatings with thermal performance comparable to conventional methods, though consistency across large areas remains challenging.

For market viability, production costs must decrease to below $10 per square meter for building applications and under $5 per square meter for automotive applications. Current production costs range from $12-25 per square meter depending on performance specifications and production volume, indicating that further technological advancement and scale optimization are necessary to achieve widespread commercial adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!