The Role of Transparent Oxides in UV-Blocking Coating Technologies

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UV-Blocking Coating Technology Background and Objectives

Ultraviolet (UV) radiation protection has become increasingly important in various sectors including healthcare, construction, automotive, and consumer goods due to growing awareness of UV-related health risks and material degradation. The evolution of UV-blocking coating technologies has progressed significantly over the past decades, transitioning from simple physical barriers to sophisticated multi-functional coatings with enhanced durability and performance characteristics.

Transparent oxide materials have emerged as pivotal components in modern UV-blocking technologies, offering a unique combination of optical transparency in the visible spectrum while effectively absorbing or reflecting harmful UV radiation. The historical development of these materials began with simple zinc oxide and titanium dioxide applications in the 1930s, primarily in sunscreens and basic protective coatings. By the 1970s, research expanded into more complex oxide systems and their nanostructured variants, enabling greater control over spectral selectivity.

The current technological trajectory is moving toward multi-component transparent oxide systems that can provide broadband UV protection (covering both UVA and UVB ranges) while maintaining excellent visible light transmission. These advanced materials are increasingly being engineered at the nanoscale to optimize their optical properties and integration capabilities with various substrate materials.

Key technological objectives in this field include developing transparent oxide coatings with enhanced UV-blocking efficiency across the entire UV spectrum (280-400 nm), improving long-term stability against photodegradation, and ensuring compatibility with environmentally friendly manufacturing processes. Additionally, there is significant interest in creating multifunctional coatings that combine UV protection with other desirable properties such as self-cleaning capabilities, antimicrobial activity, and scratch resistance.

The scientific community is particularly focused on understanding the fundamental mechanisms of UV interaction with transparent oxide structures, including the roles of crystal structure, defect chemistry, and surface morphology in determining UV absorption and scattering properties. This knowledge is essential for designing next-generation materials with tailored optical responses.

From an industrial perspective, the objectives include scaling up production of high-performance transparent oxide coatings while reducing manufacturing costs, developing application-specific formulations for diverse sectors, and meeting increasingly stringent regulatory requirements regarding material safety and environmental impact. The integration of these materials into existing manufacturing processes without significant modifications represents another critical goal.

As climate change concerns and health awareness continue to grow, the development of more effective, durable, and versatile UV-blocking technologies based on transparent oxides remains a priority research area with substantial commercial potential and societal benefits.

Transparent oxide materials have emerged as pivotal components in modern UV-blocking technologies, offering a unique combination of optical transparency in the visible spectrum while effectively absorbing or reflecting harmful UV radiation. The historical development of these materials began with simple zinc oxide and titanium dioxide applications in the 1930s, primarily in sunscreens and basic protective coatings. By the 1970s, research expanded into more complex oxide systems and their nanostructured variants, enabling greater control over spectral selectivity.

The current technological trajectory is moving toward multi-component transparent oxide systems that can provide broadband UV protection (covering both UVA and UVB ranges) while maintaining excellent visible light transmission. These advanced materials are increasingly being engineered at the nanoscale to optimize their optical properties and integration capabilities with various substrate materials.

Key technological objectives in this field include developing transparent oxide coatings with enhanced UV-blocking efficiency across the entire UV spectrum (280-400 nm), improving long-term stability against photodegradation, and ensuring compatibility with environmentally friendly manufacturing processes. Additionally, there is significant interest in creating multifunctional coatings that combine UV protection with other desirable properties such as self-cleaning capabilities, antimicrobial activity, and scratch resistance.

The scientific community is particularly focused on understanding the fundamental mechanisms of UV interaction with transparent oxide structures, including the roles of crystal structure, defect chemistry, and surface morphology in determining UV absorption and scattering properties. This knowledge is essential for designing next-generation materials with tailored optical responses.

From an industrial perspective, the objectives include scaling up production of high-performance transparent oxide coatings while reducing manufacturing costs, developing application-specific formulations for diverse sectors, and meeting increasingly stringent regulatory requirements regarding material safety and environmental impact. The integration of these materials into existing manufacturing processes without significant modifications represents another critical goal.

As climate change concerns and health awareness continue to grow, the development of more effective, durable, and versatile UV-blocking technologies based on transparent oxides remains a priority research area with substantial commercial potential and societal benefits.

Market Analysis for UV-Protective Solutions

The global UV-protective solutions market has witnessed substantial growth in recent years, driven primarily by increasing awareness of UV radiation's harmful effects and growing concerns about skin cancer and premature aging. The market for UV-blocking technologies reached approximately $8.5 billion in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2028, with transparent oxide-based solutions representing a significant and expanding segment.

Consumer demand for UV protection spans multiple sectors, with the cosmetics and personal care industry leading adoption. Sunscreen products incorporating transparent oxide technologies command premium pricing due to their superior protection capabilities and skin compatibility. The construction industry represents the second-largest market segment, with UV-protective coatings for windows and building materials experiencing 9.3% annual growth as energy efficiency regulations tighten globally.

Automotive applications constitute another rapidly expanding market, with manufacturers increasingly incorporating UV-protective coatings in vehicle windows and paint to extend product lifespans and enhance passenger comfort. This segment is expected to grow at 7.5% annually through 2028, outpacing the overall market average.

Geographically, North America and Europe currently dominate the UV-protective solutions market, accounting for approximately 58% of global revenue. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India showing annual growth rates exceeding 10% due to rising disposable incomes, increasing awareness of skin protection, and expanding construction activities.

Consumer preferences are shifting notably toward "invisible" protection solutions that offer high UV-blocking efficiency without compromising aesthetics. Products featuring transparent oxide technologies command a 15-25% price premium compared to conventional alternatives, indicating strong market willingness to pay for advanced protection characteristics.

Regulatory factors are significantly influencing market dynamics, with stricter UV protection standards being implemented across regions. The European Union's recent regulations mandating improved UV protection in building materials have accelerated adoption of advanced coating technologies, while similar regulatory trends are emerging in North America and Asia.

Market research indicates that consumers increasingly prioritize multifunctional UV-protective solutions that offer additional benefits beyond UV blocking, such as anti-aging properties, blue light protection, or environmental pollution defense. This trend presents significant opportunities for transparent oxide technologies, which can be engineered to provide multiple protective functions simultaneously.

Consumer demand for UV protection spans multiple sectors, with the cosmetics and personal care industry leading adoption. Sunscreen products incorporating transparent oxide technologies command premium pricing due to their superior protection capabilities and skin compatibility. The construction industry represents the second-largest market segment, with UV-protective coatings for windows and building materials experiencing 9.3% annual growth as energy efficiency regulations tighten globally.

Automotive applications constitute another rapidly expanding market, with manufacturers increasingly incorporating UV-protective coatings in vehicle windows and paint to extend product lifespans and enhance passenger comfort. This segment is expected to grow at 7.5% annually through 2028, outpacing the overall market average.

Geographically, North America and Europe currently dominate the UV-protective solutions market, accounting for approximately 58% of global revenue. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India showing annual growth rates exceeding 10% due to rising disposable incomes, increasing awareness of skin protection, and expanding construction activities.

Consumer preferences are shifting notably toward "invisible" protection solutions that offer high UV-blocking efficiency without compromising aesthetics. Products featuring transparent oxide technologies command a 15-25% price premium compared to conventional alternatives, indicating strong market willingness to pay for advanced protection characteristics.

Regulatory factors are significantly influencing market dynamics, with stricter UV protection standards being implemented across regions. The European Union's recent regulations mandating improved UV protection in building materials have accelerated adoption of advanced coating technologies, while similar regulatory trends are emerging in North America and Asia.

Market research indicates that consumers increasingly prioritize multifunctional UV-protective solutions that offer additional benefits beyond UV blocking, such as anti-aging properties, blue light protection, or environmental pollution defense. This trend presents significant opportunities for transparent oxide technologies, which can be engineered to provide multiple protective functions simultaneously.

Transparent Oxide Technology Status and Barriers

Transparent oxide materials have emerged as critical components in UV-blocking coating technologies, with significant advancements achieved globally. Currently, the most widely utilized transparent oxides include titanium dioxide (TiO₂), zinc oxide (ZnO), cerium oxide (CeO₂), and various mixed metal oxides. These materials demonstrate exceptional UV absorption capabilities while maintaining high visible light transmission, making them ideal for applications ranging from sunscreens to architectural glazing.

The global research landscape shows distinct regional specializations. Asian countries, particularly China, Japan, and South Korea, lead in manufacturing scale and process optimization of transparent oxide nanoparticles. European research institutions focus predominantly on environmental sustainability and novel formulation approaches, while North American entities excel in developing high-performance specialized applications and integration technologies.

Despite significant progress, several technical barriers persist in transparent oxide UV-blocking technologies. Particle agglomeration remains a fundamental challenge, as nano-sized oxide particles tend to cluster during formulation, reducing transparency and UV-blocking efficiency. Current dispersion technologies often require environmentally problematic surfactants or solvents, creating a tension between performance and sustainability goals.

Photostability presents another significant hurdle, particularly for applications requiring long-term outdoor exposure. Many transparent oxides, especially TiO₂, exhibit photocatalytic activity that can degrade organic components in coating matrices, leading to yellowing, chalking, and reduced service life. While doping strategies and surface modifications have shown promise in mitigating these effects, they often introduce complexity and cost to manufacturing processes.

Scale-up challenges continue to impede widespread commercial adoption of advanced transparent oxide technologies. Laboratory-scale synthesis methods that produce highly controlled nanostructures with optimal UV-blocking properties frequently encounter difficulties in industrial-scale production, resulting in quality inconsistencies and increased costs.

The regulatory landscape adds another layer of complexity, with increasing scrutiny of nanomaterials in consumer products. Concerns regarding potential environmental impacts and human health effects of nano-sized transparent oxides have led to stricter regulatory frameworks, particularly in Europe and North America, necessitating extensive safety testing and validation.

Recent technological innovations are addressing these barriers through approaches such as core-shell architectures, hierarchical nanostructures, and surface functionalization techniques. These developments aim to enhance UV-blocking efficiency while reducing photocatalytic activity and improving compatibility with various coating matrices. Additionally, green synthesis routes utilizing lower temperatures, environmentally benign solvents, and renewable precursors are gaining traction as sustainable alternatives to conventional manufacturing methods.

The global research landscape shows distinct regional specializations. Asian countries, particularly China, Japan, and South Korea, lead in manufacturing scale and process optimization of transparent oxide nanoparticles. European research institutions focus predominantly on environmental sustainability and novel formulation approaches, while North American entities excel in developing high-performance specialized applications and integration technologies.

Despite significant progress, several technical barriers persist in transparent oxide UV-blocking technologies. Particle agglomeration remains a fundamental challenge, as nano-sized oxide particles tend to cluster during formulation, reducing transparency and UV-blocking efficiency. Current dispersion technologies often require environmentally problematic surfactants or solvents, creating a tension between performance and sustainability goals.

Photostability presents another significant hurdle, particularly for applications requiring long-term outdoor exposure. Many transparent oxides, especially TiO₂, exhibit photocatalytic activity that can degrade organic components in coating matrices, leading to yellowing, chalking, and reduced service life. While doping strategies and surface modifications have shown promise in mitigating these effects, they often introduce complexity and cost to manufacturing processes.

Scale-up challenges continue to impede widespread commercial adoption of advanced transparent oxide technologies. Laboratory-scale synthesis methods that produce highly controlled nanostructures with optimal UV-blocking properties frequently encounter difficulties in industrial-scale production, resulting in quality inconsistencies and increased costs.

The regulatory landscape adds another layer of complexity, with increasing scrutiny of nanomaterials in consumer products. Concerns regarding potential environmental impacts and human health effects of nano-sized transparent oxides have led to stricter regulatory frameworks, particularly in Europe and North America, necessitating extensive safety testing and validation.

Recent technological innovations are addressing these barriers through approaches such as core-shell architectures, hierarchical nanostructures, and surface functionalization techniques. These developments aim to enhance UV-blocking efficiency while reducing photocatalytic activity and improving compatibility with various coating matrices. Additionally, green synthesis routes utilizing lower temperatures, environmentally benign solvents, and renewable precursors are gaining traction as sustainable alternatives to conventional manufacturing methods.

Current Transparent Oxide UV-Blocking Solutions

01 Metal oxide nanoparticles for UV blocking

Transparent metal oxide nanoparticles such as zinc oxide, titanium dioxide, and cerium oxide can be formulated to block UV radiation while maintaining optical transparency. These nanoparticles can be engineered with specific sizes (typically below 100nm) to effectively absorb and scatter UV light while allowing visible light to pass through. The surface modification of these nanoparticles can enhance their dispersion in various mediums and improve their UV blocking efficiency.- Metal oxide nanoparticles for UV blocking: Transparent metal oxide nanoparticles such as zinc oxide, titanium dioxide, and cerium oxide can be formulated to block UV radiation while maintaining optical transparency. These nanoparticles can be engineered with specific size distributions (typically below 100nm) to effectively absorb and scatter UV light while allowing visible light to pass through. The surface modification of these nanoparticles can enhance their dispersion in various matrices and improve their UV blocking efficiency.

- Transparent conductive oxide films with UV blocking properties: Transparent conductive oxide (TCO) films can be designed to provide both electrical conductivity and UV blocking capabilities. These films typically consist of materials like indium tin oxide (ITO), aluminum-doped zinc oxide (AZO), or fluorine-doped tin oxide (FTO). By controlling the composition, thickness, and deposition parameters, these films can be optimized to block harmful UV radiation while maintaining high visible light transmission and electrical conductivity, making them suitable for applications in electronics, photovoltaics, and smart windows.

- Doped oxide materials for enhanced UV protection: Doping transparent oxide materials with specific elements can significantly enhance their UV blocking capabilities. For example, incorporating elements like cerium, iron, or rare earth metals into zinc oxide or titanium dioxide matrices can extend the UV absorption range and improve blocking efficiency. These doped materials maintain transparency in the visible spectrum while providing superior protection against both UVA and UVB radiation, making them valuable for cosmetic formulations, protective coatings, and packaging applications.

- Multilayer oxide structures for selective UV blocking: Multilayer structures composed of different transparent oxide materials can be designed to selectively block specific UV wavelength ranges. By alternating layers with different refractive indices and absorption characteristics, these structures can provide tailored UV protection while optimizing visible light transmission. The thickness and composition of each layer can be precisely controlled to achieve desired optical properties, enabling applications in advanced glazing, optical filters, and protective coatings for sensitive materials.

- Surface-modified oxide particles for cosmetic UV protection: Surface modification of transparent oxide particles with organic compounds or silicones can improve their compatibility with cosmetic formulations while maintaining UV blocking efficiency. These modifications prevent particle agglomeration, enhance dispersion in various cosmetic bases, and improve skin feel. The modified particles can provide broad-spectrum UV protection without the white cast typically associated with conventional sunscreens. Additionally, these materials can offer photostability and long-lasting protection, making them ideal for sunscreen products, daily moisturizers, and color cosmetics with SPF.

02 Transparent conductive oxide films with UV blocking properties

Transparent conductive oxide (TCO) films can be designed to provide both electrical conductivity and UV blocking capabilities. These films typically consist of materials like indium tin oxide (ITO), aluminum-doped zinc oxide (AZO), or fluorine-doped tin oxide (FTO). By controlling the composition and thickness of these films, they can effectively block harmful UV radiation while maintaining high visible light transmission, making them suitable for applications in electronics, windows, and protective coatings.Expand Specific Solutions03 Composite materials with transparent UV-blocking oxides

Composite materials incorporating transparent oxide particles can provide enhanced UV protection while maintaining transparency. These composites typically consist of a polymer matrix with dispersed oxide particles such as zinc oxide or titanium dioxide. The incorporation of these oxides into polymers, glass, or other substrates can create materials with excellent UV blocking properties for applications in packaging, automotive windows, and protective coatings. The interface between the matrix and oxide particles can be engineered to improve dispersion and prevent agglomeration.Expand Specific Solutions04 Surface-modified transparent oxides for UV protection

Surface modification of transparent oxide particles can enhance their UV blocking efficiency and improve their compatibility with various mediums. Techniques such as silane coupling, polymer coating, or doping with other elements can be employed to modify the surface properties of oxide particles. These modifications can prevent agglomeration, improve dispersion stability, and enhance the UV absorption characteristics while maintaining transparency. Surface-modified oxides can be incorporated into sunscreens, coatings, and textiles for effective UV protection.Expand Specific Solutions05 Transparent oxide thin films for optical applications

Transparent oxide thin films can be designed with specific optical properties to selectively block UV radiation while allowing visible light transmission. These films can be deposited using techniques such as sputtering, chemical vapor deposition, or sol-gel methods. By controlling the composition, thickness, and microstructure of these films, their optical properties can be tailored for specific applications such as smart windows, displays, and photovoltaic devices. Multi-layer structures can be designed to achieve broad-spectrum UV protection while maintaining high visible light transparency.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The UV-blocking coating technology market is currently in a growth phase, characterized by increasing demand for protective solutions across various industries. The market size is expanding due to rising awareness of UV damage and regulatory requirements for UV protection in consumer products. Technologically, the field is moderately mature with established solutions, but continues to evolve with innovative approaches. Leading players include Industrial Technology Research Institute and Guardian Glass focusing on architectural applications, while companies like Croda International and LG Chem develop advanced chemical formulations. COSMAX and Idemitsu Kosan are innovating in consumer applications, while research institutions like Bar-Ilan University and Zhejiang University drive fundamental advancements. Semiconductor industry players such as Taiwan Semiconductor and Applied Materials are exploring specialized UV-blocking technologies for sensitive electronic components.

Guardian Glass LLC

Technical Solution: Guardian Glass has developed advanced transparent oxide-based UV-blocking coatings utilizing a multi-layer approach that combines zinc oxide and titanium dioxide nanoparticles in a silica matrix. Their proprietary magnetron sputtering deposition technology enables precise control of oxide layer thickness at nanometer scale, creating coatings that block over 99% of UV radiation while maintaining 90%+ visible light transmission. The company's ClimaGuard SPF technology incorporates cerium oxide dopants to enhance UV absorption properties while maintaining coating durability. Guardian's process allows for large-scale industrial application on architectural and automotive glass, with coatings that can be applied during the float glass manufacturing process, ensuring excellent adhesion and longevity.

Strengths: Superior optical clarity with minimal impact on visible light transmission; excellent durability and weather resistance; scalable manufacturing process for large architectural applications. Weaknesses: Higher production costs compared to conventional coatings; requires specialized equipment for application; limited flexibility for retrofit applications on existing glass.

Evonik Operations GmbH

Technical Solution: Evonik has pioneered AEROXIDE® transparent metal oxide nanoparticles technology for UV-blocking coatings. Their system utilizes highly dispersible titanium dioxide and zinc oxide nanoparticles with controlled particle size distribution (10-40nm) to maximize UV absorption while minimizing light scattering. The company's proprietary surface modification techniques prevent nanoparticle agglomeration, ensuring transparency in the visible spectrum. Evonik's sol-gel process incorporates these oxides into silica-based matrices with high homogeneity, creating durable coatings with UV protection extending from UVB (280-315nm) to UVA (315-400nm) ranges. Their VISIOMER® UV-reactive monomers enable crosslinking with the oxide particles, enhancing coating adhesion and scratch resistance. This technology finds applications in automotive clearcoats, wood coatings, and high-performance plastics protection.

Strengths: Exceptional particle dispersion technology preventing agglomeration; customizable UV absorption profiles; compatible with various substrate materials including polymers. Weaknesses: Requires careful handling of nanomaterials during manufacturing; potential for higher costs compared to conventional UV absorbers; performance may degrade over extended outdoor exposure.

Key Patents and Scientific Breakthroughs

Translucent coating compositions providing improved UV degradation resistance

PatentActiveUS7754801B2

Innovation

- A coating composition comprising a latex emulsion with polymeric particles, a combination of UV protectants including zinc oxide and cerium oxide particles, and hindered amine light stabilizers, which are formulated to be transparent or translucent, ensuring minimal impact on the substrate's appearance while providing enhanced UV protection.

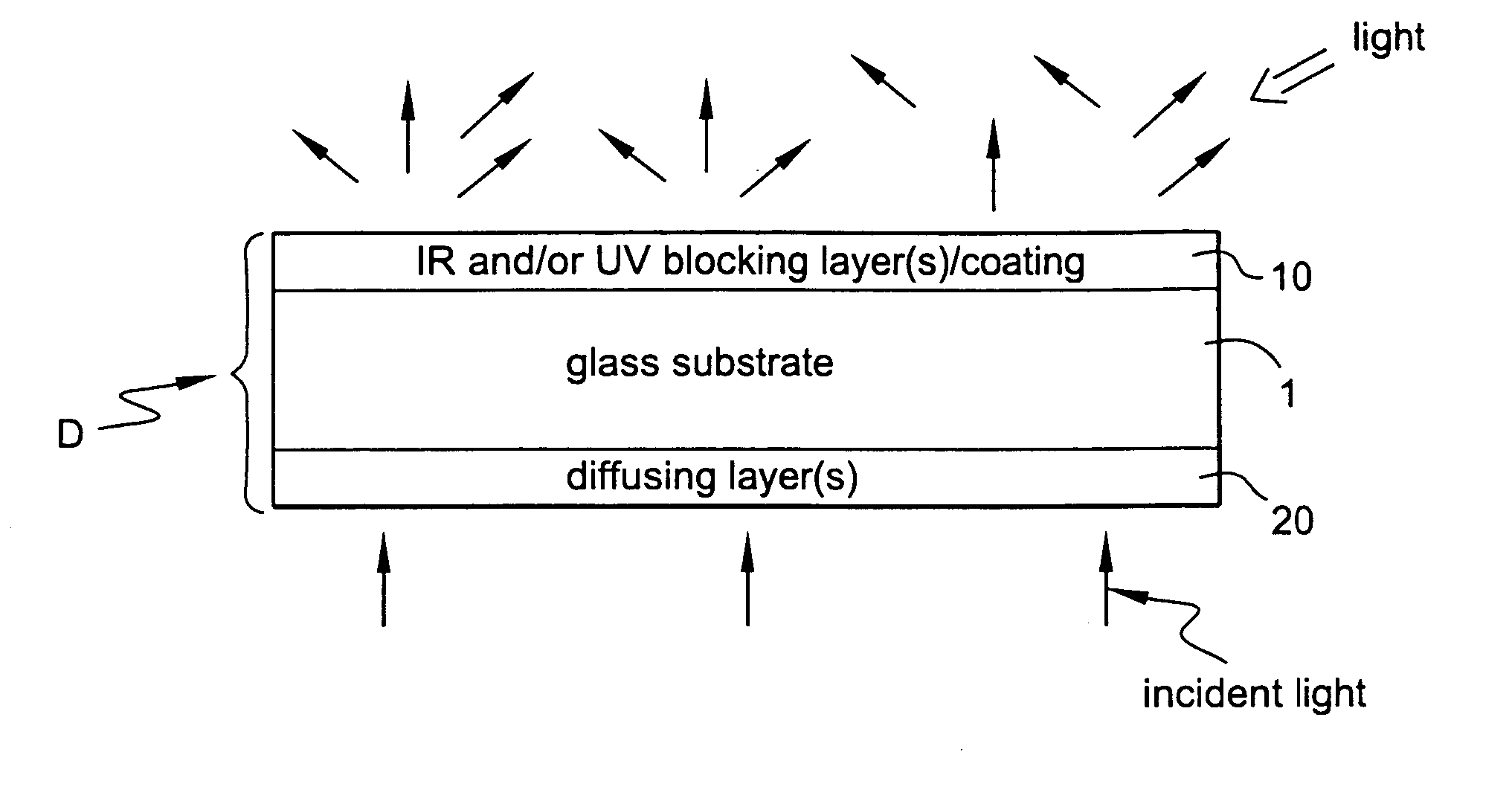

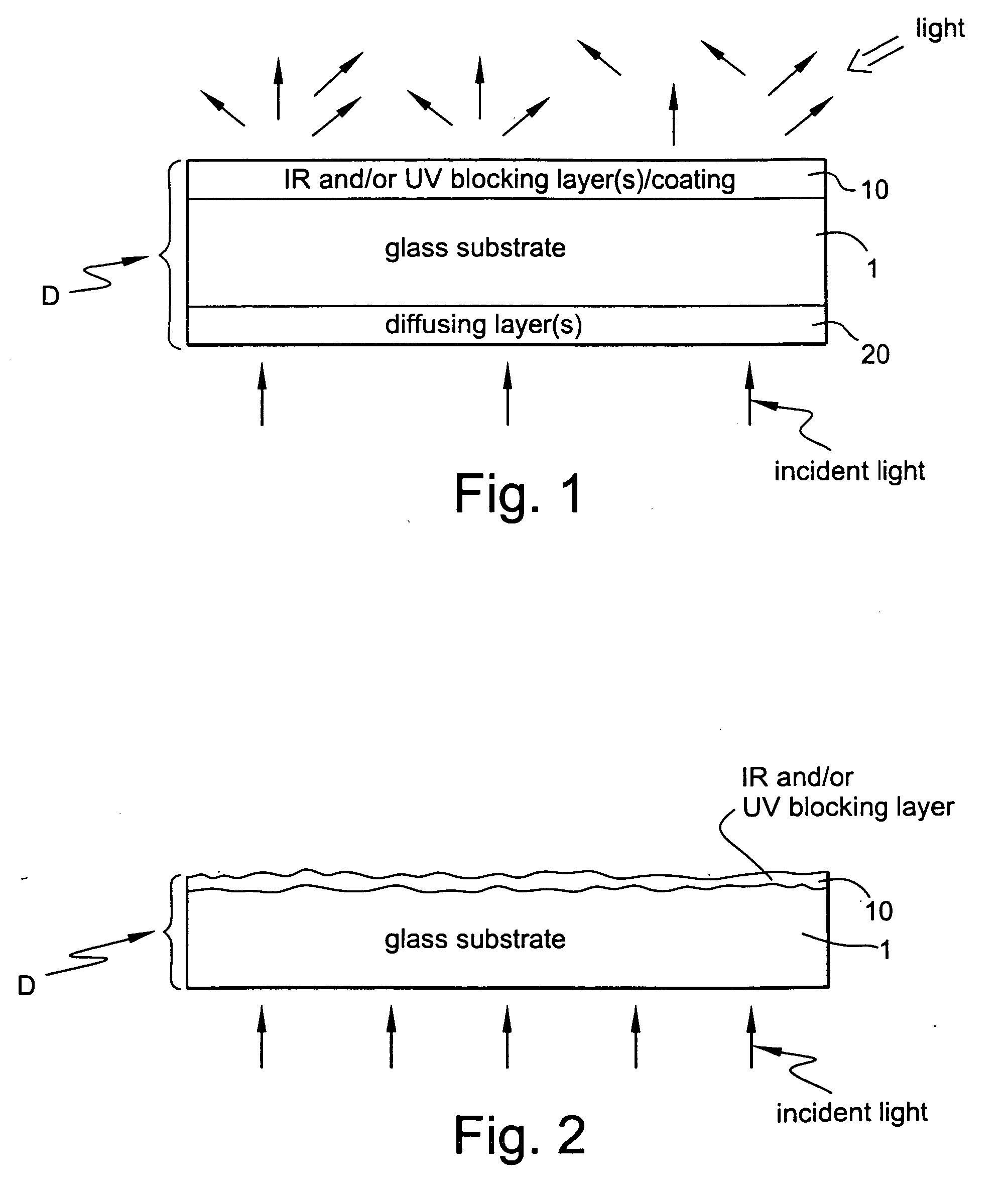

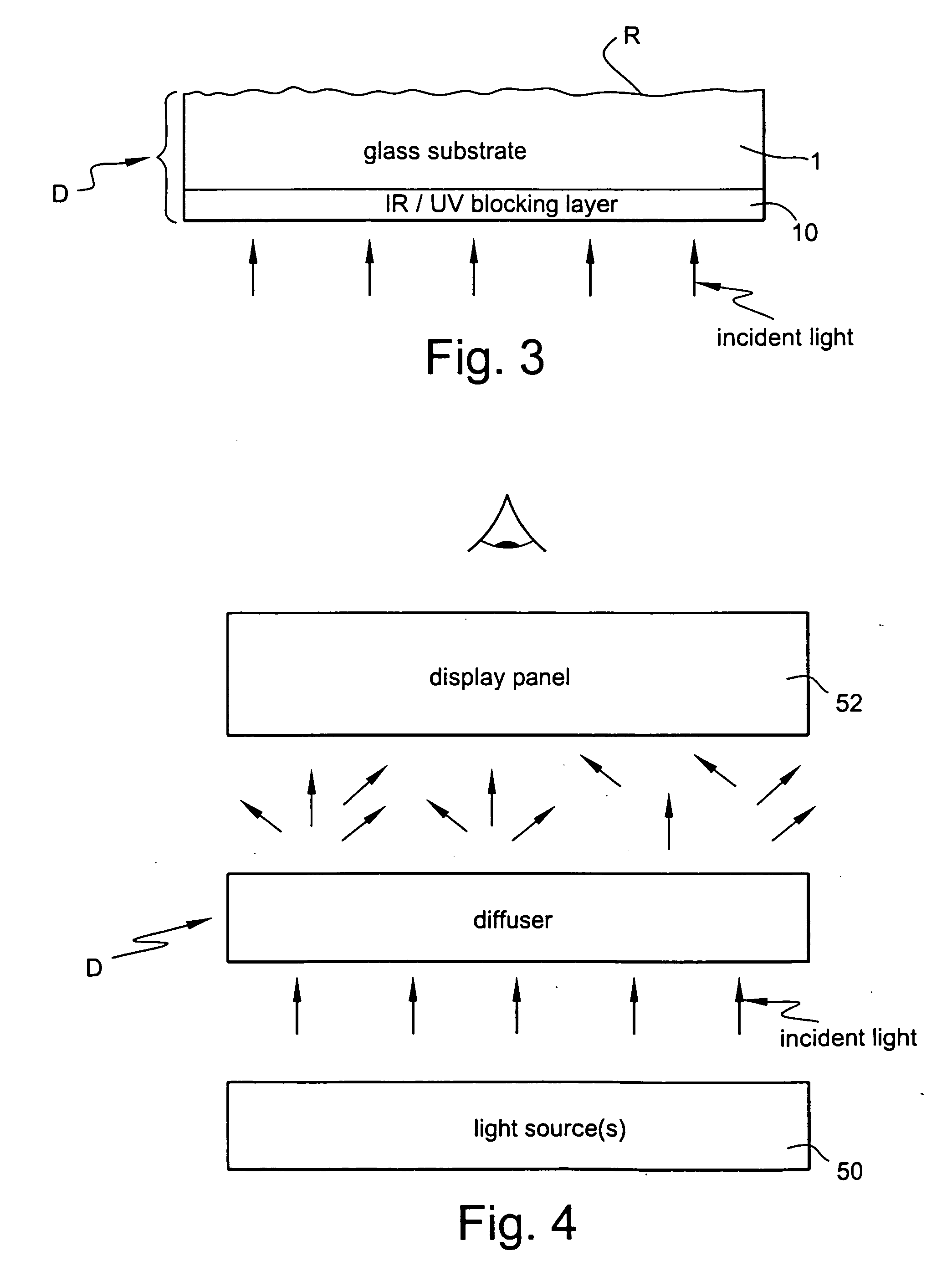

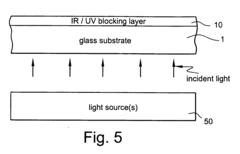

Optical diffuser with IR and/or UV blocking coating

PatentInactiveUS20070064446A1

Innovation

- A diffuser with a glass substrate coated with an IR/UV blocking layer, incorporating materials like zinc antimonite, fluorinated tin oxide, or silver for IR blocking and inorganic oxides such as Ce, Zn, Bi, Ti, Sn, and Sb for UV blocking, integrated into a high-temperature curable glassy matrix, allowing for effective IR and UV radiation blocking while maintaining light transmission and mechanical durability.

Environmental Impact and Sustainability Considerations

The environmental impact of transparent oxide-based UV-blocking coatings represents a critical consideration in their development and application. Traditional UV blockers often contain harmful chemicals such as oxybenzone and octinoxate, which have been linked to coral reef bleaching and marine ecosystem disruption. Transparent oxide alternatives like zinc oxide and titanium dioxide offer potentially more environmentally friendly options, though their environmental profile requires careful assessment.

Nanoparticle forms of these oxides present particular environmental concerns. When washed off from consumer products, these particles can enter aquatic ecosystems with uncertain long-term effects. Recent studies indicate that while bulk forms of these oxides may be relatively benign, their nano-scale counterparts might exhibit increased reactivity and bioavailability, potentially generating reactive oxygen species that could harm aquatic organisms.

Manufacturing processes for transparent oxide coatings also carry significant environmental implications. Traditional methods often involve energy-intensive processes and hazardous precursors. The carbon footprint associated with high-temperature calcination and annealing steps necessary for crystallization of these oxides contributes to greenhouse gas emissions. Water consumption and chemical waste generation during production further compound these environmental concerns.

Sustainability advancements are emerging through green chemistry approaches to oxide synthesis. Sol-gel methods utilizing less toxic precursors, hydrothermal techniques operating at lower temperatures, and bioinspired synthesis routes leveraging natural templates show promise for reducing environmental impact. Additionally, research into recyclable coating formulations and biodegradable binders for oxide particles represents important progress toward circular economy principles.

Life cycle assessment (LCA) studies comparing transparent oxide UV blockers with conventional organic alternatives reveal complex trade-offs. While oxides generally demonstrate superior photostability and reduced bioaccumulation potential, their extraction and processing may entail greater energy expenditure. The durability of oxide-based coatings, however, can offset initial environmental costs through extended product lifespans and reduced replacement frequency.

Regulatory frameworks worldwide are increasingly acknowledging these environmental considerations. The European Union's REACH regulations, Hawaii's reef-protective sunscreen legislation, and similar measures in Australia and Palau reflect growing recognition of UV blocker environmental impacts. These regulatory shifts are driving innovation toward more sustainable transparent oxide formulations that maintain effective UV protection while minimizing ecological harm.

Nanoparticle forms of these oxides present particular environmental concerns. When washed off from consumer products, these particles can enter aquatic ecosystems with uncertain long-term effects. Recent studies indicate that while bulk forms of these oxides may be relatively benign, their nano-scale counterparts might exhibit increased reactivity and bioavailability, potentially generating reactive oxygen species that could harm aquatic organisms.

Manufacturing processes for transparent oxide coatings also carry significant environmental implications. Traditional methods often involve energy-intensive processes and hazardous precursors. The carbon footprint associated with high-temperature calcination and annealing steps necessary for crystallization of these oxides contributes to greenhouse gas emissions. Water consumption and chemical waste generation during production further compound these environmental concerns.

Sustainability advancements are emerging through green chemistry approaches to oxide synthesis. Sol-gel methods utilizing less toxic precursors, hydrothermal techniques operating at lower temperatures, and bioinspired synthesis routes leveraging natural templates show promise for reducing environmental impact. Additionally, research into recyclable coating formulations and biodegradable binders for oxide particles represents important progress toward circular economy principles.

Life cycle assessment (LCA) studies comparing transparent oxide UV blockers with conventional organic alternatives reveal complex trade-offs. While oxides generally demonstrate superior photostability and reduced bioaccumulation potential, their extraction and processing may entail greater energy expenditure. The durability of oxide-based coatings, however, can offset initial environmental costs through extended product lifespans and reduced replacement frequency.

Regulatory frameworks worldwide are increasingly acknowledging these environmental considerations. The European Union's REACH regulations, Hawaii's reef-protective sunscreen legislation, and similar measures in Australia and Palau reflect growing recognition of UV blocker environmental impacts. These regulatory shifts are driving innovation toward more sustainable transparent oxide formulations that maintain effective UV protection while minimizing ecological harm.

Regulatory Framework for UV-Protective Coatings

The regulatory landscape for UV-protective coatings incorporating transparent oxides has evolved significantly in recent years, reflecting growing concerns about UV radiation exposure and its health implications. In the United States, the Food and Drug Administration (FDA) has established specific guidelines for UV-protective products, particularly those claiming sun protection factor (SPF) ratings. These regulations mandate rigorous testing protocols to verify UV-blocking efficacy and durability of coatings, with special provisions for transparent oxide-based formulations due to their unique optical and chemical properties.

The European Union's regulatory framework is governed by the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which imposes stringent requirements for safety assessment of chemical substances, including transparent oxides used in UV-blocking applications. Additionally, the EU Cosmetics Regulation specifically addresses UV filters in personal care products, establishing positive lists of approved substances and concentration limits. Transparent oxides like zinc oxide and titanium dioxide receive particular attention due to their widespread use.

In Asia, regulatory approaches vary significantly by country. Japan's Ministry of Health, Labor and Welfare has established the Japanese Standards for Cosmetic Ingredients (JSCI), which includes specific provisions for UV-protective materials. China has implemented the "Technical Safety Standard for Cosmetics" (TSSC) with dedicated sections addressing UV protection claims and ingredient safety, particularly focusing on nanoscale transparent oxides.

International standards organizations have also contributed to the regulatory framework. The International Organization for Standardization (ISO) has developed ISO 24443 for in vitro determination of UVA protection, while ASTM International provides testing standards for UV-blocking materials in various applications, including architectural coatings and textiles.

Environmental regulations increasingly impact UV-coating technologies, with particular focus on nanoparticle forms of transparent oxides. The EPA in the United States and similar agencies worldwide have implemented monitoring requirements for potential environmental impacts of nanoparticle release during manufacturing, application, and disposal of UV-protective coatings.

Industry self-regulation complements governmental frameworks, with associations like the International Nano-Safety Consortium developing best practices for transparent oxide nanoparticles in consumer products. These voluntary standards often exceed regulatory minimums and address emerging concerns before formal regulation is established.

Looking forward, regulatory trends indicate increasing scrutiny of long-term environmental impacts and potential bioaccumulation of transparent oxide nanoparticles, alongside greater harmonization of international standards to facilitate global trade in UV-protective technologies.

The European Union's regulatory framework is governed by the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which imposes stringent requirements for safety assessment of chemical substances, including transparent oxides used in UV-blocking applications. Additionally, the EU Cosmetics Regulation specifically addresses UV filters in personal care products, establishing positive lists of approved substances and concentration limits. Transparent oxides like zinc oxide and titanium dioxide receive particular attention due to their widespread use.

In Asia, regulatory approaches vary significantly by country. Japan's Ministry of Health, Labor and Welfare has established the Japanese Standards for Cosmetic Ingredients (JSCI), which includes specific provisions for UV-protective materials. China has implemented the "Technical Safety Standard for Cosmetics" (TSSC) with dedicated sections addressing UV protection claims and ingredient safety, particularly focusing on nanoscale transparent oxides.

International standards organizations have also contributed to the regulatory framework. The International Organization for Standardization (ISO) has developed ISO 24443 for in vitro determination of UVA protection, while ASTM International provides testing standards for UV-blocking materials in various applications, including architectural coatings and textiles.

Environmental regulations increasingly impact UV-coating technologies, with particular focus on nanoparticle forms of transparent oxides. The EPA in the United States and similar agencies worldwide have implemented monitoring requirements for potential environmental impacts of nanoparticle release during manufacturing, application, and disposal of UV-protective coatings.

Industry self-regulation complements governmental frameworks, with associations like the International Nano-Safety Consortium developing best practices for transparent oxide nanoparticles in consumer products. These voluntary standards often exceed regulatory minimums and address emerging concerns before formal regulation is established.

Looking forward, regulatory trends indicate increasing scrutiny of long-term environmental impacts and potential bioaccumulation of transparent oxide nanoparticles, alongside greater harmonization of international standards to facilitate global trade in UV-protective technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!