Transparent Oxides in Aerospace Applications: Material Advancements

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Transparent Oxides Background and Objectives

Transparent oxides have emerged as critical materials in aerospace applications, evolving significantly since their initial development in the mid-20th century. These materials combine optical transparency with electrical conductivity, thermal resistance, and mechanical durability—properties essential for advanced aerospace systems. The historical trajectory shows a transition from basic silica-based materials to sophisticated multi-component oxide systems engineered at the nanoscale, reflecting the aerospace industry's increasing demands for multifunctional materials.

The technological evolution of transparent oxides has been driven by the aerospace sector's need for materials that can withstand extreme conditions while maintaining optical clarity. Early applications focused primarily on simple protective coatings for cockpit windows and sensor covers. However, as aerospace technology advanced, particularly in high-altitude and space applications, the performance requirements for these materials expanded dramatically.

Current research objectives in this field center on developing next-generation transparent oxides with enhanced properties, including improved radiation resistance, reduced weight, superior thermal management capabilities, and integrated smart functionalities. Specifically, researchers aim to create materials that can adapt to changing environmental conditions, self-heal when damaged, and provide enhanced electromagnetic interference (EMI) shielding without compromising optical transparency.

The strategic importance of transparent oxide advancements extends beyond immediate applications to enabling technologies that will define future aerospace capabilities. These materials are expected to play crucial roles in hypersonic vehicle windows, space telescope optics, solar panels for satellites, and advanced display systems for aircraft. The development trajectory suggests a convergence of nanotechnology, materials science, and aerospace engineering to create increasingly sophisticated transparent oxide systems.

Recent breakthroughs in atomic layer deposition, sol-gel processing, and ion implantation techniques have accelerated progress in this field, allowing for precise control over material composition and structure at the atomic level. These manufacturing innovations have opened new possibilities for tailoring transparent oxides to specific aerospace requirements, including the development of gradient-index materials and nanocomposites with unprecedented combinations of optical, electrical, and mechanical properties.

The ultimate goal of current research initiatives is to establish a new generation of transparent oxides that can function as active components rather than passive elements in aerospace systems. This transition from passive to active functionality represents a paradigm shift in how these materials are conceptualized and utilized, potentially enabling entirely new capabilities in sensing, communication, and energy management for aerospace vehicles and systems.

The technological evolution of transparent oxides has been driven by the aerospace sector's need for materials that can withstand extreme conditions while maintaining optical clarity. Early applications focused primarily on simple protective coatings for cockpit windows and sensor covers. However, as aerospace technology advanced, particularly in high-altitude and space applications, the performance requirements for these materials expanded dramatically.

Current research objectives in this field center on developing next-generation transparent oxides with enhanced properties, including improved radiation resistance, reduced weight, superior thermal management capabilities, and integrated smart functionalities. Specifically, researchers aim to create materials that can adapt to changing environmental conditions, self-heal when damaged, and provide enhanced electromagnetic interference (EMI) shielding without compromising optical transparency.

The strategic importance of transparent oxide advancements extends beyond immediate applications to enabling technologies that will define future aerospace capabilities. These materials are expected to play crucial roles in hypersonic vehicle windows, space telescope optics, solar panels for satellites, and advanced display systems for aircraft. The development trajectory suggests a convergence of nanotechnology, materials science, and aerospace engineering to create increasingly sophisticated transparent oxide systems.

Recent breakthroughs in atomic layer deposition, sol-gel processing, and ion implantation techniques have accelerated progress in this field, allowing for precise control over material composition and structure at the atomic level. These manufacturing innovations have opened new possibilities for tailoring transparent oxides to specific aerospace requirements, including the development of gradient-index materials and nanocomposites with unprecedented combinations of optical, electrical, and mechanical properties.

The ultimate goal of current research initiatives is to establish a new generation of transparent oxides that can function as active components rather than passive elements in aerospace systems. This transition from passive to active functionality represents a paradigm shift in how these materials are conceptualized and utilized, potentially enabling entirely new capabilities in sensing, communication, and energy management for aerospace vehicles and systems.

Market Analysis for Aerospace Transparent Materials

The aerospace transparent materials market is experiencing significant growth, driven by increasing demand for advanced aircraft and spacecraft that require high-performance transparent components. The global market for aerospace transparent materials was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2028, representing a compound annual growth rate of 7.2%. This growth trajectory is supported by expanding commercial aviation fleets, increasing defense budgets worldwide, and the emergence of private space exploration ventures.

Transparent oxide materials, particularly advanced ceramics and composite oxides, are gaining prominence in this market due to their exceptional thermal stability, optical clarity, and resistance to extreme conditions. The demand for these materials is particularly strong in military aircraft, where requirements for ballistic protection and stealth capabilities drive innovation in transparent armor solutions.

Regional analysis reveals that North America dominates the aerospace transparent materials market, accounting for roughly 42% of global market share, followed by Europe at 28% and Asia-Pacific at 22%. The concentration of major aerospace manufacturers and defense contractors in these regions explains this distribution pattern. However, emerging economies in Asia, particularly China and India, are showing the fastest growth rates as they expand their domestic aerospace industries.

Market segmentation by application shows that cockpit windshields represent the largest segment (38%), followed by cabin windows (27%), sensor covers (18%), and other applications including display screens and optical systems (17%). Transparent oxides are increasingly penetrating the sensor covers and optical systems segments, where their unique properties offer significant advantages over traditional materials.

Customer requirements are evolving toward materials that offer multifunctional properties: transparency combined with electromagnetic shielding, de-icing capabilities, and reduced radar signatures. This trend is creating premium market segments where advanced transparent oxides can command higher margins due to their superior performance characteristics.

Supply chain analysis indicates potential vulnerabilities in the sourcing of rare earth elements and specialized processing equipment required for advanced transparent oxide production. These constraints may impact market growth and create opportunities for companies that can develop alternative material formulations or more efficient manufacturing processes.

The competitive landscape features established aerospace material suppliers like PPG Aerospace, GKN Aerospace, and Saint-Gobain alongside specialized materials science companies developing proprietary transparent oxide technologies. Recent market activity shows increasing strategic partnerships between material developers and aerospace manufacturers to co-develop customized solutions for specific platform requirements.

Transparent oxide materials, particularly advanced ceramics and composite oxides, are gaining prominence in this market due to their exceptional thermal stability, optical clarity, and resistance to extreme conditions. The demand for these materials is particularly strong in military aircraft, where requirements for ballistic protection and stealth capabilities drive innovation in transparent armor solutions.

Regional analysis reveals that North America dominates the aerospace transparent materials market, accounting for roughly 42% of global market share, followed by Europe at 28% and Asia-Pacific at 22%. The concentration of major aerospace manufacturers and defense contractors in these regions explains this distribution pattern. However, emerging economies in Asia, particularly China and India, are showing the fastest growth rates as they expand their domestic aerospace industries.

Market segmentation by application shows that cockpit windshields represent the largest segment (38%), followed by cabin windows (27%), sensor covers (18%), and other applications including display screens and optical systems (17%). Transparent oxides are increasingly penetrating the sensor covers and optical systems segments, where their unique properties offer significant advantages over traditional materials.

Customer requirements are evolving toward materials that offer multifunctional properties: transparency combined with electromagnetic shielding, de-icing capabilities, and reduced radar signatures. This trend is creating premium market segments where advanced transparent oxides can command higher margins due to their superior performance characteristics.

Supply chain analysis indicates potential vulnerabilities in the sourcing of rare earth elements and specialized processing equipment required for advanced transparent oxide production. These constraints may impact market growth and create opportunities for companies that can develop alternative material formulations or more efficient manufacturing processes.

The competitive landscape features established aerospace material suppliers like PPG Aerospace, GKN Aerospace, and Saint-Gobain alongside specialized materials science companies developing proprietary transparent oxide technologies. Recent market activity shows increasing strategic partnerships between material developers and aerospace manufacturers to co-develop customized solutions for specific platform requirements.

Current Status and Technical Barriers of Transparent Oxides

Transparent oxide materials have witnessed significant advancements in recent years, with applications expanding rapidly across aerospace sectors. Currently, indium tin oxide (ITO) dominates the market as the most widely deployed transparent conductive oxide, particularly in cockpit displays and sensor windows. However, the aerospace industry faces critical challenges with ITO, including its inherent brittleness and limited flexibility, which restrict its application in curved or flexible aerospace components.

The global research landscape shows concentrated development efforts in North America, Europe, and East Asia, with the United States maintaining leadership in aerospace-specific applications. Recent breakthroughs in aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO) have emerged as promising alternatives, offering improved thermal stability crucial for extreme aerospace environments.

A significant technical barrier remains the trade-off between optical transparency and electrical conductivity. Current materials struggle to maintain high performance in both parameters simultaneously, particularly when exposed to the extreme temperature fluctuations and radiation encountered in aerospace applications. Material degradation under prolonged UV exposure represents another substantial challenge, with current solutions requiring frequent replacement or additional protective coatings.

Manufacturing scalability presents another major obstacle. Laboratory-scale production of novel transparent oxides often demonstrates excellent properties, but transitioning to industrial-scale production while maintaining consistent quality remains problematic. Deposition techniques like magnetron sputtering and pulsed laser deposition show promise but face uniformity issues when scaled to aerospace component dimensions.

The weight-to-performance ratio continues to be a critical constraint. While traditional transparent oxides offer excellent optical and electrical properties, their integration often adds significant weight to aerospace systems where every gram matters. Recent developments in nanostructured transparent oxides show potential for weight reduction while maintaining functionality, though mechanical durability concerns persist.

Compatibility with existing aerospace manufacturing processes and certification requirements represents another substantial hurdle. New transparent oxide materials must demonstrate long-term reliability under extreme conditions while meeting stringent aerospace safety standards. Current testing protocols often require years of validation before implementation approval.

Recent innovations in atomic layer deposition techniques have improved interface quality between transparent oxides and aerospace substrates, addressing previous adhesion failures. However, cost remains prohibitive for widespread adoption, with high-performance transparent oxides typically costing 5-10 times more than conventional materials, limiting their application to critical components where performance justifies the expense.

The global research landscape shows concentrated development efforts in North America, Europe, and East Asia, with the United States maintaining leadership in aerospace-specific applications. Recent breakthroughs in aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO) have emerged as promising alternatives, offering improved thermal stability crucial for extreme aerospace environments.

A significant technical barrier remains the trade-off between optical transparency and electrical conductivity. Current materials struggle to maintain high performance in both parameters simultaneously, particularly when exposed to the extreme temperature fluctuations and radiation encountered in aerospace applications. Material degradation under prolonged UV exposure represents another substantial challenge, with current solutions requiring frequent replacement or additional protective coatings.

Manufacturing scalability presents another major obstacle. Laboratory-scale production of novel transparent oxides often demonstrates excellent properties, but transitioning to industrial-scale production while maintaining consistent quality remains problematic. Deposition techniques like magnetron sputtering and pulsed laser deposition show promise but face uniformity issues when scaled to aerospace component dimensions.

The weight-to-performance ratio continues to be a critical constraint. While traditional transparent oxides offer excellent optical and electrical properties, their integration often adds significant weight to aerospace systems where every gram matters. Recent developments in nanostructured transparent oxides show potential for weight reduction while maintaining functionality, though mechanical durability concerns persist.

Compatibility with existing aerospace manufacturing processes and certification requirements represents another substantial hurdle. New transparent oxide materials must demonstrate long-term reliability under extreme conditions while meeting stringent aerospace safety standards. Current testing protocols often require years of validation before implementation approval.

Recent innovations in atomic layer deposition techniques have improved interface quality between transparent oxides and aerospace substrates, addressing previous adhesion failures. However, cost remains prohibitive for widespread adoption, with high-performance transparent oxides typically costing 5-10 times more than conventional materials, limiting their application to critical components where performance justifies the expense.

State-of-the-Art Transparent Oxide Solutions for Aerospace

01 Transparent Conductive Oxide (TCO) Materials

Transparent conductive oxides are materials that combine electrical conductivity with optical transparency. These materials are typically metal oxides such as indium tin oxide (ITO), zinc oxide, and tin oxide. They are widely used in electronic displays, solar cells, and touch screens due to their unique combination of properties. The transparency and conductivity can be controlled through doping and processing techniques to optimize performance for specific applications.- Transparent Conductive Oxide (TCO) Materials for Electronic Devices: Transparent conductive oxides are materials that combine electrical conductivity with optical transparency, making them essential for various electronic applications such as displays, touch screens, and solar cells. Common TCO materials include indium tin oxide (ITO), zinc oxide (ZnO), and aluminum-doped zinc oxide (AZO). These materials are typically deposited as thin films using techniques such as sputtering, chemical vapor deposition, or sol-gel processes to achieve the desired balance of transparency and conductivity.

- Manufacturing Methods for Transparent Oxide Films: Various manufacturing techniques are employed to produce transparent oxide films with controlled properties. These methods include physical vapor deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), and solution-based processes. Each technique offers different advantages in terms of film quality, deposition rate, substrate compatibility, and scalability. Post-deposition treatments such as annealing can further enhance the transparency and electrical properties of the oxide films.

- Transparent Oxide Semiconductors for Display Technologies: Transparent oxide semiconductors are increasingly used in display technologies, particularly for thin-film transistors (TFTs) in flat panel displays. Materials such as indium gallium zinc oxide (IGZO) offer advantages including high electron mobility, good transparency, and low processing temperatures. These properties enable the production of high-resolution displays with improved energy efficiency and performance. The amorphous nature of many transparent oxide semiconductors also allows for uniform electrical characteristics over large areas.

- Transparent Oxide Materials for Optical Applications: Transparent oxides are widely used in optical applications due to their ability to transmit light while providing specific functional properties. Materials such as titanium dioxide (TiO2), silicon dioxide (SiO2), and aluminum oxide (Al2O3) are employed in anti-reflective coatings, optical filters, and waveguides. These materials can be engineered to have specific refractive indices and dispersion characteristics, making them valuable for controlling light propagation in optical devices and systems.

- Transparent Oxide Composites and Nanostructures: Advanced transparent oxide materials include composites and nanostructured forms that offer enhanced properties compared to conventional bulk materials. These include nanoparticles, nanowires, and multilayer structures that can be tailored for specific applications. By controlling the composition, size, and arrangement of oxide nanostructures, researchers can achieve unique combinations of optical, electrical, and mechanical properties. These advanced materials find applications in areas such as photocatalysis, sensors, and energy conversion devices.

02 Fabrication Methods for Transparent Oxide Films

Various deposition techniques are used to create transparent oxide films, including sputtering, chemical vapor deposition, sol-gel processing, and atomic layer deposition. These methods allow for precise control over film thickness, composition, and crystallinity. Post-deposition treatments such as annealing can improve transparency and electrical properties. The choice of fabrication method significantly impacts the final properties of the transparent oxide film.Expand Specific Solutions03 Applications in Display and Optoelectronic Devices

Transparent oxides are crucial components in modern display technologies and optoelectronic devices. They serve as transparent electrodes in liquid crystal displays, organic light-emitting diodes, and touch panels. These materials enable the creation of invisible circuits that can transmit electrical signals while allowing light to pass through. The development of flexible transparent oxides has expanded their application to wearable electronics and flexible displays.Expand Specific Solutions04 Transparent Oxide Semiconductors

Transparent oxide semiconductors represent a class of materials that combine semiconductor properties with optical transparency. These materials, including zinc oxide, indium gallium zinc oxide, and tin oxide, are used in thin-film transistors and other semiconductor devices. They offer advantages such as high electron mobility, wide bandgap, and the ability to be processed at relatively low temperatures. These properties make them suitable for next-generation electronics where transparency is required.Expand Specific Solutions05 Transparent Oxide Coatings for Energy Applications

Transparent oxide coatings play a significant role in energy-related applications, particularly in solar cells and energy-efficient windows. These coatings can selectively filter different wavelengths of light, allowing visible light to pass while blocking infrared or ultraviolet radiation. In solar cells, transparent oxides serve as front electrodes that collect charge while maximizing light transmission to the active layer. For architectural applications, these coatings help regulate heat transfer through windows, improving energy efficiency in buildings.Expand Specific Solutions

Leading Aerospace Materials Manufacturers and Research Institutions

The transparent oxides aerospace market is in a growth phase, characterized by increasing demand for advanced materials with optical and structural properties suitable for extreme aerospace environments. The market is expanding as aerospace applications require more sophisticated transparent materials for cockpit windows, sensor covers, and display systems. Technologically, the field is advancing rapidly with companies like Boeing and GKN Aerospace leading application development, while materials innovation is driven by research-focused entities such as Semiconductor Energy Laboratory, Applied Materials, and Naval Research Laboratory. Corning and Pilkington Group contribute significant expertise in specialized glass formulations, while academic institutions like Northwestern University and Industrial Technology Research Institute bridge fundamental research with practical applications. The integration of transparent oxides into aerospace systems represents a convergence of materials science and aerospace engineering, with substantial growth potential.

The Boeing Co.

Technical Solution: Boeing has developed advanced transparent oxide coatings for aerospace applications, focusing on multi-functional oxide systems that provide electromagnetic interference (EMI) shielding while maintaining optical transparency. Their proprietary technology incorporates indium tin oxide (ITO) and aluminum-doped zinc oxide (AZO) layers optimized for aircraft windows and sensor covers. Boeing's approach includes plasma-enhanced deposition techniques that create highly uniform transparent conductive oxide films capable of withstanding extreme temperature variations (-65°C to +85°C) encountered during flight operations. Their recent advancements include self-healing transparent oxide coatings that can repair minor damage through thermal activation, extending component lifespan in harsh aerospace environments. Boeing has also pioneered the integration of these materials with aircraft power systems, allowing for electrically controlled opacity changes in cabin windows.

Strengths: Extensive real-world testing capabilities in actual flight conditions; vertical integration allowing for complete system optimization; proprietary deposition techniques ensuring aerospace-grade reliability. Weaknesses: Higher production costs compared to conventional materials; longer certification timelines for novel materials in safety-critical applications; limited scalability for some specialized formulations.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed cutting-edge deposition technologies specifically for transparent oxide materials in aerospace applications. Their "AeroTCO" platform enables precise atomic-level control of multi-component oxide structures including indium tin oxide (ITO), aluminum zinc oxide (AZO), and gallium-doped zinc oxide (GZO). The company's proprietary physical vapor deposition (PVD) and chemical vapor deposition (CVD) systems allow for large-area uniform coating of complex aerospace components with transparent conductive oxides that maintain performance under extreme conditions. Applied Materials has pioneered advanced process control techniques that ensure consistent electrical and optical properties across production batches, critical for aerospace certification requirements. Their recent innovations include high-mobility amorphous oxide semiconductors with enhanced radiation resistance for space applications, maintaining transparency and conductivity even after exposure to high-energy particles. The company has also developed specialized annealing processes that optimize the microstructure of transparent oxides for maximum durability in aerospace environments.

Strengths: Industry-leading expertise in thin film deposition equipment and processes; advanced process control capabilities ensuring consistent material properties; extensive R&D infrastructure for materials innovation. Weaknesses: Primary focus on equipment rather than end materials; reliance on customers for application-specific implementation; limited direct aerospace certification experience compared to dedicated aerospace manufacturers.

Key Patents and Research Breakthroughs in Aerospace Transparent Oxides

Enhanced transparent conductive oxides

PatentInactiveUS20100203454A1

Innovation

- Incorporating discrete metallic particles and nanostructures into TCO layers to manipulate optical, thermal, and electrical properties through light manipulation, photocurrent reactions, and localized surface plasmon resonance, allowing for enhanced conductivity and optical management, including the use of sub-wavelength particles to control absorption and scattering, and larger particles for light trapping or reflection.

Enhanced emissivity in high-speed window materials and radomes

PatentWO2025179177A1

Innovation

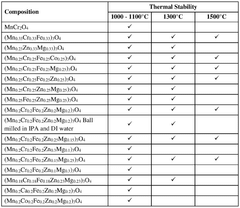

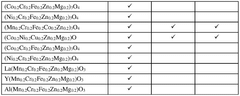

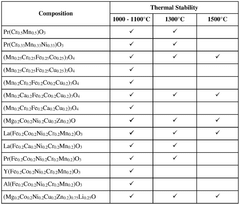

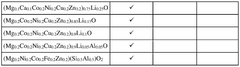

- Development of mixed metal oxides comprising four or more metal species, engineered to exhibit high emissivity in the visible/near infrared region and transparency in the mid-wave or long-wave infrared region, or broadband emissivity across the visible to infrared regions, with RF transparency, using synthesis methods like dry mixing, calcining, and solution-based processes.

Environmental Impact and Sustainability Considerations

The aerospace industry's increasing adoption of transparent oxide materials necessitates careful consideration of their environmental impact throughout their lifecycle. Manufacturing processes for transparent conductive oxides (TCOs) like indium tin oxide (ITO) and aluminum-doped zinc oxide (AZO) often involve energy-intensive deposition techniques such as sputtering and chemical vapor deposition, contributing significantly to carbon emissions. Additionally, the extraction of rare elements like indium presents sustainability challenges due to limited global reserves and environmentally disruptive mining practices.

Recent advancements have focused on developing more sustainable manufacturing routes for transparent oxides. Low-temperature solution processing methods have emerged as alternatives to conventional high-energy vacuum deposition techniques, reducing energy consumption by up to 40%. These approaches include sol-gel processing, hydrothermal synthesis, and spray pyrolysis, which operate at lower temperatures and require less specialized equipment.

Material composition innovations are addressing resource scarcity concerns. Research into indium-free alternatives such as fluorine-doped tin oxide (FTO) and graphene-based transparent conductors represents a promising direction for reducing dependence on critical raw materials. These alternatives not only mitigate supply chain vulnerabilities but also often exhibit improved recyclability profiles.

End-of-life considerations for transparent oxide components in aerospace applications have gained increasing attention. The complex integration of these materials into multi-layer systems presents recycling challenges, as separation processes can be energy-intensive and yield-limited. Innovative design approaches incorporating principles of Design for Disassembly (DfD) are being implemented to facilitate more efficient material recovery and reuse.

Life Cycle Assessment (LCA) studies comparing traditional aerospace materials with transparent oxide alternatives reveal mixed results. While transparent oxides enable weight reduction and improved fuel efficiency during the use phase, their production phase often carries a higher environmental burden. Comprehensive cradle-to-grave analyses suggest that the environmental benefits typically outweigh the impacts when considering the extended operational lifespan of aerospace components.

Regulatory frameworks worldwide are increasingly influencing material selection in aerospace applications. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have prompted manufacturers to develop transparent oxide formulations with reduced toxic element content. This regulatory pressure has accelerated research into environmentally benign alternatives that maintain required performance characteristics.

Recent advancements have focused on developing more sustainable manufacturing routes for transparent oxides. Low-temperature solution processing methods have emerged as alternatives to conventional high-energy vacuum deposition techniques, reducing energy consumption by up to 40%. These approaches include sol-gel processing, hydrothermal synthesis, and spray pyrolysis, which operate at lower temperatures and require less specialized equipment.

Material composition innovations are addressing resource scarcity concerns. Research into indium-free alternatives such as fluorine-doped tin oxide (FTO) and graphene-based transparent conductors represents a promising direction for reducing dependence on critical raw materials. These alternatives not only mitigate supply chain vulnerabilities but also often exhibit improved recyclability profiles.

End-of-life considerations for transparent oxide components in aerospace applications have gained increasing attention. The complex integration of these materials into multi-layer systems presents recycling challenges, as separation processes can be energy-intensive and yield-limited. Innovative design approaches incorporating principles of Design for Disassembly (DfD) are being implemented to facilitate more efficient material recovery and reuse.

Life Cycle Assessment (LCA) studies comparing traditional aerospace materials with transparent oxide alternatives reveal mixed results. While transparent oxides enable weight reduction and improved fuel efficiency during the use phase, their production phase often carries a higher environmental burden. Comprehensive cradle-to-grave analyses suggest that the environmental benefits typically outweigh the impacts when considering the extended operational lifespan of aerospace components.

Regulatory frameworks worldwide are increasingly influencing material selection in aerospace applications. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have prompted manufacturers to develop transparent oxide formulations with reduced toxic element content. This regulatory pressure has accelerated research into environmentally benign alternatives that maintain required performance characteristics.

Certification and Testing Standards for Aerospace Materials

The certification and testing standards for transparent oxide materials in aerospace applications represent a critical framework that ensures safety, reliability, and performance under extreme conditions. These standards are primarily governed by organizations such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and military specifications like MIL-STD-810.

For transparent oxide coatings and materials, the AS9100 quality management system serves as the foundational certification requirement for aerospace manufacturers. This standard incorporates ISO 9001 requirements while adding specific aerospace industry considerations for quality and safety management.

Optical transparency testing follows ASTM F1300 and MIL-G-25871 standards, which specify procedures for measuring light transmission, haze, and clarity under various environmental conditions. These tests must demonstrate that transparent oxides maintain at least 85-90% transparency across operational wavelengths while withstanding thermal cycling from -65°C to +150°C.

Mechanical property verification adheres to ASTM E1820 for fracture toughness and ASTM C1161 for flexural strength. Aerospace-grade transparent oxides must typically achieve fracture toughness values exceeding 2.5 MPa·m^1/2 and flexural strength above 150 MPa to qualify for structural applications.

Environmental durability testing follows MIL-STD-810G protocols, subjecting materials to salt fog exposure (Method 509.6), humidity cycling (Method 507.6), and sand/dust exposure (Method 510.6). Transparent oxides must demonstrate less than 5% degradation in optical properties after 1,000 hours of accelerated environmental exposure.

Electromagnetic compatibility testing under RTCA DO-160 ensures transparent conductive oxides do not interfere with aircraft communications and navigation systems. This is particularly important for materials incorporating indium tin oxide (ITO) or aluminum-doped zinc oxide (AZO) with conductive properties.

Fire resistance certification follows FAR 25.853 and requires materials to be self-extinguishing within specific timeframes when exposed to flame. Smoke density and toxicity testing under ASTM E662 and ASTM E1354 ensures that transparent oxide materials do not produce hazardous byproducts during combustion events.

The certification process typically requires extensive documentation, including material composition analysis, manufacturing process controls, and traceability records. Third-party testing laboratories accredited by NADCAP (National Aerospace and Defense Contractors Accreditation Program) must validate all test results before materials can receive final certification for aerospace applications.

For transparent oxide coatings and materials, the AS9100 quality management system serves as the foundational certification requirement for aerospace manufacturers. This standard incorporates ISO 9001 requirements while adding specific aerospace industry considerations for quality and safety management.

Optical transparency testing follows ASTM F1300 and MIL-G-25871 standards, which specify procedures for measuring light transmission, haze, and clarity under various environmental conditions. These tests must demonstrate that transparent oxides maintain at least 85-90% transparency across operational wavelengths while withstanding thermal cycling from -65°C to +150°C.

Mechanical property verification adheres to ASTM E1820 for fracture toughness and ASTM C1161 for flexural strength. Aerospace-grade transparent oxides must typically achieve fracture toughness values exceeding 2.5 MPa·m^1/2 and flexural strength above 150 MPa to qualify for structural applications.

Environmental durability testing follows MIL-STD-810G protocols, subjecting materials to salt fog exposure (Method 509.6), humidity cycling (Method 507.6), and sand/dust exposure (Method 510.6). Transparent oxides must demonstrate less than 5% degradation in optical properties after 1,000 hours of accelerated environmental exposure.

Electromagnetic compatibility testing under RTCA DO-160 ensures transparent conductive oxides do not interfere with aircraft communications and navigation systems. This is particularly important for materials incorporating indium tin oxide (ITO) or aluminum-doped zinc oxide (AZO) with conductive properties.

Fire resistance certification follows FAR 25.853 and requires materials to be self-extinguishing within specific timeframes when exposed to flame. Smoke density and toxicity testing under ASTM E662 and ASTM E1354 ensures that transparent oxide materials do not produce hazardous byproducts during combustion events.

The certification process typically requires extensive documentation, including material composition analysis, manufacturing process controls, and traceability records. Third-party testing laboratories accredited by NADCAP (National Aerospace and Defense Contractors Accreditation Program) must validate all test results before materials can receive final certification for aerospace applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!