Transparent Oxides as Catalysts in Chemical Sensor Technologies

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transparent Oxide Catalysts Background and Objectives

Transparent oxide materials have emerged as a significant technological advancement in the field of chemical sensing over the past three decades. Initially developed for their optical properties in display technologies, these materials have evolved to become crucial components in modern sensor applications due to their unique combination of electrical conductivity and optical transparency. The evolution of transparent oxides began with simple binary compounds like tin oxide (SnO₂) and zinc oxide (ZnO), progressing to more complex ternary and quaternary systems that offer enhanced catalytic properties.

The technological trajectory of transparent oxide catalysts has been shaped by increasing demands for higher sensitivity, selectivity, and stability in chemical detection systems. Early applications focused primarily on gas sensing for environmental monitoring, but recent developments have expanded their utility to biomedical diagnostics, food safety, and industrial process control. This diversification of application domains has driven significant innovation in material design and synthesis techniques.

Current research objectives in this field center on addressing several key challenges. First, enhancing the catalytic efficiency of transparent oxides at lower operating temperatures to reduce power consumption in portable sensing devices. Second, improving selectivity toward specific target analytes in complex mixtures, which remains a persistent challenge in real-world sensing environments. Third, developing sustainable and cost-effective synthesis methods that maintain precise control over material properties while reducing environmental impact.

The integration of transparent oxide catalysts with emerging technologies represents another critical objective. This includes their incorporation into flexible and wearable sensing platforms, integration with Internet of Things (IoT) networks for distributed sensing applications, and combination with artificial intelligence for advanced pattern recognition and predictive analytics in sensor data interpretation.

From a materials science perspective, research aims to establish clear structure-property relationships that govern catalytic performance. This involves understanding how factors such as crystal structure, defect chemistry, surface morphology, and electronic band structure influence catalytic activity and selectivity. Such fundamental knowledge is essential for the rational design of next-generation transparent oxide catalysts with tailored properties for specific sensing applications.

The ultimate goal of current research efforts is to develop multifunctional transparent oxide catalysts that can simultaneously serve as sensing elements, signal transducers, and protective barriers in integrated chemical sensor technologies. This multifunctionality would enable the creation of more compact, efficient, and reliable sensing systems capable of addressing emerging challenges in healthcare, environmental protection, and industrial safety.

The technological trajectory of transparent oxide catalysts has been shaped by increasing demands for higher sensitivity, selectivity, and stability in chemical detection systems. Early applications focused primarily on gas sensing for environmental monitoring, but recent developments have expanded their utility to biomedical diagnostics, food safety, and industrial process control. This diversification of application domains has driven significant innovation in material design and synthesis techniques.

Current research objectives in this field center on addressing several key challenges. First, enhancing the catalytic efficiency of transparent oxides at lower operating temperatures to reduce power consumption in portable sensing devices. Second, improving selectivity toward specific target analytes in complex mixtures, which remains a persistent challenge in real-world sensing environments. Third, developing sustainable and cost-effective synthesis methods that maintain precise control over material properties while reducing environmental impact.

The integration of transparent oxide catalysts with emerging technologies represents another critical objective. This includes their incorporation into flexible and wearable sensing platforms, integration with Internet of Things (IoT) networks for distributed sensing applications, and combination with artificial intelligence for advanced pattern recognition and predictive analytics in sensor data interpretation.

From a materials science perspective, research aims to establish clear structure-property relationships that govern catalytic performance. This involves understanding how factors such as crystal structure, defect chemistry, surface morphology, and electronic band structure influence catalytic activity and selectivity. Such fundamental knowledge is essential for the rational design of next-generation transparent oxide catalysts with tailored properties for specific sensing applications.

The ultimate goal of current research efforts is to develop multifunctional transparent oxide catalysts that can simultaneously serve as sensing elements, signal transducers, and protective barriers in integrated chemical sensor technologies. This multifunctionality would enable the creation of more compact, efficient, and reliable sensing systems capable of addressing emerging challenges in healthcare, environmental protection, and industrial safety.

Market Analysis for Chemical Sensing Technologies

The global chemical sensing technologies market is experiencing robust growth, valued at approximately 22.3 billion USD in 2023 and projected to reach 31.5 billion USD by 2028, representing a compound annual growth rate (CAGR) of 7.2%. This expansion is primarily driven by increasing industrial safety regulations, environmental monitoring requirements, and healthcare diagnostics advancements.

Transparent oxide-based chemical sensors represent a rapidly growing segment within this market, currently accounting for about 15% of the total market share with expectations to reach 22% by 2027. The integration of these materials as catalysts in sensing technologies has created new market opportunities across multiple sectors.

Industrial applications constitute the largest market segment (38%), where transparent oxide catalysts enable more precise detection of toxic gases and volatile organic compounds in manufacturing environments. The environmental monitoring sector follows closely (27%), utilizing these sensors for air quality assessment, water contamination detection, and emissions control systems.

Healthcare applications represent the fastest-growing segment with a 9.8% CAGR, as transparent oxide-based sensors offer enhanced capabilities for breath analysis, disease biomarker detection, and continuous patient monitoring. Consumer electronics applications are also expanding rapidly (8.7% CAGR), with integration into smartphones, wearables, and smart home devices.

Regionally, North America leads the market (34% share), followed by Europe (28%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the highest growth rate at 10.2% annually, driven by rapid industrialization in China and India, alongside increasing environmental regulations.

Key market drivers include miniaturization demands, with sensors becoming increasingly compact while maintaining or improving sensitivity; integration capabilities with IoT systems; and cost reduction pressures as applications expand into consumer markets. The push for improved selectivity and reduced cross-sensitivity represents a significant market opportunity, as current technologies often struggle with interference from similar chemical compounds.

Market barriers include high initial development costs, technical challenges in achieving both transparency and catalytic activity, and regulatory hurdles for certain applications, particularly in healthcare and food safety. Additionally, competition from alternative sensing technologies such as MEMS-based sensors and optical sensing methods creates market pressure.

Customer demand increasingly focuses on multi-gas detection capabilities, wireless connectivity, extended sensor lifespan, and reduced calibration requirements. These trends align well with the inherent advantages of transparent oxide catalysts, positioning them favorably for continued market expansion.

Transparent oxide-based chemical sensors represent a rapidly growing segment within this market, currently accounting for about 15% of the total market share with expectations to reach 22% by 2027. The integration of these materials as catalysts in sensing technologies has created new market opportunities across multiple sectors.

Industrial applications constitute the largest market segment (38%), where transparent oxide catalysts enable more precise detection of toxic gases and volatile organic compounds in manufacturing environments. The environmental monitoring sector follows closely (27%), utilizing these sensors for air quality assessment, water contamination detection, and emissions control systems.

Healthcare applications represent the fastest-growing segment with a 9.8% CAGR, as transparent oxide-based sensors offer enhanced capabilities for breath analysis, disease biomarker detection, and continuous patient monitoring. Consumer electronics applications are also expanding rapidly (8.7% CAGR), with integration into smartphones, wearables, and smart home devices.

Regionally, North America leads the market (34% share), followed by Europe (28%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the highest growth rate at 10.2% annually, driven by rapid industrialization in China and India, alongside increasing environmental regulations.

Key market drivers include miniaturization demands, with sensors becoming increasingly compact while maintaining or improving sensitivity; integration capabilities with IoT systems; and cost reduction pressures as applications expand into consumer markets. The push for improved selectivity and reduced cross-sensitivity represents a significant market opportunity, as current technologies often struggle with interference from similar chemical compounds.

Market barriers include high initial development costs, technical challenges in achieving both transparency and catalytic activity, and regulatory hurdles for certain applications, particularly in healthcare and food safety. Additionally, competition from alternative sensing technologies such as MEMS-based sensors and optical sensing methods creates market pressure.

Customer demand increasingly focuses on multi-gas detection capabilities, wireless connectivity, extended sensor lifespan, and reduced calibration requirements. These trends align well with the inherent advantages of transparent oxide catalysts, positioning them favorably for continued market expansion.

Current Status and Challenges in Transparent Oxide Catalysis

Transparent oxide catalysts have emerged as a significant area of research in chemical sensor technologies, with global development showing varied progress across regions. Currently, the United States, European Union, Japan, and China lead in transparent oxide catalyst research, with each region focusing on different application aspects. The U.S. emphasizes fundamental research and commercialization pathways, while the EU prioritizes environmentally sustainable applications. Japan excels in miniaturization and integration technologies, and China has made substantial investments in manufacturing scale-up.

The current technological landscape presents several critical challenges. First, the selectivity of transparent oxide catalysts remains insufficient for complex chemical environments, often resulting in cross-sensitivity issues that compromise detection accuracy. This limitation is particularly problematic in industrial settings where multiple gas species coexist. Second, long-term stability under varying environmental conditions continues to be a significant hurdle, with performance degradation observed after exposure to humidity, temperature fluctuations, and interfering gases.

Material synthesis reproducibility presents another major challenge, as slight variations in preparation methods can lead to substantial differences in catalytic performance. This inconsistency hampers large-scale production and standardization efforts. Additionally, the transparency-activity trade-off remains unresolved; enhancing catalytic activity often compromises optical transparency, which is crucial for certain sensing mechanisms and integrated optoelectronic applications.

Energy efficiency constraints also limit widespread adoption, as many transparent oxide catalyst systems require elevated operating temperatures (typically 200-400°C) to achieve optimal sensitivity. This requirement increases power consumption and complicates integration into portable or wireless sensing networks. Furthermore, the cost-effectiveness of high-performance transparent oxide catalysts remains problematic, with many formulations relying on expensive rare earth dopants or precious metals.

Recent advancements have partially addressed these challenges through innovative approaches such as hierarchical nanostructuring, heterostructure engineering, and surface functionalization. However, significant gaps remain between laboratory demonstrations and commercially viable solutions. The field also faces a knowledge gap in understanding fundamental catalytic mechanisms at the molecular level, which impedes rational design strategies for next-generation materials.

Regulatory constraints further complicate development, particularly for medical and environmental monitoring applications where stringent certification requirements must be met. Despite these challenges, the growing demand for advanced chemical sensors in healthcare, environmental monitoring, industrial safety, and smart city applications continues to drive research and development in transparent oxide catalysis.

The current technological landscape presents several critical challenges. First, the selectivity of transparent oxide catalysts remains insufficient for complex chemical environments, often resulting in cross-sensitivity issues that compromise detection accuracy. This limitation is particularly problematic in industrial settings where multiple gas species coexist. Second, long-term stability under varying environmental conditions continues to be a significant hurdle, with performance degradation observed after exposure to humidity, temperature fluctuations, and interfering gases.

Material synthesis reproducibility presents another major challenge, as slight variations in preparation methods can lead to substantial differences in catalytic performance. This inconsistency hampers large-scale production and standardization efforts. Additionally, the transparency-activity trade-off remains unresolved; enhancing catalytic activity often compromises optical transparency, which is crucial for certain sensing mechanisms and integrated optoelectronic applications.

Energy efficiency constraints also limit widespread adoption, as many transparent oxide catalyst systems require elevated operating temperatures (typically 200-400°C) to achieve optimal sensitivity. This requirement increases power consumption and complicates integration into portable or wireless sensing networks. Furthermore, the cost-effectiveness of high-performance transparent oxide catalysts remains problematic, with many formulations relying on expensive rare earth dopants or precious metals.

Recent advancements have partially addressed these challenges through innovative approaches such as hierarchical nanostructuring, heterostructure engineering, and surface functionalization. However, significant gaps remain between laboratory demonstrations and commercially viable solutions. The field also faces a knowledge gap in understanding fundamental catalytic mechanisms at the molecular level, which impedes rational design strategies for next-generation materials.

Regulatory constraints further complicate development, particularly for medical and environmental monitoring applications where stringent certification requirements must be met. Despite these challenges, the growing demand for advanced chemical sensors in healthcare, environmental monitoring, industrial safety, and smart city applications continues to drive research and development in transparent oxide catalysis.

Current Technical Solutions for Transparent Oxide-Based Sensors

01 Transparent metal oxide catalysts for oxidation reactions

Transparent metal oxides such as titanium dioxide, zinc oxide, and tin oxide exhibit catalytic properties for various oxidation reactions. These materials combine optical transparency with catalytic activity, making them suitable for applications where light transmission is important. The catalytic properties can be enhanced by controlling the crystal structure, surface area, and dopants, allowing for efficient conversion of reactants in environmental remediation and chemical synthesis.- Metal oxide catalysts for oxidation reactions: Transparent metal oxides such as titanium dioxide, zinc oxide, and tin oxide exhibit catalytic properties for various oxidation reactions. These materials can be used to catalyze the conversion of harmful gases into less harmful substances, making them valuable for environmental applications. The transparency of these oxides allows for their use in applications where optical clarity is important while maintaining catalytic functionality.

- Doped transparent conductive oxides with enhanced catalytic activity: Doping transparent conductive oxides (TCOs) with various elements can significantly enhance their catalytic properties. Common TCOs like indium tin oxide (ITO) or fluorine-doped tin oxide (FTO) can be modified with dopants to create active sites for catalysis while maintaining optical transparency. These materials show improved performance in electrochemical reactions and can be used in photocatalysis, electrocatalysis, and other catalytic applications.

- Transparent oxide nanostructures for photocatalysis: Nanostructured transparent oxides exhibit enhanced photocatalytic properties due to their high surface area and quantum confinement effects. These materials can effectively utilize light energy to drive chemical reactions, particularly for environmental remediation and renewable energy applications. Various morphologies such as nanoparticles, nanorods, and nanosheets can be synthesized to optimize the catalytic performance while maintaining transparency.

- Transparent oxide catalysts for fuel cell applications: Transparent oxide materials serve as effective catalysts in fuel cell technologies, facilitating electrochemical reactions at lower temperatures. These materials can replace or reduce the need for expensive noble metal catalysts while providing good electrical conductivity and catalytic activity. The transparency of these oxides also enables in-situ monitoring of electrochemical processes, which is beneficial for research and development of advanced fuel cell systems.

- Transparent oxide catalysts for organic synthesis: Transparent oxide materials function as heterogeneous catalysts for various organic synthesis reactions, offering advantages such as easy separation from reaction mixtures and potential for reuse. These catalysts can promote selective oxidation, reduction, and coupling reactions under mild conditions. The transparency of these materials also allows for real-time monitoring of reaction progress using spectroscopic techniques, enhancing process control in both laboratory and industrial settings.

02 Transparent conductive oxides with catalytic functionality

Certain transparent oxides like indium tin oxide (ITO) and fluorine-doped tin oxide (FTO) combine electrical conductivity with catalytic properties. These materials can facilitate electrochemical reactions while maintaining optical transparency, making them valuable for applications in photocatalysis, electrocatalysis, and sensing devices. The dual functionality of transparency and conductivity enables their use in advanced catalytic systems where light interaction and electron transfer are both required.Expand Specific Solutions03 Nanostructured transparent oxide catalysts

Nanostructuring of transparent oxides significantly enhances their catalytic properties due to increased surface area and active sites. These nanostructured materials, including nanowires, nanoparticles, and nanoporous structures, demonstrate improved catalytic efficiency while maintaining optical transparency. The controlled synthesis of these nanostructures allows for tuning of both optical and catalytic properties, enabling applications in photocatalysis, environmental remediation, and chemical transformations.Expand Specific Solutions04 Doped transparent oxides for enhanced catalytic activity

Doping transparent oxides with metals or non-metals can significantly enhance their catalytic properties while preserving transparency. Common dopants include noble metals, transition metals, and non-metals such as nitrogen or sulfur. The introduction of dopants creates defect sites, oxygen vacancies, or modified electronic structures that improve catalytic performance. These materials show enhanced activity for various reactions including oxidation, reduction, and photocatalytic degradation of pollutants.Expand Specific Solutions05 Transparent oxide catalysts for photocatalytic applications

Transparent oxide materials exhibit photocatalytic properties when activated by light, particularly UV radiation. These photocatalysts can harness light energy to drive chemical reactions while maintaining optical transparency. Applications include self-cleaning surfaces, air and water purification, hydrogen production, and organic synthesis. The combination of transparency and photocatalytic activity makes these materials particularly valuable for solar-driven catalytic processes and integrated optical-catalytic systems.Expand Specific Solutions

Leading Organizations in Transparent Oxide Catalyst Development

The transparent oxide catalyst market in chemical sensor technologies is currently in a growth phase, characterized by increasing research activities and commercial applications. The market size is expanding due to rising demand for advanced sensing solutions in environmental monitoring, healthcare, and industrial safety. Technologically, the field is maturing with significant contributions from both academic institutions and industry players. Leading research entities like MIT, National University of Singapore, and Indian Institute of Science are advancing fundamental understanding, while companies including Samsung Electronics, Sensirion AG, and Honeywell International are commercializing applications. JSR Corp and Eastman Kodak are leveraging their materials expertise to develop novel oxide-based sensing platforms, indicating a competitive landscape where academic-industrial partnerships are driving innovation and market expansion.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed advanced transparent oxide catalyst technology primarily for integration into their environmental monitoring systems and smart home devices. Their approach focuses on indium gallium zinc oxide (IGZO) materials with precisely engineered surface properties to enhance catalytic activity while maintaining excellent optical transparency. Samsung's manufacturing process employs RF magnetron sputtering to create uniform thin films with controlled stoichiometry and defect concentrations[8]. Their sensors utilize a unique microheater design that enables rapid temperature cycling, allowing for dynamic sensing protocols that significantly improve selectivity. Samsung has implemented these materials in their air quality monitoring products, achieving detection limits below 50 ppb for common indoor pollutants such as formaldehyde and benzene. A key innovation in Samsung's technology is the integration of their transparent oxide catalysts with their semiconductor manufacturing capabilities, enabling mass production of highly miniaturized sensor arrays on flexible substrates[9]. Their recent research has focused on developing self-powered sensing systems that combine transparent oxide photocatalysts with energy harvesting technologies to create maintenance-free environmental monitors.

Strengths: Excellent integration with consumer electronics ecosystems; highly miniaturized form factors suitable for mobile devices; low manufacturing costs through established semiconductor processes; good sensitivity to common indoor pollutants. Weaknesses: Limited performance in detecting certain industrial gases; moderate cross-sensitivity issues requiring algorithmic compensation; potential long-term stability challenges in outdoor applications.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced transparent oxide catalysts for chemical sensing applications, focusing on metal oxide semiconductors like In2O3, SnO2, and ZnO. Their research has demonstrated that these materials can be engineered with specific surface defects and oxygen vacancies to enhance catalytic activity and selectivity. MIT's approach involves atomic layer deposition techniques to create precisely controlled oxide layers with tailored porosity and surface area. Their sensors exhibit remarkable sensitivity to target gases at parts-per-billion levels while operating at lower temperatures (200-300°C) compared to conventional sensors. MIT researchers have also developed composite structures combining different transparent oxides to create p-n heterojunctions that significantly improve electron transfer rates and sensing performance[1]. Recent work has focused on doping strategies using noble metals and rare earth elements to further enhance catalytic properties while maintaining optical transparency.

Strengths: Exceptional precision in material synthesis allowing atomic-level control of catalyst properties; strong integration capabilities with MEMS and CMOS technologies; superior sensitivity and selectivity. Weaknesses: Higher manufacturing costs compared to conventional sensors; complex fabrication processes requiring specialized equipment; potential long-term stability issues in harsh environmental conditions.

Key Patents and Research in Transparent Oxide Catalysis

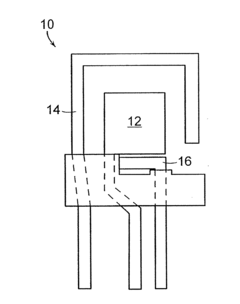

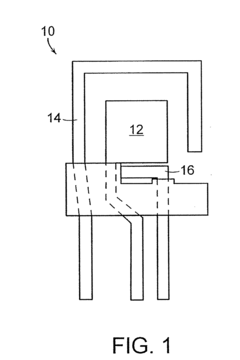

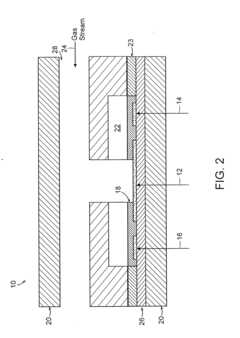

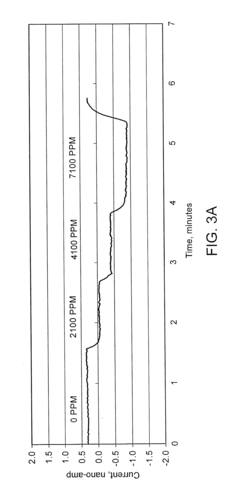

Electrochemical carbon dioxide sensor

PatentInactiveUS20110005928A1

Innovation

- A solid electrochemical carbon dioxide sensor utilizing a non-conductive substrate with metal oxide sensing electrodes, a reference electrode, and a counter electrode in contact with a solid polymer electrolyte anion-exchange membrane, which employs reversible electrochemical reactions to detect CO2, allowing for quantitative measurement and operation across a wide humidity and temperature range.

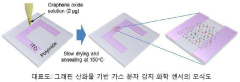

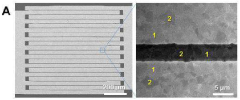

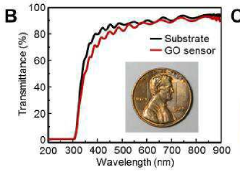

Flexible transparent chemical sensors based on graphene oxide and method for preparing the same

PatentActiveKR1020140144362A

Innovation

- A flexible transparent chemical sensor using graphene oxide as the active layer, which operates at room temperature and is fabricated with low power consumption, utilizing a substrate, sensing electrode, and a sensor active layer formed by graphene oxide.

Environmental Impact and Sustainability Considerations

The development and deployment of transparent oxide catalysts in chemical sensor technologies necessitate careful consideration of their environmental footprint throughout their lifecycle. These materials, while offering significant technological advantages, present both environmental challenges and opportunities that must be systematically evaluated. The manufacturing processes for transparent oxide catalysts often involve energy-intensive methods and potentially hazardous precursors, contributing to carbon emissions and environmental pollution if not properly managed.

Resource efficiency represents a critical aspect of transparent oxide catalyst sustainability. Many of these materials incorporate rare or strategic elements such as indium, gallium, or platinum group metals, raising concerns about resource depletion and supply chain vulnerabilities. Research trends increasingly focus on developing catalysts with reduced critical material content while maintaining or enhancing performance characteristics, thereby addressing both environmental and economic sustainability concerns.

End-of-life management for chemical sensors utilizing transparent oxide catalysts presents another significant environmental consideration. The complex integration of these materials into sensor devices often complicates recycling efforts, potentially leading to electronic waste accumulation. Advanced recovery techniques, including hydrometallurgical and bioleaching processes, are emerging as promising approaches for reclaiming valuable components from spent sensors, though these methods require further optimization for commercial viability.

The operational phase of transparent oxide-based sensors offers substantial environmental benefits that may offset manufacturing impacts. These sensors enable more precise environmental monitoring, facilitating early detection of pollutants and supporting regulatory compliance across industries. Additionally, their enhanced sensitivity and selectivity can reduce false readings, minimizing unnecessary remediation activities and their associated environmental costs.

Lifecycle assessment (LCA) studies comparing transparent oxide catalysts with conventional alternatives demonstrate varying sustainability profiles depending on application contexts. While manufacturing impacts may be higher for some transparent oxide systems, their extended operational lifetimes and superior performance characteristics often yield net environmental benefits over complete product lifecycles. These assessments highlight the importance of considering both immediate and long-term environmental implications when evaluating catalyst technologies.

Regulatory frameworks increasingly influence the development trajectory of transparent oxide catalysts, with restrictions on hazardous substances driving innovation toward greener synthesis routes and more benign material compositions. Forward-looking research increasingly incorporates green chemistry principles, exploring bio-inspired synthesis methods, ambient processing conditions, and water-based precursor systems that significantly reduce environmental impacts while maintaining catalyst performance.

Resource efficiency represents a critical aspect of transparent oxide catalyst sustainability. Many of these materials incorporate rare or strategic elements such as indium, gallium, or platinum group metals, raising concerns about resource depletion and supply chain vulnerabilities. Research trends increasingly focus on developing catalysts with reduced critical material content while maintaining or enhancing performance characteristics, thereby addressing both environmental and economic sustainability concerns.

End-of-life management for chemical sensors utilizing transparent oxide catalysts presents another significant environmental consideration. The complex integration of these materials into sensor devices often complicates recycling efforts, potentially leading to electronic waste accumulation. Advanced recovery techniques, including hydrometallurgical and bioleaching processes, are emerging as promising approaches for reclaiming valuable components from spent sensors, though these methods require further optimization for commercial viability.

The operational phase of transparent oxide-based sensors offers substantial environmental benefits that may offset manufacturing impacts. These sensors enable more precise environmental monitoring, facilitating early detection of pollutants and supporting regulatory compliance across industries. Additionally, their enhanced sensitivity and selectivity can reduce false readings, minimizing unnecessary remediation activities and their associated environmental costs.

Lifecycle assessment (LCA) studies comparing transparent oxide catalysts with conventional alternatives demonstrate varying sustainability profiles depending on application contexts. While manufacturing impacts may be higher for some transparent oxide systems, their extended operational lifetimes and superior performance characteristics often yield net environmental benefits over complete product lifecycles. These assessments highlight the importance of considering both immediate and long-term environmental implications when evaluating catalyst technologies.

Regulatory frameworks increasingly influence the development trajectory of transparent oxide catalysts, with restrictions on hazardous substances driving innovation toward greener synthesis routes and more benign material compositions. Forward-looking research increasingly incorporates green chemistry principles, exploring bio-inspired synthesis methods, ambient processing conditions, and water-based precursor systems that significantly reduce environmental impacts while maintaining catalyst performance.

Scalability and Manufacturing Processes

The scalability of transparent oxide catalysts in chemical sensor technologies represents a critical factor for their widespread industrial adoption. Current manufacturing processes primarily utilize physical vapor deposition (PVD), chemical vapor deposition (CVD), and sol-gel methods, each offering distinct advantages for different application scenarios. PVD techniques, particularly magnetron sputtering, demonstrate excellent control over film thickness and composition but face challenges in uniform coating of complex geometries.

Chemical vapor deposition methods have shown promising results for large-area deposition of transparent oxide catalysts, with atomic layer deposition (ALD) emerging as a particularly valuable technique for creating highly uniform, conformal coatings with precise thickness control down to the atomic level. This precision becomes especially important when fabricating multilayer sensor structures where catalyst performance depends on nanoscale dimensions.

Solution-based processes, including sol-gel and hydrothermal methods, offer cost-effective alternatives for mass production. These approaches enable easier doping and composition control, which is essential for tuning the catalytic properties of transparent oxides. Recent advances in solution processing have addressed previous limitations regarding film uniformity and reproducibility, making these methods increasingly viable for commercial sensor production.

Roll-to-roll processing represents a significant breakthrough for scaling transparent oxide catalyst production. This continuous manufacturing approach allows for high-throughput deposition on flexible substrates, potentially reducing production costs by orders of magnitude compared to batch processes. Several research groups have demonstrated successful implementation of roll-to-roll sputtering and solution processing for transparent conducting oxides, with emerging applications in chemical sensing technologies.

The integration of transparent oxide catalysts with existing semiconductor manufacturing infrastructure presents both opportunities and challenges. While compatibility with standard CMOS processes would accelerate adoption, the high-temperature processing often required for optimal catalyst performance can complicate integration. Recent developments in low-temperature processing techniques, including plasma-enhanced deposition and photonic curing, show promise for overcoming these limitations.

Quality control and reproducibility remain significant challenges when scaling production. Variations in stoichiometry, crystallinity, and surface properties can dramatically affect catalytic performance. Advanced in-line characterization techniques, including optical emission spectroscopy and real-time electrical measurements, are being developed to enable continuous monitoring during manufacturing, ensuring consistent sensor performance across production batches.

Chemical vapor deposition methods have shown promising results for large-area deposition of transparent oxide catalysts, with atomic layer deposition (ALD) emerging as a particularly valuable technique for creating highly uniform, conformal coatings with precise thickness control down to the atomic level. This precision becomes especially important when fabricating multilayer sensor structures where catalyst performance depends on nanoscale dimensions.

Solution-based processes, including sol-gel and hydrothermal methods, offer cost-effective alternatives for mass production. These approaches enable easier doping and composition control, which is essential for tuning the catalytic properties of transparent oxides. Recent advances in solution processing have addressed previous limitations regarding film uniformity and reproducibility, making these methods increasingly viable for commercial sensor production.

Roll-to-roll processing represents a significant breakthrough for scaling transparent oxide catalyst production. This continuous manufacturing approach allows for high-throughput deposition on flexible substrates, potentially reducing production costs by orders of magnitude compared to batch processes. Several research groups have demonstrated successful implementation of roll-to-roll sputtering and solution processing for transparent conducting oxides, with emerging applications in chemical sensing technologies.

The integration of transparent oxide catalysts with existing semiconductor manufacturing infrastructure presents both opportunities and challenges. While compatibility with standard CMOS processes would accelerate adoption, the high-temperature processing often required for optimal catalyst performance can complicate integration. Recent developments in low-temperature processing techniques, including plasma-enhanced deposition and photonic curing, show promise for overcoming these limitations.

Quality control and reproducibility remain significant challenges when scaling production. Variations in stoichiometry, crystallinity, and surface properties can dramatically affect catalytic performance. Advanced in-line characterization techniques, including optical emission spectroscopy and real-time electrical measurements, are being developed to enable continuous monitoring during manufacturing, ensuring consistent sensor performance across production batches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!